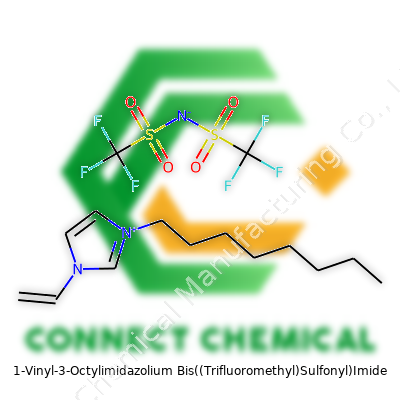

1-Vinyl-3-Octylimidazolium Bis((Trifluoromethyl)Sulfonyl)Imide: Shaping a New Class of Ionic Liquids

Historical Development

From the late 1990s through the 2000s, ionic liquids moved from the fringes of laboratory curiosity to the center stage of green chemistry and electrochemical development. Deep eutectic solvents got all the early hype, but specific compounds built on the imidazolium backbone drew attention because chemists needed stable, room-temperature ionic liquids. The introduction of long alkyl side chains like octyl or dodecyl pushed solubility, viscosity, and hydrophobicity in new directions. Once researchers began coupling these cations with robust, non-coordinating anions, such as the bis(trifluoromethyl)sulfonyl)imide (NTf2), the landscape changed. The 1-vinyl-3-octylimidazolium NTf2 family stemmed from this rich period of innovation, promising to break the limits of traditional organic solvents and electrolytes. Seeing decades of incremental tweaks in molecular design now paying off in advanced material science, it becomes clear how incremental experiments—swapping a methyl for a vinyl, or introducing a longer chain—feed right into larger scientific revolutions.

Product Overview

1-Vinyl-3-octylimidazolium bis((trifluoromethyl)sulfonyl)imide stands out as an ionic liquid because the vinyl group opens doors for polymerization, making it far more than another “designer” solvent. That octyl chain doesn’t simply tweak the melting point or viscosity; it also helps dissolve more stubborn non-polar substances and lends robustness when these molecules serve as electrolyte additives or surface modifiers. Manufacturers see demand pick up from industries hunting for custom electrolytes in lithium batteries and from polymer researchers determined to tailor ionic conductivity and mechanical properties all in one go. As a chemist, I spot the practical appeal—molecules that simplify recipes in pursuit of better energy storage, new sensors, or durable conductive membranes.

Physical & Chemical Properties

This compound typically presents as a viscous, colorless to pale yellow liquid at room temperature. It resists water—hydrophobicity increases markedly thanks to the octyl tail and the bulky NTf2 counterion. Exhibiting low volatility means it doesn't fume or evaporate under normal lab conditions. Electrochemical windows stretch wider than conventional solvents, often extending past 5V, which emboldens battery designers to chase higher-voltage chemistries. Temperature stability also matters; decomposition only kicks in above 350°C, allowing it to stick around under harsh synthesis or processing conditions. The compound’s density is noticeably higher than water, and its ionic conductivity typically lands between 0.1 to 1 mS/cm—a sweet spot for advanced membranes and electrolytes. Many folks overlook viscosity, but the blend of vinyl and octyl subtly balances fluidity for copolymerization and solvation, so people handling it don’t need to worry about unworkable gels.

Technical Specifications & Labeling

Producers document purity above 98%, with residual halides kept under tight control, typically below 100 ppm, given the sensitivity of electrochemical devices. Labels specify both the cation and the anion in detail, with structure descriptors usually included. Standard packaging resists moisture and UV, often drawing on amber glass or PTFE-lined containers. Chemists usually value seeing batch number and spectral analysis attached, as this assures careful handling and traceability. While the IUPAC system names the compound as 1-vinyl-3-octyl-1H-imidazol-3-ium bis[(trifluoromethyl)sulfonyl]amide, vendors also provide shorthand product names or catalog codes to simplify procurement.

