3-Isocyanatopropyltriethoxysilane: A Deep Dive into Its Science and Role in Industry

Historical Development

The path to 3-Isocyanatopropyltriethoxysilane's commercial production goes back to the surging demand for advanced coupling agents in polymer chemistry during the 1970s and 1980s. Chemists wanted a molecule that could link organic polymers to inorganic surfaces without sacrificing adhesion or flexibility. Through focused research, teams in Europe and Japan explored alkoxysilanes with reactive isocyanate groups, gradually refining synthetic methods as safety data accumulated. Large-scale manufacturing took off once regulatory bodies recognized the value of these organosilicon compounds in boosting the strength and weather resistance of composites.

Product Overview

3-Isocyanatopropyltriethoxysilane acts as a well-established silane coupling agent, supporting both adhesion and surface modification in a range of industries. Its structure features a triethoxysilyl “tail” that bonds with glass, stone, or metal surfaces, while the isocyanate “head” reacts with resins, polyurethanes, and epoxies. Factories that rely on glass-filled plastics, fiber-reinforced materials, or moisture-cured elastomers typically keep this chemical on hand for boosting interfacial adhesion. Manufacturers welcome its predictable chemistry, fast reactivity, and compatibility with coating, adhesive, and sealing compositions.

Physical & Chemical Properties

This organosilane appears as a colorless, mobile liquid. Its molecular weight hovers around 247 g/mol, and it boasts a boiling point near 255°C, which makes storage quirkier than with simpler alcohols or amines. The isocyanate group delivers a pungent aroma and displays notable reactivity toward nucleophiles. Anhydrous storage keeps the bottle free from unwanted hydrolysis—moisture rapidly converts the ethoxy groups to silanols and ethanol. In the lab, care is taken to prevent contact with water, acids, or alcohols, since those trigger quick changes to the material and sometimes produce heat and off-gassing.

Technical Specifications & Labeling

Commercial product usually exceeds 97% purity, with moisture content below 0.1%. Material safety data sheets warn users about the sensitivity of the isocyanate group. Suppliers puzzle over the delicate labeling—shipping containers always need hazard markings for respiratory and skin sensitization, alongside clear instructions for fire prevention. Barcode-based tracking has become common so facilities don’t lose track of shelf life.

Preparation Method

Chemists favor a route that couples 3-aminopropyltriethoxysilane with phosgene or phosgene substitutes, like triphosgene, under anhydrous conditions. The process releases hydrogen chloride, which must be carefully neutralized or scavenged in situ. Manufacturers demand batch-to-batch consistency by operating closed reactors with automated feed controllers, rigorous inert gas purges, and real-time byproduct analysis. Waste streams end up in scrupulously monitored scrubbers or incinerators, given the environmental impact of trace isocyanates and chlorinated chemicals.

Chemical Reactions & Modifications

3-Isocyanatopropyltriethoxysilane owes its utility to fast addition reactions. The isocyanate group latches onto amines, alcohols, and even some thiols in room-temperature conditions, forming stable ureas, urethanes, or thiocarbamates. Polymer scientists often adapt the silane for tailored crosslinking or as a surface treatment to boost the compatibility of glass or mineral fillers in composite resins. In paint shops, small tweaks to the silane allow manufacturers to fine-tune curing rates or solvent resistance, all by coaxing the right reaction at the right time.

Synonyms & Product Names

Chemical catalogs and patent filings list this compound under several aliases. Besides “3-Isocyanatopropyltriethoxysilane” or “ICPTES,” buyers run into names such as “γ-Isocyanatopropyltriethoxysilane,” “triethoxy(3-isocyanatopropyl)silane,” or CAS number 24801-88-5. Brand names pop up, from Dynasylan ICPTES (Evonik) to Silquest A-Link NCO (Momentive), but careful readers still double-check structural diagrams to avoid confusion in multi-product orders.

Safety & Operational Standards

Strict air-handling, PPE, and emergency procedures fill the playbook for handling 3-Isocyanatopropyltriethoxysilane. Workers wear full goggles, gloves, and in some cases, powered air-purifying respirators. Sensitization remains a risk, both through skin and inhalation exposure. Facilities lean on local exhaust ventilation, closed transfer systems, and continuous training. Spills trigger immediate evacuation and response: adsorbent pads mop up the chemical, while contaminated waste goes straight to hazardous disposal drums. Health monitoring includes pre-employment screening and routine checks for respiratory effects. Nobody skips the fume hood.

