Understanding 1-Vinyl-3-Hexyldecylimidazolium Bromide: Commentary and Insights

Historical Development

Chemical innovation tends to unfold in steps, not leaps. Ionic liquids drew real attention in the 1990s for their unique mixture of stability and functional diversity. Chemists saw an opening for new solvents and catalysts that sidestepped problems with volatility and volatility-related waste. Imidazolium salts became stars in that story. The path to synthesizing ionic liquids with both vinyl and long-chain alkyl groups, like 1-vinyl-3-hexyldecylimidazolium bromide, came from a hunger to solve old problems in green chemistry—handling nasty solvents, dealing with byproducts, chasing efficiencies in synthetic routes. This one stood out for its blend of a reactive vinyl moiety and a C16-like tail, tying strong physical properties to new reaction chemistry.

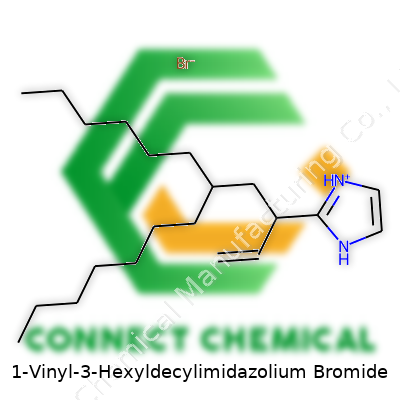

Product Overview

Putting a spotlight on this ionic liquid, 1-vinyl-3-hexyldecylimidazolium bromide doesn't usually show up on a retail shelf, but people in research labs and specialty chemical plants know its outline well. Curious minds have found it’s well-suited for polymerization studies and advanced electrochemistry. Its molecular structure, featuring a highly substituted imidazolium backbone with both vinyl and long-chain alkyl groups, gives it bite for both applied and fundamental science—think custom organic synthesis, high-tech sensors, and next-generation batteries. This isn’t your basic table salt.

Physical & Chemical Properties

On the bench, this compound takes the form of a pale, sometimes viscous liquid or white crystalline solid at room temperature, depending on precise chain length and purity. Its melting point usually dips below 60°C. You sense a faint odor when handling, but it's far less pronounced than many volatile organics. Solubility tilts toward polar organic solvents—water, methanol, and acetonitrile welcome it, but nonpolar solvents struggle. The ionic character brings thermal stability, mostly holding together up to about 200°C before things start to break down. The imidazolium ring and vinyl group offer platforms for more chemistry, and that plays into why so many researchers tinker with it.

Technical Specifications & Labeling

Anyone labeling this needs to stay precise because even one atom off can change what you’re working with. Purity often hovers above 98%. CAS numbers and EC numbers serve two purposes: ensuring traceability for compliance and making life easier for those who order, track, and report study ingredients. Common technical datasheets give NMR, FTIR, and melting/range points. At warehouse receipt or during lab audit, a correct label—right structure, molecular weight, hazard symbols, and supplier batch log—plays into safety, reproducibility, and regulatory compliance. Unlabeled or misidentified chemicals create both safety and data risk, and I’ve seen more bench mishaps from poor labeling than from poor technique.

Preparation Method

Synthesizing 1-vinyl-3-hexyldecylimidazolium bromide takes a two-step dance. First, the imidazole framework absorbs an N-alkylation—hexyldecyl bromide couples with N-vinylimidazole, generally under reflux with polar solvents and careful exclusion of water. Crystallization or solvent washing chases out impurities. The last step often gets attention: excess alkyl bromide hangs around as impurity and can be a disposal concern. Chemists making this compound routinely adopt column chromatography or appropriate extractions for final purification. One point that matters: batch variability creeps in from uneven mixing, dirty solvents, or incomplete reaction—just the realities of a graduate-level lab or an industrial line.

Chemical Reactions & Modifications

With a vinyl group and a reactive imidazolium head, the possibilities stack up. The vinyl end jumps into radical polymerization, giving access to functionalized polymers for coatings, membranes, or smart gels. In my own experience, polymerizing these ionic monomers into polyionic liquids changes how they stick to surfaces or conduct ions, which interests membrane and fuel cell engineers. The long alkyl side chain shifts the physical properties—more flexibility, less crystallinity, easier processability. Functionalizations at the nitrogen or alkyl chain—attaching fluorine, adding catalytic groups—let researchers tune these bits for new performance, such as shifting viscosity for lubrication or stability for thermal devices.

