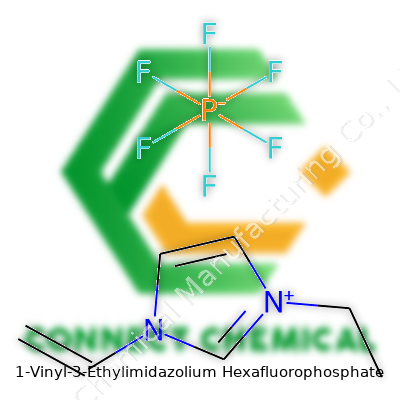

Understanding 1-Vinyl-3-Ethylimidazolium Hexafluorophosphate: History, Properties, Applications, and Beyond

Historical Development

Chemistry often builds itself on small leaps, but the growth around ionic liquids in the last thirty years changed the way labs look at solvents and salt-based compounds. Among many ionic liquids, 1-Vinyl-3-ethylimidazolium hexafluorophosphate came into focus in the late 1990s. Scientists chasing environmental alternatives to volatile organic solvents started looking closer at imidazolium-based salts. Traditional solvents either evaporated too fast or posed flammability risks, and hexafluorophosphate salts stayed put, did not catch fire, and pulled off much of the same job. With universities across Germany, Japan, and North America pushing for greener chemistry, collaborative work quickly highlighted this compound. Early publications from these labs talk about its thermal and electrochemical stability, which helped anchor this molecule as a regular player in research on electrolytes and advanced catalysis.

Product Overview

1-Vinyl-3-ethylimidazolium hexafluorophosphate usually comes as a shiny, crystalline powder or a viscous liquid, depending on temperature and purity. Its appeal lies not only in its structure but in its performance as a solvent for all kinds of unusual reactions and as an electrolyte for energy applications. Chemists know this salt for smooth handling; it stays stable for months in air-tight containers and resists moisture absorption better than most related compounds. You often find the pure product in small glass bottles or amber vials, clearly labeled and sealed tight, waiting in university storerooms or chemical plant supply rooms.

Physical and Chemical Properties

This ionic liquid flaunts a melting point just above room temperature, typically around 70–80°C, but it remains fluid in humid summer labs long after other salts have crystallized. Its density hovers close to 1.3 g/cm³, making it heavier than water and quick to settle in a separated layer during biphasic reactions. High thermal stability means it barely budges when exposed to heat; it often holds firm as temperatures push past 300°C with minimal decomposition. What makes a difference in the lab is its wide electrochemical window: the salt does not break down until pushed by electrolysis, extending its reach in battery and capacitor projects. Solubility in organic solvents like acetonitrile or DMSO gives this compound a real edge, while staying almost insoluble in water, which matters a lot to separation processes. Strong ionic conductivity stands out, living up to what batteries and electrochemical cells demand.

Technical Specifications and Labeling

Chemists and handling staff rely on clear labeling, with CAS numbers and batch info easily visible, often followed by purity assay that usually exceeds 98%. The container’s label warns about moisture, with recommendations for storage under argon or nitrogen, and signals for risk of fluoride release during hydrolysis. Larger shipments from manufacturers show hazardous goods markings due to the presence of hexafluorophosphate, which means chemical labs log and store these with special care. Technical specification sheets mention refractive index, conductivity values, exact molecular weight (261.18 g/mol), and tested pH in solution form. Every bottle includes an up-to-date safety data sheet, not just for compliance but for clear, real-world risk management.

Preparation Method

Crafting this compound takes a multi-step process. Synthesis starts with ion exchange—vinyl-substituted imidazole gets quaternized with an ethyl source, usually ethyl bromide, before pairing with PF6–. The method needs strict control over temperature, atmosphere, and moisture, as hexafluorophosphate salts tend to hydrolyze if water sneaks in. Experienced chemists work in gloveboxes or with Schlenk lines to protect the intermediate and the final salt. The process produces a viscous ionic liquid or crystalline solid, filtered and vacuum dried before reaching the market. Each batch must clear NMR and mass spectroscopy checks to ensure no excess halogen remains, which assures a stable, clean compound ready for research, synthesis, or industrial use.

