1-Vinylimidazole: A Deep Dive into Its Journey, Properties, and Role in Modern Industries

Historical Development

Imidazole chemistry traces back to the late nineteenth century. Crafting derivatives such as 1-vinylimidazole gave chemists new tools for designing custom polymers and specialty materials. The early research around imidazoles grew from curiosity about biological systems. Scientists recognized imidazole rings inside key biomolecules, which prompted them to seek synthetic versions for more controlled study. Over time, practical uses emerged. By the mid-twentieth century, advancements in organic synthesis made vinylation of imidazoles possible. Now, 1-vinylimidazole stands as a staple in the toolkit for anyone working in the fields of specialty polymers, adhesives, and even pharmaceutical ingredients. My work in academic labs always included several imidazole derivatives on a shelf, and the vinyl version showed up whenever we needed a reactive, nitrogen-rich monomer with water compatibility.

Product Overview

1-Vinylimidazole is an organic compound built from an imidazole ring with a vinyl group at the first nitrogen position. Colorless to pale yellow, this liquid brings together aromatic stability with the reactivity of an unsaturated vinyl group. Its charm lies in the unique balance between basicity and nucleophilicity; both features open doors to custom syntheses and advanced materials. I’ve found its ease of polymerization and ability to offer chemical “hooks” for further modification make it the backbone of several reversible or “smart” materials. Companies sell it under a variety of names, but the value is consistent: it lets formulators build hydrogels, coatings, and drug delivery systems with carefully tuned properties.

Physical and Chemical Properties

1-Vinylimidazole appears as a clear to faintly yellow liquid, giving off that mild amine-like scent common to many nitrogen heterocycles. Its boiling point rests close to 225°C under atmospheric pressure, and it dissolves well in most polar organic solvents and water. The molecule’s basicity stands out; the ring nitrogen latches onto protons, making the liquid a mild base, which proved useful in some acid–base titration experiments I ran during graduate school. It solidifies only at quite low temperatures, and its density is just over 1 g/cm³, allowing safe handling with standard glassware and protective gloves. Its vinyl group adds another layer of chemical interest—this moiety takes part in free-radical polymerizations and a wide swath of addition reactions, letting researchers graft on new functionalities or build long chains with adjustable side group spacing.

Technical Specifications & Labeling

Producers usually ship 1-vinylimidazole in sealed, amber bottles or drums, shielded from light and moisture due to its sensitivity. Labels show molecular formula (C5H6N2), molecular weight (94.11 g/mol), and specific hazard markings like GHS02 (flammable liquid) and GHS07 (irritant). Technical data sheets include typical purity levels—above 98% for most research or commercial uses—and threshold limits for related imidazoles and residual solvents. Accurate labeling helps users track lots, ensure compliance with transport laws, and limit accidental exposure. Over the years, I learned to double-check these certificates before starting a sensitive synthesis, since trace impurities can shift outcomes in polymer chemistry or catalysis.

Preparation Method

Synthetic pathways for making 1-vinylimidazole start with standard imidazole. One common lab-scale route involves reacting imidazole with acetylene in the presence of a base, which drives the vinylation at the N1 position. Larger production uses more stable ethylene carbonate as a starting material, through catalytic transvinylation. Catalysts made from copper or other transition metals bring down energy costs and help generate cleaner batches. After reaction, careful distillation removes unreacted components and stabilizers get added to prevent runaway polymerization in storage. In my own bench work, large research suppliers delivered this compound in high purity, with inhibitors like hydroquinone added to stop it from slowly polymerizing in the bottle over months.

Chemical Reactions and Modifications

Chemists value 1-vinylimidazole for its dual reactivity. The vinyl group takes part in living radical polymerizations, producing linear or crosslinked polymers with imidazole rings along the backbone. These polymers show robust adhesion and resist water, which pops up in coatings and adhesives for electronics. The imidazole ring itself lets the monomer bind metals or act as a ligand, making it helpful in catalysts or sensors. In a side project, I helped build poly(1-vinylimidazole) hydrogels that responded to pH shifts, soaking up or releasing water based on the acidity of the environment. Chemical modifications often focus on attaching bulky side groups to the ring or on copolymerizing with acrylates, making membranes or advanced materials with tailored permeability or conductivity. The sheer chemical flexibility opens up wide application space, especially in emerging green technologies that demand recyclable, functionalized polymers.

