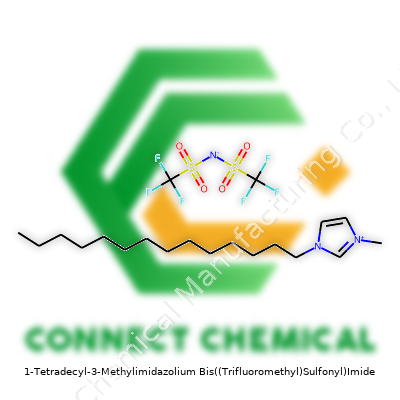

1-Tetradecyl-3-Methylimidazolium Bis((Trifluoromethyl)Sulfonyl)Imide: Progress, Properties, and Prospects

Historical Development

Before ionic liquids touched just about every corner of research labs, classic solvents like acetone and toluene dominated the workspaces. By the late 1990s, the discovery of new ionic liquids began changing the rhythm of chemistry, shifting attention toward compounds that combined low volatility and tunable properties. Among the family of these strange salts, 1-Tetradecyl-3-methylimidazolium bis((trifluoromethyl)sulfonyl)imide grew popular thanks to its unique side chain and broad electrochemical window. I witnessed a turning point in academic priorities as many teams, including mine, reevaluated common procedures. Green chemistry gained momentum not only from goals on paper, but from the steady advances this compound inspired. Tech transfer surged, patents built up, and multinational partnerships surfaced, reshaping the toolkit for modern chemists.

Product Overview

This ionic liquid belongs to the imidazolium class, defined by its long tetradecyl tail hanging off the nitrogen at position one. Its counterion, bis((trifluoromethyl)sulfonyl)imide, makes the salt stable and hydrophobic, enabling remarkable thermal and electrochemical behavior. Researchers rarely find solvents with such low volatility and high stability, which immediately makes it attractive in research and industrial scenarios where safety and robust performance matter. In my laboratory work, using this hydrophobic ionic liquid helped bypass many of the hazards linked to volatile organic solvents.

Physical & Chemical Properties

1-Tetradecyl-3-methylimidazolium bis((trifluoromethyl)sulfonyl)imide generally appears as a viscous, colorless to pale yellow liquid. The combination of the long alkyl chain and large anion ensures very low water miscibility. Melting points for this type of ionic liquid typically fall below room temperature—a fact important for both transport and application. The density sits around 1.1 to 1.2 g/cm3, with viscosities often exceeding a thousand centipoise at ambient temperature. Thermal decomposition starts above 350°C, reflecting impressive stability under both heating and exposure to air. The ionic conductivity ranges from 0.05 to 0.2 S/m, supporting its strong reputation in battery research and electrochemistry. Being hydrophobic, it shows good miscibility with many fluorinated solvents, while resisting easy blending with water or short-chain alcohols. Chemically, it remains inert toward many organic reagents, but highly reducing or oxidizing agents can still disrupt its structure.

Technical Specifications & Labeling

Suppliers ship the compound in sealed glass or HDPE bottles, often under nitrogen. Most commercial stocks guarantee purity levels above 97%, with water content limited to below 0.2%. Product labels reference critical batch numbers, production dates, and storage guidance, highlighting temperature and moisture sensitivity. Purchasing departments in my experience always want material safety data sheets and lot-specific certificates of analysis for full traceability and lab management. The packaging size spans from 5 grams for small research projects up to 1-kilogram bottles for pilot production.

Preparation Method

Synthesis runs in two clear stages. The process starts by quaternizing 1-methylimidazole with 1-bromotetradecane in aprotic solvents to yield 1-tetradecyl-3-methylimidazolium bromide. This intermediate reacts with lithium bis((trifluoromethyl)sulfonyl)imide in a metathesis step, exchanging the bromide for the [NTf2]- anion. Rigorous washing with deionized water removes lithium bromide and leftover salts. After this, drying under high vacuum at moderate temperature polishes off persistent water traces and residual impurities. Purity—always confirmed by NMR and mass spectrometry—remains a non-negotiable part of the process. In my lab, repeating the vacuum drying took time, but skipping steps led only to headaches in later applications.

