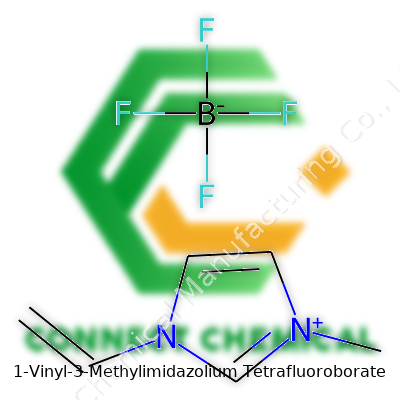

1-Vinyl-3-Methylimidazolium Tetrafluoroborate: A Practical Exploration

Historical Development

Curiosity and a need for alternatives to traditional organic solvents have drawn chemists toward ionic liquids for decades. In the late 20th century, interest in imidazolium-based compounds grew after pioneers noticed their unusual properties—low vapor pressure and stability under harsh conditions. 1-Vinyl-3-methylimidazolium tetrafluoroborate (abbreviated as [Vmim][BF4]) entered the spotlight as researchers found the imidazolium core could be tuned. Organic chemists began shifting from chlorinated analogues toward tetrafluoroborate systems, betting on environmental advantages and unique reactivity. Around the 1990s, the ability to polymerize the vinyl group stood out, opening the door for applications in membrane materials and electrochemical devices. Today, this compound benefits from years of trial, error, and incremental improvement, making its way from chemistry journals into industrial labs and creative research projects.

Product Overview

1-Vinyl-3-methylimidazolium tetrafluoroborate has carved a niche among room-temperature ionic liquids. The compound stands out with its imidazolium ring sporting a methyl group on one nitrogen and a vinyl group on another, paired with a tetrafluoroborate anion. This pairing doesn't just look good on paper—it delivers in the lab by offering a liquid that remains fluid over a wide range of temperatures. In conversations with colleagues, its signature feature has often been described as a harmonious union of stability and reactivity. Researchers looking for a solvent that doesn’t boil or evaporate under normal conditions see immediate value.

Physical and Chemical Properties

Anyone handling 1-vinyl-3-methylimidazolium tetrafluoroborate will notice its pale yellow color and viscosity. Its density sits around 1.2 g/cm³ at room temperature, and it burns slowly if set alight, releasing a harmless-sounding but surprisingly complex mix of fumes. Its melting point hovers below typical room temperature, letting it remain liquid for most experiments. The tetrafluoroborate anion keeps it stable when exposed to air and moisture, but extensive exposure to open air nudges it toward hydrolysis and decomposition. What sets this ionic liquid apart is its balance between cation and anion: the imidazolium ring resists decomposition under mild heating, while the anion provides a measure of coordination chemistry often seen in fluoride-based compounds. Solubility plays in its favor—mixing easily with polar solvents, yet maintaining some separation from nonpolar ones. That's a practical feature for those designing selective extraction procedures.

Technical Specifications & Labeling

Product labeling uses recognized identifiers for safety and clarity. Chemists in the industry know this substance by its CAS number: 174501-65-6. Packaging often highlights purity, which usually exceeds 98% for research use. Safety datasheets describe potential hazards, including mild irritancy and sensitivity to moisture. Storage recommendations call for sealed containers, kept away from extreme heat. From my own time managing chemical inventories, I’ve noticed reliable suppliers provide clear batch testing data, ensuring users can trust the purity and the actual ionic content. Labeling also pinpoints water content—a crucial parameter for ionic liquid stability—and notes minor by-products like imidazole remnants, which crop up if synthesis or purification runs into snags.

Preparation Method

The route to 1-vinyl-3-methylimidazolium tetrafluoroborate usually starts with 1-methylimidazole and a vinyl halide, like vinyl chloride or vinyl bromide. Alkylation in an organic solvent gives the key cation intermediate. Nucleophilic substitution follows, using sodium tetrafluoroborate or hydrogen tetrafluoroborate to swap the halide for the tetrafluoroborate anion. Purification can challenge even seasoned chemists—impurities from incomplete alkylation or excess reagents demand careful washing and sometimes chromatography. I’ve found that controlling for residual halide content improves both shelf-life and experimental performance. Yields tend to be respectable, provided that humidity and by-product removal get proper attention throughout the workflow.