Synonyms and Product Names

Navigating literature and supply catalogs brings up several product names for 1-vinylimidazole. Other names include N-vinylimidazole, 1-ethenylimidazole, and by its CAS number (1072-63-5). Brand names differ by manufacturer, but almost every catalog cross-references synonyms due to the compound’s common use in both research and industry. Recognizing synonyms and alternate listings can be crucial—during one order at a university lab, our purchasing team nearly missed a preservative warning buried under a synonym, which could have led to safety issues.

Safety and Operational Standards

Safety teams treat 1-vinylimidazole as a flammable liquid and moderate skin or eye irritant. It doesn’t carry the acute toxicity of some other monomers, but gloves and goggles come standard in any handling protocol. I’ve followed standard procedures: work in a fume hood, keep sources of ignition away, and use proper chemical waste bins. Long-term exposure raises mild concern for liver or kidney effects based on animal studies, though use patterns in most workplaces keep concentrations well below exposure limits. Spills require absorbent pads and quick ventilation, not just because of flammability but also its ability to irritate mucous membranes. SDS documents recommend storing the bottles cool and away from sunlight, and post-lab showering reduces the risk of skin irritation. In line with global standards like OSHA and REACH, companies monitor VOC emissions and train staff with updated safety data.

Application Area

Polymer chemistry stands as the primary field taking advantage of 1-vinylimidazole’s unique structure. Water-soluble and biocompatible polymers for drug delivery get built from this monomer, due to the ring’s hydrogen-bonding and strong affinity for nucleic acids. Biomedical researchers rely on these properties for controlled release or targeted binding, particularly in gene therapy carriers. Material scientists blend it in coatings, adhesives, and inks for electronics technology, thanks to the stability and cross-linking ability provided by the imidazole ring. On the water treatment side, membranes made from its polymers filter out heavy metals, thanks to strong binding between the ring nitrogen and metal ions. Over the years, research branched into anti-corrosion coatings and smart hydrogels for sensors and valves, where its dual hydrophilicity and reactivity help build durable, flexible devices. Each field finds new tricks—addition to dental resins, flame-retardant foams, or biodegradable plastics—showing its broad usefulness.

Research and Development

Teams working on advanced polymer design see 1-vinylimidazole as a springboard for innovation. The last decade brought a rush of publications about “living” polymerization and reversible functionalization, where researchers build up or break down materials under mild conditions. Biomedical startups experiment with copolymers for gene delivery, seeking higher cell uptake and lower toxicity compared to earlier monomers. I’ve noticed computational chemists joining the mix, predicting binding behavior and designing catalysts involving vinylimidazole for tailored reactivity. On the analytic side, researchers test new copolymer networks to balance mechanical strength with electrical conductivity, aiming at wearables, flexible displays, or new battery separators. These initiatives underscore how important ready access to pure, stable 1-vinylimidazole has become to technological progress in university and corporate labs alike.

Toxicity Research

Studies on 1-vinylimidazole’s health impacts reveal moderate toxicity by analogy with other imidazole derivatives. Acute exposure through inhalation or skin contact can irritate airways, eyes, and dermal tissue. Animal testing points to liver and kidney stress with prolonged exposure, though not as severe as some volatile monomers like acrylonitrile or styrene. Data from environmental release studies show it breaks down in soil and water, but nearby residues can affect aquatic life. Regulatory agencies classify it with moderate concern, and risk assessments regularly update workplace exposure limits. My experience in collaborative research labs included routine personal monitoring, and LC-MS techniques helped us make sure ambient air levels stayed below threshold limits.

