2-(Ethoxycarbonyl)Ethyltriphenylphosphonium Bromide: Foundation, Features, and Future in Chemical Synthesis

Historical Development

Chemists keep pushing for more effective ways to make carbon–carbon bonds, and this need guided the discovery of organophosphorus compounds throughout the twentieth century. 2-(Ethoxycarbonyl)Ethyltriphenylphosphonium Bromide sprang up from the search for reliable ylide precursors, especially for the storied Wittig reaction that changed how we think about olefination. George Wittig’s Nobel Prize was rooted in this type of chemistry, and for decades his work has been built into the practice of both research labs and the pharmaceutical industry. The specificity of the ethoxycarbonylethyl group added another arrow in the quiver, letting chemists synthesize acrylic esters and other α,β-unsaturated carbonyl compounds that just don't come together as easily any other way. That history traces through countless academic papers, patents, and commercial routes for key fine chemicals.

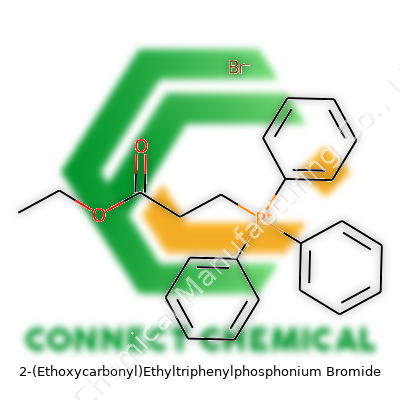

Product Overview

2-(Ethoxycarbonyl)Ethyltriphenylphosphonium Bromide turns up in the catalogs of most chemical suppliers who cater to organic labs. The compound stands out for its role as an ylide precursor—especially one that contains a masked carboxyl group on a flexible ethyl chain, which helps target enone and acrylate scaffolds. Researchers see it in its white to off-white crystalline form, often packaged in tightly sealed bottles because the material pulls in water from the air. The product usually comes in purities exceeding 98%, making it ready for further transformation in synthetic sequences.

Physical & Chemical Properties

You get a white to almost off-white powder, dense and usually granular without strong odor. The compound's molecular weight lands at 475.36 g/mol, and the formula is C23H24BrO2P. It doesn’t dissolve in water, but it readily goes into polar organic solvents—particularly dimethylformamide or acetonitrile, which helps it behave nicely in ylide-forming conditions. Its melting point lands between 220 and 230 °C, so it will not volatilize under typical lab conditions. The phosphonium core provides good shelf stability unless humidity drifts, since hygroscopic tendencies require careful bottle handling.

Technical Specifications & Labeling

Commercial labeling focuses on chemical name, batch number, lot purity, hazard warnings, and storage advice. Labs should note its hygroscopic nature and keep it sealed. Bottles generally show UN numbers for hazardous materials, though this one rarely travels under high risk. Shipping documentation often comes with hazard statements about respiratory and skin irritation, and suppliers emphasize the need for gloves, goggles, and fume hood use. A Material Safety Data Sheet (MSDS) links toxicity findings and cleanup routines. For research-grade work, labels typically promise purity above 98%, minimal residual solvents, and absence of triphenylphosphine oxide.

Preparation Method

Making 2-(Ethoxycarbonyl)Ethyltriphenylphosphonium Bromide relies on tried-and-true organophosphorus routes. Most labs and suppliers start with triphenylphosphine and stir it in a polar, aprotic solvent—like acetonitrile—before dropping in the relevant alkyl bromide. For this compound, ethyl 3-bromopropionate is the alkylating agent, and the reaction moves at moderate temperature for several hours. After the reaction, the product often crystallizes when the solvent gets replaced with a less polar liquid like diethyl ether. Several reports push for further purification, including recrystallization or washing with cold solvents to cut away colored byproducts. Advanced users try to minimize excess triphenylphosphine and triarylphosphine oxide, both of which complicate downstream reactions.

Chemical Reactions & Modifications

The real workhorse property of this molecule is how easily it forms ylides when treated with a strong base. To generate the Wittig reagent, researchers drip in sodium hydride, potassium tert-butoxide, or similar strong base at low temperature to deprotonate the methylene group next to the phosphonium center. The ylide that forms acts as a nucleophile towards a range of aldehydes, driving the famous Wittig reaction to create α,β-unsaturated esters in compounds ranging from flavor molecules to pharmacophores. Some researchers run further elaborations, swapping out the ethoxycarbonyl group for more complex ester chains, or even hydrogenating and then hydrolyzing to chase novel acids. The scope pulls in a broad set of aldehyde partners when seeking to customize the terminal double bond.

