1-Vinyl-3-Dodecylimidazolium Tetrafluoroborate: A Modern Ionic Liquid with Broad Horizons

Historical Development

The story of ionic liquids picks up real momentum in the late twentieth century, when chemists began searching for safer alternatives to volatile organic solvents. Researchers around the world noticed that imidazolium-based salts stayed liquid at room temperature and displayed a knack for dissolving a wide range of materials. Those efforts crystallized into the widespread use of functionalized imidazolium salts. The introduction of 1-vinyl-3-dodecylimidazolium tetrafluoroborate opened the door for materials scientists and electrochemists to experiment with a compound possessing not only a flexible imidazolium core but also a long dodecyl chain and a reactive vinyl group. This combination came out of a desire to give scientists more levers to pull when designing solvents, catalysts, and functionalized polymers.

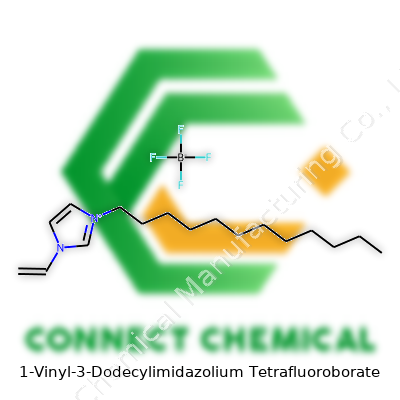

Product Overview

1-Vinyl-3-dodecylimidazolium tetrafluoroborate shows up as a colorless to pale yellow liquid or a waxy solid, depending on temperature. The structure features an imidazolium ring substituted with a vinyl group at the first position and a dodecyl chain at the third. The counterion, tetrafluoroborate (BF4-), brings ionic stability and decent air- and moisture-tolerance. Unlike simple solvents or salts, this molecule offers opportunities both as a reactive monomer and as a functional ionic material. Its amphiphilic design allows it to bridge oil-like and salt-like environments, which unlocks unique physicochemical properties and broad application territory.

Physical & Chemical Properties

The blended character of this compound defines how it behaves. With a molecular weight in the 400s, it holds relatively low volatility and, in its pure form, does not ignite easily under standard laboratory conditions. Its melting point hovers just above room temperature, pushing it into liquid form on a warm day or under mild heating. Solubility follows expectations for ionic liquids, mixing well with polar organic solvents (like acetone, DMSO, acetonitrile) but resisting water thanks to the dodecyl anchor. Its viscosity runs higher than typical organic solvents but lower than many salts with similar size due to the flexibility of the side chains. The vinyl group sets this molecule apart—the double bond becomes a site for radical polymerization, allowing the formation of ionic polymers and specialty materials.

Technical Specifications & Labeling

Manufacturers typically supply 1-vinyl-3-dodecylimidazolium tetrafluoroborate at greater than 95% purity, with certificates of analysis covering water content, residual halides, and trace metals. Labels include UN numbers, hazard icons, production lot numbers, and recommended storage conditions (tightly capped, away from light and moisture). Material safety data sheets warn about possible irritancy but present no acute hazards in small-scale laboratory handling. Instead, attention falls on the need for personal protective equipment and proper containment in synthesis and transfer to avoid contamination or accidental contact.

Preparation Method

Production starts from the 1-vinylimidazole core, which reacts with dodecyl bromide (or chloride) in a straightforward alkylation step, typically performed in acetonitrile or another polar aprotic solvent. This intermediate—the dodecylimidazolium bromide—is then treated with sodium tetrafluoroborate through a metathesis (ion-exchange) process, yielding the free-flowing tetrafluoroborate salt alongside sodium bromide byproduct. After separation and thorough washing, careful drying under vacuum removes final traces of water and solvents, producing a material ready for direct application or further modification. Lab synthesis takes a few hours to a day, depending on the scale and equipment setup.