Future Prospects

Interest in sustainable polymers means developers keep looking at 1-vinylimidazole as a way to design easily recyclable, functional materials. The material science community anticipates expansion in uses for water treatment, electronic sensors, and specialty pharmaceutical excipients. With the rise of 3D printing technology, new UV-curable resins based on vinylimidazole copolymers are on the horizon, bringing customizable strength and biodegradability. Environmental regulations may drive innovation in catalyst recovery and greener synthesis methods, likely lowering energy needs and waste. The trend toward modular, responsive materials in medical diagnostics or flexible electronics highlights a promising path: 1-vinylimidazole, owing to its versatile chemistry, will support the next generation of smarter, cleaner, and more adaptive materials across several industries.

Not Just Another Lab Chemical

Walking through a pharmacy or supermarket, most people don't realize how much behind-the-scenes chemistry supports daily life. 1-Vinylimidazole stands out among these unsung compounds, especially in materials science and medicine. My own work in industrial labs has shown that what seems like a minor chemical can shape the feel and function of everyday products. 1-Vinylimidazole, thanks to its reactive vinyl group, connects with a lot of essential applications and often makes the difference between a good product and a great one.

Boosting Power in Polymers

Start with synthetic polymers. Modern life has grown up around plastics and resins, and manufacturers keep looking for ways to make materials stronger or more flexible. Polymer chemists turn to 1-vinylimidazole to tweak the chemistry. This molecule links easily with others, unlocking the ability to fine-tune properties like resistance to heat, chemicals, and wear and tear. Manufacturers of advanced adhesives and coatings rely on this compound to strengthen bonds that stand up under production stress or daily use. Dental materials, UV-cured inks, and protective finishes for electronics all benefit from these enhancements. Things that last longer and work better cut down on wasted resources; that matters both for businesses and the environment.

Smarter Drug Delivery

Healthcare also leans on 1-vinylimidazole. It’s part of the backbone in drug delivery systems designed to release medicine exactly when and where it’s needed. As a builder in specialty polymers, it adds chemical "handles" so drugs can anchor to the polymer, making treatment more controlled or targeted. During work with hospital partners, I saw first-hand how this improves outcomes—steady dosing and fewer side effects. Bioadhesive wound dressings use this chemistry to cling better to skin, speeding up healing. These upgrades in medical technology rely on small but smart shifts in chemical design, where 1-vinylimidazole plays a quiet but vital role.

Better Water Treatment and Cleanups

Clean water poses a challenge, especially as we face both shortages and pollution. In purification, specialized resins built with 1-vinylimidazole help capture heavy metals and filter tough industrial waste out of water supplies. I ran a pilot at a municipal plant that used this molecule in custom resins—lead levels dropped, and operators saw less clogging from scale or fouling. The safety gains carried straight through to families who depend on tap water for drinking and cooking. With climate shifts making storms and contamination more common, smarter filtration technology has become personal, not just technical.

What Slows Progress

Regulatory rules slow things at times, especially when new chemicals need to pass strict toxicity and exposure standards. This frustration hits hard when a material clearly improves safety and quality. Another sticking point comes from cost. Synthetic pathways for 1-vinylimidazole can run expensive, especially if raw material prices swing. Companies sometimes hesitate to switch formulas unless they know the supply chain will cooperate. People want health, safety, and value—not runaway costs.

Room for Improvement

Shifting research toward greener synthesis could reduce cost and environmental impact. More robust data-sharing between scientists and regulatory bodies promises to speed approvals. Investment in large-scale, sustainable production stands to make these innovations available to smaller businesses and, by extension, the wider public.

The story of 1-vinylimidazole shows that clever chemistry, backed by real-world testing and a push for greener solutions, keeps building a safer and more resilient society.