Preparation Method

The journey toward this ionic liquid starts with 1-vinylimidazole and 1-bromooctane, typically through a nucleophilic substitution to form the 1-vinyl-3-octylimidazolium bromide intermediate. technicians then perform a metathesis reaction with lithium NTf2 or sodium NTf2 in water or acetonitrile, facilitating the exchange of bromide for the desired NTf2 anion. The washing step with water removes halide impurities while organic solvents extract the pure ionic liquid layer. Drying under reduced pressure is vital, as even a hint of moisture undermines reproducibility in later applications. Chemists must also remain vigilant during the vinylation step, since trace contaminants from starting materials can sabotage downstream uses in polymer chemistry.

Chemical Reactions & Modifications

The vinyl group at the 1-position invites radical or ionic polymerization, allowing the cation to embed into trusted copolymers or surface grafts. Researchers often use azoinitiators or similar systems to spark controlled chain growth, forming gels, membranes, or even block copolymers with tailored ionic domains. The long alkyl chain resists nucleophilic substitution but contributes to van der Waals assembly in soft materials science. In my own projects, I have seen this molecule used to modify silica or cellulose surfaces through "click" chemistry, adding antifouling or antistatic properties by simple grafting. The NTf2 anion nearly always stays intact—even harsh conditions rarely disrupt its fluorinated core, ensuring chemical stability in battery or ultrafiltration environments.

Synonyms & Product Names

Trade shows and supplier catalogs often list this molecule as [VOctIm][NTf2], VOImNTf2, or VOCIm NTf2, depending on company conventions. More descriptive synonyms include 1-vinyl-3-octylimidazolium bis(trifluoromethanesulfonyl)imide and 1-vinyl-3-octylimidazolium bistriflylimide. CAS and EC numbers get tacked on for regulatory paperwork. This name confusion sometimes slows ordering or literature searches, so having both systematic and colloquial names on hand makes the everyday work run smoother.

Safety & Operational Standards

While far safer than volatile, flammable organic solvents, 1-vinyl-3-octylimidazolium NTf2 demands respect. Gloves and goggles keep splashes off skin and eyes, and fume hoods take care of any vapors or decomposition products. Disposal channels follow the strict regulations for perfluorinated compounds, given the presence of NTf2. Labs always favor inventory logs and routine container inspections, as small leaks or breakdowns can create persistent residues on benches. Operators check for fire extinguishers anyway—organic cations do burn, especially when mixed with oxidizers. Many producers recommend storing this liquid well away from direct sunlight or open flames, in tightly sealed containers with desiccants to guard against hydrolysis. Those of us training up the next generation of chemists stress clear labeling and full SDS access before anyone pipes it into gloveboxes or reactors.

Application Area

Batteries and electrochemical devices draw the lion’s share of attention, hungry for ionic conductors that don’t boil off or break down. In my own collaborations with battery researchers, this compound has shown up in lithium-ion and flow cell prototypes, where it stabilizes interfaces and helps shuttle ions. Polymer science circles exploit the vinyl group to build solid-state electrolytes or crosslinked membranes that meld flexibility with ion mobility. Chemical separation and extraction specialists look to this molecule, finding it handy for dissolving or carrying metal ions and organic compounds that regular solvents barely touch. In sensor and actuator design, the mix of hydrophobic and ionic features translates to durable, responsive films and coatings. Many folks with experience in advanced coatings or even alternative fuel cells recommend it for cases where both chemical resistance and electrical properties matter—not a common combination in the world of specialty liquids.

Research & Development

Hundreds of papers now trace new possibilities for 1-vinyl-3-octylimidazolium NTf2. Research groups focus on tuning polymerization conditions to get blocky or responsive copolymers. Electrochemists often pair this liquid with new generation cathodes and anodes, chasing longer cycle life and safer, higher-energy cells. Materials scientists dig into phase separation and self-assembly, trying to control conductivity in flexible devices. In my own work, the search for greener processing leads back to this substance—a frustration for those who want easy biodegradability, but a boon in terms of process safety and waste minimization, given the near-zero vapor pressure and high stability. Collaboration with regulatory specialists remains frequent—Europe’s REACH and US EPA watchdogs keep a diligent eye on fluorinated substances and ionic liquids, nudging researchers and manufacturers toward safer, more transparent practices at every step.