Chemical Reactions & Modifications

The molecule’s reactivity mostly tracks with its vinyl substituent. Researchers leverage this group for radical polymerizations, creating poly(ionic liquid) networks that blend ionic conductivity with mechanical strength and tailorability. Certain teams use the dodecyl chain for self-assembly, making micelles or nanostructures in solution. The imidazolium ring itself can participate in nucleophilic addition or serve as a ligand in organometallic complexes, though less commonly. The tetrafluoroborate ion offers stability but can undergo slow hydrolysis, especially above neutral pH or at high temperatures, which users need to monitor. Some groups swap BF4- for PF6- or other anions to fine-tune solubility or thermal resistance.

Synonyms & Product Names

This compound appears in catalogs and journals under names such as 1-vinyl-3-dodecylimidazolium tetrafluoroborate, 1-vinyl-3-dodecylimidazolium boron tetrafluoride, and its common acronym [C12vim][BF4]. Sigma-Aldrich, TCI Chemicals, and Aladdin Reagents list it under these trade names, usually with the associated CAS number for clarity. Some articles simply call it ionic liquid monomer with a C12 tail, especially when discussing polymer science.

Safety & Operational Standards

Even though this ionic liquid avoids most of the volatility and flammability of typical organics, it pays to treat it with respect. The imidazolium core can cause irritation if it touches skin or eyes, and accidental ingestion must be avoided at all costs. Nitrile gloves, lab coats, and goggles keep accidents from escalating. Good ventilation is smart policy, especially during polymerization where radical initiators or byproducts form, and any waste must be collected in halogenated organics streams per environmental guidelines. Emergency showers and eyewash stations remain necessary in laboratories handling concentrated volumes, and spill kits should stand ready in case of accidental release.

Application Area

Polymer chemists prize this monomer for making conductive polymers with higher environmental stability than many traditional ionomers. Electrochemical engineers build ionic membranes for batteries and capacitors, leveraging the compound’s broad voltage windows and ability to transport lithium ions without dissolving battery electrodes. Some teams experiment with 1-vinyl-3-dodecylimidazolium tetrafluoroborate as an additive in electrolyte blends, hoping to tame dendrite growth and electrolyte breakdown. Materials scientists investigate its use as a surfactant-like additive in nanoparticle synthesis, where the dodecyl chain brings order to growing clusters. Biotechnologists try it for protein stabilization or drug delivery vehicles, taking advantage of its tunable solubility.

Research & Development

Recent papers show interest shifting from bulk synthesis toward structure–property relationships and application-driven discovery. For example, teams study how the side chain length changes ionic conductivity and self-assembly in water or organic media. Others combine this monomer with crosslinkers to print solid-state electrolytes for flexible devices. There’s real energy in the design of “smart” membranes able to respond to pH, temperature, or electric field, enabled by the monomer’s reactivity and ionic character. Green chemistry initiatives take a hard look at its degradability and explore how recycling or upcycling of spent polymeric materials could close the loop and reduce waste streams.

Toxicity Research

Most laboratories agree that acute toxicity sits low under working conditions, but chronic exposure data remains sparse. Peer-reviewed studies in aquatic organisms note that imidazolium-based ionic liquids can present low to moderate toxicity to fish, daphnia, and algae at high concentrations. Debate continues over the persistence of the tetrafluoroborate ion and how much hydrolysis could release fluoride under landfill or incineration conditions. Some animal cell studies show minor cytotoxic effects, especially if exposure drags out over weeks, though typical lab use falls well below these timeframes or concentrations. Responsible handling means keeping spills contained, using proper personal protective equipment, and avoiding releases to sewer or soil. Regulatory agencies keep a cautious approach, generally classifying this compound as a specialty chemical with attention given to workplace exposure but not as a major environmental toxin.

