10-Bromodecanoic Acid: Exploring a Niche Chemical with Big Implications

Historical Development

Back in the early twentieth century, chemists never stopped digging for new derivatives that could handle more precise transformations. 10-Bromodecanoic acid surfaced as a natural extension of carboxylic acids chemistry, building off advances in halogenation methods developed in the labs buzzing across Europe and North America. Gradually, improvements in bromination techniques improved yields and purity, paving the way for further biochemical research. As synthetic chemistry picked up, researchers started to recognize the potential of brominated fatty acids — a niche family at the crossroads of organic synthesis, surfactant creation, and biochemistry modeling.

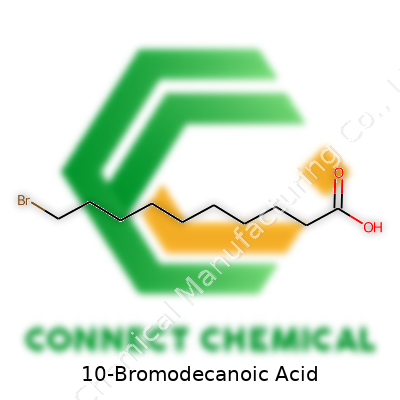

Product Overview

The molecule carries a straightforward formula: a ten-carbon chain capped with a carboxylic acid at one end and a bromine atom stuck to the tenth carbon at the other. The presence of bromine makes it reactive, useful, and a bit tricky to handle. Suppliers provide it in the form of a crystalline powder or flakes. Chemists reach for it when constructing compounds where they want a controlled spot for reactivity, or when modeling biological fatty acids that need halogen tags. Industrial users tap it to create surfactants, intermediates, and specialty reagents, anchoring processes that stretch from pharmaceuticals to materials science.

Physical & Chemical Properties

10-Bromodecanoic acid doesn’t blend in like your typical aliphatic acid. It brings a dense molecular weight—around 263 grams per mole—and a melting point that hovers near 48-52°C, which proves handy for certain purification methods. Bromine adds heft and makes the compound less volatile than sister decanoic acids. It dissolves well in alcohols and ethers but barely stirs in water, a reflection of its long hydrophobic chain. Chemists appreciate its stability at room temperature, but the molecule stays sensitive to strong bases or reducing agents, thanks to that bromine atom sitting at the far end.

Technical Specifications & Labeling

Quality assurance matters every time a specialty chemical gets ordered. For 10-bromodecanoic acid, manufacturers and labs check the purity—often aiming for levels past 98%—using gas chromatography or NMR. Labels mark the CAS number, formula (C10H19BrO2), and often a batch code for traceability. Product sheets highlight shelf life, recommended storage (dry, cool, out of direct sunlight), and precautions for safe handling. Industry standards require clear identification of hazards, with pictograms and UN classification for transport since regulations for halogenated organics can be strict.

Preparation Method

Anyone who’s spent time in a synthetic lab knows the method for these acids usually involves classic carboxylation or oxidation, followed by a bromination step. One common path starts with decanoic acid, then uses phosphorus tribromide or N-bromosuccinimide to swap a terminal hydrogen for a bromine atom. Reaction temperatures, solvents, and durations all shape the final yield. Washing, recrystallization, and vacuum drying step up the purity. Even small tweaks in protocol can push yields higher or drop unwanted side-products, so process improvement never really ends in labs making this chemical at scale or pilot size.

Chemical Reactions & Modifications

There’s a lot you can do with an alkyl bromide at the tail end of a fatty acid. Nucleophilic substitutions let a chemist swap that bromine for nearly any functional group: thiols, amines, or azide for tracing in biological assays. Oxidative reactions eat away at the terminal group, transforming the acid or launching it into ring closure schemes. Researchers often reach for 10-bromodecanoic acid as a building block—attaching fluorescent probes, linking bioactive fragments, or creating new surfactants and detergents for protein extraction. Catalytic methods are opening new doors, letting more complex manipulations take place under milder conditions, which cuts down on side reactions and waste.

Synonyms & Product Names

Chemists and suppliers recognize this molecule under several names. Besides “10-bromodecanoic acid,” databases list it as “decanoic acid, 10-bromo-” or “capric acid, 10-bromo derivative.” Some catalogs abbreviate it as “BDA” or give alternative IUPAC formats. These aliases can cause headaches if someone’s not careful with orders, so double-checking catalog numbers and molecular weights helps to avoid mistakes or mix-ups. Listing synonyms and trade names on labels and Safety Data Sheets keeps communication clear between manufacturers, buyers, and regulators.