Chemical Reactions and Modifications

Chemists lean heavily on the vinyl group in the cation for post-synthetic modifications. The unsaturated bond enables radical and ionic polymerization pathways, letting researchers craft polymeric ionic liquids directly from the monomeric form. This tailorability gives rise to membranes with selective transport properties and custom ion conductivities. On the anion side, the tetrafluoroborate ensures non-coordinating behavior, though working with reactive metals sometimes nudges researchers toward swapping in other anions for compatibility purposes. Despite the general robustness of the imidazolium ring, it faces nucleophilic attack under very harsh basic conditions—an event best avoided, as degradation produces both toxic by-products and diminished performance.

Synonyms and Product Names

Lab catalogs and supplier websites might list 1-vinyl-3-methylimidazolium tetrafluoroborate under a variety of short names: [Vmim][BF4], 1-vinyl-3-methylimidazolium tetrafluoroborate, or simply VMIM BF4. Some database entries favor abbreviations like VMI BF4 or 1-methyl-3-vinylimidazolium tetrafluoroborate. Despite the range of names, structures remain consistent, and seasoned users recognize it from its characteristic ionic liquid label and SMILES (Simplified Molecular Input Line Entry System) notation. In my own lab notes, mnemonic abbreviations keep things moving fast, but consistency ensures mistakes don’t slip past during ordering or inventory checks.

Safety and Operational Standards

Handling 1-vinyl-3-methylimidazolium tetrafluoroborate demands thoughtful attention, just as any fine chemical does. Direct skin contact brings mild to moderate irritation. If the liquid splashes in the eyes, flush quickly and seek medical attention. Though not as volatile as traditional solvents, inhaling vapors during heating can result in respiratory discomfort. Safe handling in the lab means working in a well-ventilated space, using chemical-resistant gloves and safety goggles. Disposal procedures must account for persistence of the compound—ionic liquids take longer to degrade in the environment than alcohols and ketones. Avoid dumping into municipal drains. Chemical waste bins managed by trained professionals keep hazardous materials out of the local water supply. If accidental spills occur, absorb gently with inert materials and clean promptly. My time as a lab manager drove home the value of keeping meticulous records—safety incidents often decrease when everyone tracks reactions and storage conditions accurately and promptly.

Application Area

This compound’s most prominent use shows up in electrochemical devices, often in lithium battery electrolyte research. Its stable liquid range makes it ideal for transporting ions at a steady rate, so researchers constantly aim for higher performance in next-generation batteries and fuel cells. Polymerized forms create durable, selectively permeable membranes for gas separation and water purification. Some labs, eager to ditch volatile organic solvents, explore [Vmim][BF4] as a solvent for organic synthesis, noting better selectivity and yield compared to classic systems. Because it dissolves a wide range of metal salts, it fits nicely in metathesis reactions and in the separation of rare earth elements. In my own research, the ease of tuning physical and chemical properties by modifying side chains or anion selection sparked lots of experimentation—fine-tuning material performance or catalysis outcomes became more of a creative exercise than a slog through predetermined options.

Research and Development

Current development trends center around optimizing the compound’s electrochemical stability, with labs around the world trying to push the upper voltage window while minimizing by-product formation. Environmental researchers examine its behavior under real disposal scenarios, inspired by growing regulations that target persistent chemicals. Collaborative projects between academic and industrial scientists probe the microstructure of polymers derived from this compound. Combined with modern spectroscopic and computational tools, results start to draw a clear map of how ion movement, side chain modifications, and polymer flexibility come together. Research groups also test biocompatibility in targeted applications, ranging from solvents for enzyme-catalyzed reactions to carriers for controlled drug release. Practical concerns—cost, purity, shelf life—drive minor but important ongoing improvements.

