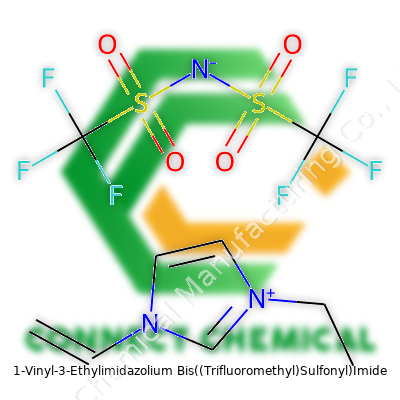

1-Vinyl-3-Ethylimidazolium Bis((Trifluoromethyl)Sulfonyl)Imide: A Deep Dive

Historical Development

Chemical innovation runs on the ability to tweak familiar molecules and keep discovering new combinations that matter. Years ago, laboratories across Europe and America focused on making ionic liquids more versatile and environmentally friendly. 1-Vinyl-3-ethylimidazolium bis((trifluoromethyl)sulfonyl)imide, commonly shortened to [VEIm][NTf2], hit the scene as researchers searched for room-temperature ionic liquids with better thermal stability and electrochemical windows. The recipe took off partly because chemists in the 1990s recognized the limitations of more traditional ionic salts, which often showed poor stability and limited solubility for more modern industrial chemistries. In the last two decades, research groups connected imidazolium-based ionic liquids with the robust bis(trifluoromethyl)sulfonylimide anion, accelerating discovery in solvents, catalysts, and battery electrolytes. Those working in university labs told the story of ionic liquids shifting from oddities to essential electrolytes, and today [VEIm][NTf2] finds steady use in both specialty research and growing industrial circles.

Product Overview

1-Vinyl-3-ethylimidazolium bis((trifluoromethyl)sulfonyl)imide stands out among ionic liquids for its manageable viscosity, chemical stability, and low volatility. Its unique pairing — a vinyl group attached to an alkyl-substituted imidazolium ring and a perfluorinated sulfonyl imide anion — forms a salt that remains liquid at room temperature. Chemically, the compound falls in line with other imidazolium systems but branches out with its monomeric vinyl group, supporting further polymerization. This makes [VEIm][NTf2] a favorite not just as a solvent, but as a building block in specialty polymers and advanced electrolytes.

Physical & Chemical Properties

The physical look of this compound is an almost colorless to light yellow viscous liquid, depending on purity and storage. Its melting point sits well below ambient temperature, which means it pours like oil even in a chilly laboratory. With a very low vapor pressure, the risk of inhalation exposure during typical handling remains minimal. The [NTf2] anion, packed with electron-withdrawing trifluoromethyls, delivers great chemical and thermal stability, allowing the compound to stand up to strong alkalis, acids, and even some oxidizers. Its high ionic conductivity and electrochemical window (often above 4 V) drive demand in batteries and supercapacitors. The hydrophobic nature of the anion results in poor water solubility, so it mixes better with other nonpolar or moderately polar organic solvents, unlike many earlier salts.

Technical Specifications & Labeling

On a bottle, the product name appears as 1-vinyl-3-ethylimidazolium bis(trifluoromethanesulfonyl)imide. The CAS number attached to this substance sits high on specification sheets, along with purity grades, moisture content, and weight per volume. Manufacturers often specify water content below 0.1%, since even tiny traces of water can disrupt applications in electrochemistry or catalysis. Safety data sheets point out its molecular formula (C10H13F6N3O4S2), molar mass (441.35 g/mol), and typical shelf-life under inert atmosphere or in sealed glass. Reputable suppliers include storage conditions, often suggesting cool, dry, and shaded areas away from direct sunlight.