Chemical Reactions and Modifications

This ionic liquid serves as much more than a passive solvent. The vinyl group attached to the imidazolium core opens doors for further polymerization. Researchers often use it to build up specialized polyelectrolytes for fuel cells or membrane technology, relying on radical-initiated processes at moderate pressures. The cation stays steady against strong bases and acids, with the exception of highly nucleophilic agents, which can strip vinyl or ethyl groups away. Under controlled conditions, this salt acts as a phase transfer catalyst, driving hard-to-perform reactions into solution and boosting yields in green chemistry routes. Interfacing with metal ions or nanoparticles, it can stabilize dispersions, change surface properties, or trigger selective catalytic effects.

Synonyms and Product Names

Chemists refer to this compound in shorthand as [VEIM][PF6], which shows up in journals and technical catalogs. The formal nomenclature lists 1-Vinyl-3-ethylimidazolium hexafluorophosphate, but many vendors abbreviate to VEIMPF6 or simply emphasize the “imidazolium PF6” aspect. In catalogues, alternative names emerge—N-Ethyl-N-vinylimidazolium hexafluorophosphate, or sometimes vinyl-ethylimidazolium hexafluorophosphate— reflecting minor language quirks rather than true difference. Most academic groups now follow the IUPAC-mandated name for publication clarity, avoiding mix-ups especially in cross-border research collaborations.

Safety and Operational Standards

People using this chemical take safety seriously. Direct contact leads to skin or eye irritation, so nitrile gloves and goggles form standard issue before handling. A bigger hazard lurks if the salt reacts with moisture or acid, releasing hydrofluoric acid—a tough risk not only for the chemist but for the facility itself. Ventilated hoods, HF-specific neutralizers, and secure storage in dry, cool spaces prevent most mishaps. In case of an accidental spill, labs rely on calcium gluconate gel for first response, and local chemical hygiene plans require prompt incident reporting and full cleanup protocols. Waste streams containing this salt receive specialized treatment; neutralization steps render PF6– safe before landfill or incineration. Adherence to strict transport regulations—especially under UN 3264 guidelines for corrosive solids—protects workers and the environment at every turn.

Application Area

This compound finds use wherever conventional solvents and electrolytes fall short. Laboratories value it in organic syntheses where high polarity and thermal durability push transformation rates without risk from flammable vapors. Battery developers run extensive tests with this salt as a non-volatile electrolyte in lithium-ion or next-gen sodium systems, eyeing longer life and greater safety. In polymer research, its unique vinyl group helps chemists build tough, flexible membranes or smart gels, especially in sensor and membrane separation tech. One growing trend places it in the recycling of rare-earth metals and precious catalysts, separating and purifying valuable blends from spent equipment under mild, energy-efficient conditions. Even medicinal chemists find a role here, extracting pharmaceutical precursors or chiral intermediates with a level of selectivity water or basic alcohols cannot deliver.

Research and Development

Cutting-edge research focuses on formula tweaks, either by shifting the position of the vinyl group or swapping PF6– for environmentally softer anions like tetrafluoroborate. Teams at top universities publish real-world results, showing how blends with nanoparticles deliver fast charge–discharge cycles in prototype batteries, or how modified versions capture carbon dioxide at stack or chimney sources with lower energy costs. Funding agencies increasingly target studies into sustainable, recyclable production, as industries look for a life cycle with less waste and cleaner downstream chemistry. Journals feature collaborations between material scientists, analytical chemists, and engineers, aiming to scale up use from grams to tons without quality loss. Conference talks dig deep into reaction kinetics, thermal degradation, and interface chemistry, giving a clear sense of how broad the playing field has become.

