1-Vinyl-3-Methylimidazolium Trifluoromethanesulfonate: An Industry and Academic Perspective

Historical Development

At the close of the 20th century, chemists across the globe started turning away from traditional organic solvents, searching for alternatives that could better handle environmental scrutiny. Ionic liquids, starting with the imidazolium family, emerged as an answer. 1-Vinyl-3-methylimidazolium trifluoromethanesulfonate, built on the backbone of earlier imidazolium discoveries, followed in the early 2000s. Researchers began to grasp its potential beyond simple solvent substitution. This compound, like other newer ionic liquids, grew out of efforts to increase chemical flexibility and thermal stability. In university labs and startup workshops, teams tweaked its structure for better performance, setting benchmarks for others keen on green chemistry and electrochemistry.

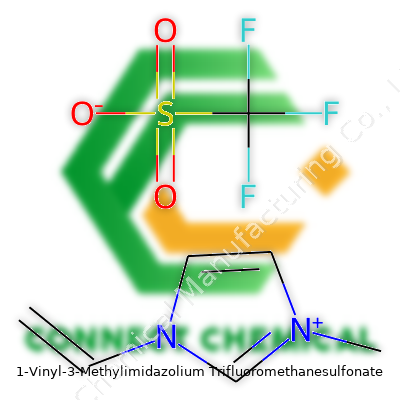

Product Overview

1-Vinyl-3-methylimidazolium trifluoromethanesulfonate comes from the fusion of the imidazolium core—known for ionic stability—with a vinyl group, plus the electron-withdrawing CF3SO3 anion. It carries the CAS number 174899-66-2, and you’ll often see it under names like [VMIM][OTf]. Labs order it as a clear to pale yellow liquid, or sometimes as low-melting crystals, depending on the temperature. This chemical finds its way into a surprising number of research areas: electrodeposition, green solvents for biocatalysis, and advanced polymeric materials, to name three growing branches. People tend to notice that it's not just another ionic liquid—the vinyl group gives it polymerization abilities, so it isn’t just “solvent.”

Physical & Chemical Properties

Anyone familiar with ionic liquids expects some basics: low volatility, high thermal stability, nonflammable nature. 1-Vinyl-3-methylimidazolium trifluoromethanesulfonate delivers on all these. Density tends to range from 1.27 to 1.34 g/cm3. It doesn't sport much odor, at least not at room temperature, thanks to its near-zero vapor pressure. A melting point near room temperature, somewhere between 20–30°C, separates this liquid from many others in its class. With the triflate counterion, it takes on added hydrophobicity—this means improved solubility for certain organic compounds, opening fresh possibilities in synthetic chemistry. Water absorption stays relatively moderate, so working with it doesn’t feel as tricky as with some other ionic liquids that suck up moisture from the air in minutes.

Technical Specifications & Labeling

Companies supplying this chemical note its purity routinely tops 98%. Most bottles show both molecular formula (C8H11F3N2O3S) and batch analysis data. Academic users check for low halide and water content—after a few attempts at polymerizing with contaminated batches, no one wants to cut corners again. Labelling under GHS recommends caution: chemical laboratories store it away from oxidizers, acids, base-sensitive reagents, and moisture, just to avoid surprises. Material safety data sheets (MSDS) cover toxicity, first aid, accidental release, and waste disposal guidelines, with warnings about inhalation and contact, even though its vapor pressure stays low.

Preparation Method

Synthesis happens in stages. Starting with 1-methylimidazole, the route typically involves vinylation—reaction with vinyl halides under nitrogen—forming 1-vinyl-3-methylimidazolium halide as an intermediate. Anion exchange follows: introduce sodium or silver trifluoromethanesulfonate, mix it up, let the halide salt precipitate or filter out, and then purify the desired ionic liquid. The last step usually uses column chromatography or several washes with organic solvents to scrub out metal ions or colored impurities. Synthesis scale runs from a few grams in a university flask to several kilograms for industrial supply. Efficiency depends on reaction time, degree of agitation, and the dryness of solvents, which means any water in the starting materials can throw off the whole yield.