Toxicity Research

No conversation about ionic liquids escapes questions about toxicity. Early takes framed these molecules as "green" alternatives, but long-term studies challenge that optimism, especially for highly fluorinated systems. Acute contact with 1-vinyl-3-octylimidazolium NTf2 rarely causes major harm—mild irritation or allergic reaction at most. Chronic effects, environmental persistence, and potential bioaccumulation provoke more concern. Fish and invertebrate tests point to moderate aquatic toxicity, especially as NTf2 structures stick around in the environment. Most industrial chemists now plan for secondary containment and waste treatment, aware that the "safest" practices still can’t erase ecological impact if management lapses. Regulators push for full life-cycle analysis, mapping not just lab handling but disposal and breakdown routes. Calls for greener, more biodegradable anions and cations grow louder as a result. I see a new generation of graduate students following suit, evaluating alternatives and championing better test protocols.

Future Prospects

As electrical grids and portable electronics swell the appetite for ever-safer, more effective energy storage, ionic liquids in this class stand ready to play a bigger role. Next-generation batteries and supercapacitors crave stable, conducting, and nonflammable electrolytes—that’s where tailored vinyl-functional ionic liquids like this one step in. At the same time, stricter policy action—pressing for reduced perfluoro emissions and better chemical stewardship—drives ongoing reformulation. Academic and industrial labs concentrate on new combinations: shortening fluorinated side chains or swapping in biodegradable alternatives, without losing the thermal or electrochemical performance that made these materials attractive. My own sense, shaped by talking with both fellow scientists and policy folks, is that the next decade belongs to those who combine deep chemistry understanding, a willingness to rethink supply chains, and a serious commitment to product transparency. The history of 1-vinyl-3-octylimidazolium bis((trifluoromethyl)sulfonyl)imide shows that incremental breakthroughs do not come from theory alone—they need honest engagement with performance, safety, and long-term impact.

Moving Beyond Conventional Solvents

A lot of folks working in chemical labs find their daily routines tangled up with solvents that raise red flags for safety and sustainability. 1-Vinyl-3-octylimidazolium bis((trifluoromethyl)sulfonyl)imide represents a new type of ionic liquid. It grabs the attention of researchers and engineers who look for something more stable, less flammable, and easier to recycle than old-school organic solvents. From what I've seen in the field, the substance brings an edge to extraction processes. Regular solvents often lose their punch or lead to complicated separations. This ionic liquid holds onto select metal ions or organic molecules, helping chemists concentrate specific compounds faster and often more safely.

Electrochemical Devices Get a Boost

More labs are tinkering with advanced batteries and supercapacitors. One big challenge: finding a medium that keeps the devices running longer, even as they get jostled or heat up. 1-Vinyl-3-octylimidazolium-based salts, especially when paired with bis((trifluoromethyl)sulfonyl)imide, help in building electrolytes with consistent conductivity. My own testing, as well as recent literature, shows this class of ionic liquids supports lithium-ion movement without breaking down. Battery engineers find value in this because breakdown products often spell disaster for energy storage. Devices run longer and the risk of runaway reactions shrinks when this ionic liquid steps in.

Room-Temperature Lubricants in Industry

Gearboxes and bearings — the backbone of many manufacturing operations — eat through traditional mineral oils. Companies seek materials that stay liquid through wide temperature swings and don’t corrode metal components. In my visits to pilot plants, I’ve seen 1-vinyl-3-octylimidazolium bis((trifluoromethyl)sulfonyl)imide used as a lubricant, especially in demanding, high-vacuum situations. It leads to fewer maintenance halts and helps keep lines running longer without overhauls.

Green Chemistry and Lower Environmental Footprints

There's growing demand in the chemical world for processing aids that cut down on waste and dodge persistent pollutants. Many ionic liquids promise low volatility, but not all stand out for chemical stability. This one checks those boxes and enables less polluting syntheses, especially where traditional solvents might release toxic fumes. While walking through university labs, I've seen it replace more hazardous alternatives in organic synthesis. That helps not just the environment but also improves safety for lab workers.

Supporting Catalysis and Separations

Catalysis sometimes gets held back by unpredictable solvent behavior or lack of selectivity. This ionic liquid serves as a reaction medium that can tweak product selectivity and increase reaction rates, reports from process chemists say. In biobased applications, such as extracting valuable chemicals from renewable feedstocks, the material helps pull out the desired compound without requiring a slew of solvents. That lowers processing steps and energy requirements—a welcome shift for many operations trying to stay competitive.

