3-Carboxypropyltriphenylphosphonium Bromide: An In-Depth Commentary

Historical Development

As the landscape of organophosphorus chemistry shifted in the 20th century, researchers started exploring compounds that could act both as synthetic intermediates and as functional reagents. Out of this intellectual ferment, quaternary phosphonium salts with carboxyl side chains emerged. Once triphenylphosphine joined forces with haloalkanoic acids, chemists realized that 3-carboxypropyltriphenylphosphonium bromide offered clean conversions and reliable reactivity. The demand for ylide precursors and carbon-carbon bond-forming partners drove this salt’s adoption. Decades later, the practical lessons learned during those early days still guide its modern preparation as well as its use in both bench-scale procedures and scaled-up syntheses.

Product Overview

3-Carboxypropyltriphenylphosphonium bromide stands out as a functional building block, not just for its predictable performance but also because it straddles an intersection of organic reactivity and biochemical interest. Lab-scale chemists find real value in its crystalline solid form, which makes handling and weighing straightforward. The pronounced ionic character ensures easy solubility in polar solvents—water, methanol, dimethyl sulfoxide—though it resists dissolving in typical organic hydrocarbons. Suppliers focus on purity as its downstream use in sensitive coupling or alkylation steps leaves little margin for error.

Physical & Chemical Properties

This salt presents itself as a white to off-white crystalline solid, which my own hands have found to be robust under ambient conditions, though it clumps if exposed to atmospheric moisture over time. Its melting point rarely strays from 235-240°C (decomposition), forming dense lattices that reflect the bulkiness of three phenyl rings attached to phosphorous. In terms of solubility, the bromide ion and carboxyl functionality pull the molecule toward polar solvents, making it practical for most lab scenarios. Under UV, its aromatic profile neither fluoresces nor interferes with detection by standard detection methods. Storage requires only a dry bottle in a well-ventilated stockroom.

Technical Specifications & Labeling

Users deserve to know exactly what they’re getting, so specifications tend to list purity—above 98% by HPLC—a finely screened mesh size, and identification by NMR and FTIR. Labels provide the full chemical name followed by its CAS number (26347-53-3 for reference), hazard statements, GHS pictograms, and sometimes spectral data. I’ve watched procurement officers ask for certificates of analysis before accepting any shipment, having learned the hard way that “mostly pure” does not cut it for demanding synthetic routines.

Preparation Method

Few synthetic routes match the reliability of reacting triphenylphosphine with 4-bromobutyric acid under reflux in a suitable solvent (toluene or ethanol often do the trick), followed by slow cooling that encourages product precipitation. I once made a batch by dissolving the acid in ethanol, adding triphenylphosphine, and then letting the mixture react for a day, yielding a granular product ready for filtration. Sometimes recrystallization from ethanol or acetone strips away adventitious impurities, generating a sparkly white solid that meets analytical grade.

Chemical Reactions & Modifications

The phosphonium salt shines as a ylide precursor for Wittig reactions, letting chemists convert aldehydes and ketones into alkenes. The carboxypropyl arm broadens the application window: after ylide generation, it encourages coupling with various electrophiles. Custom modifications—such as esterification of the carboxylic acid—let users tune reactivity or introduce tagging groups for bioconjugation work. In my own experiments, I’ve alkylated the carboxyl group to make derivatives more cell-permeable for enzyme studies. It reacts predictably across a range of pH, resisting hydrolysis up to moderate bases but breaking down under strong acidic or basic conditions. This flexibility fosters curiosity-driven chemistry, opening the door to tailored transformations.

Synonyms & Product Names

The corridors of chemistry have given this substance multiple names. “(Carboxypropyl)triphenylphosphonium bromide” describes it straight, though catalogs also call it “3-(Triphenylphosphonio)propanoic acid bromide” or abbreviate to “TPP-COOH Br.” I’ve even seen researchers in collaborative projects coin shorthand like “Triphenyl-CPB,” because no one wants to repeat a tongue-twister every time the compound appears in a protocol.

Safety & Operational Standards

Every prudent chemist reviews safety data before uncapping a new bottle. This salt, though less threatening than volatile solvents or alkyl halides, requires gloves and goggles. Inhaling powder or allowing skin contact brings risk of irritation, though it does not vaporize readily under normal lab conditions. Disposal must follow local regulations for phosphonium reagents and bromide wastes. On a plant scale, dust suppression and spill containment protect both workers and the environment, especially when handling kilo batches. Emergency procedures lean hard on effective ventilation and training every staff member to recognize early signs of exposure.