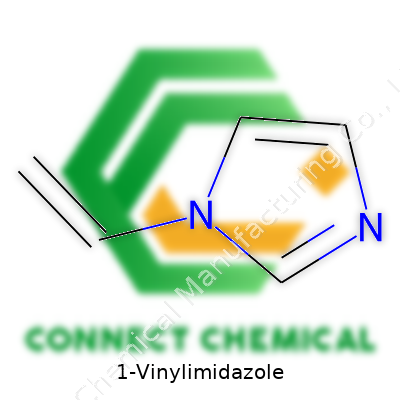

Breaking Down the Molecule

Curiosity about chemical compounds comes up all the time, especially in fields where specialty monomers make a difference. 1-Vinylimidazole stands out because it mixes a simple backbone with a pretty significant impact in both scientific labs and industry. The chemical formula of 1-Vinylimidazole is C5H6N2. In its structure, you'll find an imidazole ring—a five-membered aromatic ring holding three carbons and two nitrogens. Attached directly to the nitrogen at the first position sits a vinyl group (–CH=CH2).

This vinyl group brings reactivity. The imidazole ring itself—shared with the bases found in DNA—offers some unique electron characteristics. Chemists have long known that the arrangement of atoms in 1-vinylimidazole creates a smart mix of rigidity from the aromatic system and flexibility from the vinyl side chain. That design invites all sorts of custom applications, from polymer science to fine chemicals.

Why Chemical Structure Matters

For chemists, the placement of each atom points toward how a molecule will behave. The double bond in the vinyl end gives options for polymerization. Researchers can string these molecules together in water-based processes, something much greener compared to traditional petrochemicals. The aromatic imidazole ring keeps the molecule resistant to breakdown and helps anchor it in all sorts of conditions, not just lab glassware.

Having worked on lab teams focused on functional monomers, I've seen people pick 1-vinylimidazole not just for its reactivity, but for its ability to adjust pH or bind selectively to certain metals. Students sometimes brush past these subtle details, but companies looking to design specialty coatings or hydrogels know that one small change in a ring or side group shapes the whole game.

The Relevance of 1-Vinylimidazole

A lot of industries lean on 1-vinylimidazole for solid reasons. Its imidazole backbone thrives in the world of ion-exchange resins, water treatment, and even pharmacy research. The vinyl side acts as a door for further reactions, which means it dodges obsolescence in a market where companies need building blocks that work in mass manufacturing and precise syntheses alike.

Numbers show growing interest, too. According to ChemSpider and PubChem, request rates for technical data and sourcing keep climbing. Chemical suppliers list 1-vinylimidazole as a popular specialty intermediate, with the major producers based in both the United States and Asia. MSDS documents highlight the importance of respecting its strong odor and skin sensitivity, so attention to safety standards keeps things running smoothly.

Building a Safer and Smarter Use

Safer handling and clear labeling remain central. From my work in lab safety committees, measures like local ventilation, nitrile gloves, and label clarity help prevent unnecessary exposure. For greener chemistry, exploring biosourced precursors for such monomers could drive the field forward. Research teams can experiment with natural feedstocks to lower the overall footprint of vinylimidazole production.

Training sessions focused on both young bench chemists and experienced workers make a difference. Experience tells me that regular reviews and hands-on training catch mistakes before they happen. In the future, more transparent reporting of supply chain impacts and broader open data sharing will let innovators improve both safety and sustainability.

Understanding 1-Vinylimidazole

1-Vinylimidazole pops up in labs and industrial settings, finding its way into adhesives, coatings, and even some advanced resins. This chemical isn’t as familiar as common solvents or plastics, but it shows up in places where specialty chemistry drives product innovation. I remember reading several safety data sheets during grad school; chemicals like this always raised a few eyebrows, especially when nobody could pronounce their names the same way twice.

What Science Says About Risks

Diving into published research, 1-vinylimidazole indicates some real safety warnings. The safety data from the European Chemicals Agency shows respiratory irritation. Inhalation can lead to sore throats or headaches. Eye contact burns. Skin contact sometimes leads to redness or itching. Chronic exposure hasn’t been linked with cancer or major long-term illness, but it’s never wise to roll the dice. Sometimes just an hour in an organic chemistry lab is enough to teach anyone why chemical gloves matter.