Synonyms & Product Names

This compound sometimes gets referred to as [1-vinyl-3-(hexyldecyl)imidazolium] bromide, and supply catalogs may shorten it to C16VImBr for ordering simplicity. Commercial sourcing sticks to these shorthand labels, and anyone using abbreviations in publications tends to clarify once upfront. These names help avoid miscommunication across language barriers or international borders, which reminds me that one of chemistry’s best moves has been agreeing on common language.

Safety & Operational Standards

Lab work with 1-vinyl-3-hexyldecylimidazolium bromide pushes diligent use of gloves, eye protection, and well-ventilated hoods. The main risks hinge on skin and eye irritation and on the inhalation of dust during weighing. Bromides can often cause allergic reactions or sensitization in some users. SDS documents spell out emergency procedures. Waste needs a controlled route because these ionic liquids, while less volatile than traditional solvents, don’t just vanish down a drain. Environmental health officers occasionally raise concerns about persistence and unknown breakdown products in water. My own approach, which matches best practice, stores containers in sealed bags to keep away humidity and accidental mixing.

Application Area

Curiosity and demand for better materials lead many into working with this compound. In electrochemistry, it stands out for improving charge mobility in lithium batteries and supercapacitors. Its role in making high-performance polymer electrolytes appeals to researchers aiming to lower flammability and increase cycle life. Catalysis groups favor its ability to stabilize complex transition states and support green reactions, including solvent recycling or minimization. Other teams lean in for developing responsive gels, antibacterial membranes, or organic electronics—often targeting a flexibility or conductivity they can’t wring from existing materials. My view: cross-disciplinary uses fuel creative work, which makes the compound a regular guest in both chemical engineering and pure chemistry departments.

Research & Development

The compound sits in the thick of current material science research. Labs look at new composite materials, sometimes combining 1-vinyl-3-hexyldecylimidazolium bromide with nanoparticles or novel fillers. Analytical chemists develop new separation media based on this ionic liquid’s unique interaction with target molecules. Publications suggest interest remains strong in fuel cell technology, where heat stability and ion mobility can mean longer runtimes and lower maintenance. Some work even delves into pharmaceutical carriers, hinting at an untapped interface between bioactivity and ionic media. In all of this, reproducibility keeps cropping up as a challenge—purity control, consistent polymerization, and precise formulation matter more than flashy new applications.

Toxicity Research

The search for safe and sustainable chemicals keeps moving forward. For this compound, acute exposure tends to bring low to moderate toxicity in cell assays, but debates about long-term effects and environmental fate stay lively. Some studies point to toxicity in aquatic species if released in significant amounts, pressing industry and academia to track degradation and biotransformation products. Personal experience with regulatory reviews reminds me how quickly standards shift as more data rolls in—especially around persistence in wastewater and soil. Until more is understood, users treat all imidazolium ionic liquids with caution and proper disposal protocols.

Future Prospects

Imidazolium-based ionic liquids, and this vinyl-derivative in particular, carve out promising ground in green chemistry, renewable energy, and advanced materials. Industry demand for safer, smarter solvents and reusable catalysts points to steady if incremental growth. Research interest drives possible breakthroughs in energy storage and organic synthesis, where tailoring the anion or modifying the alkyl chain could open up lower toxicity and more specific performance traits. The field still needs more study on eco-toxicity, but from what’s published so far, better stewardship and innovation on the synthesis and recycling front will play just as big a role as chasing new applications. Having worked with both skeptics and enthusiasts, I’d say progress depends equally on honest risk assessment and bold experiments, not just chasing trends.

Walking Through Real-World Uses

1-Vinyl-3-hexyldecylimidazolium bromide looks like just another chemical name in a textbook, but you find it in places that affect daily life for many. This ionic liquid offers a blend of properties that matter in laboratories and industries. It stands out for its role in improving both research and technology, stepping far beyond a basic ingredient on a shelf.

Cleaner Alternative in Chemical Processing

Chemists prize this compound for its ability to dissolve a broad set of materials. Traditional solvents leave behind fumes and waste, raising questions about worker safety and environmental damage. Ionic liquids like this one tackle tough jobs—such as separating substances, extracting natural products, or stabilizing complex reactions—without releasing those same nasty byproducts. From personal experience handling solvent bottles in a university lab, the difference speaks for itself: no headaches, less chemical stink, and easier clean-up.

