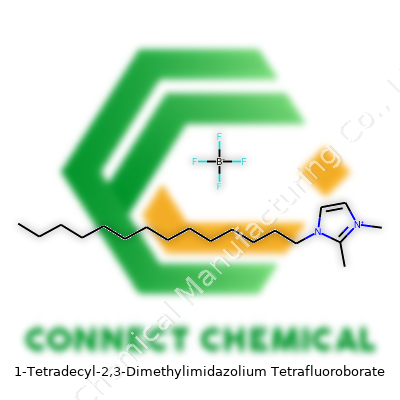

1-Tetradecyl-2,3-Dimethylimidazolium Tetrafluoroborate: A Deep Dive into Its Story and Science

Historical Development

Brushing through the pages of ionic liquid chemistry over the last several decades, one notices the steady climb of imidazolium-based compounds into mainstream lab talk. The specific story of 1-Tetradecyl-2,3-Dimethylimidazolium Tetrafluoroborate shows how research pivots as new needs come up. Early on, chemists cast a wide net with imidazoliums because their tunable nature attracted folks digging for solvents that buck volatility and corrosiveness. Over coffee with old lab mates, I still hear excitement over how longer-chain imidazoliums like the tetradecyl variety set the stage for controlled phase behaviors and handled hydrophobic guests better than the regular short-chain crowd. It didn’t take long for engineers and chemists to test every aliphatic tail and tweak side groups, chasing after enhanced separation, electrochemical, and catalytic uses. These tweaks came less from some grand plan and more from trial, error, and raw curiosity.

Product Overview

Tetradecyl-based imidazolium salts landed on the specialty chemicals market in response to lab and industry requests for molecules that last in high-salt, high-temp, or high-stress scenarios. The molecule’s imidazolium nucleus provides thermal resilience, while the long tetradecyl tail stretches its reach into nonpolar environments—plus, the BF4 anion brings non-coordinating stability. Think: a fluid that plays well both with water-haters and, thanks to its charge and backbone, materials that shrug off most organic solvents. Folks who work with lithium batteries or electroplating routines turned to this compound for electrolyte research, eager for something beyond old-school options that lose steam after a few clicks above room temperature. Compared to earlier ionic liquids, this one offers a sweet spot between viscosity, hydrophobicity, and chemical stubbornness.

Physical & Chemical Properties

You feel the weight of this compound the moment it pours from a bottle. At room temp, it rolls out as a dense, colorless to pale yellow liquid. Its melting point rests below the boiling point of water, and it boasts a high decomposition threshold, easily crossing the 300°C barrier before breaking down. Its tetradecyl chain makes it more viscous and less prone to evaporating than shorter-chain cousins, a relief for those used to the stink of volatile organics. Conductivity drops as that hydrocarbon tail grows, but for many applications, the tradeoff matters less than its chemical tenacity or its ability to dissolve both polar and nonpolar solutes. The tetrafluoroborate anion helps keep things stable, resisting hydrolysis except under extremely acidic or hot conditions.

Technical Specifications & Labeling

Bottles shipped to your lab typically carry batch-specific purity—at least 98% on reputable labels—plus a moisture content that stays under 0.5% for most applications. People tend to ask for CAS numbers and lot past the certificates these days, seeking assurance over heavy metal and halide footprints down to parts-per-million. The best suppliers break down every trace, listing total organic content and residual solvents, catering to regulatory pressure and the ever-increasing worry over process contaminants. You also see storage details in bold: keep tightly capped, out of sunlight, and at less than 30°C. The warnings never sound casual: avoid contact with skin and eyes, wear gloves and goggles, and never pipette by mouth (a real throwback, that last one, but necessary).