The U.S. National Library of Medicine signals that the acute toxicity, based on animal studies, sits in the moderate range. Swallowing even small amounts causes internal discomfort—none of us want to be guinea pigs for that, especially with obscure industrial chemicals. The vapor isn’t especially pungent, but sensitive folks develop headaches or dizziness if ventilation lacks. There’s no excuse for finding out the hard way that chemical fumes can make your skin crawl.

The Problem with Chemical Exposure

Reading reports from workers using 1-vinylimidazole, it’s easy to see patterns in chemical safety. The chemical finds its way into adhesives used on labels or medical devices. People may not realize there’s a hazardous chemical on those plant floors—bad ventilation, bare hands, a missed label or two. Just about everyone knows someone who’s developed sensitivity to workplace solvents or has walked away from work with a weird rash. I remember my own mild chemical burn in a lab—one bad glove and you never forget the lesson.

That’s not to say the chemical poisons every worker instantly. The danger comes from repeated or badly managed exposure. Many stories from industrial plants highlight poor personal protective equipment. Spraying adhesives in a tight room without a mask leads to stinging eyes, rough throats. If management shrugs off those risks, real problems brew over years—not just for staff but for the environment when chemicals spill or are disposed improperly.

How to Stay Safe

Working around 1-vinylimidazole, basic chemical hygiene matters. Chemical-resistant gloves (nitrile trumps latex for most solvents), splash goggles, and airy workspaces cut the risk. Labeling containers clearly helps the next shift avoid mistakes. In better-run facilities, engineers routinely test the air and analyze exposure levels. I keep hearing from industry old-timers that good ventilation and basic respect for the unknown keep more folks healthy than any fancy guideline document.

Many companies train staff with real-world examples, not just theory. Spill kits, eyewash stations, and emergency plans can’t just collect dust in corners. If people handle chemicals, practical drills and honest risk assessment go further than posters or memos ever will.

Simple Solutions, Real Outcomes

Modern labs and factories do their best by mandating protective gear, updating protocols, and encouraging a safety culture. Government watchdogs should keep an eye on chemical suppliers, especially as new uses pop up. Workers shouldn’t have to wonder if that headache after a late shift signals something more serious.

Smart safety never overcomplicates things: don’t breathe it, don’t touch it, don’t get lazy about labeling. That’s how everyone stays out of trouble, even with chemicals as tricky as 1-vinylimidazole working behind the scenes.

Understanding the Chemical

1-Vinylimidazole comes up often in labs focused on polymer chemistry, coatings, and adhesives. The liquid gives off a strong, fishy scent and evaporates into fumes that can quickly irritate skin and eyes. In my experience, small spills feel serious right away, reminding me that it doesn’t take a major leak to cause problems. It’s a chemical that always made me double-check my gloves and fume hood before starting any weighing or transfers.

Eyeing Potential Hazards

The dangers around 1-vinylimidazole line up with other imidazoles. Vapors irritate eyes and the respiratory tract even during brief exposure, and direct skin contact leads to redness, itching, and burns. The liquid also catches fire more easily than water boils. Factory safety data sheets back this up—showing flash points below 85°C and classifying it as harmful if inhaled or swallowed. There’s no excuse for skipping lab coats, gloves, and goggles. Even on a rushed day, safety always comes first.

Trusting the Right Storage Methods

I’ve learned that temperature and moisture control matter most for this chemical. 1-vinylimidazole doesn’t handle water exposure well—trace moisture kicks off unwanted reactions and spoils its use in specialty applications. A sealed amber glass bottle, tightly capped and tucked in a dry cabinet, keeps air and light from creeping in. In shared spaces, I’ve seen too many bottles clumped by the door, easy for someone to knock over. The best practice keeps flammable liquids like this in a vented chemical storage cabinet, away from oxidizers and acids. Labeling stays visible and clear, even after months on the shelf.

Safe Practices in Handling

Preparation always takes priority before opening any fresh container. I map out the transfer steps, check that the fume hood draw stays strong, and keep spill kits close by. Pipetting by mouth never crosses my mind. For small volumes, disposable plastic syringes or wide-bore pipettes work well, letting me avoid splashes or drips. Gloves go on first, and they’re made of nitrile or butyl rubber—not latex. I remember one coworker rushing, choosing bare hands “just for a minute.” He got a rash that lingered for days.