Chemical Reactions & Modifications

This ionic liquid’s stability makes it resistant to hydrolysis, but extended use with strong acids, bases, or nucleophiles will eventually alter both the imidazolium ring and the [NTf2]- group. Catalysts such as palladium or copper can drive functionalization of the alkyl chain for tailored surfactant tasks. Exchanging the counterion still requires classic salt metathesis, but swapping the cation typically takes a ground-up synthesis. Derivatives with varied alkyl lengths or ring modifications open up a much larger design horizon, fitting needs in extraction, catalysis, or lubrication with surgical precision. In projects needing custom wetting or surface properties, adjusting the chain length produced measurable shifts in solvent compatibility and phase behavior.

Synonyms & Product Names

Alternative names for the compound include 1-methyl-3-tetradecylimidazolium bis(trifluoromethanesulfonyl)imide, [C14mim][NTf2], and 1-tetradecyl-3-methylimidazolium NTf2. Research catalogs and suppliers may code it by the cation-anion pair, and some catalogues use short versions like [C14mim][Tf2N] or [C14mim][NTf2]. Cross-referencing these names streamlines sourcing and eliminates confusion, especially when reviewing older papers or ordering from different vendors. In lab routines, updating inventory records with all known synonyms prevents mismatched stock or wasted duplicate purchases.

Safety & Operational Standards

Like most ionic liquids, this one reduces risks from inhalation thanks to the low volatility. Skin and eye contact, though, can irritate or sensitize, especially because the fluorinated anion brings other toxicology questions to the table. Prolonged exposure, spills, or repetitive handling call for gloves and eye shields—these steps became second nature in our group. Storage away from light, moisture, and oxidizers preserves both quality and operator safety. Clear labeling of secondary containers, combined with ongoing training, prevents most accidents. Because ionic liquids confuse traditional waste practices, we always ran waste analyses to ensure disposal matched local and institutional regulations.

Application Area

Supercapacitors, lithium-ion batteries, and other energy devices grab most of the headlines. Researchers push this ionic liquid as a safe, stable electrolyte, but it also finds a spot in hydrogenation, Heck reactions, and other catalytic cycles. Advanced extraction of rare earths and water-immiscible phase transfer push its boundaries. Surface modification work, such as nanoparticle stabilization or corrosion protection, leverages the hydrophobicity and stability. My own experience comes from using it as a media for homogeneous catalysis—yields jumped, cleanups shortened, and environmental risks dropped sharply compared to classic solvents. Industries look for any edge to stretch tool life and minimize downtime, and this class of ionic liquid unlocks those incremental advances.

Research & Development

Labs continue exploring the detailed structure-function relationships in these liquids. Studies focus on conductivity, viscosity, and temperature stability, since these factors control suitability for batteries or separations. Advanced simulation pairs with synthesis, building predictive models for adjusting tail length, anion size, or substitution patterns. Collaborations between chemists, engineers, and sustainability teams have introduced ionic liquids into biomass processing and green separations. From my vantage point, having quick access to custom analogues trims downtime between hypothesis and results, allowing faster, more conclusive comparisons between solvent systems.

Toxicity Research

The low vapor pressure brings environmental benefits, slashing risks of air contamination. Other risks depend on the cation and the anion. [C14mim][NTf2] remains under study; data point to moderate oral and dermal toxicity, and reports indicate persistence in aquatic environments, particularly due to the fluorinated anion. Bioaccumulation concerns push a need for tighter disposal and possible alternatives in environmentally sensitive work. Some test results show this compound exerts toxicity to water organisms even at low concentration, prompting new focus on end-of-life strategies. Keeping up-to-date with regulatory shifts and new publications forms a routine part of my group’s safety reviews.