Chemical Reactions & Modifications

The presence of the vinyl group lets researchers create new functional ionic polymers. Radical or UV-initiated polymerizations generate cross-linked gels or films—both for electrochemical devices and selective separations. People have found that simple mixing with comonomers like acrylates or styrenics leads to new copolymers. Its imidazolium ring offers tantalizing modification targets: alkylation or arylation on unoccupied nitrogen offers tuning options for hydrophobicity or electronic properties. Triflate, as a non-nucleophilic anion, resists most side reactions, letting the cation take the spotlight for chemical modifications. Recent studies also look at using it as a reaction medium for transition-metal catalyzed cross-coupling, as the ionic liquid can sometimes boost catalytic turnover, especially at non-traditional temperatures.

Synonyms & Product Names

Look up this chemical and you’ll see several alternative labels: [VMIM][OTf], 1-vinyl-3-methylimidazolium triflate, 1-vinyl-3-methylimidazolium trifluoromethylsulfonate, or simply VMIM-OTf. Distributors might label samples as ionic liquid monomer VMIM OTf. Having worked in research cataloguing, I've dealt with occasional confusion from students ordering the wrong variant. Double-check CAS numbers (174899-66-2) and IUPAC names before placing orders, especially if comparison with similar imidazolium ionic liquids is needed.

Safety & Operational Standards

Large-scale users benefit from good chemical hygiene: gloves, closed systems, and goggles stay mandatory. Many ionic liquids promise lower risk than volatile solvents, but accidents still happen. Skin absorption hasn’t been dismissed, so touching pure samples without protection remains a bad idea. Good ventilation means less chance of inhaling mists during transfers. Standard operating procedures stress compatibility checks with plastics and rubbers, since some gaskets or O-rings degrade in ionic liquid contact. Waste disposal needs special tanks or high-temperature incineration—dumping in the drain could create headaches for water treatment plants. Companies follow REACH or TSCA inventory rules, updating registration as new toxicity results come in.

Application Area

Since early days, the main draw of this ionic liquid has been its dual personality: it dissolves organic and inorganic materials, but also polymerizes into functional materials. Electrochemical studies rely on its wide electrochemical window and thermal resistance; batteries, supercapacitors, and fuel cells keep pulling researchers back to test new electrodes pairings. Polymer chemists benefit from its radical polymerization, merging the ionic liquid features into polymer networks—helpful for building next-generation sensors or membranes. Many green chemistry fans use it to replace traditional solvents in biocatalysis, finding that enzymes often hold activity and stability better, with less denaturation from organic vapor. In the pharmaceutical sector, it sees action as a reaction medium, often giving high yields in sticky syntheses. Additive manufacturing and 3D printing also see some work using it in photopolymerizable resins.

Research & Development

Universities and industrial R&D groups keep diving deeper into the versatility of 1-vinyl-3-methylimidazolium trifluoromethanesulfonate. Ongoing studies in solid polymer electrolytes point toward improved battery safety and longer lifespans, addressing industry demand for safer energy storage. Analytical chemists measure its ion transport mechanisms using NMR and impedance, mapping out how charge carriers move differently than in aqueous or traditional organic solvents. Researchers in materials science design new composite materials embedding this ionic liquid, aiming to combine flexibility with conductivity. Recent grants emphasize not just application but scale-up—the goal remains to move new ionic liquid technologies from bench to affordable manufacturing, reducing waste and improving recycling.

Toxicity Research

Toxicologists examine ionic liquids with increasing scrutiny. Early marketing as "green" alternatives led to some unintentional complacency, but lab animal studies reveal nuanced risks. 1-Vinyl-3-methylimidazolium trifluoromethanesulfonate, like other imidazolium derivatives, shows low vapor toxicity, but persistent aquatic exposure can harm microorganisms and aquatic invertebrates. Acute oral and dermal toxicity stay moderate, but chronic effects—particularly bioaccumulation or low-dose hormone disruption—require longer-term testing. Some safety standards mirror those for similar industrial solvents: regular reviews, employee health monitoring, and regular checks for any harmful metabolite formation. Continued research on biodegradation, especially in real wastewater, will clarify its long-term impact.

