1-Vinyl-3-Methylimidazolium Hexafluorophosphate: An In-Depth Commentary

Historical Development

Chemists have spent decades searching for new solvents and catalysts that match the pace of modern industry. The story of 1-Vinyl-3-Methylimidazolium Hexafluorophosphate started in the push for more efficient, adaptable ionic liquids. Researchers knew imidazolium salts could be tuned for various applications, but it took breakthroughs in synthesis strategy, especially during the 1990s, for the vinyl-substituted analogs to gain traction. Lab notebooks and journal articles from those years show that organic and physical chemists wanted an alternative to traditional volatile organic solvents. Their work shifted the focus from simple salt formation toward complex anion/cation combinations. By the time academic labs produced milligrams for study, large chemical producers already sensed a market on the horizon for specialized, safer ionic liquids.

Product Overview

1-Vinyl-3-Methylimidazolium Hexafluorophosphate stands out as a versatile ionic liquid with a wide range of uses in industry and research. The imidazolium ring, coupled with a vinyl group at position one and a methyl group at position three, offers rare prospects for both structural modification and functional diversity. Hexafluorophosphate acts as a robust, non-nucleophilic counterion. You won’t find this compound among bulk chemicals for commodity applications. Rather, it attracts interest from those who value nuanced solvent systems, catalyst supports, or polymerization media. My own work in electrochemistry introduced me to its low volatility and wide window of electrochemical stability. That experience highlighted possibilities in plastics manufacturing and electroplating that traditional solvents couldn’t match.

Physical & Chemical Properties

In the lab, 1-Vinyl-3-Methylimidazolium Hexafluorophosphate presents as a colorless to pale yellow, oily liquid, often exhibiting high viscosity and remarkable hygroscopicity. Water absorption can alter many of its key properties. Unlike standard organic liquids, it resists evaporation at room temperature and maintains chemical stability across wide ranges of pH and temperature. The PF6− anion resists nucleophilic attack, contributing to its appeal for harsh synthesis environments. It dissolves numerous organic and inorganic substances, offering chemists a solvent with a unique mix of polarity, conductivity, and heat endurance. Electrochemical stability windows above 4 V make it a candidate for high-end batteries and capacitors, not just as a solvent but as an electrolyte itself. These traits draw the attention of both academic researchers and industrial engineers.

Technical Specifications & Labeling

Producers standardize this ionic liquid by noting purity, usually 98% or greater for advanced work, and residual water content, often below 0.5%. Density hovers close to 1.26 g/cm3 at 25°C, with melting points generally below -30°C, ensuring liquidity even in cold conditions. The molecular formula C6H9F6N2P sets the expectation for mass balance and elemental analysis. Shipping labels indicate “Corrosive” and “Moisture Sensitive,” and warehouse shelves require desiccators or hermetically sealed containers to protect from environmental moisture. During a couple of late-night syntheses, I learned the hard way that a simple seal breach means starting over — even minutes exposed to air can ruin the batch.

Preparation Method

Synthesis draws from established organic and inorganic routes. Workers react 1-vinylimidazole with methylating agents, typically methyl iodide, to produce the corresponding monocation. Anion exchange with potassium hexafluorophosphate follows in aqueous or acetonitrile environments. Efficient purification involves washing with volatile organic solvents, filtration, and vacuum drying. Large-scale production transfers these steps to glass-lined reactors and solid-phase extractors, but reproducibility stays highly dependent on operator technique and raw material quality. A single misstep—too much water, uneven mixing—compromises product quality. These steps need skill and attention to control yield and purity.

Chemical Reactions & Modifications

The vinyl group at the core of this molecule reacts readily with radical initiators, allowing polymerization into functional ionic polymers with tunable mechanical and conductive properties. Chemists exploit this reactivity to create membranes for separation technology or advanced sensor platforms. Coordinating agents, like transition metal salts, interact with the nitrogen atoms of the imidazolium ring, providing additional tuning of physical and catalytic properties. Laboratory tests show the liquid remains stable in the presence of strong bases and acids, so reaction design options multiply. I’ve observed teams graft this functionality onto silica supports, enabling use in catalysis or as stationary phases for chromatography, expanding utility far beyond simple solvent roles.