Application Area

Composites manufacturers accept no substitutes for silanes when they want reliable glass-resin bonding. ICPTES delivers, particularly in automotive and construction markets where weight and longevity matter. Cable coatings, electronics encapsulants, and specialty adhesives all pull this chemical off the shelf for its dual action: it bonds the toughest fillers and resins, weatherproofs concrete or stone, and improves chemical resistance. In the lab, researchers keep stock ready for making robust coatings or seeking stronger mechanical properties. Areas demanding resistance to moisture and temperature swings view this silane as a workhorse material, not just a laboratory curiosity.

Research & Development

Development teams always look for better ways to limit worker exposure while bumping up performance. Recent academic work investigates low-toxicity substitutes for isocyanates without losing that coveted reactivity. Other studies focus on combining ICPTES with nanoscale fillers for improved mechanical or electrical performance in composites. Feedback loops between users, regulators, and suppliers now shape new process controls, blending greener chemistry with the demands of modern manufacturing. Open calls for continuous improvement have nudged several producers to reduce waste and energy during synthesis by tweaking catalysts and process design.

Toxicity Research

Toxicologists aim to map out the range of effect, from skin irritation to longer-term lung sensitization. Early animal studies documented inflammation at exposure levels found in unventilated spaces. Chronic studies in workers who handled isocyanates observed asthma, skin rashes, and sometimes delayed hypersensitivity. Inhalation studies drove home the importance of strict containment and medical monitoring. Major journals continue to publish updates to threshold limit values and personal protection guidance, echoing industry trends toward closed systems and remote monitoring to protect workers and downstream users alike.

Future Prospects

Sustainability demands reshape the conversation around all organosilanes. Environmental researchers press for renewable starting materials and recyclable products, while buyers want more data on end-of-life safety. Some chemical startups pitch water-stable isocyanate alternatives; others develop faster-curing formulations that cut down on volatile emissions. As regulations adjust to new toxicology, market leaders insist on traceability and transparency, knowing that tomorrow’s customers read labels and safety disclosures as closely as technical data sheets. Future improvements will hinge on practical chemistry, worker advocacy, and honest data-sharing across the entire supply chain.

Why This Chemical Matters in Manufacturing and Everyday Life

Walk through a car factory, or tour a building site, and you’ll see hundreds of different composite materials stuck together. They need to survive vibration, heat, and water. Some of these bonds keep skyscraper glass in place or hold electronics tightly sealed from moisture. Many rely on specialty chemicals bridging organic materials, like plastics, with inorganic ones, like glass or concrete. One name pops up all the time in technical sheets: 3-Isocyanatopropyltriethoxysilane.

I worked a summer job in a door and window plant. Workers there told me stories about leaky joints, and how years ago people would just patch things in place, only for rain or wind to break bonds apart. Today, assembly lines trust silane coupling agents to create much tougher seals. 3-Isocyanatopropyltriethoxysilane stands out among these, mainly because it can connect things that usually hate sticking together.

How 3-Isocyanatopropyltriethoxysilane Actually Works

This chemical wears two hats. On one side, its isocyanate group grabs onto urethane or epoxy resins—stuff found in foams, adhesives, and coatings. On the other side, the triethoxysilane end reacts with glass, metal oxides, or stone. Imagine building a LEGO bridge where one end locks with plastic bricks, and the other end uses pegs designed for wooden blocks. Without something like this, companies would need twice as many adhesives, and reliability would drop off.

In electronics, I saw large display screens exposed to all sorts of temperature swings. A quick visit behind the scenes revealed silicone adhesives modified with specialty silanes. Downtime hurts business, so the techs lean hard on solutions that stop moisture creeping in. In paint and coatings, 3-Isocyanatopropyltriethoxysilane helps resins stick to glass beads or mineral fillers, cutting down the odds of coatings chipping under sunlight or grit.

What the Science and Safety Say

Chemical suppliers often highlight how this silane can reduce the risk of material failure. Market research from 2023 estimates thousands of tons of silane coupling agents sold yearly, especially for automotive and construction sectors. Reliability studies from ASTM and ISO labs support these claims, showing higher peel strengths and extended life in products using silane-modified adhesives.

The downside is health and safety. The isocyanate group can cause allergic reactions or asthma in workers. Manufacturers now provide strict protective gear, ventilation, and training. Some alternative chemistries aim to cut health worries, but nothing quite matches the performance of 3-Isocyanatopropyltriethoxysilane under the harshest conditions. Regular audits, improved handling practices, and closed systems help companies keep risks down.

