1-Tetradecylimidazole: Exploration and Impact

Historical Development

Back in the days of early heterocyclic chemistry, curiosity often led scientists to uncover unexpected molecular frameworks. 1-Tetradecylimidazole entered the lab scene as researchers extended their gaze from short-chain alkyl imidazoles into longer chains. In the late 20th century, interest in surfactant-like molecules and functional amphiphiles drove teams toward creating hybrids that bridge polar and lipophilic systems. Hearing older chemists recount their experiments, they usually mention the excitement that followed the first successful alkylations. By the early 2000s, the landscape had shifted toward amphoteric molecules for drug delivery, self-assembly, and membrane mimicry, and 1-tetradecylimidazole started to catch more attention.

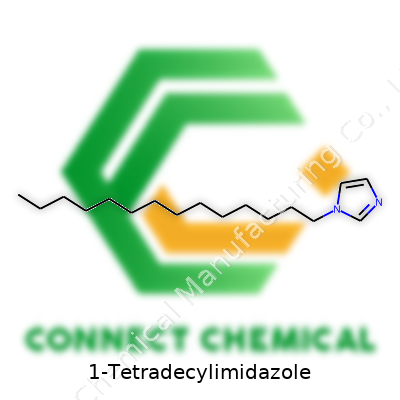

Product Overview

1-Tetradecylimidazole means an imidazole ring with a fourteen-carbon straight chain stretching from its first position. You can think of it as a marriage between a hydrophilic imidazole head and a robust fatty tail, offering a unique mix of solubility and surface activity. Over time, product forms expanded from practical chemistry-grade powders to highly purified analytical standards. I've seen suppliers offer samples ranging from small glass vials to industrial bulk blends. As demand grows, more labs and companies flag its presence in product catalogs, with quality controls evolving along with application range.

Physical & Chemical Properties

In the flask, 1-tetradecylimidazole presents as a waxy or oily solid at room temperature. That fourteen-carbon tail creates a higher melting point than shorter analogs, pushing it into a creamy paste in a warm room. Odor is faint, but with prolonged exposure, you sense echoes of both fatty chemicals and slight amine tinge from the imidazole ring. The molecule resists water, loving organic solvents, yet the imidazole end gives a shot at modest water interaction, especially under acidic or basic conditions. As an amphiphile, it lines up at the air-water interface, and forms micelles at higher concentrations. It usually remains stable in dry storage, but can slowly degrade if left exposed to light or air.

Technical Specifications & Labeling

Quality standards depend on application, but reports from suppliers list purity values above 98% for research, sometimes exceeding 99% in pharmaceutical batches. Molecular weight tallies up at 276.45 g/mol. The CAS number most often referenced is 3529-73-9. Visual inspection verifies color and appearance, sometimes with a melting range between 48–52°C. Labels need a clear signal about “Irritant” or “Harmful if Swallowed,” together with recommended storage at 2–8°C, safe from direct sunlight. Transport requires sturdy sealing to prevent leaks, and regulatory descriptions state it falls under standard organic chemicals with restricted inhalation and ingestion.

Preparation Method

Alkylation of imidazole with 1-bromotetradecane under basic conditions became the leading method in most labs I visited or read about. A traditional approach places imidazole and the bromide in a polar aprotic solvent. Heating encourages the nucleophilic nitrogen to snatch up the long alkyl chain, producing our product alongside sodium bromide or potassium bromide waste. Purification by crystallization or column chromatography ensures a clean batch. Variations appeared over time, with industrial syntheses favoring greener solvents, better atom economy, and less hazardous waste by replacing old-school reagents with phase-transfer catalysts or microwave-assisted heating.

Chemical Reactions & Modifications

1-Tetradecylimidazole carries a pool of reactivity mainly through the imidazole ring. Sites at N-3 or positions 4 and 5 can take on further groups, depending on what the chemist needs. In oxidation, mild conditions keep the molecule safe, but strong oxidants break the tail or open the ring. Under acidic conditions, quaternization produces salts valuable as ionic liquids or surfactants. Acylation and sulfonation at the imidazole add further layers for specialty chemistry. I’ve watched research groups use it as a starting point for more complex cationic surfactants, fabricating custom interfaces for sensors and emulsifiers.

Synonyms & Product Names

In catalog searching, researchers spot “1-tetradecylimidazole” listed alongside names like N-tetradecylimidazole. European suppliers sometimes use linear notations, but the chemistry community sticks with the obvious. Trademarks emerged for specialty derivatives, especially ionic liquid forms and modified drug carriers. 1-(n-Tetradecyl)imidazole also appears in certain pharmaceutical and materials labeling.