Synonyms & Product Names

The molecule gets tagged by a handful of alternative names: 2-(Ethoxycarbonyl)ethyltriphenylphosphonium bromide, Ethyl 3-(triphenylphosphonio)propionate bromide, and sometimes as the Wittig salt for ethyl acrylate synthesis. Chemists familiar with older literature may refer to it by CAS number 35635-39-1. Vendors sometimes use abbreviated forms like "ECEP Phos Salt". Regardless of the name, the core phosphonium structure and its reactivity remain unmistakable to anyone planning a synthetic route.

Safety & Operational Standards

Working with this salt calls for standard precautions expected for organophosphorus compounds. Inhalation and skin contact may lead to irritation, so gloves and eye protection are typical. Accidental ingestion carries similar hazards seen with other bromide salts. Organophosphonium compounds in general don't carry the acute toxicity linked to, say, organophosphates used in pesticides, but it's still smart to minimize dust and avoid heating above decomposition temperatures. All waste goes in properly labeled halogenated solid waste containers, with spill clean-up covered by the lab’s safety protocol. Documentation always matches up with regulations like REACH and OSHA for safe handling of chemical intermediates.

Application Area

Synthetic organic chemistry leans heavily on this compound, because it opens the door to robust Wittig and related olefination reactions. Industrial applications turn up especially in flavors, fragrances, and small-molecule APIs (active pharmaceutical ingredients). It's not unusual for a pilot plant to scale this chemistry up several kilograms at a time to connect carbon frameworks in bulk drug manufacture. In academic labs, researchers leverage it for methodology development—especially in total syntheses of natural products, where the α,β-unsaturated ester motif is everywhere from prostaglandins to pheromones and vitamins. Students use it in teaching labs, not just for bond construction but to see the interplay between physical properties and reactivity in real time.

Research & Development

Chemistry departments keep expanding the toolbox for phosphorus ylides, and this salt remains a starting point for new modifications and study. Recent experiments have explored swapping the ethoxy ester for other electron-withdrawing groups or examining new bases that can form ylides under milder and safer conditions. Multistep synthesis pathways sometimes call for a mix of ylide reagents to tune selectivity for E/Z-alkene outcomes—especially important in drug synthesis, where geometric purity can be key. Papers also highlight greener solvent systems and continuous-flow setups to boost efficiency and safety. Research programs compare modified phosphonium salts side-by-side with this classic version to see if newer analogs really earn their keep or simply add to procurement complexity.

Toxicity Research

On the toxicity front, this compound hasn't drawn strong concern, but comprehensive animal studies remain limited. Most available data trace back to broader work on phosphonium salts, where chronic exposure mostly triggers slow respiratory or dermal irritation, without clear links to systemic disease. Ecological impact hasn't caused headlines, though chemical hygiene emphasizes keeping all organobromide compounds out of drains or into incineration waste. The field keeps an eye on downstream metabolites in reaction waste, especially in pharmaceutical contexts: regulatory frameworks encourage careful logbooks for tracking both used and excess material. Toxicologists and regulators encourage ongoing tracking in scholarly literature, especially with rising global regulatory pressures on all phosphorus-based reagents.

Future Prospects

Chemistry keeps evolving, and 2-(Ethoxycarbonyl)Ethyltriphenylphosphonium Bromide holds a place as both a workhorse reagent and a test bed for better, safer phosphorus chemistry. The push for greener, more sustainable synthesis routes keeps challenging suppliers to reduce waste, both in synthesis and application. Labs around the world keep testing new ylide precursors for better selectivity, atom economy, or easier handling, but this bromide remains a solid comparison benchmark in reaction screening. Scaling up production continues to lean on classic batch chemistry, but flow-chemistry techniques and automation have begun to make inroads. Expectations in the coming decades point to even tighter purity standards, more robust documentation for environmental safety, and innovation in asymmetric versions to meet the needs of chiral drug development. The material’s legacy is clear, but its story will keep growing as long as chemists search for ever-better ways to connect carbon atoms with purpose and precision.

Behind the Name: Breaking Down Its Structure

Long chemical names can scare people off, but taking apart these names shows what’s actually going on in a molecule. 2-(Ethoxycarbonyl)Ethyltriphenylphosphonium bromide sports a mouthful of a title, yet decoding it isn’t such a puzzle with a little logic and background in organic chemistry. This compound features both an ester group and a phosphonium ion—pieces that play a big role in how the molecule behaves in real applications like organic synthesis and research labs.