Ways to Tackle Challenges Going Forward

Product engineers and environmental scientists talk about better application methods—robotic sprayers, lower-dose formulations, and push-button monitors for air quality. Cleaner chemistries hold promise. For now, nobody wants skyscraper joints or electric car parts glued with something less reliable. Been there, patched that, threw out the batch. Until greener solutions can deliver the same track record, many shops will keep a tight grip on controlling exposure and squeezing the most value out of every drop.

Learn from the folks who assemble, install, and maintain; their experience with 3-Isocyanatopropyltriethoxysilane proves it has made things safer, longer-lasting, and more affordable on the whole. As the push for sustainability grows, this chemical stands at a crossroads between performance and responsibility.

Safe Storage Starts with Understanding

3-Isocyanatopropyltriethoxysilane isn’t just any old chemical. On paper, it’s a clear or slightly yellowish liquid used extensively in coatings and adhesives, celebrated for its ability to bond organic and inorganic materials. In practice, even minor oversights in handling this stuff can cause reactions or degrade its quality. I remember walking into a storeroom as a junior chemist and seeing old metal cans sweating in the summer heat—nobody bothered to check if the seals were tight, or if vapor was starting to build up. That’s not just careless, it’s dangerous.

Keep It Cool, Keep It Dry

Warm air and humid conditions spell trouble for isocyanate-based chemicals. Over the years, I’ve seen these silanes react with moisture—subtle at first, just a rise in pressure inside the container, but it doesn’t stay subtle. The isocyanate group loves water, and this reaction releases carbon dioxide and forms sticky polymers, which’ll mess up both your product and your workspace. That means storage in a cool, shaded area, away from direct sunlight or sources of heat. Standard industry guidance recommends 2°C to 8°C (a typical chemical storage fridge does the trick), but more important than sticking to a single number is making sure the temperature stays steady.

Sealed from Air and Water

Oxygen and water vapor in the air both play the spoiler with this silane. I once worked in a lab where the bottles had loose caps, and a crusty white substance built up on the outsides within weeks. That’s the hydrolysis byproduct—a waste of money, plus a contamination risk. Keep containers tightly closed, use original packaging if possible, or opt for HDPE or glass with reliable seals. Silanes have a sneaky way of tracking in air from the headspace, so minimizing the number of times you open the bottle pays off. Some people replace the air above the liquid with dry nitrogen to cut the risk even further.

Separate from Incompatibles

Hazards don’t announce themselves until it’s too late. Many folks stack containers wherever there’s space, but silanes belong nowhere near acids, alkalis, oxidizers, or amines. Mix-ups can cause reactions that release heat or hazardous vapors, not to mention wrecking your chemical batch.

Label Clearly—Because People Forget

A smart labeling system means fewer crises later. Avoid worn-out markers and scribbled notes. Keep the product name, date of receipt, and an expiry or retest date on every bottle. Even with proper storage, 3-isocyanatopropyltriethoxysilane can degrade over time—its shelf life is typically a year, if handled right. After just a few months in poor storage, purity drops, and you may find yourself trouble-shooting failed experiments or product returns.

Ventilation for Safety

Volatile compounds like this one release vapors, and nobody wants these building up to hazardous levels in a closet or storeroom. Stash all containers in a well-ventilated area or fume hood. The smell alone is unpleasant, but respiratory irritation and longer-term health risks matter much more. A simple exhaust fan or, better yet, a walk-in chemical storage room with a dedicated HVAC setup improves both air quality and peace of mind.

It’s About More Than Just Compliance

It’s easy to treat these precautions as just another checklist, but there’s a real-world impact: wasted raw materials, safety hazards, downtime, or product failures all cost money and credibility. Some companies invest in automated inventory systems or walk-around checks with digital logging so mistakes don’t slip by unnoticed. These systems may seem like overkill, but after years in this work, I’ve seen small lapses turn into big incidents far too often.

The Nature of the Challenge

Working with chemicals like 3-Isocyanatopropyltriethoxysilane isn’t a walk in the park. It's easy to look at a material safety data sheet and think the advice only applies to scientists in white lab coats. My experience in a small polymer lab taught me otherwise—anyone pouring a liquid or mixing solutions stands face-to-face with real risks. This compound brings specific dangers, especially to the skin, eyes, and lungs. One careless moment, such as a splash during transfer or a wisp of vapor escaping because of a badly fitting glove, proves why the right steps matter.