Safety & Operational Standards

Handling guidelines echo common-sense rules for lipophilic organics. Gloves and splash goggles prevent skin or eye irritation. Spilled material gets swept—never vacuumed—while rooms need adequate airflow, especially if heating is involved. Although acute toxicity runs low based on available data, long-term exposure safety takes priority, particularly where workers handle heated forms or high concentrations. Disposal routes funnel waste into incineration or controlled chemical neutralization, circumventing groundwater contamination. A friend once shared a story where mishandling led to sticky surfaces and mild dermatitis, serving as a caution about skipping basic protection in a rush.

Application Area

Research labs, pharmaceuticals, and materials science rely on 1-tetradecylimidazole in applications that tap both the imidazole and alkyl characteristics. As a cationic surfactant, it gathers attention for micelle formation and drug delivery vehicles. Biomedical teams exploit its membrane-mimicking skills to ferry cargo across biological barriers. Recent years saw it tested in anti-microbial coatings and liposomal assemblies, addressing the constant hunt for stable, biocompatible molecules. Beyond life sciences, formulation scientists introduce it in corrosion inhibitors, oilfield recovery, and lubricants, welcoming its thermal stability and wetting action. Success in one industry, such as controlled drug release, often spills over as a proof-of-concept for food-grade and agrochemical innovations.

Research & Development

Ongoing work probes deeper into the molecule’s quirks. Teams experiment with substitutions on the imidazole ring to check if pharmacological or material properties improve. Systems employing 1-tetradecylimidazole as part of nanoemulsions or smart hydrogels show promise in preclinical studies. University-industry collaborations aim to lower raw material costs and boost sustainable sourcing, focusing on efficient production and renewable feedstocks. In conversations with researchers at conferences, the molecule’s blend of lipophilicity and reactivity keeps popping up as a reason for new PhD projects and grant proposals.

Toxicity Research

Publications suggest limited acute oral or skin toxicity for most imidazole alkyl derivatives, though comprehensive studies on the tetradecyl chain remain scarce. Some teams monitor bioaccumulation and chronic effects, concerned about residues in aquatic environments where surfactants often end up after use. Early toxicology essays chase after organ toxicity signals or endocrine disruption, while in vitro tests explore its interactions with human cells, noting only slight irritation at moderate doses. Researchers keep calling for more detailed, independent assessments, fueling debate on whether new regulations may appear if industrial uptake increases.

Future Prospects

Voice in the field suggests 1-tetradecylimidazole will ride the growing demand for sustainable, multifunctional molecular tools in pharma, biotechnology, and materials chemistry. Its promise as a building block for targeted delivery, green catalysts, and environmental remediation gets stronger as more teams publish results on tailored modifications. Upscaling eco-friendlier synthesis will likely turn into a central issue, especially if regulators clamp down on environmental persistence and residues. Watching investment shift toward renewable precursors, I expect future work to tie the molecule’s unique features to broader circular economy goals. With every passing year, the conversation matures, blending molecular insight with real-world impact where both science and society benefit.

How This Odd-Sounding Chemical Makes Things Happen

Plenty of people don’t recognize the name 1-Tetradecylimidazole unless they’ve waded through the world of lab work, detergent chemistry, or specialty coatings. To be honest, before digging deep into specialty chemicals, the name sounded like one more tongue-twister out of a synthesis textbook. Now, after years chasing down molecules for projects in coatings and cleaning products, it’s obvious certain chemicals play much bigger roles than anyone on the outside suspects.

1-Tetradecylimidazole belongs to a group that chemists call imidazoles—these molecules have an unmatched knack for stabilizing things. In the simplest terms, this particular one carries a long tail with fourteen carbons. That’s the part that helps it blend and stick in oily or waxy systems. The imidazole head adds the real magic—binding to metals, tweaking surface properties, encouraging certain reactions, or helping other molecules dissolve.

Breaking Down Real-World Uses

In industrial corrosion control, 1-Tetradecylimidazole serves as a corrosion inhibitor. Many metal pipelines and tanks face constant attack by water, oxygen, and salts. The problem can wreck expensive equipment if nobody steps in. This chemical latches onto metal surfaces and forms a shield, pushing back water and rust-promoting stuff. Pipes hauling oil and other fluids don’t last long without protection like this—especially in refineries or water-rich environments.