Managing Accidents and Waste

Minor spills bring plenty of trouble. Absorbents such as vermiculite soak it up, but it’s the aftermath—bagging the waste, labeling it as hazardous—that often gets skipped. Ventilating the room helps clear away vapors, but only proper disposal sends the risk out the door. For glassware and pipettes, a thorough initial rinse with acetone limits residue, then everything heads to the hazardous waste stream. Leaving even a small crust of material behind can mess up the cleaning crew’s day.

Working Toward Fewer Incidents

Safety doesn’t come from a manual—habits make the biggest difference. Keeping storage areas tidy, double-checking PPE, updating labels, and reviewing procedures go further than the strictest rules on paper. Clear training for newcomers and honest conversations when accidents happen create a culture where mistakes don’t get hidden. If you handle 1-vinylimidazole, stay cautious, plan ahead, and treat even small amounts with respect. Fact-based decision making, paired with hands-on habits, builds trust between people and their workspaces.

Why 1-Vinylimidazole Draws Industry Attention

More often, industries and research labs reach for 1-vinylimidazole due to its crucial role in creating specialty polymers, improving adhesives, or developing advanced coatings. It carries a vinyl group on its imidazole ring, giving it the reactive push needed for a range of chemical processes. In practice, the efficiency and purity of synthesis matter as much as making the compound itself. Poor choices or careless steps lead to impurities, wasted materials, and lost time—a headache for anyone in the lab or on the production floor.

Two Pathways Stand Out

People often ask about the most straightforward approach in the lab. Most chemists rely on the alkylation of imidazole with acetylene or a vinyl halide, as these tend to balance accessibility, cost, and cleanliness.

The Acetylene Route

Imidazole reacts with acetylene in the presence of a strong base like potassium hydroxide. The chemistry looks simple:Imidazole + Acetylene + KOH → 1-Vinylimidazole + H2O

The base pulls a proton from the nitrogen, making it a better nucleophile, and the acetylene acts as the electrophile. This classic method survives years of lab work because acetylene feeds are cheap, and the necessary base sits on most chemical storeroom shelves. Still, working with pressurized acetylene can be a fire hazard, and the gear needs regular checks to prevent leaks.

Vinyl Halide Method

Another choice uses a vinyl halide like vinyl bromide or vinyl chloride in the presence of a base. This nucleophilic substitution lets the nitrogen in imidazole attack the carbon attached to the halide. Labs prefer this method when handling gases isn’t practical, or regulation clamps down on acetylene use.

Resourceful researchers sometimes turn to phase-transfer catalysis or vary the solvent to push the yields higher. Still, this road can drag in more side-products if the vinyl halide has impurities. Handling halides raises its own set of safety and environmental rules.

Common Headaches in Synthesis

No process flows perfectly. Polymerization hovers as the biggest risk. Vinyl groups love to react with themselves under the wrong conditions, leading to sticky messes or gunked-up reactors. Oxygen and heat both push cure rates faster, so labs set up inert atmospheres or add inhibitors.

Maintaining temperature and pH gives another set of worries. Too much heat, or the wrong pH swing, and the yield falls or impurities sneak in. Running small batches helps solve scale-up headaches, but commercial outfits still need to wrestle with variables.

The Push for Greener Reactions

Modern synthesis demands more than just making product; environmental groups and green chemistry guidelines stand watch. Many researchers try water-based systems, ionic liquids, or finely-tuned catalysts to shed unwanted byproducts. Reducing solvent waste and power use not only trims costs but also earns trust with regulators and clients who track environmental footprints closely.

Looking Forward

Knowing the main synthetic routes for 1-vinylimidazole means researchers and manufacturers can choose wisely for their own setups. They weigh purity against cost, safety against efficiency, and regulatory pressure against tradition. The best chemists adapt. They watch for new methods, like continuous-flow processes or cleaner catalytic systems, to make this workhorse easier to access, safer to produce, and less of a burden on the wider world.