Synonyms & Product Names

Commercial and academic literature features the product under various names, such as 1-vinyl-3-methylimidazolium hexafluorophosphate, VMIM PF6, and N-methyl-N-vinylimidazolium hexafluorophosphate. Product codes differ depending on supplier, muddling ordering unless full IUPAC or CAS numbers are referenced. Even technical sales teams rely on synonyms to bridge requests across continents and industries. Despite these inconsistencies, word-of-mouth remains strong in the chemistry community, as most researchers recognize the structure through the shorthand “vinylimidazolium PF6.”

Safety & Operational Standards

Handling guidelines demand attention. The PF6− anion can hydrolyze under acidic or alkaline conditions, producing toxic HF gas. Routine operations require gloves, eye protection, and well-ventilated hoods. Direct skin exposure risks irritation, so even short handling sessions call for care. Many safety data sheets stress environmental persistence and aquatic toxicity of PF6–containing compounds, leading institutions to anchor procedures on safe waste disposal and accidental release mitigation. Regulatory bodies in North America and Europe now require robust worker training and incident documentation for labs and companies using this ionic liquid in routine or experimental phases.

Application Area

Research groups and developers see broad potential, starting with green chemistry as a solvent replacement for traditional, often hazardous, organics. High ionic conductivity suits it to lithium-ion battery and supercapacitor electrolytes. Co-polymerization with other vinyl monomers yields robust, ionically conductive plastics for sensors and actuators. Electroplating, environmental remediation via CO2 capture, and fine chemical synthesis round out the portfolio. Specific projects on drug delivery and analytical separation hint at even wider scope. In practice, I’ve seen startup founders pitch ionic liquids as future stars in sustainable energy and environmental technology, suggesting the reach exceeds current markets.

Research & Development

Teams worldwide push innovations in synthesis, recycling, and end-use integration. Ongoing projects test alternative anions to lower toxicity and raise conductivity, or engineer the cation for increased functional group compatibility. Partnerships connecting academia with chemical manufacturers speed process optimization and batch scalability. Conferences buzz with talk of how subtle tweaks in the anion or side chains yield dramatic changes in thermal behavior, toxicity, or electrochemical performance. As environmental regulations grow stricter, labs scramble for scalable post-use recycling strategies, aiming to keep ionic liquids from accumulating in ecosystems or landfill. These efforts redefine what sustainability means in specialty chemicals.

Toxicity Research

Studies show 1-Vinyl-3-Methylimidazolium Hexafluorophosphate can pose moderate to significant toxicity in aquatic environments, especially if hydrolysis liberates hexafluorophosphate or forms fluoride ion derivatives. Data from recent toxicology reports signal persistent, cumulative ecological impacts when disposal escapes proper channels. Chronic inhalation risks sit low, but ingestion or concentrated vapor exposure represent real dangers. Researchers identify organ-level loading and bioaccumulation patterns, especially in small invertebrates and fish. Regulators and safety assessors push for expanded toxicological testing, spanning acute, chronic, and reproductive endpoints. Few comprehensive epidemiology studies exist for humans, but animal models raise persistent questions about safe manufacturing, shipment, and use at scale.

Future Prospects

Ionic liquids grow more relevant each year as cleaner process engineering guidelines and advanced materials push aside traditional solvents. Next-generation batteries, recyclable polymers, and high-stability catalysts depend on specialty ionic liquids to solve tomorrow’s energy and environmental hurdles. Markets shift as research addresses toxicity and recycling, positioning 1-Vinyl-3-Methylimidazolium Hexafluorophosphate within regulatory frameworks instead of outside them. Success relies on better synthesis routes, greener substitutes for the hexafluorophosphate anion, and closed-loop use cycles. Startups and global chemical groups alike invest in routes for production, purification, and end-of-life recovery, creating opportunities for safer, more efficient chemistry in a future shaped by environmental constraints and technical demand.

