2-(2-Bromoethyl)-1,3-Dioxane: An In-Depth Commentary

Historical Development

Chemists started tinkering with dioxane rings in the early 20th century while looking for more flexible building blocks in organic synthesis. Through decades of research, the demand for functionalized dioxanes rose, and the idea to add a 2-bromoethyl arm grew out of the need for selective reactivity; bromine offered an effective leaving group for nucleophilic substitution. Researchers valued compounds like 2-(2-Bromoethyl)-1,3-dioxane for their versatility. By the 1960s, several specialty chemical manufacturers refined protocols to boost yield and purity, and lab syntheses started popping up in patent literature. At the bench, few other molecules with a six-membered oxygen ring and a bromoethyl handle saw as much adaptation in fine and specialty chemical labs.

Product Overview

2-(2-Bromoethyl)-1,3-dioxane falls under the haloalkyl-dioxane family. Chemists working in pharmaceutical and agrochemical pipelines count on its unique ability to combine the dioxane ring’s stability with the bromoethyl moiety’s efficient reactivity. It crops up often as a choice precursor for designing protected intermediates, making it useful for transforming more sensitive groups further downstream in a synthesis. Unlike many other bromoalkanes, the presence of two oxygens within the ring structure impacts both electron density and ring conformation, leading to certain selectivity benefits.

Physical & Chemical Properties

The compound exists as a colorless liquid at room temperature. It has a slightly sweet yet ether-like odor, owing to its dioxane backbone. The boiling point hovers around 85-90°C at 3 mm Hg, but it decomposes somewhat around 220°C under atmospheric pressure. 2-(2-Bromoethyl)-1,3-dioxane dissolves well in organic solvents such as dichloromethane, toluene, or ethyl acetate. Its density stands near 1.45 g/cm³, higher than most common solvents, reflecting the bromine atom’s heft. Moisture doesn’t hydrolyze it quickly; the dioxane ring shields the bromoethyl group. Still, strong acids or bases and especially nucleophilic conditions (such as alcohols or amines) attack the bromo site, producing a wide range of derivatives.

Technical Specifications & Labeling

Vendors provide this compound with purity levels over 98% as determined by gas chromatography. Most bottles display the molecular formula C6H11BrO2 with a molecular weight of around 195.06 g/mol. Labels often note its sensitive nature to strong light, which can cause slow decomposition, so suppliers pack it in amber vials and recommend cold storage. The Safety Data Sheet flags it as hazardous and provides information about inhalation, ingestion, skin, and eye contact. Labels include signal words “Warning” or “Danger” alongside eye and skin hazard pictograms, reflecting a careful approach toward handling. Detailed lot analyses accompany most shipments, showing water content, residual solvents, and major volatiles, supporting the trust between buyers and sellers.

Preparation Method

Method development for synthesizing 2-(2-bromoethyl)-1,3-dioxane usually starts with acetalization between ethylene glycol and an appropriate bromoaldehyde or bromohydrin under acid catalysis. Some labs use the one-pot route, combining 1,3-dioxane ring formation and selective bromination by treating the parent alcohol with N-bromosuccinimide or phosphorus tribromide. Controlling reaction temperature prevents side reactions and degradation, and solvent choice—often dichloromethane or acetonitrile—affects yield and selectivity. Once the process is dialed in, flash column chromatography typically purifies the product, separating out any starting alcohol and side products. Each synthetic run generates a substantial solid waste and halide byproducts, putting a premium on efficient waste treatment. Environmental stewardship starts with these choices in the prep room.

Chemical Reactions & Modifications

Chemists turn to 2-(2-Bromoethyl)-1,3-dioxane because that bromo group opens a path to a long list of nucleophilic substitutions and couplings. Reacting this compound with alkoxides, amines, or even thiols swaps out the bromine cleanly, yielding the corresponding ethers, amines, or thioethers. In one of my own projects, we needed a masked diol; converting this molecule’s bromoethyl end to a hydroxyethyl group provided the right balance between reactivity and protection. Transition-metal catalyzed couplings, like Suzuki or Heck reactions, haven’t shown the same efficiency here—few examples survive under those less-mild conditions. Down the road, hydrolyzing the dioxane core across mild acid releases ethylene glycol and the new substituted moiety, delivering building blocks for peptide, oligonucleotide, or other complex organic work. That ability to unmask and convert intermediates on demand gives this molecule a flexible niche in the synthetic chemist’s cabinet.