Preparation Method

Anyone who’s tried to make this in a decent yield knows the process calls for patience. Starting from 2,3-dimethylimidazole, alkylation with 1-bromotetradecane runs best in refluxing acetonitrile or DMF, keeping an inert gas blanket to avoid side reactions. After hours—or overnight—the reaction mix gets coaxed into exchanging its halide for BF4 by stirring with sodium tetrafluoroborate. Extraction flushes away inorganic trash, and repeated washing plus recrystallization strips the compound down to usable purity. Each step—especially drying—reminds you that ionic liquids greedily suck up water and can spoil a batch if not handled with care. It pays to check each intermediate for completeness with NMR and elemental analysis before calling it finished.

Chemical Reactions & Modifications

Long-chain imidazoliums don’t just sit and look pretty on a shelf. The cation handles alkylation, quaternization, and even some nucleophilic substitutions on the imidazole ring, as long as you protect the right groups during the synthetic route. At the surface of metals or oxides, the hydrophobic tail lays flat, acting almost like a molecular rug—useful for modifying interfaces during catalysis or in corrosion science. Chemists also tweak the counterion, swapping BF4 for PF6, NTf2, or other exotic anions if they need to tune solubility or thermal windows. The base structure opens doors for grafting onto polymers or crosslinking to make advanced membranes—uses that keep popping up as more industries start looking inward at their functional fluids.

Synonyms & Product Names

Product catalogs showcase names like 1-Tetradecyl-2,3-dimethylimidazolium tetrafluoroborate, C14DMIM BF4, or C14MIM BF4. Some researchers gloss over the full name and just use shorthand like C14-imidazolium, but supply chain managers demand all the details for import regulations and customs. Different suppliers compete on purity and moisture content, pushing brands with subtle spelling differences that spark heated debates over reproducibility in multi-center studies.

Safety & Operational Standards

Lab workers and floor managers keep a close eye on safety sheets for this class of ionic liquids. Spills leave oily puddles that slip underfoot and stick to gloves, so cleanup needs absorbent pads and disposal in hazardous waste, not the general trash. While not flammable by normal standards, inhalation or accidental injection cause irritation and, in rare situations, nerve damage—stories circulate of old-timers who ignored the rules and paid a steep price. Fume hoods get used for all transfers, and local exhaust runs constantly during synthesis or extended handling. For transport, bottles sport secondary containment: regulations have grown stricter, especially for bulk moves across borders, reflecting a growing awareness of both the health and environmental risks tied to persistent organofluorine compounds.

Application Area

Battery engineers keep vials of this ionic liquid in their toolkits, especially for testing wider-voltage electrolytes in next-gen lithium or sodium batteries. Its chemical stubbornness also wins over those building sensors or running electrodeposition setups, where traditional solvents fail due to reactivity or short operational lifespans. In my own experience, screening catalysts in alkylations and oxidations runs smoother in this medium; substrates and reagents that barely mingle in water or alcohols dissolve cleanly, and separation after reaction gets streamlined with its sharp phase boundaries. Folks in pharmaceuticals, too, have begun to look beyond lab-scale as soon as regulatory agencies start publishing safety data transparent enough to allow scaled purification and post-reaction recovery.

Research & Development

The most exciting research angles chase after new ways of integrating this ionic liquid into membranes, composite electrolytes, or even green processing. Studies at universities and R&D arms of chemicals firms now team up, hunting for ways to recycle these compounds, recover them from scavenging material, or graft their ionic motifs onto backbones as part of circular economy initiatives. Other researchers track reaction pathways, modeling solubility and interfacial tension changes to pin down what makes this molecule tick—and how tiny tweaks to its structure move the needle in selectivity or stability. Recent years have seen grant money pouring into projects that use this ionic liquid in fuel cells and carbon capture, reflecting both market and climate needs.

