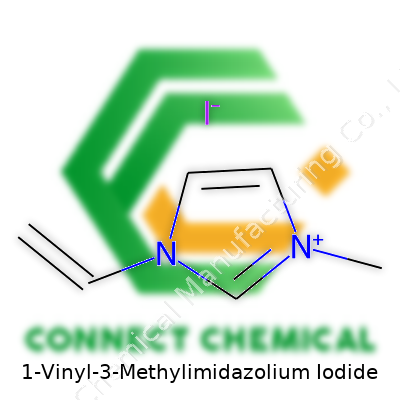

1-Vinyl-3-Methylimidazolium Iodide: In-Depth Analysis & Commentary

Historical Development

Researchers have explored the field of ionic liquids for decades, with breakthroughs dating back to the mid-20th century. The journey leading up to 1-Vinyl-3-Methylimidazolium Iodide unfolded alongside expanded studies into imidazolium derivatives. Lab reports from the seventies document chemists seeking alternatives to traditional solvents, noticing that imidazolium salts often defied volatility and handled heat better than organic solvents available at the time. 1-Vinyl-3-Methylimidazolium Iodide emerged in the late twentieth century as chemists discovered its potential in polymer science, sensing a shift in how recyclable, low-volatility solvents could transform industrial practices. This focus shaped much of the way current research approaches synthesis, safety, and application.

Product Overview

1-Vinyl-3-Methylimidazolium Iodide belongs to the class of ionic liquids defined by the imidazolium cation structure. Its rise to prominence traces back to needs for specialized ionic environments, opening new routes for both laboratory and commercial-scale reactions. Industry and university labs source this compound for its stability and ion-conducting tendencies. The vinyl group embedded in the molecule enhances its versatility, bridging utility between catalysis, electrochemistry, and polymer development. Chemists quickly picked up on its potential, not just as a green solvent, but as a building block for advanced functional materials.

Physical & Chemical Properties

This salt appears as a pale yellow to off-white crystalline solid at room temperature. The presence of the iodide anion brings higher density and a distinct melting point—often above 100°C, though slight purification changes can impact the crystallization profile. The compound dissolves readily in water and polar organic solvents, driven by the hydrophilic imidazolium ring. Chemical stability holds up against light oxygen exposure but can degrade under intense UV radiation or in the presence of strong nucleophiles. From my experience in polymer chemistry, its resilience under moderate heat far exceeds what one encounters with simple organic solvents, making it useful in prolonged syntheses or catalysis.

Technical Specifications & Labeling

Reputable vendors ship this compound with a purity exceeding 98%, accompanied by an analysis that specifies key parameters: melting point (commonly 120-130°C), solubility, grade, molar mass (approximately 264.1 g/mol), and the CAS number. Its chemical formula reads C6H9IN2. Labels also note storage precautions—airtight container, no exposure to direct sunlight, and for best results, a cool, dry place. Product datasheets present the molecular structure along with recommended personal protective equipment requirements for laboratory use, reflecting regulatory demands for transparent, safe handling.

Preparation Method

Synthetic routes for 1-Vinyl-3-Methylimidazolium Iodide revolve around quaternization reactions. Typically, one starts with 1-methylimidazole, reacting it under controlled conditions with 1-vinyl halides, often using vinyl iodide or substituting with vinyl bromide followed by halide exchange. The process involves maintaining a moisture-free environment to avoid hydrolytic side reactions. In practical chemistry work, care during addition steps—especially with reactive vinyl halides—prevents side product formation. Yields routinely reach or surpass 85% after purification through solvent washes and recrystallization. Some commercial routes now use one-pot synthesis, reducing procedural steps and contamination risk.

Chemical Reactions & Modifications

One significant trait of 1-Vinyl-3-Methylimidazolium Iodide is its adaptability. The active vinyl group serves as a reactive handle for further polymerization through radical or ionic initiation. Its imidazolium core tolerates several modifications without losing structural integrity, allowing production of polymeric ionic liquids with tailored conductivity or mechanical flexibility. In electrochemical research, the iodide ion participates in redox chemistry, supporting electrodeposition or halide exchange for fine-tuned catalytic environments. Having worked with similar ionic liquids in polymerization, it's clear that adjusting substituents on the imidazolium ring or swapping counterions directly alters solubility and reactivity, which customizes the compound for niche technical needs.

Synonyms & Product Names

In the chemical trade, this compound appears under several names: 1-Vinyl-3-methylimidazolium iodide, [C1VinIm][I], VMI, and sometimes as N-methyl-N-vinyl-imidazolium iodide. Distributors may abbreviate it simply as VIMII. Differences in naming reflect the idiosyncrasies of international suppliers, though the CAS number remains the standard for clarity across research papers and industrial catalogs.