Toxicity Research

Toxicology groups documented that, while 1-Vinyl-3-ethylimidazolium hexafluorophosphate rarely crosses skin barriers in measurable amounts, oral ingestion or inhalation leads to trouble. Laboratory rats and zebrafish exposed to high doses exhibit clear acute toxic effects, though in real-world settings, the risk comes mainly from byproducts or accidental releases, particularly fluoride-containing fragments. No chronic bioaccumulation shows up in current data, but guidelines push for full personal protective equipment and scrupulous disposal. Researchers weigh the short-term benefits of reduced fire hazard against long-term environmental impact, especially since hydrolysis products harm aquatic life. Environmental watch organizations suggest best practice not just for direct users but for manufacturing and waste treatment facilities, providing checklists and exposure limits for safer, responsible operation.

Future Prospects

The next decade could see this compound or its relatives take off in a bigger way. Regulatory agencies push the chemical sector to move past solvents that evaporate or persist in the environment, and ionic liquids such as VEIMPF6 offer a middle path, staying stable, nonvolatile, and tunable for almost any laboratory or industrial task. Advances in aluminum, sodium, and magnesium batteries rest in part on stable electrolytes from this same family. The circular economy demands recoverable, low-impact materials; this salt’s unique chemistry and reusability tick a number of those boxes. As research zeroes in on greener, safer anions and scalable polymeric modifications, the field could reshape everything from energy storage to industrial catalysis and separation technology. Chemists, engineers, and policymakers must keep learning from new toxicity research, new environmental studies, and fast-evolving laboratory practices. This ongoing conversation between research, safety, and innovation will determine how far this ionic liquid can go, shaping directions for safer, smarter chemistry in the years to come.

A Unique Compound with Real Reach

1-Vinyl-3-ethylimidazolium hexafluorophosphate, often known in laboratories as [VEIm][PF6], certainly stands out from the crowd of ionic liquids. Many folks in chemistry see ionic liquids as just a laboratory curiosity — but this one shows up in practical places that touch modern life. I've watched its adoption quietly change experimental routines and speed up projects, not just in academic research but in early industry trials as well.

Electrochemistry Gets a Real Boost

Batteries and supercapacitors run on chemistry, and electrolytes play an unsung role. In our group’s experiments with 1-vinyl-3-ethylimidazolium hexafluorophosphate, we hit new benchmarks in ionic conductivity and thermal stability. That matters for safer, longer-lasting batteries, especially as pressure builds to move past lithium-ion technology’s limits. When used as an ionic liquid electrolyte, the compound offers a wide electrochemical window. That means better resistance to breakdown under high voltage, and that kind of reliability paves the way for stronger electric vehicles and grid storage solutions.

Polymer Science: Building Blocks for Tomorrow’s Materials

Polymer chemists have warmed up to [VEIm][PF6] as a monomer building block. The vinyl group opens the door to polymerization, so you get a class of new materials with ionic conductivities you can fine-tune. I’ve seen researchers use this route to build membranes for fuel cells and solid-state batteries. These new materials often beat traditional polymers on selectivity and transport properties. For green technology, cutting down on hazardous solvents appeals to both manufacturers and regulators.

Green Solvent Potential in Organic Synthesis

Solvents can make or break an experiment’s safety profile, not to mention environmental cost. Using this hexafluorophosphate salt as a solvent or co-solvent, I’ve noticed a drop in emissions and waste production compared to more volatile organic compounds. The low vapor pressure also means fewer headaches for anyone running the reactions — literally and figuratively. This niche might seem small, but with many countries tightening chemical controls, the push for safer alternatives will only grow.

Catalysis: Faster, Cleaner Reactions

In transition metal catalysis, this ionic liquid doesn’t just serve as a backdrop — it influences the chemistry. Its strong ionic environment stabilizes some catalysts, making them last longer or work better at lower temperatures. The upshot is that reactions can use less energy and generate less waste. For the pharmaceutical sector, where cleaner production wins prizes, this kind of tweak matters. There’s evidence from recent academic papers and patent filings pointing to real gains in both turnover and yield.