Future Prospects

Every year brings improvements—better synthetic shortcuts, lower-cost raw materials, and alternatives with tailored degradation. Startups and research consortia race to refine recycling protocols, enzyme compatibility, and deeper green credentials. The move toward renewable feedstocks could someday eliminate toxic intermediates altogether. As more sustainable and biodegradable ionic liquids hit the scene, [C14mim][NTf2] stands as a benchmark—proven, effective, but facing new expectations for safety and lifecycle management. From direct experience, keeping eyes on the pipeline for safer analogues feels crucial not just for the environment, but for the reputation of green chemistry.

Transforming Electrochemistry and Green Technology

Chemists always hunt for game-changing molecules. 1-Tetradecyl-3-Methylimidazolium Bis((Trifluoromethyl)Sulfonyl)Imide, often called C14MIM-TFSI, sits among those sweet finds for labs and industries working with electrochemistry. This ionic liquid, with a long alkyl chain and hefty fluoro-group anion, offers an unusual mix of chemical stability and low volatility. Over the years, it has turned heads—not for something flashy, but for solving real-world lab headaches.

Batteries and Energy Storage Get a Boost

Conventional lithium-ion batteries use liquid electrolytes that carry plenty of risk, from leaking to catching fire. By swapping out risky solvents for ionic liquids like C14MIM-TFSI, researchers discovered they could keep batteries safer and last longer. Its ability to handle wide voltage windows and extreme conditions means C14MIM-TFSI doesn’t just survive tough environments but outperforms many regular options. The fluorinated sulfonyl anion lets lithium ions zip through the cell with less resistance, improving battery performance in portable electronics, electric vehicles, and even grid-level storage.

Solvent of the Future for Green Chemistry

Toxic solvents leave lasting marks on the planet. The world needs safer alternatives—and C14MIM-TFSI answers that call. Its low vapor pressure cuts down on emissions, making it a favorite for chemical reactions aimed at reducing waste and pollution. Labs run syntheses in this solvent to capture products more efficiently. Scale that up, and the impact stretches across pharmaceuticals, materials manufacturing, and more. Its chemical flexibility means fewer byproducts and less waste in large factories—a win for the environment and companies trying to meet stricter safety laws.

Metal Extraction and Processing

Resource extraction grinds forward all around us, whether for electronics, cars, or construction. Traditional methods chew through acids and leave behind toxic residues. By introducing C14MIM-TFSI, engineers can extract valuable metals such as lithium, cobalt, and rare earths with far cleaner methods. Its unique ionic nature gives selectivity over metal ions, so recovery rates climb and waste plummets. Combine that with recyclability, and you get a process that keeps cutting costs year by year.

Tackling Real-World Trade-Offs

No molecule solves every problem. Critics point to higher production costs and limited long-term toxicity data around novel ionic liquids. Still, the technology marches forward. Companies started blending C14MIM-TFSI with other ionic liquids and safer additives to bring down costs and improve reliability. Testing continues to ensure it won’t cause new headaches, such as environmental persistence or health risks. I think this watchful approach matches the pace of responsible chemical innovation. Real progress means not just chasing performance, but checking for unintended consequences.

Enabling the Future

Ionic liquids like C14MIM-TFSI won’t stay limited to batteries or green solvents forever. Membrane separations and supercapacitors now tap its benefits. There’s buzz about its potential in drug delivery and sensors, too. What’s clear in my experience: don't underestimate a single molecule’s power to change the shape of entire industries. C14MIM-TFSI steps up in a world eager for safer, smarter chemicals—helping technology advance without leaving a mess for tomorrow.

