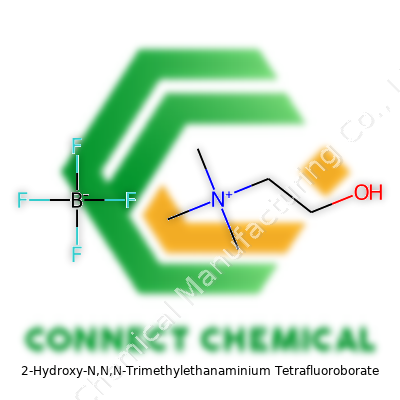

2-Hydroxy-N,N,N-Trimethylethanaminium Tetrafluoroborate: Insights into a Unique Chemical

Historical Development

Chemistry often advances through the humble workhorse compounds that never see the limelight, yet grease the gears of progress. 2-Hydroxy-N,N,N-Trimethylethanaminium tetrafluoroborate fits this mold. In the late twentieth century, as synthetic methods matured and electrochemical techniques demanded ever-purer conducting salts, chemists looked for straight-forward, stable, and safe quaternary ammonium salts. This compound, spun from the reaction of choline with tetrafluoroboric acid, found its way into research labs during the 1980s, bringing non-volatile and moisture-tolerant cations to ionic liquids. Its path intersects with the popularization of non-aqueous electrolytes, driven by innovations in batteries and capacitors, in pursuit of safety and reliability. Development never paused, as better protocols for synthesis, crystallization, and control of impurities cropped up, reflecting both industrial and academic influences.

Product Overview

At its core, the chemical walks the line between commonality and specialty. It belongs to quaternary ammonium salts: manageable solids with a reputation for versatility. Sold as a white, hygroscopic powder, the product typically features high purity, as impurities are rarely tolerated in its high-tech applications. Laboratories, universities, and chemical producers worldwide stock this item for its use in research, prototyping and quality analyses. Bulk containers can carry kilo-scale quantities, packed to limit exposure to air, guarding against caking or clumping from environmental humidity.

Physical & Chemical Properties

At room temperature, 2-Hydroxy-N,N,N-Trimethylethanaminium tetrafluoroborate appears as a white to off-white powder, crystalline yet tender to the touch. Solubility characterizes it: the compound dissolves easily in water, thanks to its ionic nature, though it keeps its structure in many organic solvents as well. Heat isn't kind to it—above 200°C, decomposition can take over, releasing irritating fumes. Its pH sits near neutral in aqueous solutions, making it compatible with a broad range of reactions. In lab use, its hygroscopic nature prompts storage in sealed vessels with desiccant packs. On the benchtop, it resists most weak acids and bases, yet suffers under strong oxidizing agents. Density hovers close to 1.3 g/cm³, fitting well among its chemical siblings.

Technical Specifications & Labeling

Suppliers list specifications that do more than fill out a datasheet. Purity often exceeds 99%, checked through NMR, HPLC, and elemental analysis. Labels read with the precision needed for inventory tracking: batch number, CAS number, lot number, and detailed hazard symbols. Moisture content and residual solvents rarely slip past quality control. Regulatory compliance appears front-and-center, outlining GHS signal words, pictograms, and sentences to reflect real risks. Customers demand transparency; no one in research or production has patience for ambiguous paperwork.

Preparation Method

Simple chemistry often hides unexpected hurdles. Production routes typically start from choline chloride, a commodity chemical in its own right. Reacting choline with tetrafluoroboric acid—usually in aqueous solution—precipitates the salt, after which careful filtration, drying under vacuum, and repeated washing with alcohol follow. Commercial scale-up never replicates the textbook process line-for-line; scaling, filtration speeds, and solvent recovery create headaches for chemical engineers. Those who studied this salt’s synthesis often complain about humidity sensitivity, as clumped product forms if air control slips. Modern preparations adopt inert-atmosphere drying, automated crystallizers and even continuous flow technology to deliver reproducible batches.