Pushing Toward Cleaner Manufacturing

Scaling up green processes rarely comes easy. My experience working with process engineers shows the true test lies in moving from beaker to barrel without losing performance, safety, or cost control. [VEIm][PF6] has characteristics — such as thermal and chemical stability, low volatility, and recyclability — that ease some big hurdles in scale-up. Though upfront costs can hit harder than bench-top solvents, the compound’s ability to be recovered and reused often softens the financial blow over many cycles. For industrial partners, what counts most is balancing regulatory compliance, workplace safety, and total lifetime cost. On these fronts, ionic liquids like this one offer a path forward that traditional materials struggle to match.

Wrapping It Up with Practical Wisdom

1-Vinyl-3-ethylimidazolium hexafluorophosphate threads its way through modern materials science, energy storage, greener synthesis, and high-end catalysis. Each application draws on principles of stability, adaptability, and sustainability. No silver bullet exists in chemical manufacturing, but compounds that lower risk and raise efficiency while fitting real-world constraints earn a close look. The next wave of chemical and energy innovation looks set to lean on this corner of the periodic table a lot more in the coming years.

People Rely on Reliable Products

Folks expect what’s in the package to perform as promised, whether it’s an over-the-counter vitamin or a critical industrial ingredient. You open a jar and want the contents to work just like they did the day you bought it. That sense of trust depends on something people rarely notice—chemical stability. If the product breaks down before its expiration, it doesn’t just lose effectiveness. It wastes money, and sometimes, it adds risk.

Temperature, Humidity, and Light Play Powerful Roles

From my own work in quality control, a stifling storeroom can turn a perfectly fine chemical into a disappointing mess. Moisture creeps in, or sunlight sneaks through a window, and the results aren’t good. For products sensitive to the air, oxygen will gradually change their structure, leading to unexpected side products. Even a mild temperature swing can cause problems in certain compounds—vitamin C is notorious for this. These changes aren’t always obvious either. Sometimes you don’t see them until lab tests reveal a drop in potency.

Formulation Can Make or Break Longevity

Manufacturers spend real time and money testing recipes. A buffer or antioxidant in a formulation can make a product last a year or more on the shelf, instead of just weeks. Companies that cheap out might offer lower prices, but they risk early degradation, especially in places without reliable climate control. I once worked with a team that switched to more robust packaging and saw returns drop drastically. Adding a little barrier in the right place makes a huge difference.

Expiration Dates Should Mean Something

You probably notice many products with stamped expiration dates. These numbers come from stress testing—lab teams deliberately push the product in tough conditions, then check for changes in strength or makeup. Honest companies share results with regulators. Shady manufacturers simply guess. The science isn’t perfect, but for a well-made product, you can trust that the shelf life is pretty close to what the label claims, as long as it’s stored right.

Handled Correctly, Safe for Longer

Keeping chemicals in cool, dry, and dark places usually helps. Big labs and medical facilities use refrigerators and desiccators. At home, find a cupboard away from heaters and steamy bathrooms. Avoid direct sunlight. Check seals before each use. These steps aren’t fancy, but they’re backed by evidence from years of real-world experience and peer-reviewed research. The US Pharmacopeia, along with organizations like the FDA, spells out best practices. Their guidance comes from teams of experts and thousands of product stability tests.

Accountability Matters Most

Reliable suppliers publish certificates of analysis and batch test reports. They welcome customer questions and offer practical advice on storage. If they dodge questions or refuse to share test data, pick a different brand. Quality assurance isn't just box-ticking; it’s about giving people safe, useful products for as long as possible.

The Bottom Line

Every time you buy something that depends on chemical stability, ask for documentation. Store it well. Insist on traceable, transparent sourcing. These habits keep households safer and our work more dependable. No one wants to gamble with safety or performance.

Why Storage Matters

Anyone working with chemicals quickly learns that careful storage isn’t just following a checklist—it's a safeguard for health and property. 1-Vinyl-3-Ethylimidazolium Hexafluorophosphate, often used in electrochemistry and green chemistry research, fits right into the group of compounds that ask for extra attention. A bottle tucked away the wrong way can spell trouble, from damaged equipment to harm for those nearby. I treat my own workspace like a watchdog, because one careless day could cost a lot more than a lost experiment.