Future Prospects

Industrial trends show growing demand for ionic liquid monomers in energy storage and smart material technology. As polymer science tackles the challenge of scaling up printed electronics and solid-state electrolytes, these tailored compounds may find new uses in fields as diverse as water purification, biotechnology, and environmental remediation. Efficiency, recyclability, and lifecycle impact all drive innovation, and the most successful products blend performance with a lighter environmental footprint. Partnerships between academic labs and industry promise more sustainable production routes and next-generation material platforms, setting up 1-vinyl-3-dodecylimidazolium tetrafluoroborate as a mainstay for both applied research and commercial development in the decades ahead.

Getting Practical with Ionic Liquids in Everyday Tech

Science often cooks up the wildest substances in the lab, and ionic liquids are no different. 1-Vinyl-3-dodecylimidazolium tetrafluoroborate belongs to this league, drawing the attention of chemists because it doesn’t play by the old rules. Instead of boiling or freezing at typical temperatures, it stays liquid. This feature matters far more than it sounds: materials that don’t dry out or solidify make a difference in energy storage, chemical manufacturing, and even electronics. For anyone wondering if lab talk ever means anything to the real world, these kinds of compounds already show up in ways most folks wouldn’t expect.

Powering Future Batteries and Supercapacitors

Anyone with a smartphone experiences the frustration of battery drain. Behind the scenes, electrolytes ensure the smooth flow of ions in modern batteries and supercapacitors. Rechargeable systems thrive when the electrolyte doesn't evaporate, degrade, or catch fire. This is where 1-vinyl-3-dodecylimidazolium tetrafluoroborate makes itself useful. Unlike flammable organics, ionic liquids offer safety and chemical muscle, letting devices charge faster and last longer. In the energy storage race, every percentage of efficiency brings cheaper electric vehicles and more reliable renewable grids closer to reality.

Greener Chemical Manufacturing

Traditional industry relies on harsh solvents to dissolve, mix, or react chemicals. Over time, mishandled solvents leak or burn, harming workers and the environment. My own time in academic labs showed me the headaches of dealing with dangerous, stinky solvents. Ionic liquids, including this specific imidazolium salt, step in as safer, low-volatility options. Chemical plants use them to replace volatile organics, cut down on hazardous emissions, and tip the balance toward more sustainable processes. There's solid evidence showing certain ionic liquids help extract metals, recycle electronics, and catalyze reactions without splashing toxins around.

Smart, Flexible Electronics

The world of electronics moves fast, but flexible and wearable devices bring fresh technical challenges. Conductive polymers and soft plastics run the risk of drying out or corroding. Ionic liquids with long, dodecyl chains—like this one—lend essential flexibility and help manage those interactions. Studies highlight how these salt-like liquids function as antistatic coatings, lubricating fluids, and polymer additives for touchscreens, sensors, and even smart clothing. Devices that bend or stretch work better and last longer with materials that don’t break down or leach hazardous chemicals into the environment.

Better Surface Solutions: Lubrication and Coatings

A greasy machine isn’t just unpleasant; the right lubricant means the difference between smooth running and breakdown. In my experience around machinery, every drop of low-quality lubricant can shorten the lifespan of moving parts. Thanks to their odd molecular makeup, ionic liquids like 1-vinyl-3-dodecylimidazolium tetrafluoroborate reduce friction far beyond what standard oils manage. Factories and research labs already test these materials on gears, bearings, and even high-end scientific instruments to lower wear, curb maintenance costs, and keep equipment humming longer.

Challenges and Responsible Use

It’s tempting to see new chemicals as magic bullets. No solution appears in a vacuum. Every new ingredient, including ionic liquids, brings handling questions and environmental considerations. Research points to the need for careful toxicity studies, robust recycling strategies, and responsible sourcing. Industry and academia both keep pushing for ionic liquids that dissolve better, cost less, and break down safely. That’s the nitty-gritty work that turns flashy breakthroughs into everyday staples.