Synonyms & Product Names

Over the years, catalog listings and literature refer to this compound using several names, each reflecting distinct naming traditions. "2-(2-Bromoethyl)-1,3-dioxane" sticks as the main IUPAC-compliant label in modern chemical catalogs. Some technical bulletins name it simply as "beta-bromoethyl-dioxane" or "dioxane-bromoalkyl ether." Historical records, especially in Russian and German patent filings, refer to "1,3-dioxan-2-yl-bromoethane," a clue for researchers sifting older studies and foreign data. To avoid miscommunication, most major chemical suppliers now include a list of synonyms and CAS number on their order pages.

Safety & Operational Standards

This compound calls for careful handling. Skin and eye irritation happens even at low exposures, and the risk of respiratory irritation means a fume hood forms part of any work protocol. I still remember spotting oily spots on the gloves after handling a similar bromoalkyl compound, learning quickly to double-glove and ventilate. OSHA and EU rules classify the compound as hazardous, and handling procedures suggest nitrile gloves, splash goggles, and chemical-resistant aprons. Labs store it away from acids, bases, and sources of ignition. Spill kits with absorbent materials stay close, especially given the slipperiness and volatility of small bromoalkanes. Safety audits check for spill records and proper segregated storage, which reduces accidents and long-term exposure risks.

Application Area

Pharmaceutical teams and materials chemists draw on 2-(2-Bromoethyl)-1,3-dioxane for its dual roles in protection and modification. The dioxane ring protects diols and similar groups, letting complex syntheses proceed without unwanted side reactions. In one university project I saw, researchers used it to install protected handles on sugars, freeing up other groups for phosphorylation without cross-reactivity. Agrochemical developers use it to introduce functionality at a defined carbon center, simplifying structure-activity relationship studies. Material scientists find occasional use as a monomer modifier or a cross-linking agent, especially in the creation of responsive polymer chains.

Research & Development

Academic and industrial labs still publish new uses for 2-(2-Bromoethyl)-1,3-dioxane, especially in asymmetric catalysis and macrocycle formation. One promising direction involves tweaking the substitution pattern to promote regioselectivity, useful in the design of prodrugs or molecular sensors. Collaborative teams, often spanning university–industry boundaries, combine this molecule with newly developed catalysts that encourage unique ring-opening or rearrangement reactions. Chromatography specialists develop better purification protocols, especially as more global labs—some with varied purity and batch standards—come to depend on this house-made intermediate. Modern R&D teams often analyze byproducts and genuine impurities by high-resolution NMR and GC-MS, finding that careful process monitoring brings better reproducibility.

Toxicity Research

Toxicologists focus on both acute and chronic risks tied to halogenated cyclic ethers. Animal studies, though limited, show that 2-(2-Bromoethyl)-1,3-dioxane acts as a moderate skin and mucous membrane irritant, and the dioxane skeleton raises questions related to potential carcinogenic breakdown products. Halogenated dioxanes resist quick metabolism, which means slow clearance after accidental ingestion or absorption; case reviews in poison control centers echo this point. Industry safety officers have updated SDS sheets in light of new toxicology data, stressing proper PPE and engineered controls. Some teams screen wastewater for halogenated byproducts, focusing on minimizing environmental contamination—a responsible move given public concerns about long-term health effects.

Future Prospects

Tomorrow’s chemists look for greener, more selective syntheses, and discussions around alternatives to halogenated protectants appear in many R&D meetings. Projects underway in process chemistry teams use flow reactors and milder reagents to cut down the hazardous waste linked to bromine chemistry. Still, the unique combination of reactivity and protection means that 2-(2-Bromoethyl)-1,3-dioxane will remain in toolkits for years, especially as custom reactions and on-demand syntheses shape the next wave of targeted drugs and specialty materials. Bridging the gap between tradition and innovation, this compound shows that a century-old molecule can still earn new roles in today’s challenging chemical landscape.