Preparation Method

Years of tinkering with synthetic routes led to a refined, reproducible synthesis for [VEIm][NTf2]. Starting from 1-vinylimidazole, chemists alkylate the nitrogen in the third position with an ethyl reagent, such as ethyl bromide or ethyl iodide, under mild conditions. This first step forms 1-vinyl-3-ethylimidazolium bromide or iodide. Next, a metathesis (ion exchange) reaction replaces the halide with lithium bis(trifluoromethanesulfonyl)imide in a biphasic system (often water and dichloromethane or chloroform). The nonaqueous phase then contains the product, which separates out easily since the NTf2 salt is barely soluble in water. After drying with MgSO4 or a rotary evaporator, the ionic liquid comes out clean and ready for use. This route minimizes waste and runs safely compared to older methods, which used harsher acids or left unwanted byproducts.

Chemical Reactions & Modifications

One feature that sets this compound apart is its reactive vinyl group, which leads to homopolymerization or copolymerization under radical or ionic conditions. Controlled addition of initiators like AIBN (azobisisobutyronitrile) turns [VEIm][NTf2] into polyelectrolyte materials with high ionic conductivity. Beyond polymerization, the imidazolium ring supports further alkylation or functionalization at the remaining nitrogen, directing development toward task-specific ionic liquids. The anion rarely reacts, providing backbone stability; still, in rare cases of very harsh nucleophiles, some degradation might pop up, something only seen at the extremes of laboratory testing.

Synonyms & Product Names

Shorthand notations crop up a lot: [VEIm][NTf2], 1-vinyl-3-ethylimidazolium NTf2, or simply the acronym VEImTFSI. Product names shift with regional suppliers but the structure stays consistent — various chemical catalogs list it under “vinyl ethyl imidazolium bis(trifluoromethylsulfonyl)imide” or “vinylimidazolium ionic liquid NTf2.” These variations help researchers find it regardless of language or brand while keeping standards clear for global markets.

Safety & Operational Standards

Safety in the lab covers personal protection and environmental practices. Pure [VEIm][NTf2] doesn't burn readily or form dangerous byproducts under mild conditions, making it less hazardous than classic organic solvents. Skin contact can provoke irritation, so gloves, goggles, and splash-proof coats make sense every time. On glassware or steel, it holds up well — no etching or rapid corrosion reported in daily lab work. Disposal must follow local regulations, keeping fluorinated compounds from entering municipal waste or waterways, given the persistence of the sulfonyl imide anion. Storage in glass under argon preserves quality, shielding the product from air and moisture that might slowly cause hydrolysis or loss of performance.

Application Area

The reach of 1-vinyl-3-ethylimidazolium bis((trifluoromethyl)sulfonyl)imide covers several high-tech fields. Electrochemists value it for crafting batteries and supercapacitors where both conductivity and stability matter. Polymer chemists exploit the vinyl group for fabricating polyelectrolyte membranes, stretchable electronics, and advanced fuel cells. Catalysis researchers test it as a solvent for transition metal complexes, reporting increased reaction rates and selectivities. Its thermal stability supports heat transfer fluids, while its low volatility fits in green chemistry protocols aiming to reduce volatile organic compound emissions. Some fraction of demand comes from analytical chemistry, where the ionic liquid functions as a medium for chromatography or as a matrix in mass spectrometry. From firsthand accounts and published conference results, interest in these applications keeps spreading.

Research & Development

Work continues on both incremental improvements and fundamental explorations. Laboratories chase after new polymerization techniques that harness the vinyl group for tailor-made materials. Collaborations between university chemists and private industry seek to implement the ionic liquid in battery electrolytes that outperform lithium-ion setups now on the market. By shifting substituents on the imidazolium ring or swapping anions for NTf2 analogs, R&D teams build families of liquids with specific performance profiles — lower viscosity, higher conductivity, or increased biocompatibility. Multinational patent filings in recent years reveal a race for next-generation materials, with [VEIm][NTf2] featured as a key ingredient.

Toxicity Research

Awareness of potential health and environmental effects runs higher than ever. Early toxicity assays show [VEIm][NTf2] produces low acute oral and dermal toxicity in standard animal studies, lower than some chlorinated solvents or phthalate plasticizers. Long-term and bioaccumulation data remains scarce, so many research institutions restrict large-scale use outside controlled circulation. The NTf2 anion resists biodegradation, so waste handling and accidental spills call for responsible clean-up and high-temperature incineration when possible. Work environments monitor air and surface levels even though the liquid barely evaporates. The chemical community keeps calling for thorough, independent studies to set occupational exposure limits and better frame risk.