The triphenylphosphonium part means there’s a phosphorus atom attached to three phenyl groups. “Phosphonium” signals a positively charged species. The “2-(ethoxycarbonyl)ethyl” side tells us there’s a two-carbon bridge linking the phosphonium to an ethyl chain capped off by an ethoxycarbonyl group—an ester unit. Don’t discount the bromide at the end: as a counterion, it balances out that positive charge on phosphorus. That’s key for the whole compound staying together and performing its function as a reagent in many chemical transformations.

The Formula: Revealing the Numbers

Breaking it down, the triphenylphosphonium grouping gives us three C6H5 (phenyl) rings plus a phosphorus atom. The ethoxycarbonylethyl stem delivers an extra C2H4 unit, a CO2 group (from the ester), and an ethoxy group (C2H5O). Bromide tacks on Br as the counterion. Counting it out, the chemical formula stacks up as C23H24BrO2P.

This isn’t just a trivia detail. The chemical formula matters because it determines how researchers measure, handle, and react this compound. Getting the subscripts off by one leads to big headaches and wasted resources in both academic and commercial settings. People working with these substances have to know what each atom is doing and where. Otherwise, results take a hit, experiments fail, and safety gets compromised. It’s like baking a cake while ignoring the actual amount of baking powder: sometimes things bubble over, sometimes nothing happens at all.

Why Molecular Precision Means Something

Experience has shown that chemistry isn’t just about mixing things together and hoping for the best. Mistakes compound quickly. Labs tracking purity and calculating yields pull out these formulas to estimate how much of each reactant goes into the flask. In my own years in synthetic chemistry, I saw smart people burn time and budget trying to track down why reactions failed—only to realize they measured the wrong weight or miscalculated the charge on a molecule. Those experiences teach some harsh lessons about respect for molecular details.

Phosphonium salts like this one function as key tools in Wittig reactions, where they help turn carbonyl compounds into alkenes. Having the exact formula C23H24BrO2P makes it possible to tally up moles, plan out protocols, and avoid leftover reactants. Modern labs use digital balances and tracking software, but all that hardware depends on the chemist handing it the right numbers. Skipping the basics never works out for long.

Getting It Right: Tracking Down the Right Information

People doing real research can’t afford sloppy work, especially with expensive or sensitive substances. Published databases list formulas, but it’s always good to double-check key structural features against reliable scientific papers or trusted chemical suppliers. Staying mindful of detail guards against both mistakes in work and unjustified claims. The more attention paid to formulas like C23H24BrO2P, the more reproducible and robust research becomes, whether it’s in a classroom, a commercial facility, or a high-level research lab.

Driving Agricultural Success

Farmers across the world know this compound by its critical role in crop production. Walk through any fertilizer store in the Midwest or look at farms in India, and you’ll see its impact. It boosts plant growth, ensuring higher yields even in tough soils. Balanced nutrition supplied by this compound leads to stronger root systems and greener crops, making a tangible difference in the food supply. Many researchers highlight its steady release properties, letting crops absorb nutrients over time, instead of being hit with it all at once. This not only saves money but prevents environmental run-off, which matters in communities relying on clean rivers and streams.

Backing Health and Nutrition

This compound doesn’t just help plants. Scientists rely on it in food processing and pharmaceuticals too. In the labs I’ve visited, technicians use it to stabilize medicines, helping those pills on pharmacy shelves stay effective longer. Some nutritionists add it to mineral supplements, providing essential elements the body needs. Looking at the data, consumers notice the difference in longer shelf life and consistent nutrient content. My own experience with nutritional supplements that boast higher bioavailability often involves this very ingredient, showing up in the fine print on the packaging.

Supporting Water Treatment Infrastructure

Communities managing hard water owe a lot to this compound’s water-softening abilities. Plumbers recommend its use because it binds unwanted minerals, saving pipes from scale build-up and keeping boilers efficient. Utility companies benefit from smoother system operations and reduced maintenance costs. In my hometown, water reports point to lower mineral content directly tied to regular use in treatment plants.

Industrial and Manufacturing Jobs

From soap makers in small towns to large-scale chemical plants, this compound pulls its weight. It acts as a buffer, keeping pH levels stable during production. Steel manufacturers use it to control impurities in metalwork, which reduces wasted product. Workers in plant operations appreciate how it streamlines day-to-day tasks. On the shop floor, fewer machine breakdowns and higher output often track back to its steady performance.