Application Area

Academic groups and pharmaceutical companies gravitate toward this salt when designing synthetic routes to α,β-unsaturated carboxylic acids or derivative drugs. In bioconjugation chemistry, researchers link the carboxyl group to biomolecules, then track the fate of triphenylphosphonium tags in living cells. One team, working on mitochondrial research, harnessed the lipophilic character of the phosphonium center to shuttle probes across cell membranes, which led to sharper imaging in live tissue. Industrial uses often include the compound as an intermediate rather than as a final product, showing up at critical moments in scale-up projects.

Research & Development

The last ten years brought a surge in mechanistic work that leverages this reagent’s predictability. Synthetic chemists published route innovations where mild conditions and reproducible yields gave the salt an edge over older, fussier ylide precursors. Collaborations with biotech labs led to trials of labeled derivatives as mitochondrial stains or drug delivery agents. High-throughput analytical methods now check each batch, so production chemists see fewer surprises at the QC stage. The expansion of “green chemistry” has also nudged researchers to cut down on solvent use and improve atom economy during synthesis.

Toxicity Research

Though it rarely tops the list of hazardous reagents, everyone in my experience treats 3-carboxypropyltriphenylphosphonium bromide with respect. Acute toxicity studies in rats report LD50 values exceeding 500 mg/kg orally, but chronic exposure data remain patchy, which keeps regulatory agencies cautious. The triphenylphosphonium moiety itself has drawn interest for its role in cell permeability and mitochondrial effects, sparking debate among toxicologists regarding long-term occupational safety. Regular monitoring, conservative exposure limits, and periodic reassessment based on new research help labs and factories keep risks in check.

Future Prospects

Advances in synthetic biology and complex molecule assembly hint that demand for functional phosphonium intermediates will rise. As researchers design mitochondria-targeting drugs or sensitive imaging tags, this compound’s flexibility shines. Improvements in catalyst systems may smoothen large-scale preparation, trimming costs and boosting purity. Automation and digital analysis will likely sharpen quality control, letting labs detect tiny deviations early. The continued focus on environmental impact may inspire greener synthesis methods and safer shipping practices, aligning new production strategies with modern regulatory goals.

A Closer Look at the Uses

3-Carboxypropyltriphenylphosphonium bromide shows up time and again in the world of synthetic chemistry. The backbone of this molecule, with its triphenylphosphonium center and extended carboxy chain, gives scientists a handle for carrying out Wittig reactions – a method people use to transform carbonyl groups into alkenes. Research labs rely on it as a reagent, especially in the formation of carbon-carbon double bonds. This is more than an academic exercise; those new bonds often form the core structure in a range of drugs and specialty chemicals.

Phosphonium salts have a reputation in organic synthesis – not just for their role in Wittig chemistry – but for the way they push reactions toward specific products. They’re a favorite for chemists looking to avoid unwanted byproducts. The carboxypropyl group in this case gives extra flexibility, allowing the molecule to participate in coupling strategies or as a building block for more complex molecules. I’ve talked with PhD researchers who say, without it, synthesizing some pharmaceutical targets would take many more steps or involve dirtier processes.

The Real-World Impact

Academic labs are not the only spaces where this compound circulates. Pharmaceutical companies often pull 3-carboxypropyltriphenylphosphonium bromide into their process development, especially when working on active pharmaceutical ingredients (APIs) that demand rigid control over structure. Precision is the name of the game, and this reagent brings it in a way few others can.

Green chemistry advocates push for more sustainable methods, and the phosphonium approach plays a part. Some processes using this bromide avoid the harsher conditions or heavy metal catalysts that can create long-term waste problems. As a bonus, it can sometimes cut down on the number of purification cycles, meaning less solvent gets dumped into the environment. That matters for any business facing tighter safety and disposal regulations.

Safety, Access, and Quality Control

Like many specialty reagents, purity and handled storage become crucial here. Laboratories need a supply chain they can trust, since contaminants have a habit of spoiling entire synthesis runs. I’ve watched research teams spend days troubleshooting a bottleneck, only to trace the problem back to a batch of impure phosphonium salt. This kind of hiccup delays timelines and burns through project budgets.