Safety & Operational Standards

Anyone handling 10-bromodecanoic acid needs to keep safety top of mind. That bromine atom gives it a bit more punch than plain decanoic acid, raising the risk for skin and respiratory irritation. Labs require goggles, gloves, long sleeves, and strong ventilation. Storage in sealed containers away from moisture protects both product integrity and people working nearby. Accidental spills demand swift clean-up with appropriate neutralizing agents and personal protective equipment, since halogenated organics have an unfortunate record for causing problems if mishandled. Disposal has to follow local hazardous waste protocols—no washing it down the drain or mixing with incompatible materials that might trigger unwanted exothermic reactions.

Application Area

The uses of 10-bromodecanoic acid stretch far beyond basic organic synthesis classes. Surfactant manufacturers tap it as a key ingredient when tailoring chemical properties for emulsifiers or specialty cleaning products. Pharmaceutical developers seek it for targeted linker chemistry—its reactive “bromo” tag lets them graft the acid to complex drug molecules or tracking isotopes. Biochemists run experiments with it as a model for fatty acid metabolism, especially when probing how halogenated lipids interact with proteins or membranes. In material science, it plugs into polymer chemistry as a length-tunable monomer where a functional end-group opens up countless design possibilities.

Research & Development

Research into 10-bromodecanoic acid draws interest because of its versatility and reactivity. Academic labs keep exploring novel substitutions on the bromine, searching for new ligands or surfactant families. The pharmaceutical world watches how such substitutions affect biodegradation or bioavailability in the body. Environmental chemists model the fate of halogenated acids, measuring how long they last in soil and water, and what kind of breakdown products emerge. These studies feed directly into product stewardship—material makers need to know both benefits and lifecycle implications, especially as responsible sourcing and green chemistry shape new projects.

Toxicity Research

Toxicologists and regulatory experts have put 10-bromodecanoic acid under the microscope, following the trail of halogenated organics that sometimes bring health and environmental risks. Animal studies suggest that short-term irritation can hit the skin or respiratory system, but data on long-term effects still remains limited. Bioaccumulation rates don’t look as dire as some persistent organic pollutants, though caution stays warranted given the molecule’s resistance to rapid breakdown. Regulatory agencies keep updating guidance based on new animal studies, in vitro models, and environmental monitoring. Lab workers know to limit exposure and wear protection, leaning on a track record of research that guards against surprises.

Future Prospects

Interest in 10-bromodecanoic acid keeps rising, thanks to innovation in specialty chemicals, surfactants, and drug design. Advances in green chemistry may soon deliver less toxic, more sustainable bromination routes, reducing costs and the environmental footprint. Analytical technology could build on existing methods, letting trace detection or in situ reaction monitoring become routine and more accurate. On the research front, attention to the fate and transformation of brominated fatty acids in living systems will shape both industrial guidelines and medical applications. Collaboration between academia and business stands as the best hope for responsible growth, forging paths toward safer, more efficient products that use this underappreciated molecule to its full potential.

Understanding the Building Blocks

Chemists lean on structure to predict how a compound behaves and interacts. 10-Bromodecanoic acid gives a real-world example of that. This molecule lines up as a ten-carbon chain, carrying both a carboxylic acid group on one end and a bromine atom ten carbons down the road. Written out, you’ll spot it as Br(CH2)9COOH, or structurally, as a string of carbon atoms where bromine replaces one of the hydrogens on the far end of the chain.

Think about it like this: decanoic acid lays the foundation with a backbone of ten carbon atoms. Attach a bromine atom to that last carbon, and suddenly, you’ve got something with new chemical potential. The carboxylic acid group (–COOH) points to water solubility at the tip, and adding bromine opens the door for the molecule to be used as a stepping stone in more complex syntheses.

The Impact of Halogenation

I’ve seen how a single halogen swap, like adding bromine, changes how a molecule behaves in the lab. You might look at decanoic acid and see an oily, relatively inert acid, but with bromine tagging along, things turn reactive. The bromine atom makes the molecule a better candidate for other transformations—chemists often reach for compounds like this to build larger molecules for pharmaceuticals or specialty chemicals.

Having bromine at the end of the chain increases its weight and changes its interactions with biological systems or other chemicals. That’s why the pharmaceutical business looks at molecules like this with keen interest. The halogen can bump up the bioactivity or offer new ways to tailor drugs, though it also demands respect for safety due to increased reactivity.

Real-World Relevance in Industry and Research

I remember working on a project where the whole aim was to make new surfactants. We leaned on long-chain acids, tweaking pieces here and there. Adding bromine onto the tail shifted how the molecule grouped with others in solution. The lesson: tweak the structure, watch the properties shift, and open up new applications.