Chemical Reactions & Modifications

2-Hydroxy-N,N,N-Trimethylethanaminium tetrafluoroborate offers a stable cation, unlikely to break apart under mild reaction conditions. Chemists can attach different substituents at the hydroxy group, yielding tailored derivatives: esters, ethers, and carbonates populate patent filings from the last decade. In organic synthesis, it often serves as a phase transfer catalyst, toggling ions across disparate liquid layers. Its tetrafluoroborate anion serves as a weakly coordinating background, useful for generating clean reaction environments without messy byproducts. Oxidation, alkylation, and substitution reactions tap the hydroxy handle, extending the structure’s reach.

Synonyms & Product Names

Product literature uses a mixed bag of synonyms, which challenges even experienced chemists trawling chemical databases. Choline tetrafluoroborate, (2-hydroxyethyl)trimethylammonium tetrafluoroborate, and Choline BF4 all point to the same molecule. Product catalogs sometimes prefer systematic names to match global inventories, while research papers lean on shorthand for speed. Database identifiers, such as CAS 32446-90-1, help bridge these semantic divides and keep supply chains honest.

Safety & Operational Standards

Workplace safety never takes a holiday, especially with hygroscopic powders. Direct skin and eye contact invite mild irritation, and inhalation of dust should be avoided. Splash-resistant goggles, nitrile gloves, and lab coats address day-to-day handling, with chemical fume hoods providing peace of mind in case of airborne particles. Standard protocols instruct disposal in accordance with local regulations, often through incineration or chemical treatment to neutralize the boron content. Fire risks don’t keep most researchers up at night, but high temperatures and incompatible chemicals—oxidizers, acids or bases in excess—must be kept at bay. Emergency showers and eyewash stations sit close to any bench space storing this compound, a nod to lessons learned from laboratory mishaps shared in safety bulletins. Training drills remind new team members to respect both the hazards and the habits that keep people safe in the lab.

Application Area

Technical applications cover a wide swath of research and industry. Energy storage systems, especially next-generation batteries and double-layer capacitors, often feature this salt in electrolyte blends. Its robust conductivity at room temperature, alongside a non-toxic profile, make it attractive for hybrid aqueous/organic systems. Chemists have also employed it in phase-transfer catalysis and ionic liquid formation, tinkering with solvent–solute interactions for greener reaction media. Pharmaceutical labs occasionally use it in choline analog studies—modeling neurotransmitter transport and receptor function—but most commercial use tilts toward electronics, sensors, and diagnostics. As sustainability pressures mount, water-soluble yet stable salts like this offer safer, more environmentally benign ways to drive electrochemical and synthetic technologies.

Research & Development

Exploration of new applications continues on multiple fronts. European consortia pour resources into optimizing these salts for use in solid-state battery electrolytes—seeking longer lifetimes, stable interfaces, and rapid charge cycles. Academic labs, especially those with environmental chemistry focus, probe ways to degrade choline derivatives for waste treatment. Ongoing studies compare this chemical to halide and perchlorate alternatives, looking for advantages in solubility, ionic mobility, and electrochemical inertness. Publications since 2015 mapped structural variants, tinkering with the cation and switching out anions, to tailor performance. Funding agencies reward cross-disciplinary projects, and 2-Hydroxy-N,N,N-Trimethylethanaminium tetrafluoroborate keeps showing up on project samples, from analytical chemistry to materials innovation.

Toxicity Research

No chemical crosses into commercial or lab use without toxicological scrutiny. Early assessments rated the acute toxicity as low: animal studies reported minimal systemic harm, provided exposure stayed within rational limits. Chronic exposure remains less well understood; like other quaternary ammonium compounds, bioaccumulation risk exists and ongoing environmental monitoring tracks traces in waste streams. Eye and skin irritation show up most in reported incidents, with appropriate PPE reducing even rare cases. Comparisons against more notorious tetrafluoroborate salts confirm a safer profile, but regulatory limits—often one milligram per cubic meter of air—keep exposure conservative. Disposal remains an issue: while the compound is less toxic, its breakdown in the environment can produce boron-containing byproducts, carrying their own ecological consequences. Universities and industrial partners must balance laboratory freedom with stewardship of waste, to keep water and soil clear of harmful residues.

