4-Bromobutyric Acid: A Practical Look from Lab Bench to Industry

Historical Development

4-Bromobutyric acid didn’t catch much attention in the early decades of organic chemistry, overshadowed by simpler halogen acids and more commercially relevant building blocks like bromoacetic acid. But as more methods popped up for selective halogenation, especially with advances in controlled bromination in the mid-20th century, this compound found its niche. The utility of the four-carbon backbone and halo-functionality positioned it as a workhorse in both academic and commercial syntheses, registering as a stepping stone to pharmaceuticals and advanced materials. Chemists started leaning toward 4-bromobutyric acid when they wanted a versatile linker, especially as research interest swelled in GABA analogs, industrial catalysts, and specialty esters.

Product Overview

The commercial demand for 4-bromobutyric acid generally centers on its ability to serve as an intermediate. Its blend of reactivity and manageable size makes it a regular fixture in process chemistry, especially in larger fine-chemical plants. The acid offers a sort of chemical “handle” in synthesis—giving downstream actors like pharmaceutical scientists or polymer specialists a way to tack on additional atoms or groups without muddying the rest of the molecule. As someone who's spent time browsing lab suppliers and running small-scale preps, it tends to show up on shelf labels in brown glass or HDPE bottles, usually as a white, sometimes faintly gray, crystalline solid with a defined, sharp odor reminiscent of weak acids and lightly halogenated organics.

Physical & Chemical Properties

This compound clocks a molecular formula of C4H7BrO2 and tips the scale at 167.01 g/mol. It has a melting point hovering around 48°C—low enough that it softens in a warm room, but not so low that handling turns sloppy. In water or methanol, it has limited solubility, which can complicate purification, especially for larger runs. Its strong acidity falls in line with other short-chain carboxylic acids, but the four-carbon tail and bromine atom boost both lipophilicity and molecular heft, nudging it into specialized territory for synthetic purposes. On a safety note: it shouldn’t be confused with the more volatile bromoalkanes, because its carboxyl group anchors down both vapor pressure and baseline reactivity.

Technical Specifications & Labeling

Regulations demand producers supply exact labeling, including the CAS number 1119-51-3 and typical purity upwards of 98% by HPLC or GC. Hazard communication usually flags it for skin and eye contact, inhalation hazards, and corrosivity. Producers send it out with proper signal words, R-phrases and precaution phrases under the GHS and reach compliance within the safety data sheet. Consistency matters as many buyers run tightly validated processes, so trace contaminants like 1,4-dibromobutane or oxidized byproducts get flagged in QC. From what I've seen, reliable suppliers tout certificates of analysis—a requirement for regulatory paperwork in pharmaceutical and agricultural development.

Preparation Method

Lab workers typically reach for straightforward synthetic routes. Bromination of gamma-butyrolactone with hydrogen bromide in the presence of a phase-transfer catalyst remains common. Another method involves reacting 4-chlorobutyric acid with sodium bromide under reflux, which produces a clean substitution, keeping side products to a minimum. For scale-up, companies often switch to continuous flow, helping to reduce hazards associated with handling gaseous or fuming brominating agents. One of my own early experiences involved a scaled-down version: patience, ice-cold water baths, and careful acid-base workup made the difference between clean product and a tarry mess. Residual solvents, moisture, and proper pH adjustment—these seemingly small steps decide the difference between a marketable product and waste.

Chemical Reactions & Modifications

This acid acts as a solid jumping-off point for nucleophilic substitution. You can swap out the bromine for azides, thiols, or even cyanide, modeling new molecules for drugs or other advanced chemicals. The carboxyl group also invites modification, either through esterification, amidation, or simple salt formation with bases. In my own hands, transforming it into a methyl ester creates a substrate ideal for polymerization studies. Both students and experienced chemists find its dual-reactive nature—easy substitution at the bromine and standard carboxylic chemistry—saves steps and opens plenty of synthetic doors.

Synonyms & Product Names

Across catalogs and research articles, 4-bromobutyric acid goes by a handful of aliases: gamma-bromobutyric acid, 4-bromobutanoic acid, or simply "Br(CH2)3COOH." The names can muddle search results and ordering, especially for newcomers who mistake it for other bromo acids with different chain lengths. Spotting the correct names on bottles or order forms has been a minor but recurring challenge, especially across jurisdictions or language barriers. This makes familiarity with naming conventions less a formality and more of a practical necessity.

Safety & Operational Standards

From a safety standpoint—this chemical asks for respect in the lab and full attention to PPE. Gloves, eye protection, and fume hoods are not optional. Even in dilute form, skin or mucosa contact brings on irritation. Regulatory bodies like OSHA in the United States and REACH in Europe demand explicit skin and inhalation warnings. Despite the solid, low-volatility nature, spills or container breaches can lead to localized contamination and disposal hassles. I remember one spill that traveled underneath the lab bench, requiring a full decontamination—so proper containment, like spill trays and labeled waste, really counts.