Toxicity Research

Most ionic liquids used to sneak past toxicology boards, but scrutiny has ramped up. Studies show that the long alkyl chains in tetradecyl imidazoliums boost aquatic persistence, and breakdown products sometimes turn out as more harmful than starting materials. Researchers now test acute and chronic effects on fish, crustaceans, and algae, aiming for honest risk profiles instead of assuming all ionic liquids equate to “green.” Workers in regulatory affairs now look at not just the immediate impact, but also at how these materials move through soil and water, checking for bioaccumulation and long-term residues. Real data beats old myths—no one has time for accidental environmental releases that come back years later as court cases or cleanup mandates.

Future Prospects

Groups across the globe chase better variants, cleaner syntheses, and new uses for 1-Tetradecyl-2,3-Dimethylimidazolium Tetrafluoroborate. Lifecycle analysis sits at the forefront, with labs collaborating to minimize waste, recover spent liquid from finished industrial cycles, and design molecules that retain performance while breaking down into safer fragments at the end of their run. Automation looms on the horizon too, promising faster screening of structural analogues and machine learning-driven discovery of combinations that’ll keep pace with both regulatory tightening and industrial demands. My optimism comes from watching persistent teams iterate—improvement rarely makes the headlines today, but the real world shifts the moment someone’s new sample outpaces an old one in safety, cost, or durability.

Unlocking the Power of Ionic Liquids

The name might sound intimidating: 1-Tetradecyl-2,3-Dimethylimidazolium Tetrafluoroborate, a mouthful that shows up more often in labs and specialized industries than in casual conversation. At its core, it's a type of ionic liquid. These liquids stay in a liquid state even at room temperature, defying traditional ideas of what a salt should look like. The advantage of an ionic liquid like this one lies in the fact that its unique structure provides a wide electrochemical window, low volatility, and the kind of chemical stability that traditional solvents struggle to match.

Looking at uses in real life, this compound shows up mainly in research settings and high-tech industry rather than in daily consumer products. Its chemical makeup gives it notable solvent abilities, and that opens doors in processes needing extreme conditions or high selectivity. For anyone who’s ever worked in a lab, finding a solvent that won’t evaporate, doesn’t catch fire easily, and stands up to electricity makes a huge difference, especially in energy storage, catalysis, or organic synthesis.

Batteries, Catalysis, and Beyond

Electrochemistry takes a big leap forward when working with these ionic liquids. As battery makers hunt for better ways to store and shuttle energy, they keep bumping into limits set by traditional electrolytes. This is where compounds like 1-Tetradecyl-2,3-Dimethylimidazolium Tetrafluoroborate prove their worth. They allow for the development of batteries that carry higher voltages, run longer cycles, and stand up better to heat. The automotive and renewable energy industries both benefit from more durable batteries, lowering the cost per kilowatt-hour and making green technology more competitive.

Catalysis often needs a fine balance of stability and reactivity. This ionic liquid creates a platform to support complex reactions. Researchers use it to provide a safe home for expensive or sensitive catalysts, letting them do their job more efficiently. It’s almost like giving a fragile artist a steady hand and quiet environment to work.

Environmental Impact and Safety Considerations

These kinds of compounds bring a double-edged sword. The industry celebrates their ability to reduce greenhouse gas emissions by replacing older, more dangerous solvents. At the same time, the introduction of any synthetic chemical into production lines must come with a watchful eye on safety and toxicity data. Early studies suggest that this class of chemicals, while low in volatility and nonflammable, can present challenges in water treatment since they don’t break down easily. Responsible management and regular review of handling guidelines are not just red tape; they keep workers and communities safe.

Solutions and the Path Forward

No single compound solves everything in chemistry or tech. A balanced approach that brings together regulation, research, and corporate responsibility helps prevent environmental and workplace hazards. Industry teams up with academics to test how these ionic liquids behave, not only in a beaker but across their full life cycle. Investing in green chemistry methods and setting firm recycling paths for solvents and residues reduces risk and protects long-term benefits.