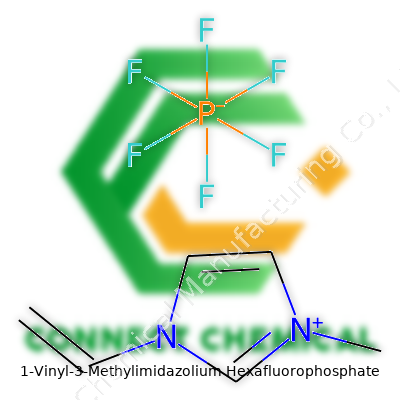

Understanding the Core: The Cation

At the center of this compound sits a rather fascinating ring. The cation, 1-vinyl-3-methylimidazolium, belongs to the family of organic salts known as ionic liquids. For those fresh to the field, think of "imidazolium" as a five-membered ring with two nitrogen atoms. One nitrogen sports a vinyl group—a carbon-carbon double bond dangling off the ring—while the opposite nitrogen wears a modest methyl group. This little tweak changes how the ring handles electrons and modifies its interactions in solution.

Chemical structure matters more here than just lines on paper. Swap out the methyl for a larger group, or lose the vinyl, and the compound starts behaving differently—different melting points, solubility, and even reactivity. The presence of both vinyl and methyl groups keeps this cation from stacking up and crystallizing tightly, making the whole compound stay liquid at lower temperatures. I see researchers taking advantage of those properties in labs everywhere, as ionic liquids can often stay fluid when regular salts turn solid.

The Anion: Hexafluorophosphate

Then comes the anion—hexafluorophosphate (PF6-). This guy, with a phosphorus atom surrounded by six fluorine atoms, doesn't like to play too close with water. Out in my own experience working near chemical labs, I've watched bottles of hexafluorophosphate salts kept tightly shut and dry. The anion keeps the overall salt from picking up water from the air and improves the overall chemical stability. A quick fact: in the context of battery electrolytes, PF6- often helps keep the ionic liquid non-volatile and robust in tough conditions.

Pieces Snap Together: The Full System

Drop the cation and anion together and you get a formula: C6H9N2+ plus PF6-. Draw it out, and it looks like this—one five-membered ring bearing a vinyl and methyl group (on the nitrogens), and a slightly larger octahedral hexafluorophosphate cluster floating nearby. It dissolves in organic solvents, stays put in dry air, and won’t boil away at room temperature, which sets this family of ionic liquids apart from old-school salts like sodium chloride.

Talking to chemists, the structure pushes a few boundaries. Tack on that vinyl group, and the compound becomes a pretty good building block for polymerizations. I’ve seen researchers use it as both a solvent and a monomer, sometimes both at once. The imidazolium core resists harsh chemical environments, so it finds itself in electrochemistry, separation science, and even in catalysis for green chemistry projects. The combination of this cation and hexafluorophosphate anion turns out to be fairly stable under high voltage, promising for tech like next-gen capacitors or specialty batteries.

Addressing Risks and the Way Forward

Some caution comes into play here. PF6- can break down in the presence of water or under extreme heat, cleaving off toxic chemicals like hydrogen fluoride. I once had a labmate suffer skin irritation from accidental contact—plenty of labs have stories like these. Stricter handling and safety training can go a long way. Substitute anions like tetrafluoroborate or bis(trifluoromethane)sulfonimide offer similar benefits without some of the drawbacks, and that sort of swap can help clean up the environmental impact.

So, learning about the chemical structure of 1-vinyl-3-methylimidazolium hexafluorophosphate means more than just memorizing atoms. Its unique pairing of imidazolium with a tough, hydrophobic anion creates a toolbox for creative chemistry and emerging technologies—while also reminding everyone to respect safety when working with complex ions.

Why 1-Vinyl-3-Methylimidazolium Hexafluorophosphate Matters

1-Vinyl-3-methylimidazolium hexafluorophosphate hits the radar of chemists and engineers for a pretty simple reason: they want solvents and reaction media that handle tough jobs, push innovation, and stay stable even under stress. I first heard about this ionic liquid while collaborating with research chemists who needed a better electrolyte for their electrochemical experiments. What started as a curiosity soon became a practical tool across a handful of labs.