Future Prospects

The story for 1-vinyl-3-ethylimidazolium bis((trifluoromethyl)sulfonyl)imide looks bright as industries push for more energy-efficient and sustainable materials. With the EU and US pressing industry to move away from volatile solvents and hazardous legacy chemicals, demand for robust, low-emission ionic liquids should expand. Ongoing research into all-solid-state batteries may pull [VEIm][NTf2] toward mass production, while the continued rise of customizable polymers boosts its polymerization value. The toughest challenge lies in making synthesis more sustainable, trimming out persistent fluorinated byproducts without giving up performance. That task will take real investment, cross-sector partnerships, and strict adherence to emerging green chemistry protocols. As more researchers share their findings, expect a sharper, more balanced view of both opportunities and challenges—driving not just discovery but the real-world adoption of safe, effective ionic liquid technologies.

Why Chemists Rely on This Unusual Liquid

Glancing at the chemical name 1-Vinyl-3-ethylimidazolium bis((trifluoromethyl)sulfonyl)imide, you might expect it belongs in a textbook instead of a workshop. In the lab, it’s known for cutting-edge results—not for making things complicated. This salt’s main claim to fame belongs to its role as an ionic liquid, a material that flows like oil but consists entirely of ions.

Ionic liquids attract attention because they refuse to evaporate like water, gasoline, or most organic solvents. That low volatility changes the game. Health and safety folks appreciate less vapor in the air. I’ve worked with researchers who swear by these substances for replacing noxious solvents. A big reason: No strong fumes, far less waste. Researchers don’t have to worry about chemical exposure every time they open a bottle.

Shapeshifting in Polymer Chemistry

Polymer chemists spend a lot of energy trying to get monomers to link up into chains, forming plastics, coatings, and specialty materials. The road tends to get bumpy: Some monomers won’t dissolve, some react at the wrong speed, and standard solvents often play hardball with the results. Here’s where 1-vinyl-3-ethylimidazolium bis((trifluoromethyl)sulfonyl)imide steps up. As a solvent, it can dissolve stubborn monomers and help build polymers that are tough to make any other way.

In real-world use, labs use it to produce so-called "ionic polymers." These plastics carry charges and can conduct ions, which means they work well in batteries, membranes, and sensors. Traditional solvents spoil the properties of these polymers or won’t even allow them to form. The unique mix of the imidazolium group and the bulky bis((trifluoromethyl)sulfonyl)imide anion in this molecule lets it stay stable and non-reactive, so the reactions get cleaner. From personal experience doing experiments with new electrolytes, nothing frustrates more than runaway side-reactions. Ionic liquids like this one give more control.

Powering Greener Chemistry and New Tech

Green chemistry pushes for fewer environmental downsides. People look to ionic liquids because they replace some of the worst-offending solvents: benzene, toluene, and the like. 1-vinyl-3-ethylimidazolium bis((trifluoromethyl)sulfonyl)imide doesn’t just lower emissions. Its structure lets it withstand high voltages and temperatures, so engineers use it in advanced batteries and supercapacitors. In the drive for electric cars and renewable energy, better electrolytes really matter.

Facts show ionic liquids like this one extend battery life and keep devices running even as the temperature swings wildly or devices get pushed hard. I’ve seen these tested in professional labs, where safety and long-term reliability define every decision.

Challenges and Better Paths Forward

No technology comes without challenges. Sourcing and making these chemicals can get expensive. Their stability helps in use, but after disposal, the molecule’s resilience can become a problem if it enters the environment. Toxicity questions haven’t gone away completely. Scientists continue to test impacts and look for safer variants.