Safety & Operational Standards

Ionic liquids as a class offer relatively lower volatility, but 1-Vinyl-3-Methylimidazolium Iodide deserves respect for its reactivity. Lab staff wear gloves, safety goggles, and, if any powders are involved, particle masks to guard against respiratory exposure. Safety datasheets note acute inhalation and ingestion risks, with symptoms similar to other mildly toxic organic salts: irritation, headache, and nausea at high doses. Labs with responsible oversight keep spill kits handy, since iodide-containing compounds can stain and cause environmental buildup in drains. I've found that quick spill response, prompt air exchange, and adherence to waste management standards reduce occupational exposures. The regulatory bar keeps rising for these salts, especially with expanding research into their chronic effects and environmental legacy.

Application Area

Use of 1-Vinyl-3-Methylimidazolium Iodide spans a surprising range. One popular application lands in the synthesis of polyelectrolytes and polymer electrolytes for batteries or fuel cells. The ionic conductivity and customizable backbone support innovation in energy storage. Organic synthesis labs draw on its mild yet versatile ionic character to push reactions that demand low volatility and broad solubility profiles. In catalysis, it enables tough carbon-carbon coupling and helps stabilize metal nanoparticles. As someone involved in the bench work for pilot battery projects, I’ve seen studies leverage this salt to boost cycle life and operational stability, hinting at its future in commercial-scale energy solutions. Its solubility profile and chemical resistance have also led to applications in extraction and separation of complex bioactive compounds, where traditional solvents fall short.

Research & Development

Universities and private labs dig into polymerization kinetics, redox properties, and ionic conductivity. Researchers keep innovating, tackling problems like viscosity, miscibility, and electrochemical stability. Current projects seek modifications of the imidazolium core to cut down on toxicity, boost biocompatibility, and tailor the compound for solid-state electrolytes. Some groups develop recycling methods for ionic liquids, closing the loop in chemical manufacturing and trimming downstream waste. The drive for scalable and affordable ionic liquids hinges on process simplification—a topic hotly debated in R&D meetings and conferences I’ve attended, where everyone agrees chemical complexity can’t slow down the rise of circular chemistry.

Toxicity Research

Toxicological studies on imidazolium-based ionic liquids reveal a mixed safety profile. Most acute toxicity results fall in ranges considered mild to moderate. Still, concerns about long-term bioaccumulation and aquatic toxicity keep regulatory and scientific attention fixed on best practices. Iodide salts, while essential nutrients at low levels, display adverse effects at higher exposures, leading researchers to conduct detailed animal and cell-culture studies. Data over the past decade highlight the need for improved understanding of how these salts interact with ecosystems—a topic that’s become central as labs train next-generation chemists in greener methods and responsible synthesis.

Future Prospects

The horizon for 1-Vinyl-3-Methylimidazolium Iodide looks promising. As more industries demand safe, recyclable, high-performance solvents and electrolytes, this compound stands out for its adaptability and rich field of possible modifications. Advances in polymer science, battery technology, and catalysis keep expanding the need for salts with well-defined properties. Work continues on lowering both manufacturing and recycling costs while researchers improve insight into safe handling and environmental fate. Based on ongoing trends and the research work in university-industry partnerships, the leap from specialty application to broad-based industrial use feels closer than ever.

Harnessing Ionic Liquids in Energy Science

Researchers keep searching for better ways to store and use energy. Energy storage, especially through solar cells, brings constant technical challenges. Here’s where 1-Vinyl-3-Methylimidazolium Iodide steps up. Its chemistry opens doors in dye-sensitized solar cells. This compound stands out because it conducts ions smoothly, allowing electrons to move through a solar cell’s electrolyte without gumming up the works. That helps push the overall efficiency of these solar panels a little higher, which is a real win for clean energy fans.

I remember sitting in a university lab, helping assemble a prototype DSSC. With standard electrolytes, we watched performance drop over time—the volatile ingredients evaporated. Substituting in ionic liquids based on imidazolium, like this one, the problem shrank. These liquids don’t just boost efficiency; they cut down on fire risks and last longer under sunlight. So people aiming to design better solar panels for harsh environments keep returning to these imidazolium-based compounds.

Building Blocks for Smart Polymers and Functional Materials

There’s real magic in polymers that respond to changes in temperature, electric current, or light. 1-Vinyl-3-Methylimidazolium Iodide brings more than good conductivity; its vinyl group gives chemists a handle to join it into larger chains through polymerization. People turn this into ionic polymers, which come in handy for custom membranes—think about fuel cells, sensors, or even drug delivery systems.