Toxicity Research

As ionic liquids grow more common in both industry and research, understanding long- and short-term toxicity becomes central to responsible chemical management. Animal studies indicate low acute toxicity, but chronic exposure data remains thin outside of anecdotal reports. In contact with aquatic life, the compound’s persistence sets off alarms for regulators. Degradation studies point to slow hydrolysis under environmental conditions, with by-products—such as tetrafluoroboric acid—posing risks to both human health and wildlife. Regulatory documentation keeps evolving, and anyone using this compound on a larger scale must regularly consult new reports and update their safety practices. In my experience, chemists committed to sound research look for safer alternatives, design reactions to minimize waste, and work closely with safety officers. Simple steps like secondary containment and wearing protective gear cut down on risk, but widespread education about toxicity ensures the entire lab community respects the hazards and reacts swiftly to any exposure.

Future Prospects

Interest in 1-vinyl-3-methylimidazolium tetrafluoroborate continues to grow. As researchers figure out how to tailor polymer length and cross-linking, new forms of membranes for electrically driven separations look closer than ever. Battery and supercapacitor teams see promise for electrolytes with better thermal stability and conductivity, while green chemistry advocates test this compound as both solvent and reagent in reactions that cut back on oil-based by-products. The next chapters for this ionic liquid depend on interdisciplinary teamwork, stronger regulation, and creative problem solving—especially as demand for sustainable, safe, and high-performing materials rises. Shifts in supply chain management, focus on renewable feedstocks, and stricter waste handling protocols all help shape the product’s future in research and industry alike.

The Role in Modern Chemistry

1-Vinyl-3-methylimidazolium tetrafluoroborate stands out in the world of chemistry, not just as a chemical with a long name, but for its relevance in today’s research and industry. This compound works as an ionic liquid. That means it remains in liquid form even at room temperature, and unlike traditional organic solvents, it doesn’t give off much vapor. No strong chemical fumes here—anyone who’s spent hours in a lab counting on a fume hood will appreciate that.

Colleagues and I first heard about these “room temperature ionic liquids” back in university, right around the time green chemistry started gaining ground. Labs still used a lot of flammable, toxic solvents for reactions, and spills created headaches. The switch to less volatile, more stable options offered relief not only for safety but for environmental impact as well. 1-Vinyl-3-methylimidazolium tetrafluoroborate became a go-to example of this new class.

Supporting Polymer Science

One significant use for this ionic liquid: making polymers. Chemists rely on 1-vinyl-3-methylimidazolium tetrafluoroborate as a monomer for polymerization. The vinyl group lends itself to radical polymerization, which produces ionic polymers found in advanced membranes and electronic materials. This matters because older polymers can break down or degrade under tough conditions, but these new ionic varieties hold up longer.

I saw this firsthand in a research lab focused on improving batteries. We tested films made from ionic polymers with this compound, aiming to create battery separators able to withstand both heat and chemical stress. The results looked promising, and it opened doors to innovations in fuel cells and flexible electronics, too. Think lighter, safer batteries for electric vehicles or resilient coatings for solar panels.

As a Green Solvent

Solvents play a behind-the-scenes role in chemical industries. They help dissolve, mix, and carry things along, and switching to safer alternatives becomes crucial as regulations tighten every year. 1-vinyl-3-methylimidazolium tetrafluoroborate steps in as a green solvent because it’s less toxic and doesn’t contribute to air pollution like older organic solvents. Its low volatility helps keep working conditions safer for lab workers and reduces fire risks.

Plenty of companies in pharmaceuticals, specialty chemicals, and even biotechnology use this compound in reaction mixtures or for extracting specific components. An added benefit: it’s often reusable. After one round, the chemist can recover and purify the ionic liquid, cutting down on waste. Some critics argue about the environmental footprint from making these ionic liquids, but life-cycle assessments suggest notable improvements over time.

Room to Grow with Sustainable Practices

Looking at the bigger picture, this compound sets still higher goals for the chemical industry. Research calls for even greener production methods and better recycling processes. Some labs experiment with bio-based starting materials, hoping to trim the environmental costs from the production side. Collaboration with waste management and chemical suppliers is already making a difference.