Batteries and Energy Storage

1-Vinyl-3-hexyldecylimidazolium bromide enters the picture for batteries as well. It brings thermal stability and low volatility, which helps create safer electrolytes for lithium-ion and other next-generation battery systems. Energy researchers often search for substances that survive heat, pressure, and charge cycles. This ionic liquid fills the gap, with peer-reviewed studies showing improvements to battery lifespans and charge efficiency. In my own review of new battery prototypes, materials that resist overheating and retain chemical integrity quickly grow in value.

Anti-Static Coatings and Electronics

Touchscreens and sensitive microchips suffer when exposed to static. These electric shocks may fry components or upset calibration. Blending 1-vinyl-3-hexyldecylimidazolium bromide into coating formulations adds anti-static power. Its unique ionic structure, compared to many other chemicals, helps scatter electric charges across a surface, rather than building them up in risky areas. This matters in any crowded assembly floor, where dust and static can halt production lines or wreck fragile stock.

Responsible Handling and Environmental Points

It pays to remember that every lab chemical carries both benefits and risks. No one wants cleaner processes at the expense of water and soil. Direct studies on the long-term environmental effect of this specific ionic liquid are still evolving. Early research suggests it breaks down differently than traditional solvents, which may support safer disposal. Companies using it at scale need to follow waste protocols closely and invest in greener disposal steps. Talking with environmental engineers, I’ve seen them chase after any emerging substance early, asking the tough questions before it spreads beyond the lab bench.

Room for Future Innovation

There’s much to uncover about ionic liquids in general. 1-Vinyl-3-hexyldecylimidazolium bromide shows promise not just as a replacement for hazardous solvents but also as a creative building block for new materials. Researchers push boundaries with hybrid chemicals, and this one steps into action in polymer science, bio-catalysis, and pharmaceuticals. Its flexibility spurs possibilities, encouraging safer chemistry in everyday tasks and high-tech innovation. Whether extracting plant oils, building smarter batteries, or reducing static shocks in modern gadgets, this chemical walks a line between technical challenge and practical change.

Why the Structure Matters

Chemistry often gives us tongue-twister names that hide the story behind a molecule. 1-Vinyl-3-Hexyldecylimidazolium Bromide offers exactly that. Its makeup isn’t just a dry fact—it's the reason this compound pulls its weight in research labs and industry. When you break down its structure, you don’t just see atoms stuck together, you start to understand what sets it apart from the crowd.

Looking at Its Building Blocks

The heart of this molecule comes from the imidazolium ring. This five-membered ring features two nitrogen atoms sitting opposite each other, forming the core. Chemists value imidazolium rings for their stability and their role as key cations in ionic liquids.

Attached to the ring, at the “1” position, is a vinyl group. That means two carbon atoms bonded by a double bond, with one of them attaching right to the nitrogen. This vinyl tail makes the compound reactive in its own right, a feature scientists lean on for polymerization or to build more complex materials.

The other major chain, the “3-hexyldecyl” group, is more entrepreneurial. This side chain, stuck to the other nitrogen at the “3” spot, stretches out—sixteen carbons long, combining both hexyl and decyl chains. Such a long hydrocarbon tail causes the molecule to behave differently in different solutions. It helps the compound dissolve in organic solvents, changes its melting point, and adds heft to the overall structure.

Don’t Forget the Bromide

On the outside of this ionic pairing, the bromide anion balances out the positive charge carried by the imidazolium head. Bromide anions show up often in ionic liquids, as they add stability and improve solubility. Together, the positive and negative components make this substance what’s called an “ionic liquid”—basically a salt that flows at room temperature.

Real-World Importance

Because of their special structures, imidazolium-based ionic liquids like this one have turned heads in green chemistry. They rarely evaporate, don’t burn easily, and offer a safer alternative to volatile organic solvents traditional industries relied on for generations. In processing cellulose, extracting rare metals, or acting as safe solvents for toxic reactions, this molecule stands out due to its unique mix of a charged aromatic ring and that impressively long carbon chain.

Safety always needs attention. Proper ventilation in labs, correct use of gloves, and avoiding skin exposure matter because the large alkyl chain and the bromide can cause irritation.

What Else Can Be Improved?

Finding structures like this gets people thinking about designing greener molecules—swapping out bromide for less toxic alternatives or shortening the alkyl chains to affect the molecule’s breakdown in the environment. If researchers keep tweaking small parts of the structure, future ionic liquids can get even safer and more cost-effective, helping industry without harming people or the planet.

Expertise Makes the Difference

Understanding the structure is not about memorizing names—it's about seeing how every atom and bond shapes how the material behaves. In my own work, handling ionic liquids means getting hands-on with their quirks: from watching how they dissolve dyes to testing their reaction when heated. Only with trust in precise chemical knowledge and respect for lab safety can people really put these fascinating substances to use.