Future Prospects

As the world shifts toward electrification, better batteries, and low-waste chemical processes, demand for multifunctional ionic liquids continues to rise. 1-Vinyl-3-methylimidazolium trifluoromethanesulfonate sits in a good position to benefit. Its ability to form polymers with intrinsic ion conductivity makes it a top candidate for stretchable electronics, sensors, and ion-exchange membranes. Regulatory pressure on traditional solvents and advances in recyclable ionic liquids push researchers to optimize for environmental safety without sacrificing performance. Partnerships between chemical manufacturers and national labs aim to tackle issues of cost and scalability. Improving methods to recycle or biodegrade used ionic liquids will matter as volumes increase. If research keeps pace with safety and environmental transparency, this unique compound looks set to anchor the next generation of high-performance green materials and processes.

Understanding an Unusual Chemical

Some compounds tend to hide out in the corners of the lab, quietly driving big change while bigger names grab the spotlight. 1-Vinyl-3-methylimidazolium trifluoromethanesulfonate, often called an ionic liquid, falls into this camp. Despite the long name, its value shows up for folks working on greener chemistry, advanced materials, and next-generation batteries.

Pushing Sustainable Chemistry Forward

Most solvents in the industry get made from volatile, often toxic organics. They create waste that takes energy and serious effort to clean up. Over the last decade, researchers got hungry for safer, more recyclable solvents. That’s where many started tuning ionic liquids like 1-vinyl-3-methylimidazolium salts. Lab teams swap in this salt instead of old-school solvents to help reactions run smoother and with less pollution. This compound holds a trifecta: low volatility, thermal stability, and an ability to dissolve all sorts of molecules. If you’re into minimizing harm, the appeal comes fast.

Electrochemistry’s Secret Sauce

Battery science needs every advantage. Traditional liquid electrolytes suffer from evaporation and degrade over time, which limits the power cycles and even risks fires. 1-vinyl-3-methylimidazolium trifluoromethanesulfonate stands out because it barely evaporates and doesn’t catch fire. In some tests, it works as an electrolyte in lithium batteries and supercapacitors. The result: longer battery lives and less danger for consumer electronics. For electric vehicle batteries struggling with heat or longevity, this compound helps engineers stretch the hardware’s life.

Bringing Cleaner Catalysis

Chemical plants churn out products using catalysts—materials that make reactions faster without being consumed. Traditional processes can clog up or wear out those catalysts, partly due to tricky solvents or byproducts. This ionic liquid acts as a gentle reaction medium: it avoids fouling the catalyst and makes it easier to separate what you actually want at the end. I’ve seen colleagues run “greener” catalytic cycles thanks to these liquids, slashing waste and working at lower temperatures, which cuts energy bills.

Advanced Materials and Membranes

Beyond the lab flask, 1-vinyl-3-methylimidazolium trifluoromethanesulfonate finds a place in making special polymers and membranes. Think water treatment filters that stand up to toxins or plastics with rugged resistance to heat and chemicals. Chemists can design films and fibers with this compound, building in selectivity for certain ions or chemicals. I once watched a team use it to tailor-make a membrane for separating rare earth metals—something almost impossible with old-school solvents.

Taking Stock and Rethinking Risk

No chemistry comes without tradeoffs. Costs sit higher than most industrial chemicals, and the long-term environmental effects aren’t perfectly mapped out. Some manufacturers hesitate to scale up until they get more data on breakdown and recycling pathways. Transparency matters here: open publication of long-term studies builds public trust and helps industry figure out safe disposal or recycling routes. Scientists need to stay vigilant, testing new uses and checking for unexpected problems.

Pathways Forward

Using chemicals like 1-vinyl-3-methylimidazolium trifluoromethanesulfonate invites a conversation about sustainable science. Industry leaders should push for more field studies and share safety data. Engineers could work with product designers to make recycling of these materials easier at the end of their first life. Regulatory bodies can step in early to guide research, encouraging innovation that doesn’t trade one risk for another.

Nobody solves industrial chemistry’s challenges overnight. Yet the willingness to dig into alternatives like this ionic liquid points toward a smarter, safer future. The progress keeps coming, one tweak at a time, with every test tube and research notebook.

Starting with the Basics: What Kind of Stuff Is This?

Anyone who’s spent enough time around chemistry labs tends to stumble into tongue-twister chemicals like 1-vinyl-3-methylimidazolium trifluoromethanesulfonate. Strip the name down to basics and you’re faced with an ionic liquid. That’s a liquid salt at room temperature, which already sets it apart from the old-school table salt everyone knows. Ionic liquids like this can bring a level of flexibility and novel behavior that traditional solvents just can’t manage.