Skin, Eyes, and Airways: Critical Points of Attention

3-Isocyanatopropyltriethoxysilane can burn skin and eyes, so once, after hearing stories from older colleagues, I doubled up on nitrile gloves and a face shield. Heat and humidity can cause gloves to break down faster, so I got into the habit of changing gloves more often than labels suggested—better an extra ten minutes lost than hours in a clinic. Splash-proof goggles and full-face shields block the irritation, redness, and, with enough exposure, even lasting damage to sight. Skin contact leaves redness and swelling, with long-term effects like chemical sensitization. That risk doesn't fade after one day; repeated exposure can turn even tiny splashes into full-blown reactions.

Keeping Vapors Under Control

People sometimes trust a fume hood to fix everything, but it works only if fans and filters stay in top shape. During a hood failure at my old workplace, one whiff of vapor led to coughing and shortness of breath. The lesson: don’t rely on old habits or "good enough." Always use a properly certified respirator when the task might stir up mists or vapors. Goggles seal out fumes, not just splashes.

Storage Habits Shape Outcomes

Leaving a bottle on a bench near sunlight or a hot pipe raises the risk of decomposition, turning a useful reagent into a health hazard. Flammable liquids cabinet, good ventilation, and steady, moderate temperatures make the difference between a safe workspace and cleanup after a leak. I’ve seen coworkers save headaches by labeling containers clearly—no improvising with old washing-up bottles. Fresh, sealed packaging and strict attention to expiry dates aren’t just for audits; chemicals lose punch or break down into nastier byproducts over time.

The Human Factor: Training and Vigilance

No chemical safety method beats well-practiced, repeatable routines. Regular drills, glove checks, and eyewash station tests kept our team sharp. One of our best habits involved every team member retracing a procedure and talking through what-ifs before opening a container. Little reminders from colleagues help plug the gaps fancy written policies miss.

According to the National Institute for Occupational Safety and Health, sensitization to isocyanates causes long-term diseases that cut into a person’s life. Picture someone who can’t walk into a lab without an asthma attack. Whether on the production floor or in a university lab, a safety-first mindset protects careers, not just health. If everyone on site takes the threat seriously, injuries drop, emergencies fade, and the job stays satisfying.

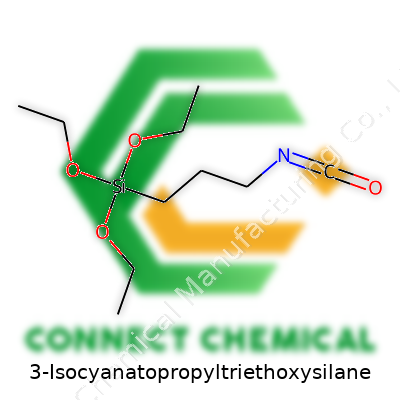

The Anatomy of a Handy Silane Coupling Agent

Look at 3-Isocyanatopropyltriethoxysilane on a chemical diagram, and you get more than a jumble of atoms. This molecule packs together a few worlds: the reactive isocyanate group, a darn useful propyl chain, and the well-known triethoxysilane block. The backbone of the molecule traces out like this: OCN–(CH2)3–Si(OC2H5)3. Each part pulls weight for surface chemistry and industrial uses.

Let’s start with the isocyanate group, NCO. This group gives the molecule a bite, since isocyanates bond well with things that have an active hydrogen—think amines and alcohols. That’s a game-changer in adhesives and coatings where strong, lasting bonds matter. The central three carbon propyl chain acts as a long-enough leash to keep reactivity in check and let both ends of the molecule connect to their partners without crowding.

Then the triethoxysilane: this group shines in making things stick—really stick—to inorganic surfaces. The Si atom in the middle bonds to three ethoxy groups (–OC2H5), which break apart in the presence of water to reveal silanol (Si–OH). That new silanol then grabs onto hydroxyl-rich materials like glass or metal oxides, anchoring the organic molecule on an otherwise stubborn surface. I’ve seen this chemistry save headaches in labs, turning stubborn glassware and powdery fillers into compatible friends for coatings, plastics, and rubbers.

What Makes This Molecule Matter?

It’s not just another name in a catalog. 3-Isocyanatopropyltriethoxysilane stands out as a bridge between organic compounds and inorganic surfaces. Its talent for forming durable chemical bonds makes it irreplaceable when looking for better adhesion, moisture resistance, or extended product life. From experience, I know this matters not just on paper, but in products people use every day—from car tires to microelectronics.