Scale matters too. Producing ionic liquids for big industrial operations, like battery gigafactories, drives up cost and energy use. The most practical solutions going forward involve recycling and reusing these chemicals, minimizing both cost and waste. Open data and honest assessment remain crucial. When people weigh the benefits in safer labs or more reliable renewable energy storage, real-world results speak loudest.

Understanding the Basics

Walking into a chemical storeroom reminds me of old summers working at a local water treatment plant. Everyone paid attention. Every bottle had its spot, every label told a story—some more frightening than others. Chemistry in real life looks less like a slick lab in a textbook and more like a constant tug-of-war between routine and risk.

Real Risks, Not Just Rules

People sometimes forget that chemicals at work don’t stay inside bottles by accident. A friend in college once stored a solvent next to a heat register. Within a week, the cap started to bulge. Thankfully, someone spotted it before fumes started to spread. At that point, nobody needed reminding—chemicals react to sloppy habits faster than anyone expects.

Fire, poisoning, and explosions don’t just break out in big research centers. Statistics from the U.S. Chemical Safety Board show that storage errors cause dozens of accidents each year, many in places people think are safe. National Institute for Occupational Safety and Health (NIOSH) has long warned about incompatible chemicals sharing shelves or even cabinets. Simple measures—like storing acids away from organic solvents—stop the kind of reactions that end up making headlines.

Storage Starts Before You Unpack

Once a container arrives, preparation makes the difference. You check the label twice, make sure your gloves fit, and look around the room for questionable graffiti (remnants of old spills). Proper ventilated storage matches a compound’s needs. Strong acids, for example, belong low, in chemical-resistant trays, to contain any leaks. Some powders, like sodium azide, hate moisture so much that even an open window can ruin a jar.

Proper refrigeration matters for volatile or light-sensitive chemicals. Someone once told me a horror story about diethyl ether left in a warm storeroom. Over several months, the container built up peroxide crystals, which can explode with the wrong nudge. If a chemical needs light protection, use amber glass and store away from windows. And for flammable chemicals, only explosion-proof refrigerators do the job. Regular fridge motors spark. You can guess what that means.

Handling: Get It Right, Every Time

Before handling, know the compound. Review the Safety Data Sheet—not as a chore, but because that slip of paper spells out everything from required respirators to emergency showers. I have seen people improvise with nitrile gloves or skip goggles “just for a second” and regret it. Some chemicals burn on contact, others keep adding up damage with every little splash.

Cleanliness cuts risk. Keep workspaces organized: don’t leave open containers or dirty pipettes lying around. Always pour, never scoop, powders outside a fume hood, and never return unused product to the original bottle to avoid contamination. If you spill, contain it and use the kit set for the job. A mop or towel can make things much worse.

Working Culture Saves Lives

All the technical advice only works in a setting where people watch out for each other. Routine training helps, but so does a habit of taking small risks seriously. For each serious accident in industry, hundreds of near-misses happen that rarely get reported. Real safety comes from a culture where people take pride in storage done right, containers checked, and training taken seriously. It isn’t glamorous, but it keeps the lab open and everyone safe.

Understanding the Chemical

1-Vinyl-3-ethylimidazolium bis((trifluoromethyl)sulfonyl)imide falls in the class of ionic liquids. People in chemical labs and specialty industries use this substance for its unique solvent properties and thermal stability. These liquids often catch the eye because they act differently from the usual organic solvents—they barely evaporate and sometimes show high conductivity. It doesn’t mean they’re automatically safer. On the contrary, some might carry risks that don’t reveal themselves at first glance.

What’s Known About Safety and Toxicity

Direct toxicity data on this specific compound isn’t easy to find. Companies and researchers experiment with a range of similar ionic liquids, so I always turn to related studies when facing gaps. Imidazolium-type ionic liquids, the family this molecule belongs to, have attracted plenty of scrutiny. Published reports suggest these substances can harm aquatic life, and some show moderate toxicity in lab animals. The process for testing human health effects takes years, so people often rely on experience with related chemicals.