Pour this stuff out and you spot a colorless to pale yellow liquid, sometimes looking deceptively like water. Unlike water, though, it won’t evaporate in an open beaker over lunch. Low volatility means fewer hazardous fumes—always a plus for people who’d rather avoid headaches and long-term health risks. That’s not the only reason labs gravitate toward it. The substance handles temperature swings remarkably well, refusing to freeze until well below zero and keeping steady all the way to over 200°C in many cases. Straightforward stability like this keeps experiments moving without the nasty surprises that come from a solvent boiling off or crystallizing out when you least expect it.

Chemical Behavior: What’s Happening Behind the Scenes?

Ask anyone mixing up electrolyte solutions for batteries or fine-tuning a tricky organic synthesis—this compound often pops up on supply lists. The trifluoromethanesulfonate anion doesn’t just hang around quietly; it brings exceptional chemical stability and stays out of most side reactions. That keeps results reproducible. The imidazolium cation on the other hand, can promote lots of interesting behaviors, including solvating a wide range of both organic and inorganic compounds. You see that in experiments where common reagents just don’t dissolve anywhere else.

What makes it compelling comes down to ionic conductivity. Battery folks and materials chemists have been dancing around the lithium-ion puzzle for ages, looking for electrolytes with solid conductivity and low flammability. This ionic liquid doesn’t just carry ions—its structure also reduces the chance of catastrophic combustion. That offers a clear safety advantage in research environments, factories, and, eventually, consumer products. Granted, these liquids can sometimes carry impurities that tamper with their conductivity, so quality control must be taken seriously, especially on the industrial scale.

Real Concerns: Environment, Safety, and the Human Factor

Stepping back, it’s crucial not to let enthusiasm override caution. Any compound containing fluorine always raises questions from the environmental crowd. Persistent chemicals can build up in water and soils, potentially causing long-term trouble for wildlife and, by extension, people. I’ve seen research teams struggle with the waste produced by fluorinated solvents because there’s rarely an easy way to neutralize them. Responsible disposal procedures and stronger regulations around handling will go a long way. I hear more discussion than action here, but the conversation has started within some companies about designing ionic liquids with greener backbones.

Another practical piece involves cost. High purity 1-vinyl-3-methylimidazolium trifluoromethanesulfonate doesn’t grow on trees, and the price tag can slow down smaller-scale or exploratory projects. Academic groups sometimes collaborate directly with chemical manufacturers to bring down costs or tweak the structure for specific applications. Such cooperation could point the way toward wider adoption—combining the best of innovation with scalable economics.

Finding the Balance: Risk, Reward, and Next Steps

Anyone working with new materials spends a lot of time weighing up risks versus benefits. For this ionic liquid, the scales tilt in favor of innovation, if users can manage the environmental and financial realities. With continued advances in green chemistry and manufacturing, and an honest conversation about the tradeoffs, it offers a promising path for more sustainable and effective chemical processes.

Why Care About Storage and Handling?

A bottle of 1-vinyl-3-methylimidazolium trifluoromethanesulfonate rarely grabs anyone’s attention unless you work in a lab or a chemical plant. Its chemistry gives it some real utility—ionic liquid fans use it for its conductivity and stability—but the flip side is that mishandling brings on headaches nobody wants. The facts matter: it doesn’t smell or fume as much as some other reagents, but ignoring standard protocols can put workers and investments at risk. Chemical burns, ruined samples, contamination, fire hazards—if someone tells you “it’s just an ionic liquid,” run.

Storing This Chemical Without Headaches

Every chemical supply cabinet has a few rules that make sense. For this one, glass or high-quality HDPE containers work best. I remember seeing a leaky cap from a mismatched plastic bottle once—it ate into the shelf and made inventory day a mess. For this chemical, everybody with some experience favors keeping the bottle tightly sealed, stored in a place that stays dry and cool, far from reactive metals and away from sources of heat. Water and humidity can affect more than purity; water in the air can mess up some of its applications, especially in synthesis.