Electrochemistry: A Game-Changer for Battery and Capacitor Work

In my experience, battery researchers spend plenty of time looking for electrolytes that tolerate both voltage and heat. 1-Vinyl-3-methylimidazolium hexafluorophosphate (often called [VMIM][PF6]) brings impressive thermal stability and a wide electrochemical window. It lets researchers push devices harder—whether in lithium-ion batteries or advanced supercapacitors. The performance for supercapacitors stands out, where other liquids fall short under heavy cycling and high voltage. Studies show the compound drags less water into energy storage devices compared to classic salts and solvents, which makes a big difference for device lifespan and safety.

Green Chemistry: Cleaner Reactions and Easier Recycling

Sustainability pushes a lot of decisions these days. I’ve seen several labs searching for “greener” ways to conduct classic syntheses. Thanks to its low melting point and chemical inertness, [VMIM][PF6] works as a non-volatile solvent, replacing traditional organic solvents that evaporate, pollute air, and sometimes put lab workers at risk. Chemists can separate out products by tweaking temperature or an added solvent instead of running fume hoods non-stop. This can cut costs for waste treatment and improve workplace safety, which matters a lot for both startups and established firms.

Polymer Science: Stronger Materials, New Surfaces

Polymer chemists lean into ionic liquids when tackling tough, precise modifications. One practical angle uses [VMIM][PF6] as a “functional monomer” in polymerization, helping build materials for anti-static coatings, membranes, or even drug delivery vehicles. The ionic character brings electrical conductivity and surface properties that standard plastics just can’t match. I’ve worked in projects where swapping in this compound opened up products with unique conductivity—alongside better resistance to heat and corrosion. This kind of technology helps electronic manufacturers and biomedical firms keep their edge.

Metal Extraction and Separation

Industries process massive amounts of metals and need better ways to pick out valuable ones without generating huge volumes of waste. 1-Vinyl-3-methylimidazolium hexafluorophosphate plays a role here by dissolving and holding metal ions efficiently. Whether recovering rare earths or cleaning up electronic scrap, the specificity of capture and release stands out. Compared with older extractants, this ionic liquid survives harsher conditions and can be recovered for re-use multiple times—saving both money and raw material.

Looking Forward: Tackling Cost and Scale-Up

Despite the promise, most of my colleagues point out real hurdles. The price tag on [VMIM][PF6] still runs high for anyone thinking about bulk applications. Efforts have begun to streamline synthesis and recycling, with researchers using renewable feedstocks or trying catalysts to lower energy use. Factoring in safety and environmental data before large-scale adoption makes sense. I’ve watched innovation cycles in chemicals before; scaling up tends to spark solutions, whether through competition or necessity. For now, the main action for [VMIM][PF6] lives in labs, pilot lines, and a handful of specialized products—but the list of possible uses keeps growing.

Understanding Why Care Matters

Handling chemicals never fits the same rules as making toast or boiling water. The stories about folks who got a chemical burn or spilled something caustic ring in my head every time I read a warning label. These aren’t rare events — according to the CDC, thousands of people land in the emergency room each year because basic precautions fell to the side. Respect for safety isn’t just a box to check off. It shows you care about yourself, your coworkers, and the people who might use that workspace next.

Personal Protective Gear Isn’t Optional

I’ve noticed lab techs sometimes treat goggles or gloves like decorations unless they smell something strong or see a puff of smoke. That way of thinking invites trouble. Even when a substance looks harmless, a splash in the eye or a small spill on the skin can become a mess fast. Whether you’re dealing with strong acids, organic solvents, or unfamiliar powders, keep those goggles tight and gloves handy. For compounds that send off fumes, add a mask or shield. Many chemical injuries happen during setup or cleanup, so keep that gear on the whole time, not just during the exciting part.

Ventilation Changes the Game

Fumes are sneaky. I’ve opened a bottle, expecting nothing, and gotten a nose full of stinging vapor. Almost every lab incident I’ve seen involving headaches or nausea came from thinking a vent hood wasn’t necessary. Even chemicals that don’t have a strong smell can linger in the air and cause problems later on, especially if you work in a spot without much airflow. Fume hoods or even basic fans make a huge difference. Spending the extra minute to turn one on creates a safer zone, even for routine transfers or dilutions.