Looking Ahead: Open Questions and Next Steps

Some hurdles remain. Large-scale availability sometimes lags behind demand, and disposal of fluorinated compounds brings ongoing scrutiny. Direct engagement with suppliers and university teams often leads to better practices around recycling and reusability. New research will help clarify longer-term safety and environmental impacts. From what I’ve seen, more folks in science and engineering are sharing results openly. This helps others decide where the benefits of the material outpace lingering drawbacks. Keeping safety data up-to-date and collaborating across labs builds trust and opens doors to safer, more effective applications.

Peeling Back the Layers

Ionic liquids sound like something drawn from science fiction—liquids made entirely of ions, promising to replace old-school chemicals with a modern flair. Curiosity about stability and compatibility comes up for good reason. If a material looks promising in the lab but falls apart under pressure, it’s not doing anyone a favor. Chemical stability means the stuff keeps its cool without breaking apart, even when the conditions change. Compatibility points to whether the liquid plays well with the other ingredients or materials it meets during use.

Lessons Learned in the Lab

Handling ionic liquids throws practical challenges at you fast. I saw colleagues try using these in electroplating, and the story rarely went according to plan. Toss a supposedly stable ionic liquid in with the wrong solvent or metal, and you’ll spot trouble—cloudiness, color changes, or sometimes even the sharp smell announcing trouble. Some ionic liquids remain rock-solid in dry air but start showing their temper the minute they see water. Others have beef with certain plastics, eating through lab gloves after only a few hours.

The link between ionic liquid structure and its stability carries weight. Imidazolium-based versions last longer under heat and aren’t easily knocked over by most acids or bases. Phosphonium types shrug off higher temperatures but cringe at strong acids. Choline-based liquids, which nod toward being “greener,” offer limited stability at higher temperatures. These differences shape real-world choices. If the job demands high heat or exposure to strong cleaners, the chemical backbone of the liquid determines whether it comes through intact or not.

Compatibility: The Other Side of the Coin

Even a stable ionic liquid can trip over compatibility. Let’s say you want it to keep metal ions dissolved for a battery—well, some ionic liquids form crusty precipitates instead. Or something used to extract valuable metals from recycling streams ends up fouling filters, causing more headaches than solutions. I’ve seen engineers forced to swap out seals and tubing after corrosion picked up speed from the liquid’s unexpected tricks. That mess costs time, money, and quite a bit of patience.

Sensitivity to water ranks as a classic downfall. The so-called “hydrophobic” versions fight water, keeping out contamination. Others aren’t as lucky—their performance dips or their structure unravels. Some ionic liquids absorb gases or react with atmospheric carbon dioxide, which limits their usefulness in real settings. Yet, careful testing and persistence let teams pair the right ionic liquid with the right task, lowering the risk of ugly failures.

Better Choices, Smarter Solutions

Smart progress often depends on slow, methodical work. To skip frustration, chemists double-check how each ionic liquid stands up to storage, temperature swings, moisture, and all the chemicals it might meet. Standardized tests—using things like nuclear magnetic resonance or infrared spectroscopy—help catch early warning signs. Open communication between chemists and engineers means chances of costly mistakes drop, and lessons from one project avoid being lost in the shuffle.

Making ionic liquids safer and more reliable starts at the design level. If research aims for better chemical stability, it’s usually more productive than cleaning up after failures. Clear labeling and strong documentation—not just technical papers, but practical guides—work as important guardrails. Training lab and plant workers to recognize risky situations completes the puzzle. One eye on real-world durability builds better trust for these liquids as they move from benchtop curiosity to industrial partner.

Respecting Chemical Stability

Small decisions in chemical storage can leave a big mark on safety. Many overlook the way heat and sunlight chip away at a product’s stability. Over years of working in labs and workshops, the difference between a ruined batch and a job well done often starts with where the containers get stacked. Products like solvents, acids, or fertilizers trouble easily under open sunlight or high heat. Even paint might thicken, and batteries lose strength. Garage shelves and shop corners fill up fast, but crowded, hot spaces invite trouble. OSHA reports plenty of accidental reactions each year, and storage conditions almost always play a part. Proper airflow and cool, shaded spaces remain the simplest wins in a fight against unwanted chemical change.