Application Area

4-Bromobutyric acid shows up in pharma as a molecular scaffold in anticonvulsant and cognitive drug research. Industrial chemists treat it as a link in custom surfactant synthesis and specialty resin formulations. Its reactivity serves well for chemists focused on ligand design, especially when a pre-installed "handle" (the bromine) simplifies downstream modification. Outside of pharma, its transformation into various esters or amide-linkage products finds space in the development of agricultural chemicals and even flavor and fragrance intermediates. Students working in organic research often reach for this molecule as a testbed for various substitution reactions—a rite of passage for many.

Research & Development

In the research world, studies on gamma-brominated acids keep expanding, especially as new methods spring up for selective carbon–halogen activation. Analytical chemists keep exploring more precise quantification by chromatography and high-resolution mass spectrometry. Projects targeting novel drug candidates based on GABA analogs often rely on stable supplies of 4-bromobutyric acid for prodrug strategies or for forming new heterocycles. I’ve read grant applications and seen research posters trumpeting the chemical as a building block in enzyme inhibitor development or as a tag in click-chemistry approaches. Academic and industry groups publish modifications that boost yields or safety, always searching for greener, less hazardous reagents—knowing any industrial adoption hinges on these improvements.

Toxicity Research

Handling this compound uncovers ongoing questions on human exposure limits. Lab animal studies show moderate oral and dermal toxicity, with symptoms tied to generalized irritation and central nervous effects. Repeated exposure risks escalate, especially with chronic handling—sensitization and cumulative effects can show up over longer timelines. Data gaps exist on full carcinogenic potential and long-term genetic impact, making conservative risk management necessary. I always err on the side of caution: no shortcuts with exposure monitoring, proper waste disposal, and thorough review of up-to-date safety data. Modern regulations, thankfully, keep pushing for better toxicological studies before higher-volume use gains approval.

Future Prospects

The coming years promise expansion as fields like medicinal chemistry, smart materials, and industrial catalysis call for more varied and reactive building blocks. Interest in “greener” methods pressures scientists and manufacturers to develop safer routes to 4-bromobutyric acid—less reliance on fuming bromine, more recyclable solvents, better overall atom economy. Even incremental improvements in catalysis or production flowlines can push down costs, lower hazardous waste, and cut barriers for smaller-scale innovators. Demand for customization and the global nature of chemical supply chains only grow sharper each year, and I see plenty of colleagues looking at 4-bromobutyric acid as a solid, adaptable choice. With changing regulations and research priorities, companies treating safety, supply-chain security, and environmental footprint seriously will lead progress—leaving behind older pathways for more sustainable and practical chemistry.

Digging Into the Science

4-Bromobutyric acid stands out in my mind not just because it’s got a name that could trip up anyone at a dinner party, but because it finds real value in chemical labs. Known for its four-carbon backbone and a bromine atom tagging along, this compound gets plenty of attention from synthetic chemists. You won’t find it on your pharmacy shelf, but if you peek behind the curtain where new medicines or specialty chemicals are being designed, chances are you’ll spot its footprint.

Key Role in Chemical Synthesis

In the business of building molecules, certain small pieces act like puzzle edges—giving shape and connection to the rest. 4-Bromobutyric acid ticks that box. Its structure makes it a favorite starting material in the synthesis of other chemicals. Researchers use it to make gamma-aminobutyric acid (GABA) analogs, compounds that tap directly into nerve signaling. By swapping and adding other atoms, scientists can develop molecules for studying neurological conditions, or even chart out routes for future drug candidates addressing epilepsy or anxiety.

Stepping Stone in Pharmaceuticals

It’s easy to shrug off the importance of a single component, but I worked on a research team where even one ingredient made or broke an entire batch. 4-Bromobutyric acid often shows up on ingredient lists during early research for central nervous system drugs, antiviral agents, or tools for mapping biochemical processes. Without a steady supply, development pipelines slow down. That matters for scientists racing to understand disease, and by extension, for everyone hoping for better treatments down the road.

Industrial and Research Applications

Outside the medical world, this compound supports the creation of specialty chemicals. Both agrochemical research and materials science benefit from 4-Bromobutyric acid. It’s used to produce intermediates that wound up as herbicides, or components for tailored polymers. In academic labs too, folks use it in reaction testing scenarios, learning more about bond formation and chemical reactivity. The lessons learned trickle out into everything from safer pesticides to better paint coatings.

Challenges and Considerations

Any compound with strong chemical activity comes with some responsibility. 4-Bromobutyric acid isn’t something to handle lightly. Exposure risks are real—chemical burns or health impacts can follow poor handling. This means good lab practices and proper ventilation stick around as rules, not suggestions. Government regulations also keep tabs on distribution and disposal, aiming to keep both workers and the environment out of harm’s way.

Room for Improvement and Safer Use

I’ve seen progress in the push for greener chemistry, and 4-Bromobutyric acid is not immune from scrutiny. Researchers are investigating cleaner manufacturing routes and substitutes that offer the same utility without some of the hazards. Awareness and education help too; regular training for scientists and technicians keeps workplaces safer and pushes the envelope on what’s possible without risking health or safety.