Working with this compound also requires a respect for its hazards. While reports show a low level of acute toxicity under handled conditions, it still qualifies as an irritant. Gloves, ventilation, and proper disposal all factor into routine protocol. Lax practices not only risk human health, but they invite regulatory headaches if agencies decide to dig into documentation.

Solutions and Future Outlook

One challenge remains access. Many smaller labs, especially in developing regions, find costs a barrier. Intellectual property rules and supply bottlenecks create scarcity. Industry groups can press suppliers to improve transparency around pricing and sourcing, enabling wider research opportunities. More open publication of reaction conditions and impurities will help users avoid pitfalls in the lab. A stronger community focus, through conferences and online platforms, encourages sharing hard-earned lessons—from reliable suppliers to clever ways to minimize waste streams.

The story of 3-carboxypropyltriphenylphosphonium bromide shows the chemistry world at its liveliest: seeking cleaner routes, fewer side reactions, and greater creativity in molecular design. Progress depends not just on access to reagents, but on a culture of careful responsibility and willingness to share the tricks and snags of daily lab reality.

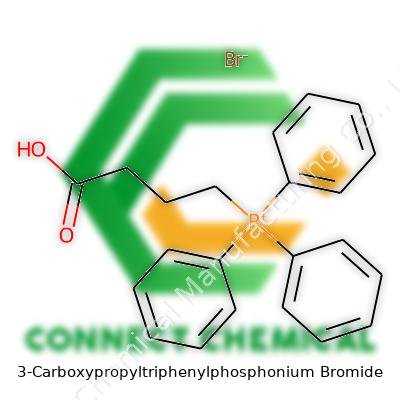

Diving Into Its Formula and Weight

Chemistry isn’t just for the lab. Sometimes, you run across a molecule that pops up in organic synthesis, biochemistry, and pharmaceutical research—3-Carboxypropyltriphenylphosphonium Bromide. The molecular formula for this compound is C22H22BrO2P. The molecular weight totals up to 429.29 g/mol. These numbers might look dry, but they speak volumes about the elements involved—carbon, hydrogen, bromine, oxygen, and phosphorus. Each forms a building block that shapes not only the structure but also the downstream uses of this molecule.

I’ve found that knowing the molecular formula lets you predict a lot about how a compound will behave in real-world settings. For chemists who deal in synthesis, the presence of the triphenylphosphonium group stands out. This moiety creates a positively charged phosphonium ion, making the molecule more reactive under specific conditions. Adding a carboxypropyl tail opens up doors for linking this compound with other molecules—vital in complex synthesis strategies. The bromide isn’t just a spectator. It rounds out the structure and influences the solubility and reactivity in both aqueous and organic media. A molecule shaped by its formula, really.

Why This Compound Matters Beyond the Numbers

If you’ve ever handled organic reactions aimed at generating ylides, then the importance of 3-Carboxypropyltriphenylphosphonium Bromide jumps out. It’s a common tool for building carbon-carbon bonds. Researchers across academia and industry depend on reliable reagents that can withstand repeated cycles of experiments—and this phosphonium salt delivers.

Its formula hints at its stability, as well. All those phenyl rings attached to phosphorus confer robust resistance against breakdown at moderate temperatures. The carboxylic group, on the other hand, triggers reactivity when paired with appropriate coupling agents. This opens up pathways not only for basic lab experiments but also for targeted drug synthesis and the creation of specialty polymers and materials.

Challenges and Real-World Concerns

One recurring challenge involves the use of bromine-based reagents. Bromides can be irritating or hazardous if not respected in the lab. I’ve known students caught off-guard by the handling risks and disposal hurdles—failures in training leave a mark in the form of hazardous waste or health scares. That’s why many facilities now push for clear safety protocols and greener alternatives where possible. When working with phosphonium salts, attention to storage and waste is crucial.

Researchers benefit from transparency in labeling and QC testing, making sure suppliers consistently provide material with the correct formula. Sloppy sourcing or ambiguous labeling leads to failed syntheses or wasted grant money—both painful lessons. Trusted sources become lifelines, and documentation matters.

Smart Practices and Solutions

Proper chemical education forms the bedrock for safe and efficient use. It goes beyond textbook definitions. Practical workshops, mentorship, and access to up-to-date safety data sheets build confidence in handling specialty reagents. Teams that keep up with evolving regulations and green chemistry guidelines reduce risk for everyone in the lab.