Labels and Storage Speak Volumes

Relying on memory leads to mistakes. I’ve seen folks store clear liquids in old water bottles or mix up containers, only to create confusion or cause near-misses. Label everything the moment you open it. Full names, concentration, and the date keep everyone in the loop. Every bottle or jar has a story; don’t turn it into a mystery. Between fridge overload and crowded cabinets, make sure each compound ends up in a spot where it won’t react with something else or tip over. Flammable, corrosive, and toxic substances each have their own requirements, and ignoring those can cost you more than a ruined experiment.

Clean Up and Disposal: The Overlooked Step

I remember sweeping up a powder spill for the first time, surprised at how sticky and clingy it got. Some compounds just want to travel on shoes, sleeves, or even in hair. Take the time to clean up slowly and completely. Follow disposal rules, even if it means extra steps like neutralizing acids, keeping solvents out of the sink, or using designated containers for sharps or contaminated glassware. Messy benches and full trash cans create risks that can add up. Oversights have real consequences — for you and anyone else who uses the space later.

Training Isn’t Just Red Tape

Thinking you know a chemical based on general chemistry class or YouTube leaves gaps. Safety data sheets (SDS) spell out what you really need to know. Take a few minutes to read them before working with something new. Workshops, short videos, and refresher sessions all pay off eventually, especially when dealing with unfamiliar compounds. Mistakes never announce themselves ahead of time, and that one shortcut can cost much more than it saves.

Respecting the Risks Brings Reward

Handling chemicals safely reflects character, not just compliance. Each right step — proper gear, airflow, labeling, cleanup, and preparation — lowers the chance of something going sideways. From classrooms to big industrial plants, there’s no substitute for showing care with the tools and materials around you.

Getting to Know the Compound

1-Vinyl-3-methylimidazolium hexafluorophosphate stands out as a member of the ionic liquid family. Chemists and chemical engineers look toward these salts since their unique properties shake up old notions around solvent behaviors, especially their use as alternatives to volatile organic compounds in industry and research. Rather than following traditional solute-solvent trends, these ionic liquids bring in a new game with their structure. The imidazolium ring, for example, brings flexibility in both molecular design and physical properties.

Facing Water: A Case of Negligible Solubility

Dissolving this compound in water leads to a nearly predictable outcome for those who have handled similar ionic liquids with the hexafluorophosphate anion. Water molecules don’t play well with the robust, hydrophobic nature of PF6-. I’ve seen crystals form and stay put even after extended stirring at room temperature. Experimental work and the literature consistently report very low to negligible solubility. As a practical consequence, working with this salt in aqueous settings mostly leads to phase separation or suspension, not a true solution.

One notable example: labs working on electrochemical applications sometimes attempt to use water as a greener solvent for ionic liquid-based electrolytes. Results show persistent cloudiness, and no measurable conductivity increase—a direct sign the salt hasn’t dissolved. Professionals considering this for aqueous catalysis or separations soon realize solvent choice must shift toward organics.

Organic Solvent Compatibility

Turning to organic solvents, the scenario changes. 1-Vinyl-3-methylimidazolium hexafluorophosphate dissolves much better in polar organic solvents without strong hydrogen-bonding tendencies, such as acetonitrile, dimethylformamide (DMF), and even acetone. I remember pulling cloudy solutions clear within minutes of mixing with acetonitrile—something that never happened with water. This makes sense when you consider the role of both the cation and anion. The imidazolium ring prefers environments where some polarity exists but without the aggressive hydrogen bonding competing for interaction sites.

Research backs this up. A study in the *Journal of Physical Chemistry* explored imidazolium-based ionic liquids and their interaction with acetonitrile. Results lined up with lab experience: a marked increase in solubility due to matching polarities and the ability for the solvent to stabilize both ions.

Real-World Implications

Solvent selection affects safety, practicality, and cost. Water’s lack of compatibility with this ionic liquid has limited its use in certain green chemistry initiatives. Purifying, processing, or recycling 1-vinyl-3-methylimidazolium hexafluorophosphate always involves solvent recovery, and the low water solubility simplifies product isolation but complicates use in aqueous technologies. Fireside chats with fellow chemists often land on the same point: the promise of ionic liquids only goes as far as their practical usability.