Recognizing the Hazards

This ionic liquid comes with some built-in challenges. Hexafluorophosphate ions can break down and release hydrofluoric acid, a substance that's not only corrosive but also toxic. Direct contact isn’t the only way to get hurt; fumes do damage over time, which becomes a silent risk in a closed lab or storage cabinet. You want this stuff far from moisture, acids, or bases, as these speed up dangerous reactions. Learning from incidents where poor storage led to leaks or exposure, prevention sits high on my list.

Environmental Control

Temperature and humidity play a bigger role than many give credit. Excess heat ruins the stability of this compound, and water in the air invites slow breakdown or even container corrosion. I always stick mine in a cool, dry cupboard, away from windows, vents, or heaters. Labs with climate control make this much easier, but I’ve seen makeshift storage go wrong after just one humid summer week.

Containers Matter

Original packaging usually comes in sealed glass or compatible plastic, which keeps out air and moisture. I never move reactive chemicals into unknown jars or bottles. If I use part of a batch, I reseal with tight, chemical-resistant caps right away, and label with both the compound name and the date opened. I’ve made mistakes before—like leaving a jar half open and returning to find crusty residues that raised a few eyebrows and not a few concerns. Integrity of the container buys peace of mind.

Segregation and Security

I use separate shelves or cabinets for anything with fluorinated anions. Mixing storage with acids, bases, or oxidizers is a recipe for disaster. Labels and hazard symbols should face outward and draw attention. At one site, a color-coded shelf system cut down on confusion, and everyone learned to check before storing something new. Spills can happen, so secondary containment—like a plastic tray—is a habit that pays off.

Ventilation and Emergency Preparedness

Closed containers should still sit in a spot with good ventilation. If vapors escape, quick dispersal keeps levels down. In my own lab, we keep a spill kit and calcium gluconate gel nearby, and everyone learns the basics of hydrofluoric acid response—not just as training, but as a required routine. Nothing builds responsibility like knowing you could save a coworker’s hand or eyesight by reacting fast.

Responsibility in Storage

Storing something like 1-Vinyl-3-Ethylimidazolium Hexafluorophosphate isn’t about red tape—it’s about shared spaces and real consequences. One person’s shortcut could become everyone’s problem. Respecting the hazards, thinking ahead, and keeping storage practical means everyone walks out as healthy as they walked in. That’s the kind of workplace culture worth building.

Spotting Hazards in Everyday Products

A lot of us don’t think twice before grabbing a bottle off the shelf. Whether it’s bleach, paint thinner, or even a battery, we assume it’s harmless since it’s being sold at a store. That couldn’t be further from the truth. Plenty of household and industrial products cause real trouble if used carelessly. Just ask anyone who’s mixed ammonia with bleach by accident. The result isn’t just a bad smell—it’s toxic gas, something you never want to breathe in.

Label reading seems basic, but it’s one of those steps many skip. I learned this lesson working part-time at a hardware store during college. People bought solvents and drain cleaners and never bothered with the fine print. More than a few returned with burned skin or stories about stinging eyes.

Why It Matters—Simple Risks, Big Problems

Risks aren’t always as obvious as a skull-and-crossbones. Take lithium-ion batteries. Most folks toss them in junk drawers, ignoring the warnings. Then they overheat or get punctured, and suddenly you’re dealing with a fire. Something as common as an aerosol can gets dangerous in the wrong conditions. It’s not just about protecting yourself—but also kids, pets, even sanitation workers who have to handle household trash.

Let’s talk numbers. According to the American Association of Poison Control Centers, over two million calls each year involve household products. Substances like cleaners, pesticides, and automotive fluids can send people to the ER. These are problems that rarely make headlines but hit home more often than we realize.