Synthetic chemists use 10-bromodecanoic acid as a starting point. The bromine acts like a hitch—other groups can be swapped at this position using substitution reactions. That versatility speeds up the creation of new compounds, and it means that a research team can experiment with different functional groups quickly.

Material science teams pay attention as well. Functionalizing solid surfaces or introducing precise anchors for further reactions can work better with a handle like the bromine on this molecule. That accuracy matters for designing smarter materials and making industrial processes more efficient.

Practical Solutions and Safer Handling

Anyone in the lab with 10-bromodecanoic acid needs solid safety ground knowledge. Brominated compounds pack more reactivity and possible toxicity compared to their non-halogen cousins. Gloves and proper ventilation aren’t optional. Chemical waste handling ramps up, with environmental regulations pushing for careful disposal, since halogen-containing organic compounds can persist in nature.

Thinking about solutions, greener chemistry offers pathways through better reaction schemes—those that cut out harsh solvents or recycle brominated by-products. Labs adopt smaller-scale synthesis where possible, using just enough brominated acid for research without piling up hazardous leftovers.

In teaching settings, breaking down the structure of 10-bromodecanoic acid offers a model for how chemistry connects lab bench work to real outcomes, from drug development to new materials. Molecules like this drive home the power, promise, and responsibility of chemistry at every level.

Understanding the Value in Laboratories

Anyone who’s followed developments in organic chemistry knows certain molecules stand out for the flexibility they provide. 10-Bromodecanoic acid falls into this group, serving as a popular building block in the laboratory. Chemists use it to build more complex molecules, and its long carbon chain with a bromine atom gives it special properties that make reactions easier to control and predict. The acid group not only lets it dissolve in water but also allows for a lot of chemical modifications, which is essential for research that’s always pushing for new molecules or better drugs.

Role in Pharmaceutical Discovery

Drug research leans heavily on compounds like 10-Bromodecanoic acid. Medicinal chemists often turn to it because its bromine acts as a convenient handle—they can swap it out for other atoms or groups at different steps in making new drug candidates. This flexibility means more efficient ways to test and develop medicines. One good example shows up in the design of molecules targeting fatty acid pathways. Small chemical tweaks on molecules like this have led to real progress in experimental treatments, especially for metabolic and neurological disorders.

Use in Creating Surfactants and Functional Materials

Industrial chemistry often borrows from lab discoveries, and 10-Bromodecanoic acid has found a place in making specialty surfactants—materials that lower surface tension and help products mix better. Thanks to its structure, this acid can be transformed into molecules that help oil and water blend, which is essential in cleaning products and cosmetics. Researchers also use it as a stepping stone to create new materials used in coatings, lubricants, or even nanotechnology. These practical uses grow out of its unique chemical features: the bromine atom helps start reactions that put the molecule together in just the right way.

Contribution to Biochemical Research

Lab studies looking at how proteins or enzymes behave often need simple, dependable chemical tools. 10-Bromodecanoic acid fits well here, especially in work related to fatty acids in cells. Scientists can track how certain enzymes process this acid, which helps uncover what goes wrong in some diseases. Since the molecule can mimic natural substances the body uses, it lets researchers probe biological pathways safely and effectively. The insights gained help push forward both academic knowledge and the long process of drug development.

Potential for Safer and Greener Chemistry

Environmental impact has become a larger part of every conversation around chemical manufacturing. 10-Bromodecanoic acid offers some clear opportunities for cleaner processes. Its reliable reactivity means fewer unwanted byproducts show up, which cuts down on chemical waste and lowers costs for purifying products. In my experience, working with substances that have predictable chemistry can make lab work easier and safer—for both people and the environment. Finding smart ways to apply this kind of molecule can contribute to a future where chemistry supports health and industry without causing harm.

Moving Forward: The Balance of Science and Usefulness

10-Bromodecanoic acid stands as a reminder that even basic chemicals can make a big impact. Across pharmaceuticals, materials science, and lab research, it powers discovery and helps practical problems find solutions. This type of chemical flexibility and accessibility encourages broader participation in both science and engineering. With more researchers sharing knowledge and experience, applications for such molecules will only keep growing.