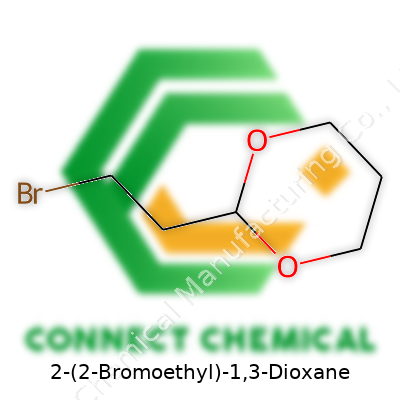

Breaking Down the Structure

2-(2-Bromoethyl)-1,3-dioxane brings together a unique arrangement of atoms. Its backbone is a six-membered ring with two oxygen atoms at the 1 and 3 positions—this gives the molecule a dioxane base. Dioxanes show up in many labs because their stability makes them useful building blocks. Attached to the second carbon on this ring is a two-carbon chain. This chain ends with a bromine atom hanging off the terminal carbon. The placement of that bromine is critical, influencing how the molecule reacts with other chemicals.

Why the Substitution Matters

Organic chemistry isn’t just about knowing which atoms are present—placement shapes everything. The 2-bromoethyl group on the dioxane ring introduces reactivity. Bromine isn’t shy; its presence on the chain encourages nucleophilic substitution. That means chemists get a chance to swap the bromine for other groups. This trick can make pharmaceutical agents, alter the properties of polymers, or create intermediates for agrochemicals.

Looking at the Uses

I remember my first year working in a lab and running a reaction where we tried to attach chlorine instead of bromine to a similar scaffold. We found that bromine’s larger size and weaker bond to carbon made reactions smoother and more predictable. This real-world advantage means compounds like 2-(2-Bromoethyl)-1,3-dioxane often show up as intermediates when researchers want control and reliability in their syntheses. For students, this means learning the foundation of organic reactions through approachable, hands-on experiments involving halogenated dioxanes.

Health, Safety, and Science

Dioxane derivatives can get a bit of a side-eye these days. Dioxane itself has been called out for potential carcinogenicity. The bromine in 2-(2-Bromoethyl)-1,3-dioxane adds extra handling concerns. One whiff or careless spill can lead to irritation or worse. In the lab, safety goggles, gloves, and a vented hood aren’t just for show. Chemists keep safety data handy and avoid skin contact to keep risks at bay. Storage also matters. Brominated compounds don’t enjoy sunlight or heat, so dark, cool bottles sit in refrigerators until they’re needed.

Finding Paths Toward Safer Reagents

Regulatory bodies worldwide, following advice grounded in solid peer-reviewed research, keep pushing for safer chemicals. The European Chemicals Agency tracks substances and issues alerts for compounds that build up in the body or linger in the environment. Green chemistry is making headway. Researchers explore alternatives, aiming to keep synthesis efficient without sacrificing well-being or the planet’s health. Halogen sources with less persistence or lower toxicity can often do the same job, trimming risks. Bench scientists try catalytic approaches to replace outright substitution.

Bringing It All Together

2-(2-Bromoethyl)-1,3-dioxane stands as a revealing example of how atomic arrangement guides utility and risk in chemistry. Experience in the lab has underscored the direct link between small changes at the atomic level and big swings in reactivity and safety. Listening to the latest research and following recommended best practices, scientists push ahead, reshaping protocols and launching safer compounds without losing performance. Curiosity keeps unlocking new chemical pathways, and attention to detail ensures these journeys don’t come at too high a cost.

Discovering the Hands-On Uses in Chemistry

Few niche chemicals draw the kind of attention from organic chemists as 2-(2-Bromoethyl)-1,3-dioxane. My time in a research group taught me that a compound like this never sits long on the shelf. Lab benches get crowded, glassware needs constant washing, and every student there seems to have their own way of using reagents like this. What makes it special—apart from that tricky bromine atom—is how it shows up in the steps where you have to build bigger molecules out of smaller parts.