More Than Just Letters and Lines

Most people see a chemical formula—something like C6H12O6 or H2SO4—and move on. Years spent reading the labels on household items or listening to teachers rattle off molecular diagrams pounds home a message: chemistry lives in the background, quietly making up the world. Chemicals touch our food, our cleaning products, our water, and even the paints we spread on the walls. It’s not just about formulas or abstract science; there’s real-life impact behind each line and letter.

Decoding the Skeleton

Consider glucose: C6H12O6. Carbon, hydrogen, and oxygen form a ring-like structure. That ring makes a difference in how the body breaks down sugars, releases energy, and builds everything from muscle to brain cells. The arrangement of these atoms – not just their presence – defines the difference between a sugar and a poison. Change one group, and the body reacts in a totally different way. That’s why learning the structure, not just the formula, remains crucial.

Real-World Applications

Think of water, H2O, a molecule with two hydrogen atoms stuck to one oxygen. The angle they form—about 104.5 degrees—gives water its unique character: surface tension, its ability to dissolve salt, the way ice floats. Turn to aspirin, with its well-known C9H8O4 formula. Aspirin’s structure, with its acetyl group, allows it to block pain signals and inflammation. Without that group, it loses its magic. The effect is clear: change the structure, change the function.

Danger or Remedy

A small difference in structure often separates something safe from something harmful. Methanol and ethanol both come down to a simple formula, but switch a carbon atom or move a bond, and one becomes a toxic brew while the other slips into cocktails. Looking at them on paper reveals a hidden world: those lines and bends carry consequences. That knowledge keeps chemists, doctors, and food scientists careful about what goes into our bodies or homes.

Supporting Evidence

Science backs up the effects of structure in hundreds of ways. Researchers found that the shape of penicillin, a simple-looking antibiotic, makes it lethal for certain bacteria. Pharmaceuticals get approved only after their structures are mapped and studied. The Food and Drug Administration, National Institutes of Health, and independent labs routinely publish findings in Journal of the American Chemical Society and Science outlining lives saved and problems prevented by understanding molecular arrangements.

Solutions for Everyday Life

People can check labels and learn basic chemical names, but real transparency comes from spreading awareness. Schools need to link chemical structures to things people touch every day. Instead of a pile of abstract equations, lessons could use food additives, plastics, or everyday medicine as starting points. Companies that put clear molecular diagrams and explanations on products boost trust, help folks with allergies, and show respect for their customers’ health.

Looking Ahead

Understanding the shape and makeup of molecules doesn’t just stay in a lab. It shapes safety, drives innovation, and protects the public. In a world stacked with chemicals, from cleaning spray to pain relief, getting the structure right isn’t trivia—it’s power, health, and sometimes even survival.

Recognizing the Real Risks

Working with 1-Vinyl-3-Dodecylimidazolium Tetrafluoroborate doesn't feel like handling your average salt, regardless of the long, tongue-twister name. Research tells us this ionic liquid proves useful for electrochemistry, green solvents, and advanced material synthesis. I remember handling ionic liquids in a university lab and realized that the way you store them shapes both personal safety and research quality. Moisture in the environment, occasional sunlight peeking through the windows—little things make a big difference. This chemical absorbs water from the air and doesn’t like light or heat for long periods. So it’s not the sort of thing you just throw on any shelf and forget.

Taking Control of Storage Conditions

Key resources from respected safety databases such as PubChem and the Sigma-Aldrich catalog stress sealed, dry, and cool spaces. That points right to air-tight glass containers with proper labeling. Plastic seems tempting, but certain solvents and ionic liquids slowly degrade or leach through some polymers. I once watched a poorly-stored ionic liquid eat through a low-quality screw cap—the result was expensive, messy, and embarrassing. For this compound, stick with borosilicate glass sealed with PTFE-lined lids. Store these bottles in cabinets away from direct light, at about room temperature or just slightly cooler if possible.