The story of 1-vinyl-3-methylimidazolium tetrafluoroborate encourages all of us—scientists, manufacturers, and consumers—to keep questioning old practices and aim for cleaner, safer, and more effective solutions. Progress often starts small, with quietly revolutionary chemicals like this one.

Why Safety Isn’t Just a Box to Check

Folks often look at safety rules as more of a nuisance than anything, but over my years in research, I’ve seen what skipping those steps can do. One slip-up with the wrong compound can leave you on the phone with poison control or grabbing for an eyewash station. Many common lab chemicals pack hidden risks. Touch the wrong surface or take one distracted breath, and things can go sideways fast.

Suit Up: Clothing Comes First

Every time I tug on a pair of nitrile gloves or zip up my coat, I remember colleagues who paid for shortcuts. Bare hands might not sting at first but skin absorbs solvents and acids. Even minor splashes can cause burns or allergic reactions. Lab coats, safety goggles, and close-toed shoes aren’t fashion statements. They buy time when it matters. I’ve seen simple trench coats keep burning chemicals off skin and goggles stop a trip to the hospital.

Ventilation Changes the Game

Most volatile compounds turn dangerous fast if vapors have nowhere to go. A good fume hood pulls fumes away from your face. Fans and open windows don’t do the job. I once worked in a cramped classroom with no working ventilation. All it took was one mistaken whiff of chloroform to get a dizzy spell and a headache that lasted hours. Good vent systems aren’t just upgrades—they protect lungs and brains from long-term harm.

Never Trust an Unlabeled Container

After a couple incidents involving mystery bottles, I live by the rule that every container gets a label. No exceptions. Even stuff you just poured won’t always look or smell different from water. All it takes is one person mixing up solutions to risk producing toxic gas or mixing acids by mistake. Reliable labs keep sharpies handy and everybody learns how to read hazard statements by heart.

Read Up and Write Down

People love to skip the material safety data sheet (MSDS), but those few minutes skimming the document can steer you clear of real danger. I’ve found that knowing where the nearest eye wash or fire blanket sits isn’t boring—it’s smart. Good labs hold quick drills and go over the latest protocol updates so everyone knows what to do if a fire or spill breaks out. Writing down each step before starting work helps catch easy-to-miss risks.

Dispose of Waste Like It Matters

It’s tempting to pour used chemicals down the drain or toss solids in regular trash, but the aftermath can haunt a whole department. Local regulations ask for special containers and disposal pickups, and I’ve watched water treatment folks catch dangerous mistakes late because a lab didn’t follow rules. Those extra steps help keep toxins out of the water supply and prevent reactions in garbage trucks or landfills.

Training Isn’t a One-Time Thing

Regular training sessions keep the basics fresh and catch new risks. Even people with decades in the field keep learning. In my experience, the best safety culture grows from teams who call out cluttered benches or improper storage without hesitation. Learning from close calls, asking questions, and supporting each other builds habits that actually stick.

Simple Habits, Big Difference

I’ve seen plenty of labs where people assume experience alone keeps them safe, and just as many close calls that start with ignoring a rule. Jumping into work before checking procedures or gear can snowball into emergencies fast. Sticking to the basics—not because someone says so, but because no experiment is worth permanent damage—gives you confidence to focus on real research.

A Practical Look at Safe Chemical Storage

1-Vinyl-3-Methylimidazolium Tetrafluoroborate might not roll off the tongue, but it sits on the shelves of labs and research centers where ionic liquids play a key role. I’ve seen all sorts of storerooms, from spotless, well-managed cabinets to cluttered corners where things get forgotten until a spill or an odd smell reminds everyone that certain chemicals demand more respect. This compound falls into that category. It calls for care, both for its own stability and for the safety of anyone sharing the same space.