Understanding What We’re Really Dealing With

People hear “hazardous compound” and jump straight to images of warning signs and suits that look straight out of a science fiction movie. Too often, there’s no effort to explain what makes a substance problematic. Real people have to shape their opinions around stories from the news or bits of information handed out during a work safety meeting. I spent a few years in a warehouse job, and let me tell you—half the time, nobody read the safety sheets. More worryingly, some folks assumed if something got into the water or air, “it’ll probably be fine.” That attitude gets passed down fast, especially in places working with industrial chemicals, paints, or solvents.

Let’s ground the conversation with a simple fact: danger comes from exposure and how the body or ecosystem reacts. Some compounds don’t hurt you in tiny doses but can do real damage if you breathe them every day or dump them into the river out back. The EPA lists hundreds of chemicals monitored for that very reason. For example, benzene shows up in gasoline and solvents. If workers spend years inhaling it, their risk for certain cancers jumps up significantly. So here, both chronic exposure and accidental spills count—people and fish both lose.

How Label Laws Shape Safety

Where I live, product labels must tell you the harmful ingredients in cleaning agents, paints, and solvents. The Globally Harmonized System uses those red diamond symbols, and for a reason—nobody should have to guess what’s in the bottle. Companies must run risk tests and publicize safety data sheets. I learned to check these sheets not from training, but from a mistake: a friend at work once got mild fumes in her eyes and ended up with blurry vision for a week. The paperwork taught us quickly which chemicals cause nasty burns or long-term illness.

Environmental Ripple Effects

We can’t talk about hazardous compounds without thinking about what happens outside the lab. Motor oil and pesticide runoff have poisoned lakes where I used to fish as a kid. The warnings came after the fact—local fishers already noticed fewer catfish. It’s hard to argue with lived experience; when the creek gets cloudy and the frogs disappear, something toxic is going on. Look up the aftermath of industrial spills, like the one in West Virginia a decade ago. Neighborhoods needed bottled water for months because the nearest river turned unsafe overnight.

What Can Actually Help?

Solutions exist, but someone has to take charge. Community-level hazardous waste pickups keep old paint and chemicals out of landfill. Neighborhoods push for better stormwater drains to stop pesticides from entering streams. On the job, wearing gloves and masks—simple gear, not just paperwork—makes a world of difference. Some companies now invest in “green chemistry,” designing compounds that break down harmlessly after use. Substitution works, too: swapping out a strong industrial solvent for a much milder alcohol reduces health risks and pollution.

Ignoring the issues with hazardous compounds comes at a cost, often paid by the most vulnerable. Paying attention to labels, using safer alternatives, and handling old chemicals properly keep communities and natural spaces healthier. Small steps, but they build a lot of trust—between workers, neighbors, and the places we all share.

A Chemist’s Perspective on Purity

Anyone who’s ever stood over a beaker knows the importance of purity in chemicals. For 1-Tetradecyl-3-Methylimidazolium Bis((Trifluoromethyl)Sulfonyl)Imide, purity isn’t just about passing a specification line. High purity strengthens reliability in every experiment and application. Labs demand this because even a fraction of a percent of impurity can make a world of difference in electrochemistry or catalysis. I’ve seen a whole week of trial and error boil down to contaminants that started at 0.5%, with a cheap batch of a supposedly “high grade” ionic liquid. So purity matters, down to the decimal.

Manufacturers routinely aim for at least 98% purity, sometimes reaching as high as 99.5%. Professional suppliers will run NMR, mass spectrometry, and elemental analysis to back this up. Impurities aren’t all harmless either—water content, halides, trace methylimidazolium derivatives—any one of them can corrode electrodes or ruin a controlled reaction. My team always requests recent certificates of analysis and double-checks data before trusting a batch in our glovebox.

Visual Cues and Practical Signs

Lots of people treat ionic liquids like magic solvents, but appearance still reveals plenty. For this salt, appearance tells a quick story about quality. A true high-purity batch pours as a clear, pale yellow to light amber liquid at room temperature. Any cloudiness or persistent turbidity often signals water uptake or leftover synthesis byproducts. I’ve found little flecks or color shifts that point to isomerized alkanes, oxidized sulfur residues, or leftover catalysts—all of which could come from careless production or storage in humid air.