Direct sunlight isn’t a friend. Even if it doesn’t break down into anything nasty, over time, exposure can raise temperatures and start unpredictable decomposition. If you work in a busy research facility or a start-up’s crowded lab, label everything. A clear “moisture-sensitive” or “reactive” label on the container stops colleagues from opening it up out of curiosity or mixing it in the wrong waste stream.

Handling Precautions That Actually Make a Difference

Having worked with a range of ionic liquids, I can say that taking the time to gear up always beats gambling. Wear gloves—nitrile, not vinyl or latex—because it won’t eat through quickly, but repeated splashes harden or crack skin over time. Porous lab coats work, but a heavier, chemical-resistant one gives better insurance. Sometimes, the liquid gets sticky; a quick swipe with a bare hand leads to unexpected rashes for some folks.

Make sure there’s fresh air. It’s not like handling benzene or chlorinated solvents, but if someone spills it, you don’t want to stand in the vapor. Basic safety glasses block splashes—goggles offer better coverage if things get messy. I’ve seen peers ignore this, get some in their eyes, and spend the afternoon washing out a burning irritation. Fume hoods aren’t just for flashy organics; use them for weighing or transferring, especially if the scale sits next to acids or reactive metals.

Waste and Spill Responses

Disposal matters more than many realize. Pouring excess down the sink is lazy and illegal, both from an environmental and a regulatory perspective. Collect waste in labeled HDPE or glass jars, away from acids or oxidizers, and arrange for regulated disposal. For small spills, reach for absorbent pads—never grab paper towels, which occasionally react or break up, spreading the mess. Finish with a wipe using a mild base or water, since bleach or harsh cleaning agents could react with triflate residues.

Small habits, like keeping the chemical away from casual office spaces and exporting a “clean-in, clean-out” routine, make long-term lab management easier. Training new team members to respect labels and update logs ensures that no one accidentally grabs the wrong material.

Better Storage and Handling = Fewer Accidents

Safe storage and careful handling might sound tedious, but they cut down on lost time, injuries, and lab drama. As ionic liquids keep cropping up in research, getting the basics right takes less effort than cleaning up a spill or explaining a burn to safety inspectors. Reliable habits, real PPE, and a clean bottle save a lot of trouble.

Real-World Testing Isn’t Optional

I once worked in a lab where the day’s excitement came from mixing chemicals and then watching for a reaction you hadn’t quite expected. New ionic liquids, such as 1-vinyl-3-methylimidazolium trifluoromethanesulfonate, brought an extra twist. The name is a mouthful, but its value in research is clear. It's got a vinyl group for chemistry tricks, an imidazolium core that influences stability, and that trifluoromethanesulfonate anion adds thermal and chemical resilience. Yet, all this engineering can’t replace the hard question: Will it play nice with other materials?

Solvent Compatibility: More than a Lab Choice

Solubility comes up fast. In my experience, ionic liquids with a trifluoromethanesulfonate anion show remarkable miscibility in polar organic solvents like methanol, acetonitrile, or dimethyl sulfoxide. This matches widely published research; ACS Sustainable Chem & Eng pointed out how triflates let ionic liquids blend smoothly with certain organic solvents, unlocking flexible synthesis and separation ideas. But drop this ionic liquid into a nonpolar solvent, such as hexane, and you’ll watch two immiscible layers form. Testing this myself, I saw only murky separation, with no usable mixture — saving an hour of hope on a project that demanded homogenization.

Chemical Compatibility: More than Just Mixing

Compatibility isn’t just about dissolving. If you throw this compound into a system with strong nucleophiles, such as sodium methoxide or sodium hydride, degradation can follow fast. The vinyl group stands out as a candidate for unwanted side reactions. I've seen over-ambitious reactions kill off the performance of the ionic liquid, especially when leftover bases lurked in the reaction flask. Acidic conditions tell a different story: the triflate anion remains stable and doesn’t break up, so applications requiring strong proton donors — think acid catalysis or ionic polymerizations — go much smoother.

Corrosive agents deserve careful consideration. Fluoride ions, abundant in some lab processes, can hit the triflate anion and trigger decomposition. Few researchers like admitting they tanked their experiment because of overlooked fluoride contamination, but it’s a story I’ve heard more than once. Water, as always, brings another angle. In modest amounts, water mixes well with this ionic liquid and sometimes helps with dissolution. But in large amounts, it can leach out some components over time or even support hydrolysis of sensitive groups in tough conditions.