Foundation in Synthesis—Precursors and Building Blocks

The backbone of most new drug molecules and specialty chemicals starts as simple rings and chains. Add in a bromine at a strategic spot—like in 2-(2-Bromoethyl)-1,3-dioxane—and suddenly the routes open up. In my earliest organic synthesis projects, people talked about alkylating agents like these as “staples in the cupboard.” What they really meant is, you reach for it to attach new groups to a molecule quickly. The bromoethyl group acts like a highly reactive handle, letting chemists connect chains or rings that would otherwise break apart or not react at all.

Pharmaceuticals and Agrochemicals—A Real-World Link

Much of the push behind better pesticides or smarter crop treatments starts in labs where researchers look for selective reactions. This compound’s bromo group can swap with other atoms, switching out for something else in the last step or so to build up complexity. Researchers chasing antivirals, cancer drugs, or just a better fungicide turn to it as a chemical intermediate. It often pops up in patents for new active ingredients. Expect few farmers or patients to know the name, but without such intermediates, many advances stall out before they leave the drawing board.

Making New Materials Possible

It's common in the materials science circles I followed in grad school to test new polymers—substances used for coatings, adhesives, or smart packaging. When someone needs to make a long-string molecule that bends just right or resists certain chemicals, dioxane-based building blocks come up. The flexibility of its cyclic core helps make custom-designed plastics that hold up to heat, stress, or even UV light. Synthetic chemists chasing the next new thing in biodegradable packaging already explored such routes, and the bromoethyl group remains one of the fastest ways to tack on secondary features.

Tackling Challenges—Safety and Efficiency

Chemists know that brominated chemicals demand respect. In my teaching lab, students always wore gloves and goggles, with reactions tightly controlled. The risk here isn’t just from toxic vapors or accidental spills—improper handling can turn a promising research line into a safety incident. Researchers keep a sharp focus on greener alternatives and lower-toxicity reagents. Industry's leaning into process optimization offers hope: better containment systems, real-time monitoring, and some exciting early research into swapping out bromine for less hazardous atoms.

Moving Forward—Balancing Progress and Responsibility

Anyone who’s worked on a drug launch or scale-up phase in a chemical firm knows speed matters, but not at all costs. The next solutions will likely involve more efficient one-pot reactions, less waste, and fewer by-products. Real progress sits at that intersection where strong chemical tools like 2-(2-Bromoethyl)-1,3-dioxane meet real commitment to safer, environmentally responsible manufacturing. Staying informed, demanding transparent sourcing, and keeping safety front and center all help maintain trust while science keeps advancing.

Respect the Risks: Why Caution Matters

Working with 2-(2-Bromoethyl)-1,3-dioxane reminds me of handling certain solvents and alkylating reagents in college labs. Gloves and eye shields weren’t just recommended, they felt essential. This organic compound, sitting in the dioxane family with a bromoethyl twist, doesn’t belong in the same drawer as mild soap or vinegar. It likely acts as an irritant and, due to the bromine atom, can raise concerns about toxicity. Accidents with halogenated organics rarely end in a shrug—they send people searching for better procedures or medical attention.

Personal Protective Equipment: More Than a Costume

Good gloves aren’t negotiable. Nitrile or neoprene fit the bill, since latex tends to break down with a lot of organics. Safety goggles keep splashes away from your eyes—losing your eyesight to a bad splash shouldn’t sit on the menu. After a spill on my own hand from a similar compound years ago, I spent a nervous afternoon waiting for symptoms. Long lab coats make sense. Use a fume hood every single time, even for quick transfers. It’s worth the walk, especially since the compound can give off noxious vapors. Fume hoods reduce exposure; a home bench does not.

Storage: Keeping Trouble Locked Away

Stashing this chemical at eye level or next to acids just opens doors to mishaps. Assign it a spot in a cool, dry, ventilated cabinet, closed tight with a clear label. Many organics eat through plastic over time, so glass, sealed with Teflon-lined caps, adds peace of mind. Incompatibilities pop up if you set it too close to oxidizers or strong bases. I’ve seen fires start from a neighbor’s careless storage, so paying attention to segregation matters.