After graduation, I tried to make an ion-conducting membrane for a personal project. The vinyl-imidazolium structure let me link the monomer up using radical polymerization, and soon I had a flexible film. This membrane let lithium ions zip through, while keeping other molecules at bay. That kind of selective transport gets real attention in battery and supercapacitor research. It’s not some distant promise—the materials are literally being mixed and stretched in labs right now.

Tough Problems in Catalysis and Green Chemistry

The push for greener chemical processes means more people are turning to ionic liquids instead of oil-based solvents. 1-Vinyl-3-Methylimidazolium Iodide’s ability to carry both organic and inorganic species means it acts as a solvent and sometimes even as a catalyst. Research in this field points to better selectivity, faster reactions, and far less hazardous waste.

Evoking a memory, I once watched a demonstration where this compound served as a reaction medium for alkylation reactions. Replacing traditional, toxic solvents with this ionic liquid cut down fumes and made cleanup quicker. Even more interesting, it let the reaction go at room temperature. The environmental impact felt smaller—not abstract, but part of the day-to-day work in greener manufacturing.

What’s Next for These Applications?

Every year, there’s a new twist in how chemists apply this compound. Right now, the top goals include cutting costs and recycling these liquids after use. Academic teams keep hunting for tweaks to the alkylation process or finding less resource-intensive methods for making the starting materials. Some researchers are developing composite materials, blending this vinyl-imidazolium with graphite or nanoparticles to make battery electrodes that last longer and deliver power faster.

It’s easy to get lost in the technical side, but the practical changes start with chemistry like this. The work done with 1-Vinyl-3-Methylimidazolium Iodide is already spilling over from journals into real devices: longer-lasting solar cells, safer batteries, and cleaner chemical factories.

Not Just Any Chemical in the Cabinet

Some chemicals handle air, light, and even a bit of heat without protest. 1-Vinyl-3-methylimidazolium iodide does not fall in this club. I learned through time in a university lab that freshly opened bottles just do not keep their character unless you respect their quirks. Subtle shifts in any chemical’s quality affect not only chemistry results but also personal safety. So, if you notice dust caking on old containers or odd discoloration—trust your instincts. Something changed.

Why Moisture is Trouble

Dampness in the air becomes a silent enemy for this compound. Even a short afternoon with a cap left loose gives moisture a chance. Iodide salts gradually clump, and even the purity gets questionable. Mixing up a reaction only to see cloudiness show up brings frustration. Moisture degrades samples, wasting money and effort. At school, our lab notebook had a running tally of ruined experiments all because someone thought “tight enough” worked for a seal.

Air and Light Play Against You

Regular exposure to air rarely brings good surprises in chemistry. Oxygen and light conspire to change molecular structure, especially in organic salts. I've seen unopened bottles from reputable companies arrive just fine, and then after a month of lazy storage, turn yellow—not the clean white crystals everyone expects. Most likely, it’s the oxidation of the iodide that creeps in, which nobody wants in their project or research.

Responsible Storage Practices

Use glass containers, not plastics, because aggressive chemicals find ways to leach their way through plastic, even if it takes a while. Screw caps lined with PTFE work best. Toss in a fresh silica gel pack or two—moisture never asks permission before wrecking a sample. Always label containers with open dates, and track how long a batch sits on the shelf. Refrigeration makes a huge difference. I store temperature-sensitive materials in fridges, set to 2-8°C, never freezers. Freezing provides no extra benefit and risks condensation each time the bottle comes back to room temperature.

Health and Safety Can’t Take a Backseat

Careful storage also keeps people safer. Iodide compounds cause irritation and sometimes worse, if left in a shared space without clear signs. At busy research labs, labels fade, but the need for Personal Protective Equipment (PPE) never does. My glove routine—even for seemingly minor unpacking jobs—never felt excessive after seeing a classmate get a hand rash because the bottle sweated under humidity. Goggles, gloves, and long sleeves don’t slow you down; they stop months of regret.

Solutions for the Forgetful

Lax habits creep in all too easily. I started keeping a checklist on the lab door: Silica replaced? Cap secure? Temp ok? This simple habit brought storage mistakes close to zero. Sharing these habits helps others skip the step of learning the hard way. Professional advice is sometimes overlooked, but talking to supply reps brings quick tips, as manufacturers often have very specific recommendations for long-term storage.

Final Thoughts: One More Minute Makes a Difference

It takes almost no extra time to store sensitive chemicals correctly. Keeping 1-vinyl-3-methylimidazolium iodide dry, away from light, sealed, and refrigerated gives better results and far less headache on lab days. Sometimes, science moves faster when we slow down enough to keep our materials in good shape.