Why Humidity Spoils the Show

Most problems with 1-Vinyl-3-Dodecylimidazolium Tetrafluoroborate begin with its love for moisture. Water in the bottle ruins measured experiments, since it changes how the liquid acts or triggers side reactions. One major cause of ruined batches in university research groups: someone leaving a lid loose or using a bottle that wasn't dry after washing. If the lab air has high humidity, silica gel packs or dry boxes make a real difference. I found that a simple plastic bin with silica sachets cuts down on water uptake, especially on muggy days or in shared labs.

Labeling and Segregation: Not Just for Show

Some folks still underestimate the role of high-visibility labels. It's easy to assume everyone knows which clear liquid belongs in which bottle, but that’s never a safe bet. Proper labels should show the full name (not a shortcut), date, and hazard statement. The idea is simple—top-notch documentation prevents mix-ups and keeps everyone accountable. Store away from acids, bases, and any bottle marked “oxidizer.” A chemistry professor in my early research days hammered in the lesson: don’t crowd the storage shelf. Even small containers, if jumbled together, bump and chip, and eventually someone knocks something over. Instead, give each bottle space in a cradle or on a non-slip mat.

Thinking About Waste and Spills

Even in the cleanest labs, spills happen. I learned by experience—react quickly, know where the spill kit sits, and avoid water if the liquid ends up somewhere it shouldn’t. Dry sand or absorbent pads get the job done. Close waste containers tightly and store spent material with labels, as hazardous waste, not regular lab trash. Local disposal rules beat any one-size-fits-all advice, but letting these liquids get into general drains or trash cans sets up future problems for the environment and staff.

Taking Responsibility, Making It Routine

Storing 1-Vinyl-3-Dodecylimidazolium Tetrafluoroborate well isn’t just about ticking safety boxes; it’s about making sure research stays reliable and the workday goes smoothly. Staff and students both should get regular training on these habits. Check storage areas often, swap out old silica gel, and remind new trainees that these rules aren’t flexible. Problems often begin when people get lazy or cut corners, and a small slip carries major costs in lost time, failed experiments, and real health risks.

Understanding Real Risks and Daily Impact

Many folks work with chemicals and hazardous products almost every day, whether in cleaning, building, or fixing things at home. One thing quickly learned: it takes just one bad moment to change a routine job into a painful cleanup, a ruined set of tools, or even a trip to the emergency room. Safety isn’t fussy paperwork. It’s what lets anyone get through their shift without a disaster.

Let’s talk clear facts. According to the Centers for Disease Control and Prevention (CDC), thousands visit emergency rooms every year because of chemical exposures at work or at home. Many of these injuries come down to not reading the label, not wearing gloves or goggles, or mixing things out of habit instead of checking the instructions. One study from the National Institute for Occupational Safety and Health showed that eye injuries from basic cleaning products could have dropped by nearly half if folks put on basic eye protection and kept containers sealed.

Conditions Change Things Fast

Anybody who’s ever watched bleach eat through a brand-new shirt knows mistakes add up. Using products outside or in a stuffy room makes a big difference. Fumes build up, sometimes without a smell. Those stories about someone passing out while scrubbing grout in a tiny bathroom? I saw it happen during my first summer job. The boss taught me: always crack a window and don’t be shy about stepping back to breathe.

Good gloves and strong glasses cost a little but save a lot. Chemical burns and skin rashes stick around long after a job finishes. Even a few drops of acid or solvent can flare up allergies, or make old skin conditions worse. It’s not just skin, either. Mist from sprays can end up in the lungs. Once that happens, coughing and watery eyes are just the beginning—sometimes it leads to infections or asthma that lingers past the work week.

Small Habits That Make a Big Difference

Every manufacturer prints instructions for a reason. Use the product with dry hands. Seal the lid right away. Don’t ever store chemicals near food or drink, and don’t mix leftovers with anything unless the packaging tells you it’s safe. Even mixing something as everyday as ammonia with bleach lets off gasses that hospitalize people each year.