Don’t Skip the Small Stuff: Spills and Disposal

A colleague once brushed off a small halogenated spill, only to deal with headaches and a lingering chemical odor. With this compound, stop work right away for leaks or spills. Toss on your PPE, get paper towels or an absorbent pad, and scoop every bit up. Skip the drain or trash bin. Store soaked materials in a sealed bag marked “hazardous” and turn them over to a certified chemical disposal service. Even small spills can turn a safe workspace into next week’s safety meeting headline.

Training and Emergency Prep

Before anyone touches that brown glass bottle, training matters. Understanding the chemical’s hazards cuts risks by half. Keep an eyewash and safety shower close enough for emergencies. The right fire extinguisher should stand ready, since organic solvents can fuel fires quick. I once worked in a shop where people ignored fire training until a small flash fire forced everyone outside.

The Trust Factor: Reliable Resources and Up-to-Date Info

Safety data sheets from trusted suppliers provide the baseline for handling protocols. Consult them before ordering or opening a new bottle. Shifts in regulations or research might change what we know about this compound, so keeping up with new guidance always matters. Health Canada and the U.S. National Library of Medicine keep current chemical fact sheets; if you work in outreach or education, sharing them can keep others in the loop.

Reducing Risk Means Respecting Chemistry

Chemicals like 2-(2-Bromoethyl)-1,3-dioxane demand respect, not routine. Proper PPE, good storage, and up-to-date training keep people and labs out of danger. These steps may look like red tape, but from what I’ve seen and lived, they let you finish every shift with nothing worse than ink stains or tired feet.

Why Purity Matters More Than a Number

Working in chemistry isn’t all swirling flasks and daydreams of Nobel prizes. Purity makes or breaks nearly every batch. For something like 2-(2-Bromoethyl)-1,3-dioxane, the label might say 98% or 99%, but the story doesn’t end there. Months spent troubleshooting an experiment that won’t work often boil down to that silent 1%. It sticks around like an unwelcome guest, throwing off reactions, slowing down production, even undermining safety.

Testing Tells the Truth

Labs stick to industry standards for purity testing because accuracy matters. Modern techniques—GC-MS, HPLC, NMR and related approaches—bring out the real picture behind purity claims. I’ve watched scientists gamble on a drum labeled “99%” by weight and end up chasing mystery peaks across spectrograms. This isn’t just a technical headache. Missed impurities start to trail through downstream products, popping up in unexpected places, from APIs to specialty materials.

Let’s get specific. For 2-(2-bromoethyl)-1,3-dioxane, reputable suppliers print purity specs right on the CoA (Certificate of Analysis). The number, usually sitting at 98% minimum (by HPLC), gives a sense of the chemical’s identity. That leaves a maximum of 2% mystery. In practical terms, things like water, chloride, and trace byproducts might sneak through. Running Karl Fisher titrations pulls out moisture data, while halogen tests confirm no halogenated leftovers. Each round of extra analysis adds time and cost, but it heads off future headaches.

Experience Shows: Purity Impacts Every Step

Explaining purity to folks outside the lab always feels like convincing relatives why hand-washing lettuce matters. Sure, 98% sounds great, but that stray 2%? It can react with the stuff in your next flask, poison a catalyst, or show up as an off-color trace in a pilot run. Hard lessons from the pilot plant stage taught me this difference. Running 2-(2-Bromoethyl)-1,3-dioxane through a scale-up, I once chased down a foul smell and failing yields to a stubborn contaminant overlooked in a purity screen. Lost days, spoiled kilos, and a fistful of paperwork followed.

For scientists spinning up medicinal compounds or specialty intermediates, that’s not just a hassle. Regulators like the FDA care about every molecule; so do QA teams and safety officers. Repeated surprises lead to rejections and missed milestones. Worse, the actual cost piles up quietly: every batch off-spec means wasted solvent, consumables, and human hours.