Future Prospects

The road ahead looks busy for this compound. Industries chasing safer, greener alternatives to classic ionic conductors find promise in its easy dissolution, stability, and low hazard profile. Innovations in battery technology, fuel cells, and smart sensors rely on ever-purer, more consistent electrolyte salts. Regulatory changes in the European Union and North America push chemical producers to spotlight salts with manageable environmental footprints and documented safety benchmarks. Synthetic chemists and materials engineers stand ready to devise new derivatives, stretching the usefulness of the basic choline skeleton. Collaboration between manufacturers, academic groups, and regulators could iron out disposal challenges, encourage recycling where possible, and safeguard communities around production centers. The next few years may see expanded use in green chemistry and biotechnology labs, where clarity, repeatability, and low toxicity pay dividends for both human workers and the planet.

Digging into the Chemistry

In the world of chemistry, some compounds capture attention for their unexpected utility. 2-Hydroxy-N,N,N-Trimethylethanaminium Tetrafluoroborate is one of those mouthful names that means a lot in synthetic labs, especially among folks working on organic reactions. To put it plainly, this is a derivative of choline, mixed with tetrafluoroborate. Choline itself gets plenty of praise in metabolic biology, but this salt’s usefulness goes much further.

A Real Player in Electrochemistry

I’ve seen this compound spark serious interest among researchers exploring electrochemical processes. The tetrafluoroborate part stabilizes the molecule, allowing it to act as an ionic liquid—in other words, a salt that’s liquid around room temperature. This form helps carry electrical current without water, which can make reactions both cleaner and more efficient.

Electrolytes like this one play a big role in batteries and fuel cells. Battery makers use them for their wide “electrochemical window”—chemistry jargon for not breaking down at high voltage. In lithium-ion batteries, for instance, a tetrafluoroborate-based electrolyte can make batteries safer and longer-lasting. It helps prevent lithium plating, which leads to dangerous short circuits over time. Safety and reliability in batteries aren’t fancy buzzwords—they mean less risk of fires and better operation in electric vehicles or phones.

A Helping Hand in Synthesis

Chemists spend a lot of time thinking about how to build molecules efficiently. 2-Hydroxy-N,N,N-Trimethylethanaminium Tetrafluoroborate offers a way to create “greener” chemical processes. A classic example: people use this compound in organic synthesis as a phase transfer catalyst. This means it helps move reactive ions between water-based and oil-based layers, so two substances can react more easily. The result? People need less energy and fewer harsh chemicals.

On a personal note, I’ve struggled with certain syntheses that stall out because reactants wouldn’t mix. Phase transfer catalysts like this one take out the guesswork—and as many students and researchers learn the hard way, getting simple tools right frees up time and resources for the actually exciting questions in science. The ability to skip extra steps, avoid strong acids or bases, and cut down on waste isn’t just about saving money. It moves the field toward more sustainable practices—something modern science circles talk about constantly, but don’t always achieve in the lab.

Challenges and Where to Go Next

Pushing this compound wider comes with a few hurdles. Sourcing high-quality tetrafluoroborate can get pricey, and production uses fluorine chemistry—not the friendliest branch, safety-wise. There’s also environmental risk if downstream products aren’t disposed of properly. For chemists pushing for sustainability, these issues force frank conversations. Maybe greener fluorine chemistry will take the spotlight. Maybe new regulations on salts like tetrafluoroborate will pressure manufacturers to step up safety and recycling efforts. From a practical angle, scientists can work with smaller batches or find related compounds with less toxic baggage.

At the end of the day, 2-Hydroxy-N,N,N-Trimethylethanaminium Tetrafluoroborate isn’t a household staple, but in the right hands, it gives electrochemical applications and organic chemistry useful tools for safer, more sustainable experiments. That’s a goal everyone shares, whether they spend time mixing chemicals or just charging their phone.