At the same time, efforts to develop chemical recycling, improved purification strategies, and alternative synthesis routes keep innovation alive. Solutions that cut reliance on hazardous components win support from safety offices and funding agencies alike. Ultimately, understanding the specifics of 3-Carboxypropyltriphenylphosphonium Bromide—the kind that comes from knowing its molecular formula—anchors all of these improvements. In chemistry, small details really do matter.

Watch Out for Moisture and Air

My earliest lab work stuck with me. Watching chemicals clump or degrade from the wrong air exposure, I quickly understood how unforgiving chemistry can be. 3-Carboxypropyltriphenylphosphonium bromide falls in that camp. This compound reacts with open air and moisture, which changes its behavior in experiments. Once too much water gets in, the material may not react as predictably, throwing entire projects off course. Moisture-proof storage isn't just a technicality. Projects waste time and money if one bottle gets lazy care.

Choose Containers That Block Light

Keeping this compound in the dark isn’t about hiding it—it’s about protecting value. Bright light and heat will break chemical bonds. I remember the first time I saw a photolabile vial break down. No technical explanation rescued those results. Many reagents degrade before any warning signs appear just by sitting on a sunny shelf. Amber glass containers make a big difference. They keep out stray UV rays from bench lamps, windows, or sunlight. Extra care with labeling—writing the date opened and checked—helps track shelf life before someone reaches for an expired powder.

Cool, Dry, and Tight-Sealed Works Best

A simple drawer in a crowded office never cuts it. Ingredients like triphenylphosphonium salts prefer a dry, well-regulated spot, often somewhere between 2–8°C. Standard household fridges won’t guarantee the right conditions, especially if they frost up or get warm during door swings. Dedicated chemical fridges or those small benchtop units rebuilt for lab use give consistent, cool results. I learned early to inspect gaskets and try to avoid crowding vials—nobody wants cross-contamination. Containers need tight, undamaged seals. O-rings or Teflon-lined lids beat crumbling corks or flimsy foil.

Label Everything and Keep Records

A bottle’s label saves hours of doubt down the line. Date of receipt, opening, and any repackaging—mark it all clearly. Labs I’ve worked in have been saved more than once by an old note on a sticker. Detailed records help spot problems faster. If a reagent shows signs of clumping, color change, or crystalline deposits, pulling the storage log can signal wider issues in the room—maybe a fridge started cycling too warm, or a humidity spike crept in unnoticed.

Personal Safety First

No chemical deserves rough handling. Powders like 3-carboxypropyltriphenylphosphonium bromide can irritate skin or eyes on contact. Even a quick container transfer ought to happen in a well-ventilated spot, with gloves firmly on. Every time I skipped PPE in a hurry, I paid for it—itching, tears, or worse. Spills mean a sharp cleanup routine. That means plenty of paper towels, waste bags clearly marked, and surfaces swept with a damp cloth. Everyone in the room wants to know nobody leaves invisible dust behind.

Takeaway: Reliable Science Needs Respectful Storage

Skimping on good storage breaks more than vials. Experiments falter, safety gets riskier, and confidence in results drops. Storing 3-carboxypropyltriphenylphosphonium bromide isn’t about fancy gear. It rests on awareness and discipline. That responsibility lands on everyone who opens the fridge or picks up the next bottle. When those habits take root, science moves smoother—and safer.

Getting the Facts Straight

For anyone moving chemicals around or keeping a close eye on what’s in the storeroom, the question of whether something is hazardous shapes our habits. The stuff with a long name—3-Carboxypropyltriphenylphosphonium bromide—sounds intimidating, but its everyday risks tend to hide in the plain data rather than clever marketing or myths.

Looking at the MSDS (Material Safety Data Sheet), you might notice there’s no bright-red hazard symbol. People working in research settings have gotten pretty used to scanning those warning signs—corrosive, flammable, toxic. This compound skips the drama but doesn’t mean you can treat it like baking soda. Phosphonium salts in general may have issues in the lungs or eyes if mishandled, and skin exposure might lead to irritation. Bromides are also notorious for causing surprises in the long run, like thyroid issues in those with long-term, careless handling. These aren’t urban legends tossed around in the industry. They come straight from hands-on experience and years of recorded incidents.

Where Things Go South

Work in the life sciences and you’ll see this salt on a reagent shelf. Most people handle it with gloves and a lab coat, no different from dozens of other white powders. A bit of dust in the eye or on bare skin can make a boring day suddenly memorable. Once saw a grad student shrug off a “routine” spill, only to regret not rinsing immediately. His skin irritations meant he missed a week’s worth of work. Not life-threatening, but a real hassle, especially with deadlines. It’s easy to get complacent, especially if a chemical doesn’t look like it came out of a horror movie. That’s a trap in any lab or prep room, no matter how much experience is floating around.