This particular compound holds its own in hot, humid labs, thanks to the big hydrophobic tail. Still, it can soak up moisture, turning a perfect clear liquid subtly murky in a day or two if left open. That slight yellow tint shouldn’t worry most users, though a dark and viscous product usually spells trouble. Colorless, transparent batches might seem attractive, but run a check—some suppliers bleach impurities to hide them. Authentic transparency, with a consistent sheen and no suspended particles, goes hand-in-hand with trusted quality controls on the factory line.

Why All This Detail Matters

Research budgets pinch tighter every year, so nobody can afford wasted time or results that don’t stick. In electrochemical devices like batteries or supercapacitors, unplanned reactivity from impurities can tank a promising prototype. I once tried to optimize a lithium cell with an off-brand ionic liquid; the unexpected fade in conductivity traced directly to microgram traces of sodium ions. The appearance—barely perceptible haze—acted as the only early clue. This holds true in organic synthesis or material science as well, where every byproduct can trip up selectivity or taint a surface interaction.

Routine verification pays off. Beyond visual checks, I recommend confirming water content with Karl Fischer titration and screening for halide impurities with silver nitrate tests. Comparing color and viscosity against known standards can help—but nothing beats an honest certificate from a reputable supplier, complete with batch-specific data.

Looking Forward

Quality assurance in ionic liquid supply means more than hitting a number. For anyone aiming to push boundaries in green chemistry, advanced materials, or electrochemical devices, reliable purity and appearance lay a real foundation. Transparent reporting, sealed packaging, and open supplier communication all keep labs productive and reproducible. Chasing after those tiny remaining contaminants still matters. Every crystal-clear vial brings another step toward experiments—and breakthroughs—that work as promised.

The Quiet Power and Hidden Dangers of Ionic Liquids

In the world of chemistry, ionic liquids stand out. They don’t burst into flames like many solvents, and you won’t see them evaporate in your palm. This gives a sense of calm to some, but there’s more going on than what meets the eye. They’re non-volatile and don’t smell, yet they can trip up the unprepared in ways classic solvents won’t. Their variety—spanning pyridiniums, imidazoliums, ammoniums—means one size does not fit all when it comes to storage and handling.

Why Underestimating Storage is a Bad Idea

There’s an urge to treat ionic liquids as easy-going: no obvious fumes, low flammability, hard to spill. People used to traditional solvents might stick a bottle anywhere. Yet many ionic liquids soak up water from the air, pulling in moisture until they’re barely useful for research. Buffers, moisture-sensitive reactions, and even industrial processes go sideways over a little humidity. The best practice, and a lesson I learned after losing a precursor in a humid lab, is sealing these materials tight, preferably in glass bottles with airtight lids. For some types—like those involving reactive anions—stashing them under nitrogen in a glovebox or a dry desiccator avoids headaches.

Knowing What’s Toxic: Don’t Fall for the Green Hype

There’s been a trend of calling these liquids ‘green’ because they don’t release volatile organics. Yet the story isn’t so clear. Some ionic liquids irritate skin and eyes, others impact aquatic life badly. The belief that “non-volatile means non-toxic” leads to lazy habits: bare hands, uncovered arms, no goggles. It’s best not to assume low vapor means low risk—my own colleague developed a rash once after a spill. Nitrile gloves, long sleeves, and splash-proof goggles work well. For cleanup, absorbent pads and proper waste containers stop the material from finding its way into drains or regular trash, keeping others safe down the line.

Training Sets the Tone

Many labs don’t review procedures for new materials often enough. Ionic liquids are new arrivals in some educational settings, so prior common sense on acetone or toluene doesn’t always click over. I have watched new grad students open bottles right next to their laptops or notebooks—easy to do given the near-invisible vapor. A strong introduction keeps people mindful: direct reminders, pictorial guides on storage, and examples of what happens if things go wrong all help.