Another big use comes in cleaning. Surfactants form the backbone of household and industrial detergents. Add the right kind in, and suddenly greasy grime slides off stoves, car parts, and oily tools. Long-chained imidazoles such as this one cut through heavy soils that regular soap or shampoo barely budges. Anyone who’s ever scrubbed industrial kitchen grease or cleaned mechanical parts knows that some stains fight back with everything they’ve got. Without strong surfactants, you’re looking at wasted hours and tired arms.

Why Care About These Tiny Helpers?

Ignoring specialty chemicals leads to big headaches—constant equipment repairs, environmental fines from leaks or spills, and huge product recalls. I’ve watched factories scramble to solve these problems with the wrong cleaners and rust inhibitors. More often than not, the “cheap fix” turns into a money drain. Choosing the right chemical early on, even if it costs a little extra, saves whole projects from disaster.

Beyond factories and workshops, there’s a growing push to ask how chemicals like this behave in the real world, especially after they get washed down the drain. Regulatory rules now call for closer tracking of how additives like imidazoles break down in wastewater and what they do to aquatic life. This puts pressure on companies to make safer, “greener” versions—or at least use these compounds more responsibly.

What Can Be Done Better?

As researchers and chemical suppliers, it’s not enough to chase performance alone. Open, clear information about how much of these substances enter the environment and what happens next is overdue. Any company handling specialty chemicals should train workers to handle, store, and dispose of these ingredients properly. Manufacturers also need to develop more biodegradable surfactants and cleaners that protect metals but leave less behind after use.

Putting these steps into practice takes real commitment. Everyone from plant managers to buyers should press for details—ask suppliers about test data, byproducts, and breakdown times. The more pressure placed on safer choices, the easier it gets for the whole industry to shift toward products that protect both machinery and the world outside.

Looking Closer at the Structure

The backbone of 1-Tetradecylimidazole offers a pretty straightforward setup. Picture an imidazole ring—a five-membered structure packed with two nitrogen atoms naturally bringing some basicity—hooked up to a long, straight 14-carbon tail. That tail carries a lot of hydrophobic weight. The imidazole head has a polar punch, the kind you find in systems that want to attract ions or form hydrogen bonds. This combo creates a molecule with both watery and oily leanings, almost like a molecular fence-sitter.

Solubility: The Long Tail Tells the Story

Pour 1-Tetradecylimidazole into water and most of it avoids dissolving. The big hydrocarbon chain wants nothing to do with H2O, so you see clustering and an urge to form micelles. Those nitrogen atoms on the imidazole don’t give up the fight, helping the head anchor at interfaces, but they can't overpower that long tail. Toss it in organic solvents—like chloroform or ether—and things change. Now the nonpolar tail blends in, so you get much better mixing. This switchable solubility stands out if you’ve ever worked with surfactants or needed to coax oil and water into awkward cooperation.

Acidity, Basicity, and Reactive Sites

Imidazole structures pop up everywhere in nature for a reason—they juggle acidity and basicity with skill. The ring in 1-Tetradecylimidazole can snag or lose protons, which means you get buffer action in solution. Folks working with pH-responsive systems or catalysts love to play with this feature. The ring has lone pairs on nitrogen, so it can coordinate with metals and create more complex structures. Chemists who build sensors or fancy reaction catalysts pay attention to that.

How It Behaves: Beyond the Test Tube

Tossing 1-Tetradecylimidazole into a mixture, you won’t miss the surfactant behavior. In practice, it drops the surface tension of water, setting the stage for everything from cleaning tech to drug delivery research. The long chain makes it stick to biological surfaces, which means it sometimes finds its way into antimicrobial mixtures or corrosion inhibitors. That hydrophobic segment slides into the lipid membranes of microbes, disrupting their routine. It’s the molecular version of a wrench in the works.

Risks and Practical Takeaways

Long-chain imidazoles like this come with environmental baggage. The structure resists breaking down in the wild, so any large-scale use should include serious waste management. Personal experience in the lab has shown that cleanup isn’t a quick job—residues linger, and you must avoid washing them down the drain. Users need gloves and decent ventilation because direct exposure can irritate skin and lungs.

Where Research Points Next

Chemists and engineers keep probing how this molecule self-assembles with others. There’s a thirst to tweak the tail length or swap out atoms on the ring to tune performance—maybe better detergents, greener solvents, or selective catalysts. Any push forward needs data on toxicity and persistence in soil and water.

What to Watch For

Those digging into synthetic work or industrial uses of 1-Tetradecylimidazole should keep their focus set on the chemical’s impact in the lab and environment. Approaching it means weighing that attractive mix of reactivity and hydrophobic muscle against the hassle of cleanup and disposal. The blend of properties in this molecule tells a bigger story about how the chemistry behind household detergents and next-generation catalysts starts with just a few atoms and a long tail.