What 1-Vinyl-3-Methylimidazolium Iodide Brings to the Table

1-Vinyl-3-methylimidazolium iodide usually comes up in lab work and specialized industries. People focus on it for its ionic liquid characteristics, and it gets plenty of attention in chemical research. On paper, these are substances that promise lower volatility and, often, more thermal stability than traditional organic solvents. Some folks view them as greener choices. Still, fewer studies cover human health risks than they do benefits to labs and processes.

Digging Into Toxicity: What Research Shows

Direct studies on this specific salt are slim. Most information comes from its cousins, other imidazolium-based ionic liquids. Animal data show that some closely related chemicals can disrupt cellular membranes. In a study published in the journal Chemosphere (2007), rodents and fish exposed to imidazolium salts showed organ toxicity with sufficient doses. Effects show up often in the liver and kidneys, with higher concentrations raising the risk.

As someone who has spent time working in university chemical storerooms, these sorts of substances come with mixed signals. Manufacturers send out Safety Data Sheets (SDS) that focus on proper handling and hint at toxicity by urging eye, skin, and respiratory protection. That points toward an approach shaped more by caution than any feeling of guaranteed safety.

Handling Risks in Daily Work

Folks who see 1-vinyl-3-methylimidazolium iodide on a shelf often ask what happens after a spill, a splash, or inhalation. Although the compound isn’t as infamous as mercury or some classic solvents, its imidazolium core raises red flags for possible irritancy and longer-term effects after chronic exposure. No data shows it is harmless—most regulatory documents push for gloves, goggles, and good ventilation.

Many years spent in academic labs hammered home the need for designated waste streams for ionic liquids. These chemicals rarely break down easily. Local agencies recognize that, and disposal rules treat them almost like special waste, with clear limits on putting them down drains or in regular trash. If a product is safer than traditional solvents, that label should not steer anyone to cut corners on safety.

Human Focus: Gaps in Assessment

Workers in research, manufacturing, and quality control become the main line of defense against hazards. Reading between the lines of incident reports tells a story of mild to moderate skin and eye irritation when proper protective gear gets left on the bench. The body of evidence stands thin compared to more common chemicals, but the few published reports point to risk after careless handling or repeated exposure.

The big lesson is this: Anything not heavily studied deserves careful respect. Even decades after a chemical enters regular use, new risks pop up. As with imidazolium salts, smarter companies push for periodic health reviews and updated safety training. That drives home a culture of care, not just compliance.

What Can Be Improved?

Information should flow more freely between researchers, regulatory authorities, and anyone on the floor who handles specialty chemicals. Transparent public databases about toxicity, access to easy-to-read fact sheets, and third-party health impact reviews make a difference. Regular re-evaluation of protective guidelines, drawing insights from related chemicals, fits the modern lab—and prevents unexpected problems.

My advice: stick with the best practices laid out in reputable SDS documents and push for clarity if any doubt arises. Never assume that lack of warning equals safety. In the world of specialty compounds, respect and up-to-date knowledge provide the best protection.

The Role of Purity in Chemical Applications

Purity shapes the outcome of most lab work. In synthetic chemistry and materials science, 1-vinyl-3-methylimidazolium iodide stands out as a key ingredient for certain conductive polymers and ionic liquids. Even a tiny drop in purity can throw off the results in polymerization or purification, sometimes leading to longer troubleshooting sessions than actual experiments. Over the years, I’ve noticed that the smallest contaminants—like halide salts or leftover starting materials—make the biggest headaches in long-term research or industrial production.

Defining Chemical Purity

Purity covers more than just the lead compound content. It deals with moisture, trace metals, organic residues, and other reagents that sneak in during manufacturing or packaging. Reputable suppliers list purity by percentage, and the pharmaceutical crowd sometimes expects figures as exact as 99.99%. In the world of 1-vinyl-3-methylimidazolium iodide, suppliers usually offer material between 97% and 99%. This margin may sound tight, but the leftover 1–3% can tilt sensitive reactions off balance. That margin incorporates everything from residual monomers to air-borne dust.

Purity: A Practical Look

Mislabeling purity isn’t just a paperwork issue. I’ve worked with imidazolium salts from a range of sources—what looks identical on a datasheet can behave in unpredictable ways in the lab. For example, a 98% sample with unknown impurities might change the melting point or tweak conductivity measurements in a supercapacitor project. Sometimes, unidentified traces lower yield during polymerization, especially in finely-tuned catalyst systems. Minute differences in color or odor often point to small impurities—many researchers smell or visually inspect before they even crack open the NMR or HPLC data.