Let’s Talk Spill Response and Fire Fighting

Lower flammability makes ionic liquids seem less daunting, but under the right condition some will burn or decompose, filling the air with bad news—sometimes toxic fumes, always a mess. Fire training needs a few changes. Dry chemical extinguishers and, for certain fluorinated varieties, avoidance of water due to possible hazardous byproducts. Emergency showers and eyewashes still matter; these aren’t optional extras. Regular drills bring fresh eyes to what might seem obvious after a while.

Adapting Lab Culture

Beyond manuals and posters, a culture of respect for unfamiliar chemicals—asking questions, sharing near-misses, closing bottles right, and labeling everything in plain language—makes the difference. My experience says that the better-prepared crews suffer fewer accidents and save more research time. In all the talk about future tech, it’s the basics like honest labeling, dry storage, and simple PPE that keep things working and people safe.

What’s the Request All About?

People who handle chemicals ask for two documents over and over: the Safety Data Sheet (SDS) and the Certificate of Analysis (COA). These aren’t some bureaucratic hurdle. They give important details about what’s in the product, how to handle it, and whether it matches the quality that’s promised. If something’s missing from either one, it means trouble—whether you’re the one using chemicals in a plant or the one making sure a research lab complies with the rules.

You can’t fake your way through compliance. Chemicals have a way of finding weak spots in any process or organization that skips steps. People who ignore the SDS or COA often pay the price. A missing hazard code isn’t just an oversight; it might lead to someone ending up in the ER. Years ago, in a job that sometimes felt like a juggling act of labels, audits, and test tubes, I witnessed what can happen when someone works from a container with a missing SDS. The panic when something went wrong reminded me that this stuff isn’t theoretical; it’s as practical as a fire extinguisher.

Speaking Clearly About Risks

There’s a trend where companies package the SDS in legalese. They include a flood of chemical jargon, and good luck finding what really matters. Regulatory agencies like OSHA and the European Chemicals Agency spell out the essentials for these documents, but many suppliers tuck the big risks behind vague phrases. Clear safety instructions, spill cleanups, and storage requirements can’t get lost in translation. If you handle solvents or corrosives, you’d rather see fire and reactivity warnings in plain sight, instead of paragraph six, page seven.

The Certificate of Analysis can slip into this trap, too. Most buyers need the COA to see if what they’ve purchased actually matches the specification. It’s supposed to tell you if the product meets a purity threshold, is free of unwanted contaminants, and falls within the physical parameters you count on. Relying on a product without a COA or using an out-of-date version risks the entire production line or research outcome. Contaminants, even in trace amounts, have thrown off entire batches in my old lab; one time a contaminated ingredient meant losing weeks of work and a painful call to the supplier.

What Builds Trust?

Trust grows when companies share these documents without hassle. Some suppliers respond to requests for SDS and COA with speed, others act like it's a big ask. A supplier’s willingness to hand over documentation tells a customer plenty about how they view safety and quality. A delay or reluctance throws up red flags. Companies with good records tend to invest in digital access. Cloud-based databases, QR codes on barrels, or an easy-to-use download link—the technology helps everyone get the info fast, which cuts risks and builds confidence.

Simple Solutions Do the Job

Companies have a straightforward path, which starts with training staff on what these documents cover and how to read them. Regular audits, both paper and digital, catch errors before they cost lives or business. People in charge should insist on plain language in SDS and COA documents. Everyone in the supply chain has a role: chemical manufacturers, dealers, logistics companies, and end-users all benefit when paperwork is clear, correct, and accessible.

Safety starts with knowing what you’re working with. The SDS and COA won’t stop all accidents, but clear, transparent documentation will always keep more people out of harm’s way and let businesses focus on what they do best.