Purity Levels: More Than Just a Number

Shoppers want to know what they’re getting, especially if the purchase concerns food ingredients, lab chemicals, or pharmaceuticals. Purity isn’t just a buzzword—it’s the main measure of a material’s fitness for serious applications. For something like analytical testing or research, purity at 99.9% and higher makes a real difference. In real-world terms, impurity often spells trouble: think unexpected reactions or skewed lab results. I’ve seen projects go sideways just because someone used off-the-shelf stock instead of a high-purity alternative. In specialty industries, small variability trips up entire production stages and loses both time and money.

For most customer needs, purity ranges run from “food grade” (which meets basic safety) up through “pharmaceutical grade,” topping out at “analytical grade.” It isn’t uncommon for research teams to insist on 99.5%, 99.9%, or higher, depending on regulatory pressure or the need for reliable data. Food manufacturers lean on certifications and reliable lot analyses, while labs ask for certificates of analysis and batch traceability. Questions about residual solvents, heavy metals, or even unwanted moisture remain at the core of every large order. Supply partners who dodge these topics rarely get a callback.

Packaging Sizes: The Realities of Buying and Using

Package sizing draws less attention—until you’re stuck with leftovers, high shipping costs, or worse, run short mid-project. In my experience, the sweet spot depends on who buys and how they plan to use it. Research labs often want small vials, bottles, or individual pouches. Their budgets don’t stretch to bulk purchases, and they prefer to avoid waste. On the other hand, manufacturers choose heavyweight bags, sacks, drums, or totes, measured in kilograms or tons.

Selling in small bottles means increased handling and packaging waste, but it’s the only way for startups or pilot programs to stretch limited funds. Some companies now offer flexible pouches and smart seals. These stop moisture, hold freshness, and let you reseal after opening. A few large chemical and food-grade suppliers even pack product under inert gases—helpful in sensitive blends or highly reactive formulations.

Transparency and Trust: What Informed Sourcing Looks Like

Well-documented specifications remain the only way for buyers to sort out what’s hype and what’s real. I’ve worked with teams who wouldn’t take delivery unless the product came with full analysis, heavy metal screening, and a clear record of packaging conditions. Buyers and regulators increasingly expect digital access to these records before agreeing to significant transactions.

There’s been welcome pressure on companies to avoid bulk deals with vague specs or missing batch information. If customers don’t get honest answers on purity, they go elsewhere. Professional standards, from ISO certifications to third-party audits, hold suppliers to account. In high-stakes fields—the kind that track every milligram—skimping on documentation risks recalls, distrust, and expensive downtime.

Pushing for Better Solutions

Some suppliers try innovations in both analysis and packaging. Digital lot tracking, blockchain certification, and tamper-proof packaging come up in conversations with forward-looking buyers. Packaging that shrinks shipping costs and stops contamination improves more than just the bottom line. A few years back, a vendor introduced a returnable drum program for bulk buyers—a move that cut landfill waste, shipping delays, and client headaches.

Better solutions start with listening to actual users about what they want in purity confirmation and how much product they can actually handle. Adaptation to supply realities—shortages, transport limits, regulatory shifts—separates long-term partners from fly-by-night operators. In my work, the most reliable suppliers combine detailed reporting with real flexibility in packaging and honest talk about what can and can’t be guaranteed. In the end, knowing what’s inside—and how much—matters more than any marketing slogan.

Taking Chemical Safety Seriously

Everyone talks about chemical safety. Sometimes it sounds routine, like something to check off a list. The truth is, a single misstep with something like 10-Bromodecanoic Acid can spark a big problem fast. This stuff finds its way into research labs, manufacturing, and specialty synthesis, and once a bottle lands in your hands, you’d better pay attention. If you’ve ever worked in a lab past midnight with one eye on your work and the other on the clock, you know what small mistakes cost. Nobody wants to deal with skin burns, chemical exposure, or environmental headaches.

What Makes 10-Bromodecanoic Acid A Hazard?

The main concern with this acid is its corrosive bite. It’s got an irritating effect on skin and eyes, and fumes can lead to coughing or worse if inhaled directly. I’ve seen peers take shortcuts with gloves or skip the fume hood to “save time.” They started out confident, but ended with red, stinging hands at best, and sometimes an emergency rinse at the eyewash station. It’s much easier to prevent problems than try to fix them after the fact.

Storage Steps that Matter

Anyone who’s cleaned up after a broken chemical bottle knows that proper storage beats any fast fix later. Keep this compound sealed tight, preferably in a glass container with a clearly marked label. Store it away from direct sunlight, at room temperature, and definitely away from water and bases, since these trigger unwanted reactions. Ventilated, dry shelving locked and reserved for corrosives keeps things safer for everyone in the lab. I’ve lost count of stories about people reaching for something unmarked or stored wrong, only to get an unhealthy surprise. It's amazing how many headaches get avoided just by using a well-organized cabinet and sturdy secondary containment trays.