Solutions for a Smoother Workflow

Lab accidents aside, planning often saves projects. Before starting a synthesis or process optimization, I compare notes on reactivity, solubility, and historical mixing data for each reagent involved. Online resources like PubChem or peer-reviewed journals now make it easier to check on previous successes and failures. Many researchers recommend small-scale compatibility screens for ionic liquids, using both target solvents and likely impurities.

Sometimes, adding a co-solvent, such as ethanol, resolves stubborn solubility headaches. Other times, tweaking the ionic liquid’s structure or purifying the reagents keeps nasty side reactions at bay. After years of working with advanced solvents and specialty salts, I’ve learned to lean on facts, published experience, and a willingness to run one more test.

Final Thoughts

Chemistry always brings surprises. Mixing new ionic liquids like 1-vinyl-3-methylimidazolium trifluoromethanesulfonate demands both caution and curiosity. Facts from published studies matter, but boots-on-the-ground testing, respect for each reagent’s quirks, and honest discussion about compatibility issues matter even more. That’s the best recipe for progress, waste reduction, and safe science.

Why Purity Matters in Chemical Research

Anyone who’s spent serious time in a chemistry lab knows the havoc that impurities can wreak on results. I’ve wasted days troubleshooting reactions, only to discover some trace impurity derailed the whole process. 1-Vinyl-3-Methylimidazolium Trifluoromethanesulfonate typically shows up with purities around 98% or higher from reputable suppliers. That percentage translates to peace of mind when pushing for clear, repeatable outcomes in synthesis or materials science projects.

I remember one project where a “96% pure” ionic liquid threw my team into weeks of rerunning NMRs. A higher grade—often labeled as analytical or research grade—made that issue disappear. Minor contaminants sometimes trigger side reactions, especially with ionic liquids that people use in electrochemistry or catalysis. If a company claims a “research grade” at or above 98%, I take that seriously before mixing it into ambitious experimental designs.

Realities of Sourcing and Packaging Sizes

Researchers rarely need kilograms of exotic ionic liquids right off the bat. In my experience, 5-gram or 10-gram bottles show up on lab benches the most. These units let you run enough trials, especially through the early, uncertain stages, without stretching the budget. Most suppliers keep 5 g, 10 g, 25 g, and 100 g options in stock. The jump to 500 g or 1 kg pricing feels steep, but large-scale users—think pilot plant folks or engineers scaling up a process—reach for those sizes.

I’ve personally spent extra to order double-sealed glass bottles for moisture-sensitive compounds. Ionic liquids like this are notorious for soaking up water from the air. Even a 5-gram order should show up tightly capped, sometimes vacuum-sealed or in foil pouches, to avoid disappointing surprises during the first use. The good vendors make it clear exactly how the material is packed. Labs running gloveboxes or requiring ultra-dry conditions pay close attention here.

Building Trust in a Lab Chemical Market

Many graduate students and postdocs learn the hard way that not all chemical suppliers deliver what they promise. I always chase down proper documentation before spending grant money. Certificates of Analysis—showing not just purity, but also test methods—sometimes make the difference in choosing one brand over another. NMR and elemental analysis results, in particular, offer assurance for people wanting to reproduce published results.

It’s not just about trusting a label. Documentation supports regulatory committees, too. Researchers submit this paperwork to prove that the reagents meet safety and compliance checks, crucial for anything near pharmaceutical investigations or academic publications. Skipping these steps sinks papers and ruins collaborations.

Improving Access and Transparency in the Industry

Some suppliers have begun listing lot-specific analysis and batch traceability directly on their websites. It’s a straightforward improvement, saving buyers time and effort. Others let customers request custom packaging—not everyone wants 25 grams, especially if budgets are tight or shelf life matters. Pushing for clear, upfront disclosure—purity, stability data, and packaging condition—levels the playing field for both established labs and underfunded startups.

Reliable access to 1-vinyl-3-methylimidazolium trifluoromethanesulfonate with known purity and package options builds confidence for careful experimentation and innovation. Open, honest disclosure remains the gold standard here, making success stories more common on both the bench and the business side of chemical research.