The Backbone of Chemistry in Daily Life

Every product I've worked with in labs, from simple table salt to complex pharmaceuticals, stands on the clarity of its chemical formula and molecular weight. Many overlook these details, but these numbers and symbols form the language scientists use to shape safe medicines, clean water, and durable materials. Chemical formulas tell us exactly what atoms combine to build a particular compound, while molecular weight gives a reliable way to measure, mix, and scale up these compounds for practical use.

Why Chemical Formulas Matter

Think of chemical formulas—such as NaCl for table salt—as the direct address for a molecule. Without this level of detail, no one could guarantee purity or safety in anything from the aspirin in a medicine cabinet to the batteries that power an electric car. Back in college, I spent long hours trying to decode mixtures with ambiguous labels, and every error in a formula meant confusion or wasted material. Industries can’t just eyeball a pile of powder and know what it does; they need the formula carved in stone.

Precise formulas spell out proportions, which keeps mistakes at bay. For example, water’s formula is H2O. Mix up those numbers, and you could end up with hydrogen peroxide (H2O2). Use that by accident instead of water, and you run into health risks instead of quenching thirst. So the formula protects us and points professionals in the right direction, helping chemists share knowledge globally and avoid dangerous errors.

The Role of Molecular Weight in Science and Industry

You can't mix, test, or ship compounds without knowing the molecular weight. Everything from calculating a safe drug dose to crafting strong polymers depends on getting this number straight. At the bench, I’ve weighed out chemicals to the milligram; if the weight was wrong, so was the experiment. Miss by a few grams, and the recipe flops or, worse, turns hazardous.

To find molecular weight, tally up the atomic masses for every atom in the formula. Take glucose (C6H12O6): carbon’s about 12.01, hydrogen’s 1.01, and oxygen’s 16.00 atomic mass units. Multiply them by the number of atoms in the formula, and finally add the totals. Skipping this calculation can ruin batch consistency, and for products sold by the ton, mistakes add up quickly.

Real-World Stakes and Solutions

Doctors, engineers, and manufacturers trust these numbers to stay healthy and keep their projects running. If a generic medicine lists the wrong molecular weight, a pharmacy can’t ensure the right dose. For environmental safety, water treatment plants must balance chemicals perfectly to keep drinking water safe; just one miscalculation risks public health.

Protecting society means training every scientist and technician to double-check these values. Educational systems have to press on accuracy in basic chemistry before anyone graduates. Factories should make digital tools available to minimize human error in weighing and labeling. For anyone who finds chemistry intimidating, think of these formulas as seatbelts keeping processes safe and reliable.

A Vital Piece of Modern Life

The care that goes into chemical formulas and molecular weights reaches beyond textbooks and lab benches. It brings safety to a child’s cough syrup and efficiency to renewable batteries. As someone who’s seen formula errors derail both learning and business, I can vouch for the value of focusing on these basics day after day.

Understanding the Product’s Nature

The unique chemical makeup of this product means its quality changes quickly if basic storage principles go neglected. Moisture, heat, and light keep their own agendas. Plastic drums kept against a warehouse window soon warp or sweat, especially during a July heatwave. Once I saw a batch lose its potency within days because the storage room had dodgy insulation. Annoying, but a real wake-up call. Reliable handling starts with knowing what this stuff reacts to, and planning around those quirks.

Temperature and Moisture — More Than Just Details

At room temperature, this product keeps stable. Temperatures above 25°C (77°F) bring trouble — separation, color changes, off odors, and even unwanted side reactions. On the flip side, cold damp rooms help mold spores find a home, which no company wants to hear about. In practice, I’ve seen too many operators just stack pallets near HVAC vents to save space. That invites condensation and ruins entire shipments. Allocating dry, ventilated storage — away from windows, heaters, and wet floors — does not just tick a box. It keeps customers coming back.