Protect Yourself Every Step

Personal protective gear can feel like a nuisance, but nobody wants to explain a chemical burn to a doctor. Nitrile gloves, a lab coat, and goggles become your frontline defense. Always handle this acid inside a chemical fume hood, not out in open air. Make sure there’s ready access to an eyewash station and safety shower, just in case. I once had a mentor who kept a bottle of skin-safe neutralizer within reach just for peace of mind. Simple routines—checking expiration dates, examining seals, and cleaning up spills right away—make the difference between routine and disaster.

What If Something Goes Wrong?

Small spills happen, so good lab teams keep spill kits close by. Neutralizing acids swiftly and disposing of waste following local regulations keeps contaminants out of drains and landfills. I’ve seen labs skip documentation for minor spills, thinking nobody notices. That’s how risks build up. Log everything, because records help spot bad patterns before they become accidents.

Building a Culture of Safety

Training must be real and hands-on, not just paperwork. Sharing close-call stories, reviewing safety data sheets, and practicing spill responses together gives everyone a reason to stay sharp. Google’s E-E-A-T principles emphasize actual expertise and trust. People listen to those who’ve handled chemicals for years and have the scars—and clean record books—to prove it. Honest talk about the risks inspires respect more than any generic poster could. In every research group and company, keeping each other safe with smart habits never goes out of style.

Why 10-Bromodecanoic Acid Needs Respect

Some chemicals demand a kind of built-in caution. 10-Bromodecanoic acid, a specialty chemical often found in labs and niche industrial settings, falls in that group. With its haloalkane structure, it brings both corrosive and irritant risks that require solid awareness on the ground—especially for those mixing, pouring, or cleaning up after a spill. Over the years, repeated exposure to problem chemicals like this one has taught me never to drop my guard in the workplace. Safety starts with respect for what a compound can do, especially if you’ve got a bad track record with skin reactions, respiratory problems or eye sensitivities.

Common Hazards: What You’re Dealing With

The biggest safety concern is its skin and eye irritant potential. Even minor spills or splashes provoke itching, redness, and sometimes blistering. Breathing in its dust or fumes isn’t wise either. Acute exposure can trigger coughing, sore throat, and in rare doses, even shortness of breath. Swallowing is a whole different level of risk; gastrointestinal discomfort and chemical burns may follow. From handling sample vials to topping up a reactor, it’s not always easy to keep your skin and eyes out of the crossfire. In my lab experience, gloves alone aren’t always enough—one slip with a pipette, and you feel the mistake.

The material also brings mild environmental concerns. Its persistence in water or soil demands responsible disposal, and yet the real threat—especially for those of us working directly with such reagents—remains personal exposure. Knowing the symptoms and acting fast beats any warning label printed on the bottle.

Personal Protective Steps Everyone Should Use

Chemical splash goggles. Nitrile gloves. Closed shoes. These must be non-negotiable. Adding a long-sleeve coat reduces the chance for skin contact. Chemical fume hoods make a difference, even for quick weighing or dilution steps. I once saw a colleague dodge a nasty face splash thanks to a shield—simple barriers save big headaches.

Good ventilation helps protect everyone, not just the person at the bench. Avoid eating, drinking, or even reaching for your phone with contaminated gloves. Simple routines like these help keep hazardous encounters rare.

First Aid Measures: Straightforward, Not Optional

Skin contact: Get to running water and wash for at least 15 minutes. Ring for medical help if symptoms stick around. Eye splash: Same deal, but keep the eyelids open under tepid flow. Never rub, and seek medical evaluation. Inhalation: Immediately move to fresh air. Shallow breathing or hoarseness shouldn’t be ignored—a spot at the nurse’s or local clinic can catch more hidden injuries. Ingestion: Rinse the mouth. Don’t force vomiting unless a doctor tells you. Rapid response can keep a minor accident from turning major.

Workplace Improvements and Smarter Habits

Training matters just as much as PPE. Anyone working with 10-bromodecanoic acid should go through yearly safety refreshers, not just the newcomers. Clear labeling, spill cleanup kits nearby, and real, hands-on drills outpace any written protocols. If your supervisor hasn’t checked the fume hood airflow in months, ask for a test. Push for spill containment gear that suits the real scale of your workspace. Safety signage and first aid stations need regular restocking.

After seeing more than one avoidable accident, I’ll always say the right habits and proper tools beat luck every time. This compound, like many in a lab or factory, rewards respect and punishes shortcuts.