Potential Routes of Exposure

The stuff definitely tastes bad—traces floating in lab air can cause a metallic flavor, even if you’re not eating your lunch at the bench. Small organic compounds with lipophilic tails like this one tend to hitch rides on aerosols or find gaps in thin latex gloves. Long-term exposure isn’t something anyone signs up for, and years later, that can lead to constant skin complaints or unexplained coughs. Data gathering by organizations like OSHA and ECHA hasn’t flagged it as a prime health hazard, but absence of proof doesn’t clear it entirely.

Tips for Safer Handling

Decent protection boils down to a handful of rules: Closed shoes, gloves (nitrile works well), splash goggles, and a fume hood if you use it on a scale larger than a test tube. Don’t skimp on handwashing. Label the bottle. If you spill, don’t sweep it up with your bare hands—use a scoop, plenty of water, and throw away any paper towels used for cleanup.

Lab managers and safety officers serve a real purpose keeping these standards visible, reminding folks not to eat or drink where powders roam. In my own years at the bench, calls to poison control have been less about explosives and more about “boring” reagents like this one. It’s usually a matter of routine meeting carelessness, and it’s the little lapses that cause trouble. As someone who’s logged more than a few incident forms, those reminders never get old.

Why Solubility Matters in Research Labs

Anyone who’s spent time with organic synthesis knows the struggle of a stubborn compound refusing to dissolve. 3-Carboxypropyltriphenylphosphonium bromide might sound daunting, but it’s just another workhorse in the phosphonium salt family. Chemists need predictable behavior—unexpected insolubility can grind experiments to a halt. Selecting the right solvent does more than just save time; it safeguards accuracy. My own experiments with quaternary phosphonium compounds showed me that using an ill-suited solvent leaves you with a gritty mixture rather than a proper solution.

Solvents That Actually Work

Water tends to be the obvious starting point, given the carboxylic acid group and bromide ion. In practice though, only a handful of phosphonium salts dissolve fully in water. 3-Carboxypropyltriphenylphosphonium bromide actually manages reasonable solubility in water, especially when gently warmed or sonicated. Make sure the water is not ice cold, as lower temperatures slow the process.

Polar organic solvents also step up, particularly dimethyl sulfoxide (DMSO) and dimethylformamide (DMF). I’ve mixed this salt into DMSO without stubborn residue left in the flask. Ethanol solves some, but not as much as pure water or DMSO. Acetonitrile just doesn’t coax this salt into solution, so I leave it out when planning reactions.

The lesson here: if you want a quick route to dissolving 3-Carboxypropyltriphenylphosphonium bromide, grab a bottle of DMSO or slightly warm water. DMF offers another solid choice, though it smells even worse than DMSO in the lab.

Why Lab-Ready Data Matters

Lab manuals and catalogues often gloss over practical details. It’s no secret that real-world results don’t always match up with datasheets. I’ve seen more than one colleague make a judgment call based on old solubility charts, only to lose a full day of work. Reliable solubility information saves resources and protects experimental timelines. European Chemical Agency (ECHA) and major chemical suppliers already publish technical data on compounds like this; cross-checking never hurts if the process seems off.

Take the time to document results and communicate them. When you write honest lab notes about successful solvents, you help out the next researcher who comes along, rather than making them repeat frustrating dead ends. Plenty of academic mishaps could have been skipped if the previous user had dropped a note about solubility in the lab journal.

Safe Handling Follows Good Chemistry

Solubility isn’t just a technical topic; it connects right into safety. DMSO and DMF both absorb easily through gloves and skin, and they carry whatever they dissolve with them. Using nitrile or even double-gloving makes sense, even for small-scale tests. Poor safety practices in pursuit of a fast solution leave the entire team at risk, especially if toxic reagents or side-products are around.

Looking Beyond the Basics

Chemistry is full of detail, and solvent choices shape the results you get from reagents like 3-Carboxypropyltriphenylphosphonium bromide. Talking with other chemists, cross-referencing technical data, and keeping safety at the front of your mind can mean the difference between frustration and a clean, publishable yield. It’s not just about dissolving a salt—it’s about keeping your work moving and accurate for the next project.