For those concerned with environmental or regulatory impact, the solubility picture lays out clear tradeoffs. Using acetonitrile or DMF means dealing with flammability and toxicity—for every solved compatibility issue, another concern pops up. Ongoing work focuses on designing new anions and cations to tweak these properties—aiming for high solubility in green or sustainable solvents.

Looking Forward

The solubility of 1-vinyl-3-methylimidazolium hexafluorophosphate highlights how molecular structure shapes practical laboratory choices. Experiences in both academic and industrial settings emphasize the need for data-driven solvent selection. Matching the right solvent to the right ionic liquid isn’t just chemistry—it’s the foundation for advancing new materials, catalysis, and environmentally sound processing. Careful engineering of both molecules and methods will lead the way forward.

Practical Choices Make a Difference

In the lab, 1-vinyl-3-methylimidazolium hexafluorophosphate doesn’t offer much leeway for mistakes. Over the years, I’ve seen what happens when chemicals get careless treatment and shortcuts replace best practices. This particular ionic liquid brings its own set of risks and quirks. Hexafluorophosphate offers performance benefits for electrochemistry and organic synthesis, but only when handled with steady discipline. Let’s talk about ways to do that right—keeping chemical talk straight and practical with real examples from actual workbenches.

Avoiding Moisture: Lessons From Experience

One time a bottle of hexafluorophosphate-based salt sat too long uncapped on a humid day, it quickly reminded us how strongly it reacts with water. That’s not just a mess—it produces toxic hydrofluoric acid and breaks down the salt’s performance in battery tests. Moisture really is the enemy here. Dry air storage makes all the difference, so silica gel packs or a good desiccator become your silent partners. Put the bottle back in a sealed container every time, no matter how quick the task.

Shielding Against Light and Heat

A sunbeam on a shelf doesn’t seem like much, until you see the yellowing of a supposedly stable ionic liquid. Ultraviolet rays—plus the slow heat from bright lights—chip away at stability. Hexafluorophosphate salts won’t always show dramatic, immediate change. The real cost comes later, in lost purity and unreliable results. I keep my ionic liquids in amber or opaque bottles, tucked far from any window or lab lamp. Room temperature works for routine jobs, but whenever schedules slip, cooler conditions help keep the decomposition rate down. Somewhere between 15 and 25 degrees Celsius usually hits the sweet spot.

Clean Surroundings Matter

Dust and organic vapors float in every busy lab. Most days you won’t notice, but these contaminants slip in fast each time a cap comes off. I made it a habit to open bottles in a glovebox or at least near a fume hood with minimal traffic. Small changes in routine matter—someone once bumped a bottle by accident, sending dust and possible solvents in. That batch never acted the same in our organic reactions. Clear bench discipline keeps batches in good shape.

Understanding the Risks: Health and Safety Counts

Anyone who ever handled hydrofluoric acid, or cleaned up a mishandled spill, knows these jobs don’t forgive slack protocol. Hexafluorophosphate can release hazardous gases if exposed to acid or moisture. Always keep safety glasses on, work with gloves rated for chemicals, and store acids and bases far from these salts. I learned early to label containers boldly—never assume someone else knows what you’ve got on a cluttered shelf.

Long-Term Storage: Think Twice

For projects running over months, I’ve shifted to keeping smaller aliquots sealed tight and only opening the main bottle for refilling. Each lid-off moment risks a small loss in quality—unseen, but real. Nitrogen or argon blankets slow degradation further for highly sensitive work. These steps seem small, but after a decade in the lab, I've learned they're what separate passable results from something you actually want to publish or use in production.

The Takeaway—Simple Routines, Lasting Stability

Extra care at each step turns “risky” chemicals into reliable tools. Storage isn’t glamorous, but it protects your time, health, and research investments. Anyone using 1-vinyl-3-methylimidazolium hexafluorophosphate can dodge problems with well-sealed containers, a dry environment, and clean habits. I’ve watched people cut corners and pay for it later. A little discipline and common sense guarantee returns in the lab, one capped bottle at a time.