Trust in new chemicals takes time, real-world experience, and clear communication between researchers, manufacturers, and the public. Compounds like 1-Tetradecyl-2,3-Dimethylimidazolium Tetrafluoroborate show that careful attention to detail, both in the way we use them and the way we monitor their effects, drives progress in science and technology without leaving safety behind.

Why Safety Starts Before the Lab Coat Goes On

Walking into the lab, I learned fast: skipping steps with hazardous chemicals could leave you with more than just a scolding. Even the most basic compound, harmless at first glance, often carries risks most people never consider. Early on, I remember a hasty mix-up that ended with a trip to the campus clinic and a ruined pair of jeans. One splash—and that’s all it took for the lesson to stick. Proper preparation is where safety actually begins.

Protective Gear Is Not Just for Show

Anyone handling chemicals hears about goggles, gloves, and that beloved lab coat. These aren’t just for looks. Even compounds considered ordinary can burn skin, damage eyesight, or set off allergies. Nitrile gloves stop most chemicals from getting through. Tight-fitting goggles protect eyes from stray drops. Lab coats act like shields, keeping splashes from direct contact with the body. Serious accidents drop sharply in spaces where everyone gears up before approaching the bench.

Good Ventilation Saves Lives

Not every risk comes from spills. Some compounds give off fumes that can cause headaches or knock you out. A fume hood pulls those invisible threats away. In my early days, I underestimated the power of a good fume hood—until the stinging smell of ammonia hit my nose. Air that’s moving in the right direction, along with carbon filters, can often prevent bigger emergencies. Never trust a smell or think you know the compound’s behavior that day: proper airflow remains a safety basic.

Labeling and Storage Prevents Tragedy

One of the smartest rules I picked up was labeling every container right after pouring. One day of distraction can lead to an unlabeled flask, and nobody wants to play guessing games with unknown liquids. Some chemicals react violently if stored near acids or bases. Flammable materials belong in fire-proof cabinets. Forgetting these habits invites trouble and turns simple mistakes into dangerous moments.

Simple Steps for Handling: My Checklist

Read up first. I never touch a compound before looking up its hazards in a safety data sheet. Quick research turns up the worst-case situations I might face, from skin burns to toxic vapors.Plan the experiment. Laying out every step leaves less room for error—especially under time pressure.Keep a spill kit handy. I once watched a peer scramble because they left the neutralizer out in another room. The mess doubled in size. Absorbent pads, neutralizers, and eye wash stations belong within arm’s reach.Wash hands, always. Chemicals linger. Soap and water after every session help prevent skin problems. Phone screens and door handles catch more than fingerprints after a lab day.

Speaking Up Really Matters

If you see a friend skipping a step, saying something shows you care more about their safety than their pride. I’ve lost count of lab partners who thanked me later for a quick nudge when gloves were left off or a bottle sat open longer than it should. In my circles, checking on each other became routine.

Building Safe Habits Beyond the Lab

These skills apply everywhere—working on car batteries, gardening with fertilizers, or handling cleaning products at home. Respect for chemicals follows the same logic: gear up, store wisely, stay informed. It’s not just about following rules but protecting yourself and everyone around you so that one mistake never becomes a disaster. That’s a lesson worth sharing, every time a new bottle hits the bench.

Beyond the Formula: What the Structure Tells Us

Every time we check the chemical structure for a product, we’re unlocking more than just shapes and bonds. Structure answers big questions about how a substance acts, how it reacts in the real world, and sometimes even why it poses a risk or offers a benefit. For example, the arrangement of atoms in acetaminophen tells a story about pain relief and safety limits. Whether a compound is a straight chain, has rings, or sports complex functional groups directly changes how our bodies break it down—or even how water carries it through the environment.

Once, I worked on a project searching for plastic additives that wouldn’t leach. Looking at chemical structures, we found differences in leaching rates just by swapping a methyl group for an ethyl. That kind of detail only pops out by really diving into the structure.