Moisture: The Silent Trouble-Maker

I learned pretty quickly that humidity ruins a lot of things in a lab, but with tetrafluoroborates, moisture spells real trouble. Exposure to air soaked in moisture triggers slow hydrolysis. The product? Hydrofluoric acid. Anyone who’s handled HF knows its bite—skin burns, respiratory risk, and silent damage to glass and steel. So, I keep ionic liquids sealed tight, in bottles made from materials as unyielding as the lab’s safety rules. Glass with screw caps lined with PTFE works best. A desiccator with silica packs brings even more peace of mind if humidity drifts above comfort.

Light and Temperature: Hidden Dangers

Some chemicals take sunlight personally. 1-Vinyl-3-Methylimidazolium Tetrafluoroborate fits that mold. Over the years, I’ve watched colleagues scoop brown-stained bottles from sunny window ledges, where heat and light speed up unwanted reactions. These ionic liquids last longer and stay safer in cool, dark places. Stable room temperatures keep the compound calm, so no wild swings near heaters, ovens, or open windows. For long-term storage, fridge temperatures work well, provided the container stays dry and tightly closed. Never store it below freezing with moisture inside; frost can crack even tough glassware and draw in more water later on.

Labeling and Accountability

Clear labeling isn’t just for newbies. Every bottle in the flammable cabinet or refrigerator fridge should wear a date, a name, and a clear signal of any special hazards. I’ve seen accidents spiral from bad handwriting or missing labels—wrong chemicals mixed or waste left where it shouldn’t linger. A proper inventory, updated every month, keeps surprises to a minimum. Waste containers need the same respect: no guessing or shortcuts, only well-labeled bottles sealed tight. Communication runs through the heart of lab safety, so regular reminders and shared responsibility help everyone breathe easier.

Handling Faulty Batches or Spills

If a batch shows signs of decomposition—strange colors, smells, cloudiness—it needs to come off the shelves right away. Don’t try to dilute the risk or dump it with ordinary trash. Fume hoods and dedicated waste containers handle failed batches. Trained staff should gear up for cleanup with gloves, pads, and PPE rated for HF and related hazards. In my own lab, a hydrofluoric acid kit sits near the chemical cabinet, and everyone runs annual spill drills. Not everyone loves these drills, but no one forgets them either.

Final Thoughts

Good habits keep both science and scientists safe. Secure containment, dry and cool storage, clear labeling, and strict accountability protect more than products. They create a culture where serious incidents become rare events. Respect for chemicals like 1-Vinyl-3-Methylimidazolium Tetrafluoroborate begins at the moment the bottle arrives, and never stops until the last drop leaves the lab.

Everyday Science in the Lab and at Home

You pick up a bottle of powder. Somewhere on the label it hints “soluble,” but you want to know more. Does it dissolve in tap water, or will only alcohol do the trick? So many products, from vitamins to cleaning solutions to pharmaceuticals, rely on this question. I remember my first chemistry class where nothing seemed more basic—until you try to mix magnesium sulfate in organic solvent and end up with a chalky mess. Turns out, solubility runs the show in both labs and on the kitchen counter.

Water Doesn’t Always Win

There’s a comfort in thinking water will take care of everything. Toss the powder in, stir hard, problem solved. Except cellulose stays stubborn, greasy stains laugh at your efforts, and some medicines refuse to dissolve without alcohol or other chemicals. Water’s famous for helping salt, sugar, and electrolytes break apart, but big, nonpolar molecules want nothing to do with it.

Consumer products tell their own stories. Instant coffee goes straight into the mug with hot water, but not all flavors or supplements play along. As a parent, I have wrestled with powdered probiotics that needed a fat or oil to become fully active. Nutrition labels rarely say “needs coconut oil to perform.” That’s more science than most of us get.

Organic Solvents—The Other Side of the Coin

People get nervous when they hear “organic solvent.” It brings up worries about safety, the environment, or harsh chemical smells. But in the right place, they make all the difference. Think of nail polish remover, paint thinners, or lab work with DNA. Many dyes or fats go nowhere in water. Try mixing olive oil and vinegar enough times, and you accept their differences.