Why care about the structure at this level? Knowledge of how each group connects helps troubleshoot problems during formulation. Curing gone wrong, moisture sensitivity, surface incompatibility—all symptoms that trace right back to the twists and turns of this molecule’s structure. Knowing what each functional group can do moves you from guessing to targeted problem-solving. Ask anyone blending new resin composites: the right silane cuts down on trial-and-error and gives you data you can trust. Published studies confirm that isocyanate-functional silanes boost both wet and dry adhesion in composites, and the U.S. National Institutes of Health’s PubChem resource catalogs its core reactions for further reading.

Pitfalls and Solutions

This chemistry works best under careful hands. The isocyanate group can react with ambient moisture, kicking off unwanted side reactions. That means handling under dry conditions and proper storage—no shortcuts save time in the long run if you want predictable results. Training workers and laying out controlled procedures in the shop goes a long way here. I’ve seen production lines grind to a halt because of overlooked humidity, a costly mistake in fast-paced industries.

Efforts to develop safer alternatives are ongoing, since isocyanates can irritate lungs and skin. Labs around the world have been exploring blocked, less volatile versions, hoping for similar bonding power with better safety records. It’s slow progress; real-world testing and regulation review take time. Until those advances come to market, best practices like personal protective equipment, ventilation, and updated safety training tie the bridge between science and safe, effective daily use.

What This Chemical Does to People

Anyone who has worked in a lab or a production plant knows the drill: follow those safety protocols or you will get burned, choked, or worse. 3-Isocyanatopropyltriethoxysilane stands as a good reminder. Its chemical structure brings together an isocyanate group and an organosilane. That combo offers unique benefits for adhesives and coatings, especially in automotives and construction. Toxicity, though, overshadows the advantages, because isocyanates can go straight for the lungs, skin, and eyes the second they get loose.

Breathing and Skin Risks

I have dealt with isocyanate vapors in cramped areas and can tell you this: it only takes a whiff to set off coughing, burning in the nose, and a shortness of breath that feels way out of proportion. Even low levels can trigger asthma-like reactions. Friends who have gotten exposed without respirators needed ER help. Chronic exposure can leave permanent lung damage or long-term asthma. Health reports from NIOSH and OSHA show these chemicals count as some of the top causes of occupational asthma worldwide.

Skin contact doesn’t go easy, either. Isocyanates bind to skin proteins fast, causing rashes, chemical burns, or allergic dermatitis. Once the body develops a sensitivity, it doesn’t forget. Even a trace exposure years later can provoke a blistering reaction, and folks who develop a sensitivity may have to leave their jobs. The CDC laid out case studies of workers who suffered severe, career-ending allergies after repeated handling.

The Eye Problem

Splashing this chemical into your eye creates immediate pain, redness, and potential for long-term injury. Some colleagues in chemical processing lost days of work and needed specialized ophthalmology care after minor accidents with even diluted solutions. Safety Data Sheets warn outright: proper goggles are non-negotiable, as even vapor exposure can cause eye watering and swelling.

Environmental and Spill Hazards

It’s not just a worker’s health issue. Once 3-Isocyanatopropyltriethoxysilane hits water or reacts with humidity, it starts releasing toxic byproducts that harm aquatic life and plants. Silanes in general, and this compound specifically, break down to form strong acids and silanol. The breakdown products can linger — just another reason spills demand a serious response. In my time with environmental clean-up teams, I’ve seen how even small leaks lead to headaches, especially if local waterways are nearby. Containment and neutralization require fast action, and mistakes can mean sanctions, fines or permanent ecosystem damage.

Solutions That Work

One lesson from years on the plant floor and in fieldwork: short-term fixes don’t cut it. Regular training and equipment checks need to become habits. That means fume hoods, air monitoring, full-face respirators, and double-checking every seal before starting work. Employers must offer regular medical screenings for anyone handling isocyanates and support those who experience symptoms, not just point to safety posters.

Labels, gloves, and emergency plans matter, but there’s no substitute for building a culture where people speak up when they spot leaks or irritants. Replacing isocyanate-based products with safer alternatives, wherever possible, has worked in some laboratories and industrial sites. The shift pays dividends in fewer sick days, less turnover, and lower long-term risk. Labor unions and safety committees can help push these changes forward, especially if leadership drags its feet.

The chemical brings clear hazard signals with it. Honest conversation, good gear, and a willingness to adjust processes make up the real protective barrier. That is the path not just to compliance, but to survival and dignity on the job.