Raising the Bar: What to Ask Suppliers

Expecting clear, reliable reporting from suppliers isn’t asking too much. I’ve learned to never settle for vague “98% by weight” numbers without accompanying spectra or impurity tables. Responsible producers hand out HPLC or GC-MS traces, outline potential byproducts, and pinpoint moisture content—showing they understand the stakes. Sometimes, pushing for 99% or 99.5% purity makes sense, especially for critical applications in pharma or electronics. Ask for heavy metal screens and halide residue checks; if a supplier can’t produce those, look elsewhere.

Companies that consistently meet or beat published specs stand out. Finding one saves time, builds trust, and helps avoid chasing after invisible ghosts in the flask. In a business where reputation runs on results, trust is earned by delivering real purity, not just a number on a spec sheet.

Keen Eyes on Chemical Safety

Anyone who has worked in a lab or manufacturing setup knows chemicals don’t forgive carelessness. 2-(2-Bromoethyl)-1,3-dioxane demands a special kind of respect—not because it shouts danger, but because its hazards creep up on people who overlook the obvious. I’ve watched co-workers find out the hard way about chemical reactivity and spills, and it’s never just a small cleanup. This compound’s bromoethyl group puts it on the list for extra attention.

Avoiding Unwanted Reactions

Moisture brings headaches. I always store moisture-sensitive chemicals in a dry, cool place, and I recommend keeping this one in tightly sealed containers. Refrigerators might seem convenient, but fluctuating temperatures cause condensation inside bottles, leading to hydrolysis or unpredictable reactions. Desiccators or purpose-built dry storage cabinets do a better job. Amber glass bottles shield the contents from light, which staves off slow decomposition. In my old workspace, a missed bottle in regular glass turned yellow from sunlight within a week—there went a batch and a day’s work.

Why Labeling and Segregation Matter

I’ve run into stacks of mystery bottles in university storage rooms, and each time I’ve seen it, someone paid for the mistake months later. Proper labeling seems obvious, but rushed shifts cause lazy habits. Each bottle holding 2-(2-bromoethyl)-1,3-dioxane wants a clear hazard label and a date of receipt, and if possible, the supplier’s information. Store this chemical away from acids, bases, oxidizers, and anything with active hydrogen atoms. Bromoethyl groups don’t play nice with aggressive neighbors. Standard operating procedures work as long as people respect them—skipping steps out of convenience sets the stage for disaster.

Handling and Exposure Controls

There’s a tendency to trust gloves and goggles as a cure-all. That attitude doesn’t cut it in real practice. Change gloves often, and don’t underestimate face shields for splash protection. Fume hoods are more than insurance—they make the difference during minor spills. In my experience, inhaling even faint whiffs from volatile organobromides can cause headaches and nausea. Local ventilation and routine checks for leaks become habits worth repeating.

Transport: Rules, Not Shortcuts

Moving chemicals by road or air follows international rules because cutting corners puts drivers and handlers at risk. I once watched a team rush to meet a deadline, jamming bottles in a car trunk. The result—reactive liquid rolled against metal tools, puncturing a lid, and the situation escalated fast. Insulated boxes with shock-absorbent packing and leak-proof liners offer peace of mind. Every time I book a courier, I ask about their handling certifications for dangerous substances. If you skip the paperwork, you might as well play roulette with public safety.

The Value of Training and Vigilance

No checklist saves a workplace where staff don’t know the why behind each instruction. I’ve run chemical safety workshops and seen how practical demos sink in deeper than any compliance poster. Good habits grow from repetition and reminders. Teams working with 2-(2-bromoethyl)-1,3-dioxane make fewer mistakes when everyone understands what’s at stake. Real stories about close calls in the industry help turn theory into practiced discipline.

Staying Proactive Beats Trouble

Taking shortcuts with hazardous chemicals often ends up costing more in damage control or health issues than time saved. From labeling and smart storage, to fully trained transport carriers and routine reviews—staying proactive shields both workers and the company from messy regrets. I’ve seen routines built around caution keep people safe for years, while just a day’s neglect creates headlines for all the wrong reasons.