That drives home the need for sealed, non-reactive containers. Not every packaging choice fits every need. HDPE drums and double-layer bags (as opposed to cheaper paper sacks) often get the nod for a reason: they block humidity and oxygen. Open containers left overnight are a fast track to contamination. I’ve lost track of the number of complaints traced back to someone forgetting to screw the cap back on between uses.

Safe Handling Isn’t Just about Labels

Smooth transitions make everyone’s job safer. Staff grabbing scoops with bare hands or mixing tools that sat unwashed overnight put more than a single batch at risk. Gloves, aprons, and—just as important—a clear policy for spills cut down on accidents. Signage and regular training keep rookies from repeating rookie mistakes. A simple mistake, like leaving a measuring cup in an unventilated corner, picks up moisture fast, which then lands in the next batch. That sounds small, but it ruins consistency.

Traceability and Accountability Score Big

Digital tracking and batch records now form a core part of compliance. Walk into a well-run facility, and you’ll spot detailed logs near every critical area. If an off-smell or weird discoloration pops up, it’s much easier to pin down if you can check what temperatures that pallet saw, or how long it took to reach the plant floor. It means fewer arguments about “whose fault,” and more time fixing actual issues.

Practical Solutions for Ongoing Challenges

Routine checks of warehouse climate systems pay dividends. I once watched a cold snap cause pipes to sweat, dripping onto stacked drums below. Fixing the insulation stopped problems for good. Investing in airflow and dehumidifying tech saves materials and headaches on busy weeks.

Worker buy-in makes the biggest difference. Regular briefings, open feedback, and clear roles shift storage from an afterthought to a part of the production routine. One plant I visited handed out quarterly bonuses for zero-waste stretches. Morale and compliance soared. Simple changes, but the payoff carries right through to end-users who get a product that does what it should. That’s the goal, every time.

Looking at the Science and Concerns

Some chemicals barely get a second glance beyond the laboratory, but 2-Hydroxy-N,N,N-Trimethylethanaminium Tetrafluoroborate—often called choline tetrafluoroborate—turns up in research and industrial settings more often than you’d expect. Its structure sounds technical, but it’s really a tweak on choline, a nutrient that feeds into many of the body’s processes. Researchers and chemical distributors list it as an ionic liquid salt, used in battery tech, catalysis, or as a solvent. It’s far from a household staple, but when a compound pops up in science, questions about its safety start to matter.

Real Health Risks

Anyone who’s worked in a lab has faced labels for “irritant,” “corrosive,” or “toxic.” Choline tetrafluoroborate doesn’t carry an obvious skull-and-crossbones, but the tetrafluoroborate part of the molecule gives reason to pause. When this type of salt meets water or acids—something that happens by accident with spills—tiny bursts of hydrogen fluoride gas can form. Breathing HF irritates your lungs, stings your eyes, and, in higher amounts, burns tissue. It grabs on to calcium in the blood, throwing heart rhythm and nerve function into chaos. Even skin contact leaves burns that feel worse later than when the splash happens.

Of course, most chemical handling happens in environments with fume hoods, gloves, and procedures to reduce any splash or spill. Still, lab safety accidents don’t just make for stories—they make headlines. A quick check of safety data sheets warns about the same things: keep dry, avoid contact, and use eye protection. From my own research experience, I’ve seen how small mistakes early in training go further with chemical salts containing fluorine. Nobody likes rushing someone to an eye-wash or running for the calcium gluconate gel.

Environmental Impact Doesn’t Let Us Off the Hook

Many modern ionic liquids, including choline tetrafluoroborate, get praise for not evaporating easily or leaking everywhere like old-school solvents. The thinking goes that if a solvent doesn’t vaporize, it can’t pollute the air as much, and it should make less mess. That argument worked well in some contexts, but nature always finds a way to surprise. Once these salts enter wastewater, the boron and fluorine atoms hang around. Some water treatment systems struggle to break down or filter out fluorinated byproducts, so they linger in rivers and groundwater.