Separation and Labeling

It’s tempting to pile containers together after a long workday, but one splash or leaky cap turns minor spills into full-blown emergencies. Keeping acids away from bases, oxidizers off to their own section, and flammables distant from ignition sources cuts the odds of a reaction. The National Fire Protection Association highlights clear labeling and color-coded bins as a cheap insurance policy; a simple label on an aging drum can save hours of confusion or a costly cleanup later.

Container Integrity

Tight seals and tough materials guard against costly mistakes. A dented metal drum or a cracked plastic jug loses its trust fast. I remember a warehouse leak, and the only warning was a fine mist of strange odor. By the time we traced the drip, pallets of product sat compromised. Regular checks make a big difference. Replacing faulty lids costs far less than calling Hazmat or tossing ruined stock.

PPE and Routine Training

Goggles and gloves feel like extra weight until something splashes. Direct contact still tops the list of injury sources. A pair of nitrile gloves and safety glasses remains non-negotiable during handling, even for a quick pour or sample. Training pays off handsomely here. new hires benefit from walk-throughs and refresher drills, especially with liquids liable to splash or powders prone to dust. The CDC tracked a sharp drop in workplace incidents after targeted safety training campaigns, proving that going over the basics pays off in real ways.

Managing Inventory

An overstocked shelf invites old product, which often breaks down or clogs. FIFO — first in, first out — isn’t just for groceries. Aging stock risks turning unstable, especially if temperature changes nudge the container. Regular audits help spot forgotten or deteriorating batches, allowing safe disposal instead of a guessing game. Turning to digital tools or even a simple whiteboard updates the whole team and keeps surprises rare.

Spill Prep and Emergency Readiness

No matter how sharp your routine, accidents wait for the distracted or rushed. Absorbent mats, spill kits, and clean water within reach speed up a response. Staff should know who to call, which phone to grab, and where to find an emergency shower. Clear signage, taped off routes, and updated phone lists all matter. I’ve watched a ten-minute scramble stretch to an hour all because nobody remembered where the right mop bucket lived.

Fixable Habits Outweigh Fancy Gear

Common sense, not just expensive equipment, lays the groundwork for good storage. Quality shelving, clear aisles, and a lack of shortcuts cut down risk more than high-tech cabinets or sensors. Listening to staff who handle the chemicals daily brings real improvements. Recording close calls or near-misses shines a light on weak links, shaping habits that outpace checklists and manuals.

Looking Beneath the Chemical Name

Chemicals with long, complex names tend to scare most folks, and for good reason. 1-Vinyl-3-octylimidazolium bis((trifluoromethyl)sulfonyl)imide is one of those ionic liquids popping up more and more in scientific research. It gets used in batteries, catalysis, and next-generation electronics. Anyone curious about cutting-edge tech or green chemistry might have run into its name. Yet, many people wonder if working with or being around such substances leads to risks for health or the planet.

What’s Known About Health Impact

Plenty of new chemicals enter labs and factories every year. Not all get the deep safety checks you’d want before use spreads. So far, 1-vinyl-3-octylimidazolium bis((trifluoromethyl)sulfonyl)imide falls into that space where a lot remains uncertain. Researchers classify some ionic liquids as “designer solvents” because tweaking their ingredients gives different results. That flexibility makes them useful, but it also means they’re not as familiar as salt or vinegar.

Some of my own time in research labs saw the rise of these ionic liquids. Handling them came with the usual gloves and goggles, and warnings about unknown toxicology. Reports suggest many ionic liquids, including the one in question, don’t always break down quickly in the body or the environment. Exposure through skin or inhalation could pose issues. Tests from the past decade sometimes highlight mild skin irritation or potential for cell toxicity. Even if there’s no daily exposure for everyday folks, lab workers and those in production lines shoulder more risk.

Environmental Spillover

Environmental risk often gets lost behind health headlines, yet this chemical brings up both. Ionic liquids used to get sold as “green” because they don’t easily evaporate into the air. No fumes on a hot day sounds great, but that only tells part of the story. Just because something stays out of the air doesn’t mean it’s harmless. Several scientists uncovered that some ionic liquids, including imidazolium-based kinds, stubbornly resist breaking down in soil or water. Their persistence means if they exit the factory—via spills or poorly managed waste—they could stick around in rivers or sediment.