Researchers at universities and regulatory bodies checked how these ionic liquids interact with living things. Results show cell damage and genetic effects crop up at certain concentrations. Toxicologists from Germany’s Federal Environment Agency published articles raising flags about the stability of the trifluoromethanesulfonyl imide part. This group can break down, especially in the environment, releasing persistent and sometimes toxic fluorinated byproducts. Europe’s REACH regulation flags similar substances for closer examination.

Risks in the Workplace and Beyond

Anyone handling this substance needs to respect basic safety. I spent a summer working in a lab that tested alternative solvents, and the “green” label didn’t always mean nontoxic. My colleagues always wore gloves, goggles, and worked under fume hoods—just as our training drilled into us. Ionic liquids feel less volatile, but skin or eye contact and even spills demand care because absorption can slip through unnoticed.

Accidental releases concern more than immediate contact. If the liquid gets into drains or soil, local plants and animal life could suffer. Certain imidazolium and fluorinated compounds don’t break down quickly, so environmental buildup becomes possible. Time and again, chemists urge safe disposal in line with hazardous waste protocols—not the regular trash or sink.

What Labs and Industry Can Do Better

Companies that buy or manufacture this ionic liquid hold the responsibility for thorough hazard assessments. They should push suppliers for detailed safety data sheets. Training matters as much as paperwork. No one should handle this without practical know-how about spill management, first aid for exposure, and proper storage. Well-run labs log every use and waste stream, so nothing slips into the wrong system.

As a community, scientists can support safer chemical design. Teams at large firms and universities now use computational models and new toxicity tests to screen potential hazards before a batch leaves the bench. So if safer alternatives pop up, adoption becomes easier.

Moving Forward with Caution

Using unfamiliar or under-tested chemicals never means dropping best practices. Anyone considering 1-vinyl-3-ethylimidazolium bis((trifluoromethyl)sulfonyl)imide in a process or experiment should treat it as hazardous unless strong evidence says otherwise. Fact: even advanced solvents and “designer” molecules need old-fashioned respect and vigilance. The burden lies on the user, the manager, and the wider scientific field to make sure these promising tools don’t create tomorrow’s regrets.

The Numbers Behind Product Purity

Purity means a lot to different folks depending on where that product ends up. In my years working closely with both suppliers and end-users, I’ve seen how purity standards can make or break an entire process. For anything going into food, pharmaceuticals, or advanced manufacturing, buyers expect numbers that often reach above 99%. Tech grade options sometimes fall a little lower, closer to 95-98%, since they're not intended for life-critical purposes.

Let’s take a closer look at products like pharmaceutical APIs or high-spec industrial chemicals. In pharma, the rules feel carved in stone. Regulators require at least 98-99.5% purity. That last half a percent takes serious effort—careful refining, advanced filtration, and endless checks. Refineries aiming at this market can’t afford shortcuts; the slightest contamination can derail a batch, cause recalls, or worse, endanger consumers.

Electronics manufacturing sets a different bar. Making semiconductors or solar panels involves chemicals with purity up to 99.9999%. Imagine that: Anything less risks performance issues in multi-million dollar projects. Having watched engineers lose days troubleshooting system failures traced back to tiny impurities, I can say those extra “nines” aren’t just for bragging rights. They keep factories running and customers satisfied.

The Real-World Challenge

Commercial suppliers don’t just decide one day to hit 99% and call it a win. Getting there means big investments in raw materials, clean production rooms, and non-stop quality control. High purity isn’t just a promise on a datasheet—it’s the end result of smart sourcing, experienced handling, and good old-fashioned attention to detail. Sometimes, even when a product leaves the plant close to perfect, things turn south during shipment or storage: moisture sneaks in, temperature fluctuates, drums get bumped. That’s where strong safety seals, clear storage guidelines, and batch tracing come in handy.

Over the years, I’ve heard frustrated buyers share stories about suppliers who quote “pharma-grade” or “reagent-grade,” yet deliver something a notch below expectation. In any regulated industry, that’s a recipe for audits, production downtime, and expensive batch failures. More than once, a clear certificate of analysis, not a handshake, made the difference. Good suppliers lay out the lot analysis with every delivery, showing actual impurity profiles and testing data. That transparency builds trust—and prevents a whole lot of headaches.