Championing Environmental Sustainability

Environmental groups have sounded alarms about excess chemical run-off for years. Formulators who switch to this compound talk about reduced leaching into nearby waterways. Its slow-release profile allows targeted support without flooding the ecosystem. Studies reinforce that fish and plant life thrive when used responsibly. Some city planners invest in education programs for local farmers, teaching how to balance crop needs with water quality goals.

Moving Forward—Better Use and Research

Farm advisors urge focusing on precision application, which saves money for growers and reduces waste. Researchers continue looking for ways to make this compound even safer and more effective, especially under climate change pressure. Community-wide conversations about dosage and innovative blends keep pushing the field forward. Experience tells me that open communication between scientists, farmers, and civic leaders leads to smarter solutions for everyone involved.

The Truth Behind Proper Storage

Years of working in a busy warehouse taught me one thing: everything, whether a can of paint or a pallet of medicine, has its own way of staying fresh and useful. I’ve seen products lose their punch just because of sloppy storage. Poor temperature, too much moisture, or sunlight can mess with a product’s quality. Some items soak up humidity like a sponge, some grow mold, and others just separate and go bad. Getting storage right isn’t just a nice-to-have, it saves money and keeps people safe.

Common Storage Conditions Explained

A lot of products ask for a “cool, dry place.” That means away from heat sources, out of direct sunlight, and somewhere air circulates. I used to stack boxes of flour in a storeroom once, with a vent blowing hot air directly on them. After a few weeks, bugs showed up. Heat and moisture together attract pests and speed up spoilage. Dry really means low humidity; try to keep it under 60% for most dry goods. For things that warn against freezing, like certain meds or glues, a frozen product might never work as expected again—layers might separate, compounds can break down, and the label’s promise goes out the window.

Why Following the Label Pays Off

There’s a reason every label gives advice about storage. A bottle of vitamins left on the dashboard of a car turns into a health gamble. One summer, a friend of mine bought a batch of protein powder during a heatwave. The warehouse storing it ignored the storage instructions. By the time it reached the customer, it smelled off and clumped together. Turns out, the active ingredients started to break down. A few weeks of exposure did more harm than customers ever realized.

How Risks Sneak Up

Not every problem jumps out right away. Many risks, especially with food, medicine, or chemicals, grow over time. Sometimes, mold starts in the sealed corners of a box and only shows itself right before use. In the worst cases, spoiled products cause health issues. Stories of infant formula spoiling on store shelves because warehouse managers missed an air conditioning problem make headlines for a reason. Real harm follows when storage gets ignored.

Simple Steps to Protect Quality

Sticking to the manufacturer’s instructions cuts down on waste. It also keeps everyone safer. In my own kitchen, I keep flour in airtight containers with silica packets to fight humidity—nothing fancy. On the worksite, I keep paints and adhesives off the ground, since concrete floors can sweat and add moisture. For medicine, the bathroom cabinet isn’t always the best choice; medicine boxes break down faster in steamy air. A shelf in the linen closet, above the reach of kids, works better. Businesses can spot-check warehouse temperatures with basic sensors, or use humidity cards to check if packets might have absorbed water. These small steps add up quickly, especially with products sensitive to air or light.

Solutions Worth Trying

Training matters. I’ve seen brands run short training videos just to show staff how to spot storage slip-ups. Good labels use clear symbols—like a thermometer or crossed-out sun—to remind users. For things needing refrigeration, backup systems for power and alarms avoid costly losses. Even households can follow these tricks, just by keeping storage areas dry, clean, and away from direct sunlight. A little attention goes further than most folks realize.

Final Thoughts

Manufacturers don’t recommend storage conditions just for fun. Clean, careful storage keeps value in the product and trouble far away. Whether you’re a warehouse supervisor, a shopkeeper, or just organizing things at home, taking those simple steps makes all the difference.

Recognizing Real Risks in the Workplace

Every person who’s worked around chemicals knows that hazards don’t hide in complicated theories—they show up in daily routines. Spilled solvents eat through skin, pressurized gases can blast loose, and even powders can damage lungs if breathed in day after day. Most folks in labs or factories have stories about close calls, even if you’re always careful. It’s not just the chemicals marked with skull-and-crossbones on the label. Sometimes even common cleaners or glues cause big trouble if handled with bare hands or mixed wrong.

Take acetone, paint thinners, acids, or ammonia. Direct contact burns or drains oils out of skin, making scabs or sore patches. Even the fumes give you headaches and can wreck your lungs, especially in closed up rooms. Some chemical vapors hang low, nearly invisible, building up until someone gets dizzy or passes out. Flammable liquids find ignition sources—one spark from a switch or cell phone can set off a fire. Without proper ventilation, or ignoring signs of leaks, a small mistake grows to an emergency fast.