Molecular Weight: Not Just a Number

Molecular weight shapes handling, mixing, and even regulatory status. A huge molecule—say, those used in modern biologics—won't easily slip through most biological membranes. That’s part of why some drugs, like insulin, need to be injected rather than swallowed. On the other hand, lightweight molecules zip around, sometimes acting fast in the body or the environment.

In the chemical industry, attention to molecular weight avoids costly mistakes. In my own experience, a pesticide formulation failed because the molecular weight was underestimated, leading to poor mixing and weak field results. That one calculation made all the difference.

Science and Safety

Ask a toxicologist about molecular weight and structure, and you'll probably see their eyes light up. Both elements shape toxicity, bioaccumulation, and potential for environmental harm. Regulatory agencies like the EPA and REACH dive straight to structure and weight when looking at new submissions. They check for certain clusters that often mean trouble, like nitro groups or halogenated rings.

Consumers rarely notice, but companies who sell cosmetics, cleaners, or food additives must take these things seriously. In 2022, a report revealed skin sensitizers hiding in fragrances; tracing back, investigators could often predict trouble just by studying chemical fingerprints and weights.

Solutions: Smarter Use of Data

Most labs now squeeze every bit of data from molecular structures using software like ChemDraw or open databases. Anyone developing a new product can model how shifting a single atom changes overall weight, then predict solubility or potential interaction with living cells. That means problems get spotted earlier and fewer nasty surprises show up after launch.

Better sharing of spectral data—like NMR or mass spectrometry—across research groups speeds up cross-checking, catching misidentified substances quickly. Crossing the lab-silo gap lets teams in quality, scale-up, and even marketing avoid translating errors.

Adopting digital product passports—basically, chemical “birth certificates” showing structure and molecular weight—makes information accessible along the supply chain. With this, both safety teams and buyers know exactly what’s in the mix, all the way back to the source.

Why It All Matters

Ignoring structure or weight costs time, money, sometimes even health. Small details on paper can mean big changes in use. Anyone working with chemicals can use these tools to make better, safer decisions—and keep mistakes from growing into headlines.

The Real Reason Storage Matters

Few chemicals spark unease like ionic liquids with elaborate names, but the nervous energy often misses the mark. In my time working around chemicals, storage mistakes never explode in Hollywood fashion. Problems build quietly—a leaking cap, a softening label, a whiff of something strange in a storeroom—and each signals that we skipped over the details. Storing 1-Tetradecyl-2,3-Dimethylimidazolium Tetrafluoroborate wrong risks damaging safety, research results, and budgets. Take this compound’s storage as a practical exercise in keeping both people and data safe.

Moisture and Air: Unseen Enemies

Some ionic liquids easily pick up water from humid air. This specific compound does it better than many. Leave a bottle open just a few minutes on a sticky summer day and you’ll find the water content creeping up. Extra water leads to unexpected reactions, rust on metal parts, and experiment failures. I’ve seen a glovebox used to open and transfer small amounts for this reason—dry nitrogen keeps air and dampness out. Researchers can avoid a lot of headaches just by re-sealing containers firmly and storing them in a dry, inert place every single time.

Temperature Swings Create Risks

Months ago, I took a call about weird crystals forming in a clear ionic liquid. Turned out, the bottle had sat near an exterior lab wall all winter. Fluctuating temperatures can separate parts of the liquid, or even degrade sensitive chemicals. Room temperature usually works, although for long-term storage a dedicated fridge—not shared with food—adds another layer of protection, especially in older labs where climate control can get sketchy.

Light Exposure—Not Harmless

Fluoroborate-based compounds sometimes degrade in bright light. A shelf drenched in sunlight or even harsh overhead bulbs can cause slow but real breakdown. You’ll want amber glass or opaque bottles, kept away from windows and strong indoor lighting. Too many researchers let bottles sit out 'just for a week'—and lose months of careful work to something as simple as UV exposure.