How Buyers Can Protect Themselves

Every purchase order tells a story about risk. Companies that need consistent quality set up regular audits and surprise checks at their suppliers’ factories. Random batch sampling and partnerships with independent labs often confirm the numbers on the paperwork. Larger buyers sometimes forge long-term deals with preferred sources to lock in not just price, but the documented assurance of quality. Eventually, buyers who take verification seriously build rock-solid supply chains, weathering price shocks and shortages better than those who just hope for the best.

Purity isn’t just a technical term in a spec sheet; it safeguards products, reputations, and people. From what I’ve seen, those who work with trusted partners and demand proof, not promises, end up ahead of the game. In a world obsessed with value and speed, purity remains non-negotiable—for those who really understand what’s at stake.

Looking at Polymerization

Real progress in polymerization comes from finding monomers and catalysts that don’t fall apart when the going gets tough. Some compounds show off a lot in lab tests but won’t put up with real-world heat, water, or strong chemical competition. If you're hoping to link up a compound for a new synthetic route, you have to know: does it stand its ground against free radicals or strong bases, or does it buckle and give you a mess instead?

Plenty of compounds that work fine as small-molecule reagents lose their shape under industrial conditions. Back when I was working on a project to make stronger yet more flexible plastics, our team looked at several "promising" candidates. Only a tiny handful survived the test reactors. We faced breakdown products, side-reactions, bad yields—the usual parade of headaches. If this compound comes with odd side chains, delicate bond types, or low stability, forget it. Real-life polymerization needs resilience before anything else.

Structure matters. If the compound has double bonds or ring systems ready for addition, and no crazy substituents to get in the way, it has a shot. On the flip side, bulky or electron-rich groups can block the reaction centers. In my lab days, a little steric hindrance spelled big problems. Quick failure means wasted time and cash.

Electrochemical Dreams and Ionic Liquids

Ionic liquids keep making headlines—sometimes for good reason. They work as green solvents, conduct electricity without burning up, and don’t evaporate like classic solvents. You can see why battery researchers, fuel cell developers, and supercapacitor designers take notice. The academic hype feels big, but only a small slice of compounds actually pull their weight in competitive electrochemical markets.

A true ionic liquid resists breaking down at both ends of the voltage spectrum. Some cations or anions survive only mild conditions before they fry or gunk up into sludge. Back in my graduate studies, we ran through dozens of “designer” liquids, testing for stability. Many fizzled, forming black tar. The winners avoided hydrolysis, oxidation, and unwanted reduction.

Solubility and compatibility drive the next hurdle. A good ionic liquid must dissolve the right salts, shuttle ions quickly, and allow smooth charge transfer at electrodes. If a compound thickens, forms layers, or blocks reactions, it knocks itself out of the running. Conductivity and viscosity go hand in hand. In every trial, I watched some star candidates sputter and fail once the temperature shifted or after cycling stress.

The Bridge: Real-World Demands

On paper, dozens of compounds look ready to jump into polymer or electrochemical roles. The truth puts a damper on that. You need something that holds strong, resists regular chemical punishment, and stays simple to handle. Toxicity, cost, and supply chain matter just as much. I’ve seen great chemistries get buried because a rare element spiked in price or a stubborn byproduct landed on a regulatory blacklist.

Teams hoping for new breakthroughs in either field need to check for thermal stability, resistance to common side reactions, and basic safety. If these points clear review, then real-life production, purification, and disposal bring their own battles. Open communication between chemists and engineers makes a difference here; guessing won’t cut it.

Path Forward

Progress comes from blending practical experience with steady testing. Making safe, strong polymers or durable ionic liquids isn’t about latching onto every new compound—it’s about careful selection, honesty about failure, and stubborn attention to safety and performance under pressure. Without that, hope fades fast.