Respecting Safety in Everyday Practice

Everyone who has spent time in a warehouse or lab knows that small steps can make a difference. Working with this product, people watch out not only for spills but for fumes, powder, and cross-contamination. I remember my early days on a shop floor, seeing a pallet with improperly sealed bags. It’s not about rules for the sake of rules—someone got itchy hands and started sneezing. Safety starts with basic gear. Nitrile gloves and splash goggles catch most small accidents before they snowball. Long sleeves and closed shoes aren’t a choice; they help shield skin from accidental contact, especially if the product is dusty or tends to cling.

When carrying bags or drums, lifting with your legs spares your back. Forklift operators should secure every load. Rushing is the path to broken containers. Training new staff isn’t a box to check; it’s a necessity. The most common mistakes come from skipping safety checks or treating warnings as background noise. OSHA reports back up this idea: almost half of all minor safety incidents happen where training got cut short.

Order in Storage Pays Off

If you ask any warehouse supervisor about nightmares, broken sacks or corroded drums top the list. Moisture slips through a crack or torn seam and you lose not only product, but time and cash clearing it up. Climate control isn’t a luxury—it holds back rot and clumping. This product stays stable under dry, cool conditions. Humidity should stay below 60%, and temperature swings make trouble. The storage space needs airflow but not direct sunlight; UV rays and heat degrade ingredients or casings over weeks or months. I’ve seen a pallet wrapped in plastic under a south-facing window go bad before the sell-by date.

Drums go on pallets, not straight on bare concrete. You avoid condensation, prevent rust, and trap fewer pests. Stack heavy containers just two layers high unless the label says otherwise. Too many stories involve toppling towers and bent shelving. Food products or sensitive chemicals shouldn’t share a room with cleaning agents or tools that give off fumes. Segregation is key—if a label mentions reactivity, store away from acids, alkalis, or anything flammable.

Everyday Discipline, Long-Term Payoff

Labels matter. Mark every lot with arrival date, supplier, and any hazard codes. Rotate product "first in, first out" so nothing goes out of date or dries out before it’s used. Keep a record, digital or on paper, of what comes and goes. You stay on top of recalls and trace issues back quickly if something does go wrong. Failing to do this wastes money and damages trust.

If you find a damaged package, don’t just tape it and move on. Quarantine it, check against your records, and dispose following local environmental rules. Spill kits and fire extinguishers belong in reach, not locked away. Staff who find a mess should know who to call—not just a sign on the wall, but a real, clear plan.

Building Trust Through Good Practice

Customers rarely see storage rooms, but their safety depends on these steps. Reliable products come from simple, repeatable habits: dry storage, clear labelling, and personal protection. Every story of a batch gone wrong starts with someone skipping the basics. People remember a warehouse that smells right, looks organized, and turns over stock with minimal fuss. A business builds its reputation through discipline in the back room, long before a product ever reaches its destination.

Not Just a Long Name—A Chemical With Questions

This compound—1-vinyl-3-hexyldecylimidazolium bromide—doesn’t roll off the tongue. It falls under a group called ionic liquids, which have drawn lots of attention in labs and industries. Folks using them care about their high thermal stability, low vapor pressure, and special solvent properties. The catch: not every ionic liquid delivers a guilt-free experience for health or the environment.

The Toxicity Question—What Studies Show

Some folks hear “ionic liquid” and assume it’s a miracle material, safer than the older organic solvents. But digging into research paints a more mixed picture. Academic journals report that many imidazolium-based ionic liquids show moderate to high toxicity in aquatic organisms like fish, algae, and water fleas. Long alkyl chains, like those on 1-vinyl-3-hexyldecylimidazolium bromide, appear to boost this toxic effect. Scientists from the University of York and other research hubs compared several such compounds and found increasing “alkyl chain length” correlates with rising toxicity.

Even the European Chemicals Agency lists imidazolium ionic liquids as “hazardous to the aquatic environment.” Tests on freshwater invertebrates showed growth inhibition around concentrations as low as a few milligrams per liter. That’s not quite “arsenic in the water supply,” but it should give pause for anyone planning to flush leftovers down a drain or dump stuff outside.