Simple Habits That Matter Most

The strongest protection comes from habits learned on the job. I always check labels two or three times and store acids away from bases, not because a manual says so, but because I’ve seen what goes wrong. Eye washes and showers stay clear—not piled up with boxes. Gloves, goggles, and lab coats hang ready. Before opening anything, I make sure fans run and vents work, especially in older spaces where last year’s fixes aren’t always holding up. Spills and sticky doorknobs mean trouble: wiping up, tossing gloves, and never skipping hand washing reduce risks that build overtime and seem invisible at first.

Learning from Real Accidents

Backing up good habits, training means actually practicing what might happen. Sooner or later, alarms ring. The best teams don’t freeze when a bottle drops or a pipe bursts—they grab absorbent pads and use spill kits kept close by. People who know which fire extinguisher type matches which liquid act instead of panicking. Quick heads-up thinking comes from drills that feel real, not just quizzes. After accidents, talking through what worked and what went sideways helps everyone find weak points. Sometimes the biggest danger comes not from a new procedure but from old routines that no one questions anymore.

Better Tech, Smarter Choices

Good workplaces invest in new safety gear for a reason. Fume hoods, automatic shut-offs, explosion-proof fridges—these upgrades don’t just check a box, they keep people healthy and business running. Clean, clear labeling and digital logs cut out confusion about what’s stored where. Even something as simple as color-coded bins and regular disposal schedules stops old chemicals from building up and turning unstable. Sharing current safety data sheets and sending alerts about recalled products keep teams up to date. Following strict rules may feel slow, but it beats the cost of injury or shutdowns every time.

Speaking Up for Safer Work

None of this works if folks dismiss warning signs. If a procedure feels wrong, or if storage racks wobble, saying something isn’t just “complaining”—it protects everyone. Reporting close calls or failures builds a culture where safety is real, not just written down. Strong teams listen, fix problems fast, and never punish people who spot mistakes early. Everybody earned the right to expect to go home in the same shape as when they arrived. That’s what responsible handling means. Living these values turns safety from a checklist into a daily promise.

Purity Shapes Results

Walking into a hardware store or browsing online chemical suppliers, the phrase “available in different purities or grades” pops up almost everywhere. Some people glaze right past it, but for anyone who’s ever tried to whip up soap at home or run experiments in a school lab, purity means the difference between success and a questionable mess.

Let’s talk simple examples: table salt and lab-grade sodium chloride. Both look the same, but the one on your fries might contain minerals safe for eating, but not right for a reaction needing exact results. In my college days, using the wrong kind in a straightforward chemistry class led to half the lab group blaming faulty scales for a ruined experiment, when the real culprit was contaminants.

Safety Depends on the Right Grade

Back in high school, a friend almost ruined his mom’s fancy cookware making homemade bath bombs. He tried using “industrial” citric acid he found in the garage. That product’s label didn’t list extra ingredients. Turns out, impurities meant for cleaning drains don’t make for safe skin contact.

This isn’t just about avoiding accidents at home. Medical and food industries rely on grade labels to protect us. Pharmaceutical-grade substances undergo strict testing for purity, as anything less could risk lives. A recent FDA report explained how batches of medication sometimes get recalled due to impurities that went undetected. Those mistakes cost trust and, in the worst cases, health.

Why Purity Listings Exist

Chemical and material grades help buyers know exactly what’s in the bottle or bag. Reagent grade, food grade, technical grade—these terms point people toward the right product for the job. Someone running a small brewery picks food grade yeast nutrients, while a lab technician orders reagent grade chemicals to make measurements count.

In construction, purity charts show up in everything from sand to copper. Using building materials with the wrong impurities can weaken concrete or cause corrosion. Homeowners might assume sand is just sand, but that bag from the nursery could have clay or organic matter, making it no good for mixing with cement. Fail to read the grade, and you could end up with crumbling bricks years later.

Solutions Start with Clear Labels

One way companies and regulators protect consumers is by making grade and purity information clear on packaging. Some stores have started color-coding labels or putting QR codes on containers that link to lab test results. These small changes give buyers quick access to everything they need to know.

Education also needs attention. Schools rarely teach the difference between analytical, technical, and food grades outside of science class. A broader push to explain this early would avoid kitchen accidents, science mishaps, and even costly business mistakes down the road.

Supporting transparency in labeling and better education about grades helps everyone—from backyard gardeners to big-city builders—make smarter, safer decisions. Once people realize what purity and grade mean in everyday life, those small words on the bag or bottle carry a lot more weight.