No One Loves Reading Manuals, But…

Nobody wants to sift through instruction sheets or safety data, but skipping this step can mean the difference between a normal day and a trip to urgent care. Manufacturers don’t always make it easy, either. Labels in tiny print, technical jargon, and not enough pictures. Sometimes my neighbors ask if I know what a certain chemical symbol means. People want straightforward warnings—burns skin, causes fires, don’t mix with x or y.

OSHA and EPA both set rules for safe storage and disposal, but it’s clear more transparency would help. Clear icons, simplified instructions, and some real-life examples on product labels could save folks from painful lessons.

Plain Solutions to an Everyday Problem

No product is worth a trip to the hospital. My advice—treat every new cleaner, battery, or can of paint as if it could be hazardous, just in case. Storing products according to the label and wearing gloves or goggles when the fine print suggests it can keep you out of harm’s way. If a product feels sketchy (super strong smell, leaky packaging), take it back or contact the manufacturer. There’s no shame in asking questions.

Schools and workplaces do a better job at training people about chemical safety. At home, most folks are on their own. Picking up a few habits—checking labels, storing products away from heat or sunlight, keeping chemicals out of reach of kids—pays off over time. If you hit a wall with confusing instructions or can’t find disposal info, local waste management or poison control centers often have the answers. No one plans to get hurt. Preparation and a healthy amount of skepticism give you the best shot at avoiding preventable risks.

Why Purity Sets the Tone

In any industry that relies on chemicals—food, pharmaceuticals, or electronics—the question often boils down to one key detail: How pure is the product? Purity isn’t a luxury. It’s a requirement that separates successful operations from costly recalls or regulatory headaches. For example, the FDA and other authorities define strict thresholds because even tiny impurities can create ripple effects through a supply chain. I once spoke with a friend in the electronics sector who explained how a minuscule contaminant in conductive paste led to weeks of product failures. That tiny gap in purity cost the company thousands.

Nuances of Purity in Real-World Applications

In food processing, anything less than food-grade quality risks consumer safety. Pharmaceutical companies won’t accept batches that drift even a fraction below specifications because consistency saves lives. Most purity grades—technical, analytical, pharmaceutical—are spelled out with percentage figures. 98%, 99%, and so-called “five-nines” (99.999%) aren’t just numbers. They set the scope of possible uses. Tech manufacturers lean toward the highest grades for precision, while agriculture may find a technical grade fits the bill. Contaminants can disrupt chemical reactions, introduce allergens, or render an entire lot unusable.

Governing bodies shape these standards for good reason. ISO and GMP guidelines emerged not out of habit, but from real incidents where impurities did genuine damage. As consumers, we rarely think about what 0.1% difference really means, but for people making products that go into our medicines or food, that number means safety or risk.

Packing Size: Not as Trivial as It Seems

Anyone running a factory appreciates the flexibility of different container sizes. Small vials make sense in research labs, while a large-scale processor may go for drums or even bulk tankers. I’ve had conversations with plant managers who stressed how even something as basic as how the material is packaged can shape efficiency and safety. Small bottles cut down on waste in a lab, but a manufacturing floor can’t lose time opening dozens of tiny packages.

Cost also plays a part. Buying in bigger batches tends to lower the price per unit, but only if storage or spoilage doesn’t offset the savings. Some suppliers offer 1 kg jars, 25 kg bags, and 200 kg drums, and a few might deliver customized sizes for unique businesses. Smaller amounts may support pilot projects or tests, larger containers feed massive production lines. It’s worth considering the impact on transport, space allocation, and even how employees handle substances—lifting a drum is a different task than pouring from a one-liter bottle.

Looking Past the Basics

Focusing on purity and packaging might sound boring on the surface, but mistakes hurt both budgets and reputations. Reliable sourcing with tight specs reduces the surprises. Some companies take another step, requesting third-party lab reports or spot-testing batches. Investing in clear communication with suppliers, periodic audits, and an understanding of local regulations produces better results than trusting labels at face value. Equipment choices, handling training, and supplier relationships all circle back to one principle: what arrives in that box shapes every step that follows.