Quality Control and Analytical Testing

Responsible suppliers use several testing methods: NMR for organic impurities, Karl Fischer for water content, and elemental analysis for rogue metals or halide ratios. Don’t settle for vague purity claims. Ask for a real certificate of analysis, showing data from these tests. I still remember trying to track down an odd reaction failure, which eventually led back to an unexpected impurity later spotted by a third-party analysis. Labs involved with high-stakes applications—like electronics or pharmaceutical intermediates—depend on this extra diligence.

Industry Needs and Solutions

Greater demand for reliable 1-vinyl-3-methylimidazolium iodide points to the need for tighter controls at the manufacturing stage. Suppliers should clearly share which impurities remain, not just a single percent value. More transparency gives chemists a chance to troubleshoot—or even purify further, if necessary. Researchers can also pool resources to perform their own verification; a quick in-house NMR can catch glaring issues before bigger investments get sunk into failed reactions. Collaboration between producers and end-users smooths out quality gaps and rewards suppliers who care about the details.

Looking Forward

Better transparency and consistent purity will help 1-vinyl-3-methylimidazolium iodide keep pace with its expanding uses. Chemistry never benefits from cutting corners on quality; cost savings from a cheaper, less pure batch often vanish after a few ruined experiments or unrepeatable results. Real progress comes when every vial lives up to its promised purity—giving researchers and industry partners confidence to keep pushing their fields forward.

What Sets 1-Vinyl-3-Methylimidazolium Iodide Apart

Scientists keep searching for smarter ways to control chemical reactions. Take ionic liquids. These quirky compounds stay liquid at room temperature and bring something fresh to the table. 1-Vinyl-3-methylimidazolium iodide stands out with its unique vinyl group—giving it potential to take part right in the action of polymerization, unlike a lot of traditional additives that just sit on the sidelines.

Why Polymerization Methods Keep Evolving

Polymers shape our everyday world—from grocery bags to medical gadgets. For years, building these chains meant sticking to tried-and-true recipes: radical polymerization for plastics, condensation for fibers, or catalytic systems for precision. Older approaches often suffer from waste, harsh conditions, and tough separation steps. The greener chemistry movement pushes both labs and factories to cut pollution and handle materials more safely. Here, ionic liquids sometimes fit the bill by skipping volatile solvents, reducing process hazards, and helping recycle catalysts.

The Role of 1-Vinyl-3-Methylimidazolium Iodide in Polymerization

Getting hands-on in the lab, I used ionic liquids to see how they perform as both solvents and monomers. With 1-vinyl-3-methylimidazolium iodide, the excitement comes from its vinyl group. This group can latch onto other monomers through addition (chain-growth) polymerization. Essentially, it’s not just hosting the reaction—it’s jumping in. Researchers report that such ionic liquids can help build smart materials, like conductive polymers for electronics or membranes for batteries. Instead of tossing in an extra solvent and hoping for the best, this compound’s structure actually becomes part of the growing polymer. The result often means a more stable product and features like ionic conductivity, which most classic plastics just can’t match.

Challenges with Stability and Scalability

Translating a cool experiment into a scaled-up process gets tricky. I’ve seen unusual compounds stall out because of cost and handling issues. 1-Vinyl-3-methylimidazolium iodide isn’t as cheap as PVC monomers. It also doesn’t like moisture, which can throw off yields or mess with product properties. Purity matters, too—any leftovers from synthesis might poison a sensitive polymerization. Labs with good quality control can handle this, but scaling up to tons per day will need new equipment and safety training.

Safety and Environmental Impact

People want safer materials—whether you're building solar panels or medical tubing. Ionic liquids like 1-vinyl-3-methylimidazolium iodide rarely evaporate, cutting fire and inhalation risks versus many mainstream solvents. Still, these substances need careful disposal, since their ecological effects aren’t fully mapped yet. It’s better than dealing with boiling barrels of benzene, but plenty of research remains on long-term breakdown and bioaccumulation.

What Could Move This Field Forward

Looking at industry reports and lab data, a few clear steps could make 1-vinyl-3-methylimidazolium iodide more mainstream. One, researchers can focus on recycling protocols or new ways to recover these ionic liquid-based polymers at the end of their life cycle. That means more circular chemistry, less landfill. Two, collaboration among chemists, engineers, and toxicologists can clarify health and safety questions, making regulators and the public more comfortable about their use. Three, partnerships between start-ups and big chemical firms may bring down costs and smooth out the supply chain hiccups that hold back adoption.