Handling Chemicals Can’t Be an Afterthought

Chemical names sometimes have a way of sounding scarier than they are, but experience taught me to treat every new name as a potential hazard until proven otherwise. 1-Tetradecylimidazole is no exception. The molecule combines an imidazole ring (common enough in medicines and biochemistry) with a 14-carbon tail, which is a setup you might expect among industrial surfactants or corrosion inhibitors. Sometimes people think if a chemical isn’t flashing with colors or sporting a skull and crossbones, it poses little risk. That can be a mistake.

I once saw a colleague react poorly after accidental skin contact with a similar imidazole compound, despite gloves. The incident stuck, and since then, I look up safety information before I even open a bottle. For 1-Tetradecylimidazole, data from chemical safety sheets points to irritant effects if it touches skin, eyes, or if you breathe in dust or vapors. You won’t find it flagged for severe toxicity on the same level as classic industrial hazards, but lack of acute toxicity doesn’t mean zero risk. Chronic exposure, especially through inhalation or long-term skin contact, can lead to problems that only show up after weeks or months.

Practical Safety: Gloves and Ventilation Matter More Than Most Think

You’ll want nitrile gloves, not latex, for handling. Standard safety glasses work unless there’s a splash risk—then go for a shield. Fume hoods make a real difference in managing vapor or dust. Let’s be honest, not every facility provides the best ventilation, but investing in mobile fume extraction or local exhaust isn’t just about regulations—it’s about avoiding headaches, nausea, and potential long-term reactions that can mess with your career. Respirators aren’t a bad call if the substance gets heated or aerosolized.

The MSDS (Material Safety Data Sheet) for 1-Tetradecylimidazole—published by respected suppliers—lists “irritating to eyes, respiratory system and skin.” That tells you all you need: chemical burns and allergic skin reactions aren’t just theoretical, especially for people who might already have sensitive skin. It’s smart to wash up right after use and avoid bringing work clothes home; I once washed a lab coat without thinking and ended up irritating my hands until I figured out why.

Understanding Why Documentation and Training Beat Guesswork

Anyone relying on rumor or tradition for chemical safety risks missing real hazards. It isn’t overkill to do a risk assessment for each new compound in the workspace and to refresh the team on proper handling and first aid every year. I’ve seen newer staff hesitate to speak up about spills because they weren’t sure about the risks—clear, accessible guides would have prevented unnecessary exposure. The classic assumptions about safety sometimes don’t fit the obscure compounds.

Looking at the long game, safe handling means less downtime, fewer accidents, and a team that takes pride in working smart. Good documentation, up-to-date MSDS access, and making sure personal protective equipment stays stocked matter more than any one-off training session. If policies fall behind new research or if a labeling system gets ignored, risk creeps back in.

Better Habits: Solutions That Actually Work

Chemistry labs and plant floors improve safety records when workers buy into the value of protective gear and get regular, honest updates about new findings on compounds like 1-Tetradecylimidazole. Management involved on the ground, listening to feedback, and making sure broken fume hoods don’t stay broken for long supports trust and compliance. In my own time, sharing stories about close calls or successes during staff meetings made people more likely to double-check gloves and goggles. Prevention costs far less than medical bills or lawsuits.

Chemistry at the Everyday Level

Chemistry books can turn off students fast, often because they fill pages with jargon and equations. For folks like me, clarity beats complexity every time. So when I see a name like "1-Tetradecylimidazole," I break it down. The “imidazole” part rings a bell from my undergraduate days—two nitrogens in a five-membered ring, something that pops up in biological systems a lot. The “tetradecyl” part signals a long, 14-carbon chain. Put these together, and the molecular formula comes alive: C17H32N2.

Behind the Formula: Real-World Context

I got my first real hands-on time with compounds like this during a research internship. In the lab, molecular formulas aren't there for show—they help decide if a chemical suits a practical need. 1-Tetradecylimidazole has that long hydrocarbon tail. That’s not just window dressing. This kind of structure turns up in surfactants and corrosion inhibitors—jobs that mean the difference between a clean pipeline and costly equipment failure.

A formula like C17H32N2 tells you more than just how many atoms come together. You get a sense of how the molecule will behave: good solubility in non-polar solvents, easy attachment to metal surfaces, possible interactions with biological membranes. These details go unnoticed outside the chemistry world, but inside, they make or break reliable performance.