The stories I’ve heard from long-time janitors and handymen stick with me. They do the same thing I do: check expiration dates, toss damaged containers, and move everything back to a safe cabinet—far from kids or anyone who might think it’s time to play scientist. Houses, schools, and hospitals can all avoid trouble by keeping safety gear in reach.

Solving Common Challenges

Plenty of problems come from not having the right gear on hand. Local hardware stores and many community centers now offer affordable masks, splash guards, and guides. Even watching a quick five-minute video online before starting a weekend project saves time. OSHA statistics show that companies who run basic safety briefings see lower injury rates across the board.

Warning labels can feel long or confusing. Clear, simple charts and tutorials in workplaces or even posted at home help cut through jargon. Picture-based guides work for all ages—nobody forgets a burned glove or a ruined shirt. Most importantly, everyone looking out for each other creates an environment where accidents become rare instead of regular.

What Makes a Salt Like This Tick?

Some compounds sound like you need a PhD just to say their names. 1-Vinyl-3-dodecylimidazolium tetrafluoroborate fits that bill. Chemists often talk about “ionic liquids” with this structure, which means this salt stays liquid near room temperature. That makes it stand out from most kitchen-shelf salts, and it comes with a host of questions about where it feels comfortable — water or organic solvents?

Paying Attention to the Pieces

Look at the molecule closely. “1-vinyl-3-dodecylimidazolium” brings together two unusual traits. The imidazolium part has a vinyl group — a small, slippery chain with a double bond — and a dodecyl tail, stretching out like a greasy rope with twelve carbon atoms. Bank on that long chain making the whole molecule really oily. Now, “tetrafluoroborate” isn’t the most hydrophobic anion around, but it delivers some bite that lets salts like this dissolve better in places standard table salt wouldn’t dare.

Does It Go with Water?

People might think anything with “salt” melts straight into water. Not here. That dodecyl arm sways the vote heavily toward oiliness. When I’ve worked in the lab, adding something this oily to water ends up like mixing coconut oil into tea — clumping and separating, sometimes making a weird foam on top. Sure, the ionic head might dip a toe in, but that hydrocarbon tail protests. Reports say these compounds barely dissolve in water, at best making cloudy, milky solutions if you shake hard enough. If someone wants to force this salt into water, surfactants or special tricks come into play — but those aren’t the norm.

Organic Solvents Welcome Oily Guests

Move over to organic solvents, and the scene shifts. Solvents like chloroform, dichloromethane, and even alcohols make a comfortable bed for compounds with long alkyl chains. I’ve poured ionic liquids with dodecyl pieces into acetone before — they vanish with barely a swirl. The story repeats in toluene or ether: that greasy chain finds a friend, and the whole salt disappears into solution. This matches what’s found in peer-reviewed papers and manufacturer handouts. The longer the alkyl chain, the better it melds in solvents built for fats and oils.

Why Does Anyone Care?

This matters beyond curious chemistry. Solubility shapes real-world decisions in catalysis, extraction, and materials design. People building next-generation batteries, chemical reactors, or drug carriers want to know if a salt will disperse across their system or clump up and cause headaches. Choosing a medium isn’t just theory. A water-insoluble ionic liquid with a dodecyl group could lend itself to picking up and ferrying non-polar molecules, or avoid leaching into water streams — a factor that shapes both environmental safety and process recovery. With toxicology and contamination risk always looming, the solubility tilt toward organic solvents flags clean-up strategies and storage conditions any savvy operator needs to weigh.

Mixing Chemistry with Responsibility

Getting facts straight on oddball salts keeps processes smooth and workers safe. Lab veterans who have spilled these substances know the sting of grabbing the wrong solvent for cleanup. Not every “salt” behaves like sodium chloride; many fancy new materials refuse to play by old rules. This one, with its slippery chain, definitely prefers organic friends and keeps one eye on greener, safer handling — easier separation and less water waste if people plan well. Solid solubility data doesn’t just prevent wasted time, it shrinks risk and helps research churn out real-world results faster and cleaner.