Studies pointed to how both boron and fluoride affect fish development and plant growth—even at low levels, excess boron deforms roots, and fluoride prevents seeds from sprouting. Drinking water regulations put tight controls on fluoride and boron content, for good reason. Once released, ionic liquids don’t just go away; they build up over time.

Better Ways to Handle and Reduce Hazards

With any chemical, substitution, containment, and training matter the most. If an experiment or process can run with a less hazardous salt, chemists pushed to try them first. Keeping amounts small, securing containers, and having spill kits close by mean that even unexpected splashes or leaks can be dealt with before turning into disasters. Good documentation plus honest talk about accidents takes away the stigma that sometimes gets people hurt.

Industry and academia both do better by designing processes that avoid chemicals creating tough-to-remove waste. There’s room for more research. Next-generation ionic liquids—maybe salts without boron or fluorine—could play the same roles in batteries or catalysts with a lighter environmental load. Giving long-term health and planet safety a front seat works out for everyone: chemists, communities, and anyone downstream.

Relying on the Basics, Skipping Them Can Burn You

In labs and factories, jars and barrels carry cryptic names, sometimes labels peeling from years of handling. One question always cuts through the jumble: “Do you have the safety data sheet for this?” I’ve had supervisors raise eyebrows if I reach for something mysterious. Colleagues lean over and whisper warnings, sometimes more out of habit than actual worry. Most know that a safety data sheet shouldn’t feel like paperwork for its own sake. It’s not just to keep regulators happy—it’s a roadmap for survival.

A good SDS walks you through fire risks, poisoning concerns, environmental fallout, spill cleanup, and what to do if things go sideways. That’s not just a legal requirement. Knowing what makes up a compound and what it does to your lungs or the inside of a storage cabinet is information nobody should discover the hard way. Chemical accidents don’t politely wait for you to read up. One slip, rapid fumes, and it’s urgency time; in those moments, anyone who ducked the paperwork pays for it.

So, Why Aren’t SDS Always Easily Available?

Sometimes people stash these documents in folders nobody has checked since the last audit. Sometimes a supplier ships chemicals halfway around the world and forgets to include them in another language. The internet is supposed to help, yet I’ve seen teams huddle over screens, piecing together PDFs with outdated logos, or worse, ambiguous references to banned substances. It slows down work. Worse, it leaves blind spots. The information gap grows for the small workshops and labs that don’t have safety officers on call.

Small business owners or teachers in high schools may have no idea how to find the latest SDS version for something their vendor dropped off last month. Platforms like Sigma-Aldrich, Fisher Scientific, and government sites from OSHA or the European Chemicals Agency do keep databases, but the truth is, there’s no universal, always-up-to-date library. This means whoever handles chemicals has to be proactive, not just for themselves, but for folks nearby who might never see an SDS. A single lost or forgotten document has ripple effects for whole teams.

Human Costs and Smarter Habits

Stories hide behind the numbers. I’ve talked to technicians who bandaged up their own chemical burns before finally getting an ambulance. In one case, a grad student handled a solvent she thought was routine. The burn from a splash took weeks to heal because the lab had only a generic SDS, missing the mix’s hidden ingredients. Hospital forms, interviews, and insurance headaches followed, all because of a missing printout.

Every workplace should keep an SDS for every compound, in a shared and accessible spot, and anybody who deals with chemicals has a right (and responsibility) to demand them. Making a habit out of checking the paperwork before popping a cap is a small act that carries real weight. Digital apps that pull the latest SDS into your phone make that easier than ever—no more fumbling through dusty binders. And when employers bake this into training, people take it seriously. This isn’t busywork. It’s self-defense.

Life gets hectic and deadlines pile up, but comfort with a process breeds risky shortcuts. The moment a spill happens or someone gets lightheaded in a storeroom, the only thing between safety and disaster is solid information you can trust—readily available, in a language everyone can understand, for every compound in use.