Connecting Structure with Impact

Learning about compounds such as 1-Tetradecylimidazole in college left me with a lasting respect for the invisible bridge between laboratory work and the products people depend on. That long carbon chain means it sticks to oily substances. The imidazole group brings some basicity and electron-sharing properties that work well in coordination complexes. This chemistry helps slow down rust in water systems or even keeps marine equipment working longer despite salt and pressure.

Industry doesn’t toss around new molecules for fun. Each variant in the lab means extra cost and time for tests. Before anything sees widespread use, careful tracking of molecular structure and formula is essential. After all, hidden differences in a formula may spell disaster if a corrosion inhibitor doesn’t hold up or, worse, kicks off unwanted side reactions.

Responsible Use and Looking Forward

As a student, I saw dangers firsthand—poorly labeled bottles, substitutes used in a pinch, and cleanup delayed due to confusion over chemical types. Mistakes here can lead to dangerous exposures or wasted money. Strong labeling practices, regular reviews of safety data, and a skeptical approach to "cutting corners" can cut down the risks. In my own projects, I keep digital inventories with clear molecular formulas precisely because it's better safe than sorry.

The molecular formula C17H32N2 isn’t just trivia. It helps chemists predict how the substance behaves, lets industry workers control costs and hazards, and keeps end-users safe. For anyone hoping to work with specialty molecules, this attention to detail shifts chemistry from blackboard theory to real-world responsibility—a lesson that sticks, long after the last lab bell rings.

Why Storage Even Matters With Specialty Chemicals

Anyone who has worked with chemicals like 1-Tetradecylimidazole knows stories about things going wrong in the stockroom. Sometimes fumes catch you by surprise. Sometimes labels start to peel and you realize nobody’s checked that bottle for months. With a compound like this, which finds its way into laboratories and industrial settings thanks to its surface activity and unique structure, ignoring safe storage can invite not just product degradation but also risks for people near it.

Conditions That Help 1-Tetradecylimidazole Last

I learned over years in shared university labs that heat and light can take a toll on a lot of chemicals. This one is no different. Storing it at room temperature in a dry place helps avoid unwanted reactions and spoiling. Think of the disastrous mess after a bottle left near a sunny window turned cloudy and ruined a week’s worth of experiments. Moisture in the air often starts slow changes in chemicals, so people end up spending more money replacing supplies that should have lasted. A dry, well-ventilated storeroom cuts down on these avoidable losses.

Sunlight can do more than just fade labels. Ultra-violet exposure sometimes kicks off tricky degradation pathways, especially for many heterocyclic compounds. Amber bottles step up here, and tight-fitting lids keep both air and light away from what's inside. Labs that cut corners with makeshift storage run into much more frequent product failures or, worse, dangerous leaks.

Common Pitfalls: What Actually Happens in the Field

Some companies haul in bulk shipments and, pressed for space, stash everything together. That brings cross-contamination, even the slight chance for some chemicals to interact and create unexpected hazards. I’ve seen old absorbent pads reused instead of fresh containment trays, leading to sticky messes and confusion that could all be avoided with a little forward planning.

Labels fade or get written hastily. A bottle that once read "1-Tetradecylimidazole" winds up covered in dusty fingerprints, confusing even the sharpest technician on a tough shift. Good labeling doesn’t come just from one-time attention, but regular inspections. No one wants to be the person who finds out too late what’s really in that unmarked container.

Safe Storage Looks Like This

At its best, chemical storage stays rooted in practical, lived routines. Dedicated cabinets keep specialty organics away from acids, bases, and oxidizers. Properly marked shelves organize bottles by risk class, not by how fast someone wants to grab them. Fire safety rules vary by country, but using metal cabinets with self-closing doors shows a basic level of care that protects not just property, but people.

I’ve watched so many new technicians want to build habits fast, but lasting safety culture comes from repeated walk-throughs and honest discussions about what could go wrong. Keeping up-to-date safety data sheets in easy reach helps everyone know, in concrete terms, what they’re dealing with. Encouraging this habit means fewer mistakes and more peace of mind all around.

Simple Solutions Make a Huge Difference

People sometimes think only big budgets bring about good storage, but even small organizations pull off successful systems. Cheap hygrometers and temperature monitors tell you at a glance if conditions need adjusting. Routine cleanup days help declutter shelves and remind everyone what’s on hand. Creating a log for checking bottles—just a binder by the door—catches issues well before something escalates.

In the end, 1-Tetradecylimidazole does best in the same environment most specialty chemicals want: dry, cool, protected from light, and clearly labeled. A little effort at the front end keeps the whole operation running smoother, safer, and ultimately more affordable for everyone invested in getting their work right.