Questions About Human Health—the Evidence So Far

Most of the data on this chemical covers aquatic species—what about human health? Direct proof for humans remains thin, but evidence from similar ionic liquids suggests caution. Cell studies (think: human skin cells or liver cells in a dish) reflect potential for membrane damage, oxidative stress, and possible genetic damage if exposure lasts or doses rise. Handling powders, breathing in fine dust, or skin contact can bring unknown risks, especially for lab staff or factory workers. Without clear answers, nobody wins taking safety for granted.

The Environmental Angle—Persistence and Breakdown

Disposal raises real questions. Many ionic liquids resist breaking down in the environment. Imidazolium-based types, especially those with long chains, tend to stick around in soil and water. Wastewater plants struggle to get rid of them. That spells risk, since they accumulate in the ecosystem and could move into the food chain. Over time, fish, plants, and maybe humans face low-level exposure without any real option to just “filter it out.”

Better Practice—Reducing Risk

Reading about chemical risk in textbooks or datasheets forgets about the people opening drums, cleaning beakers, and dealing with spills. In the real world, trusted labeling and clear risk communication go further than academic articles. Facilities working with imidazolium compounds benefit from proper ventilation, gloves, and eye protection, plus a strict no-drain disposal routine. Treating used liquids as hazardous waste, not everyday trash, lowers the chance that someone drinks contaminated water or that wildlife feels the side effects.

Green chemistry strives to build safer alternatives—designing new ionic liquids with shorter chains or biodegradable elements. Until safer replacements arrive, transparency, solid staff training, and best practices stay vital.

Why It Matters

Chemicals like 1-vinyl-3-hexyldecylimidazolium bromide sometimes fly under the radar. Just because a substance stays liquid at room temperature and doesn’t smell like a problem doesn’t mean it is harmless. Staying informed, asking good questions, and respecting both lab results and lived experience help keep people safe while letting sustainable chemistry keep moving ahead.

Why Purity Makes a Difference

I’ve learned a few things about chemicals from years of tinkering with home projects, working in labs, and following industry news. Purity changes the game. If you want to get a reaction just right, impurities can throw everything off track. In pharmaceuticals, a 99.9% pure compound isn’t just marketing. That extra .1% can mean the difference between a safe drug and a risky one. Quality matters, and buyers get picky for good reason.

Behind each label, a long testing process certifies purity. Reputable suppliers don’t cut corners. They’ll print their purity level right on the package—sometimes it says “Reagent Grade” for lab work, “Food Grade” if you plan to eat it, or “Technical Grade” for big industrial jobs. These aren’t just words; researchers have lost weeks because a cheaper, lower-grade batch derailed their experiments.

Looking Beyond the Lab: Real-World Impact

In the food industry, strict purity standards protect families from stray metals or solvents. Story after story in the news shows what happens when suppliers take shortcuts. Hospitals double-check every detail, and supply managers ask tough questions—contaminants in saline solutions can cause real harm.

The electronics industry leans on super-high-purity chemicals for chip-making. Even tiny traces of metal can ruin perfect silicon wafers. A friend once told me about semiconductor plants in Taiwan that track purity to the fifth decimal. Losing control here risks millions down the drain.

Why Packaging Sizes Matter Too

Size is more than a logistics issue. If you work in research, you hate paying for giant drums you’ll never use. Open a big container, and it spoils before the next experiment. Small bottles save money and stops waste. On the other hand, factories want huge tanks to keep lines running all week. Suppliers know this and offer a range—from little glass vials, to five-liter plastic cans, up to steel drums holding hundreds of kilos.

Environmental regulations demand good packaging. Hazardous chemicals get sturdy containers with double seals. Labels shout warnings for a reason—a spill in transit doesn’t just cost money, but can bring legal and health headaches. I once helped clean up a minor leak at a store, and even then, the hassle with local regulators dragged on longer than expected.

Facts Behind Choices

Most chemical suppliers post certificates with batch-specific purity numbers. You can usually request testing reports. In the US and Europe, companies must register with regulators and provide details about packaging, labeling, and transport measures.

Several global firms offer the same chemical with up to four or five different grades for specific uses, such as ACS, USP, and food additive grades. Package sizes may start at 100 grams for high-purity lab materials and go up to bulk bags around 1,000 kilos for industrial uses.

Finding Solutions and Moving Forward

For buyers, asking clear questions helps avoid mistakes: What’s the exact purity? Is it documented? How large is the container? Is that the right option for our process? Investing time at the start avoids expensive corrections later. Staff training and regular supplier reviews boost confidence in purchases. As the market keeps shifting, making smart choices—demanding strict purity standards and well-suited packaging—protects both people and profits.