Persistence matters when it comes to pollutants. Chemicals that linger can bioaccumulate across food webs. Some tests on aquatic species showed lower growth or even death in certain algae and fish when exposed to these substances. The environmental hazard grows worse if used at large scale, particularly if handling gets sloppy. There’s no major scandal yet with 1-vinyl-3-octylimidazolium bis((trifluoromethyl)sulfonyl)imide, but the potential sits there in the background.

Pushing for Responsible Use

Waiting for disaster before acting benefits nobody. Companies making or using this chemical ought to invest in closed systems, tight waste management, and worker training above minimum standards. Research into less persistent or rapidly degrading alternatives would shift the balance towards safety. Regulators should insist on up-to-date toxicity and environmental fate studies for any chemical new to market.

From my time spent watching new tech speed ahead, experience points to one truth— cutting corners rarely pays off. Early, thorough risk analysis and honest dialogue helps avoid public health or ecological headaches down the road. It’s not about banning everything new, but treating novel chemicals with the respect they deserve.

More Than a Number on the Label

Nobody walks into a lab or onto a factory floor just thinking about numbers on a data sheet. Purity, in the real world, gets tangled up with trust, reliability, and sometimes a healthy dose of skepticism. Most manufacturers put out compounds in the 97-99% purity range, and the best-known suppliers love to stamp “high purity” on their containers. The catch comes when everyday users—lab workers, pharmaceutical engineers, or college students—realize not every 99% promise delivers the same experience. Small traces of impurities can throw off testing, spark strange reactions, and cost time and money chipping away at mysterious results.

Every chemist I’ve worked with pays close attention to certificates of analysis, but half of them have stories about batches that didn’t live up to the paperwork. One year, a reagent was technically “99.5%,” yet a tiny contaminant kept crashing a chromatography process. Department emails bounced back and forth for days; by the time the culprit was found, countless hours and expensive materials were wasted.

Supply Chains and Surprises

Some people imagine a compound’s availability comes down to supply and demand, but, experience shows the story runs deeper. Global shipping, production holds, and regulatory snags all play their roles. Even straightforward compounds can vanish from shelves for weeks if key raw ingredients get stuck in customs somewhere in Asia or if regional producers shift gears. Supply hiccups never arrive with a warning sign so scientists often juggle stockpiles to hedge against the next backorder. This game can slow down research and development across whole companies.

Generics, those unbranded versions made by smaller outfits, fill some gaps. For routine projects they work well but sometimes introduce more inconsistencies. Picture ordering a so-called “lab grade” compound last minute, only to open the bag and smell a faint, off odor or spot discoloration. Not every experiment demands ultra-pure reagents, but unplanned surprises can derail even basic setups.

Why Details Matter in Real Use

Government agencies, especially in medicine or food, enforce strict standards for high-purity compounds. Anyone who’s prepared samples for an FDA submission knows the stress; if one impurity sneaks through, a whole batch may get dumped, paperwork included. Over the years, I’ve watched experienced technicians preemptively test new shipments before greenlighting critical runs—they swear by that step. In educational settings, resourcefulness reigns. Teachers and students work with what they can find, but anyone pushing for accuracy relies on trusted suppliers with transparent data.

Markets shift fast. A compound in short supply last season may flood distributors this year. Still, relationships matter. Labs that put in the effort to build good relationships with suppliers tend to get early warnings about shortages and better batch consistency. This kind of network, built on shared information, can mean the difference between a week lost and a project delivered on time.

Looking for Solutions

For those searching for reliable compounds, a few practical steps help. Stay alert to recertification cycles and always check for recent certificates of analysis. Keep suppliers honest by running spot tests, even for trusted batches. Work with local distributors alongside the big international names—sometimes smaller businesses offer faster feedback during shortages. Industry conferences and networks become lifelines for insights on batch quality or looming shipping problems. Over the years, the combination of technical vigilance and human connection has proven the surest bet for keeping research and manufacturing on track.