The market for beauty products has learned this lesson. Face creams split between “water-based” and “oil-based” for a reason. Some vitamins, like A, D, E, and K, refuse all efforts with water but blend right into an oil serum. Anyone who has tried to mix essential oils using only water knows the result: wasted time, floating puddles, and frustration.

Safer Solutions and Smarter Choices

If companies choose to advertise a product’s solubility, they have a job to explain what that means for you. Sometimes, they keep quiet, expecting customers to figure it out. This can mess with product safety, shelf life, and even health outcomes. I have seen cleaning powders sold as “quick dissolve” only to leave clumps behind unless used with hot water and firm mixing.

Some researchers have tested solvent systems, blending water with a bit of alcohol or using surfactants, to help more products dissolve. Simple guides or clear labels can help prevent mixing mistakes. Lately, regulations and consumer demand push companies to prove their claims, show real test results, and provide better instructions. As buyers demand more transparency, companies have started to offer solubility charts or at least detailed mixing guides.

The Takeaway

Understanding if a product mixes with water, organic solvents, or neither can save time and money—and prevent safety headaches. For manufacturers, clear guidance based on real testing goes a long way. For consumers, asking “what dissolves in what” will always matter. Science, at its heart, meets real life every time you open a package or mix up a drink.

Understanding Purity in Everyday Terms

People hear “purity” tossed around in countless conversations, yet the details often blur. Sometimes folks picture a product as either pure or impure, black or white, safe or risky. Life outside the lab doesn’t usually run on such strict binaries. In the real world, suppliers offer different grades. These levels directly shape price, safety, and legal standing.

Why Purity Levels Matter

Let’s put this into everyday perspective. A baker reaching for flour doesn’t worry much about “pharmaceutical grade.” Anyone working in a chemistry lab, though, learns fast that those extra fractions of a percent in purity make an enormous difference. Impurities might seem small, but in research settings, they lead to failed experiments or misleading results. In medicine, extra contaminants bring health problems or even legal trouble.

My own time in scientific settings showed me this first-hand. Reagents marked as “technical grade” sometimes looked the same as “analytical grade,” but outcomes didn’t match up. A contaminated batch once wiped out an entire week’s work in a microbiology lab I trained in. Contaminants hidden away in a bottle can mean wasted money and effort. Product quality and trust ride heavily on those little numbers.

Typical Grades You See in the Market

Most products arrive in several standard grades. Each one suits a particular use, whether for science labs, factories, farms, or home use. Here’s a breakdown you’ll spot often:

- Technical Grade:

Usually found in industrial or manufacturing settings. Purity floats somewhere around 90% to 95%. These versions work fine in large-scale cleaning, certain chemical processing steps, or as starting points for less sensitive jobs. For anyone in research or medicine, this level doesn’t cut it.

- Laboratory or Reagent Grade:

Purity jumps higher, sometimes starting at 96% and reaching up to 99%. Intended for general laboratory use — think high school chemistry or basic quality control. Sometimes reliable for demonstrations, teaching, or routine tests. In specialized work, even this isn’t pure enough.

- Analytical Grade (ACS or AR):

Here, guarantees run stricter. Purity exceeds 99% as certified by the American Chemical Society or equivalent standard bodies. Folks trust this grade for professional research, pharmaceuticals, and legal compliance. Hospitals, top research labs, and high-end manufacturing won’t use anything less.

- Pharmaceutical or USP Grade:

Meant for direct human consumption or use in drug manufacturing. Meets purity, safety, and consistency standards set by the United States Pharmacopeia. This level costs more but brings peace of mind for health and legal compliance.

Problems and Next Steps

Supply chains don’t always keep things straight. Mislabeling or poor storage can spoil even high-grade material. Authorities cracked down after stories broke about tainted substances causing mass recalls or legal suits. Relying on certified suppliers, ensuring proper handling, and independent verification through certificates of analysis build reliability.

Nobody wants to gamble with something as simple as purity. Every percent matters—sometimes, lives depend on it. Working with trusted sources and making sense of the labels saves more than dollars. It preserves trust and safety for everyone who uses these common materials.