Containment for Spills and Fumes

Most ionic liquids carry low volatility, but not none. This one can still give off trace vapors, particularly if warm. I keep these in spill trays with sealed lids. If something leaks, it stays contained. Label everything with the full chemical name, not just abbreviations, so a tired grad student won't misread it at 2 a.m. Good practice demands gloves, eye protection, and fume hoods for every transfer, even if examples of people “getting away with it” exist all over campus. Shortcuts work until they don’t.

Protecting Both People and Research

Ignoring storage quality rarely hurts right away. It’s the long game—degraded samples, failed reactions, incorrect data, health complaints among staff. Risk stays low if each dose of 1-Tetradecyl-2,3-Dimethylimidazolium Tetrafluoroborate goes from container to fume hood to sealed storage without stopping to “air out” on a bench. Simple rules win: dry spaces, steady temperatures, dark shelves, inside tough-walled containers. From graduate students to seasoned chemists, storage discipline protects research—and the people running it.

Understanding the Concept from the Ground Up

Think about making a cup of coffee. After pouring in sugar, you stir until the grains disappear. That’s solubility in action—something solid becoming part of a liquid. In chemical language, solubility tells us how much of a substance dissolves in a particular solvent at a specific temperature. It shapes workflow across labs, pharmacies, and industry plants every day. Yet, a simple question—how does this compound behave in water and organic solvents—sits at the center of research and product design alike.

Why Solubility Guides Decisions

Water gets most attention in classrooms and homes because it’s all around us, and safe. Many compounds break apart easily in water, forming solutions people use for everything from cleaning to chemical synthesis. Salt and sugar illustrate this: both dissolve quickly, owing to the polar nature of water molecules and their ability to interact with charged atoms or groups. But not every compound fits this profile. Mixing olive oil with water proves the point—oil sticks together, refusing to combine. That story repeats in labs with plenty of chemical powders.

Switch scenes to organic solvents, and the game changes. Solvents like ethanol, acetone, or hexane attract and dissolve compounds that water cannot handle well. Non-polar molecules, including fats, oils, and certain medications, move right into these liquids. Pharmaceutical teams check solubility in organic solvents to determine the best formula for pills or injections, because you can only deliver what dissolves well enough to reach the body’s target.

Real Consequences in Health, Research, and Environment

Ignoring solubility leads to problems. Medicine needs solubility to work safely. Active ingredients stuck in undissolved chunks offer little help and sometimes harm. Aspirin dissolves in water just enough to move through the stomach. Fat-soluble vitamins, such as A and D, ride along with dietary fats, making absorption a matter of diet as much as pills.

Solubility also shapes research decisions. Scientists set up experiments by picking solvents that match their compounds. Miss the mark and results look odd, or nothing happens at all. Chemical spills put the spotlight on environmental stakes. Oil slicks spread because oil floats on water, causing trouble for wildlife and cleanup crews. Knowing how fast and how much a compound dissolves points rescue efforts in the right direction.

Testing and Improving Solubility—Tools on Hand

In practice, testing starts with small samples and solvents chosen for their history of success. A research assistant adds measured amounts of the compound to water, shakes, and observes. If no change occurs, organic solvents become next options on the bench. The process can feel slow, but systematic steps avoid wasted work and spot the best match for further development.

Boosting solubility sometimes calls for smart tweaks. Changing temperature alters how much dissolves, a trick used in everything from making rock candy to crystallizing drugs. Scientists design derivatives—new compounds with friendly features that fit the solvent better. Add a hydrophilic group, and water solubility jumps up, easing burdens for pharmacists and environmental engineers alike.

Wrapping Up With Practical Sense

No one formula fits all when handling solubility questions. Each compound comes with quirks, and each solvent holds strengths. Sound research, careful observation, and knowledge grounded in daily practice drive progress. Those working in chemistry, health, or cleaning never ignore solubility—or leave it to guesswork—because results depend on understanding what dissolves, and where.