At its core, the story of 4-Bromobutyric acid highlights how complex our modern world is—scientific advances depend on small, sometimes tricky chemicals. Efforts to make their use safer and research more efficient don’t just benefit labs, but the public health and environment too.

Chemistry in Real Life

It’s easy to glance over the name “4-Bromobutyric Acid” and push it aside as jargon for chemists in lab coats. Yet this small molecule carries lessons about the structure of organic compounds, the predictability of chemical logic, and the importance of clear understanding in a world shaped by molecules. When I learned organic chemistry in college, I wrestled with names like this, not for lack of curiosity, but because it seemed so removed from daily life. A molecular formula plants chemistry back into firm ground.

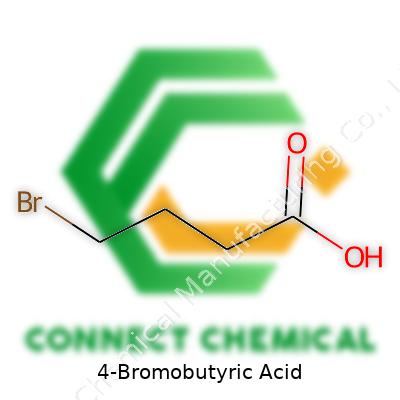

Finding the Structure

Let’s break it down from the basics. Butyric acid has four carbons in a chain (butan-), with a carboxylic acid group at one end. Slap a bromine atom on the fourth carbon, and you’ve got 4-Bromobutyric Acid. The chain looks like this: Br-CH2-CH2-CH2-COOH. Each carbon atom wants to make four bonds, hydrogen fills the gaps, and the formula falls into place.

Add up the elements: Four carbons, seven hydrogens, one bromine, and two oxygens. The formula: C4H7BrO2.

Why Details Matter

The value of this exercise goes far beyond memorization. I’ve seen lab mistakes spiral into costly setbacks because someone mixed up 3-Bromobutyric Acid with 4-Bromobutyric Acid—a single digit off, yet they give different products down the line. Even for folks outside the lab, overlooked details muddy communication. Drug designers, clean-tech founders, and teachers all benefit from formulas that cut through confusion. A formula like C4H7BrO2 does a lot of heavy lifting in a short space, handing anyone the building blocks they need to picture and use the molecule correctly.

This isn’t just about getting homework right. Synthesis in chemical manufacturing relies on these formulas. Suppose someone's scaling up a process: if the numbers don’t add up, reactors clog, batches fail, and raw material is wasted. Errors like this played a role in the 1980s Tylenol cyanide disaster, where uncontrolled chemistry threatened lives. These lessons are why safety officers and quality engineers train teams to check, double-check, and run simple formula calculations.

Pathways Toward Better Understanding

No one expects the world to become chemists overnight. Still, clear resources and open discussion do more for understanding than hiding behind technical language. I often recommend flashcards and ball-and-stick models to beginners, but the true key lies in repetition and context. Once the habit forms—breaking chemical names into pieces, drawing chain structures, counting atoms—confidence grows. Sharing molecular drawings in textbooks, offering interactive digital models, or hosting molecule-building workshops makes chemistry tangible, not just theoretical.

Schools and universities can foster this skill with hands-on activities and projects that tie into real products and challenges. For instance, connecting 4-Bromobutyric Acid’s formula to its use in the creation of pharmaceuticals or plant protection agents bridges the gap between blackboard and marketplace.

Moving Forward

Chemistry shapes medicine, food, technology, and the very air we breathe. At its core, getting the molecular formula right unlocks a deeper understanding and opens doors to safe, responsible innovation. So next time you encounter a name like 4-Bromobutyric Acid, take a closer look. The formula isn’t just a code—it’s a map for discovery and safety, connecting labs and lives everywhere.

Understanding Why Storage Matters

Dealing with 4-bromobutyric acid in any research lab or chemical workspace requires a real respect for its properties. People who work with chemicals know that a slip in storage can quickly turn an interesting experiment into a costly cleanup, or worse, a safety incident. Considering its status as a corrosive and moisture-sensitive compound, leaving storage on autopilot isn’t an option.

Keeping Chemical Degradation at Bay

Four years ago, I watched a colleague open a container of supposedly fresh 4-bromobutyric acid. Instead of a clear solid, he found a sticky mess. It didn’t take much detective work to figure out moisture had crept inside. Air and water both spell trouble. Water triggers hydrolysis, so the compound doesn’t stay pure. Inhaled vapors bring real health risks too, causing damage to lungs, skin, and eyes. Storing this chemical in a tightly-sealed, high-density polyethylene or glass container is the first step. Forget recycled bottles, any trace of moisture inside spells trouble.

Controlling Temperature and Light

Shelves near windows or heat vents don’t cut it for this acid. Sunlight speeds up decomposition, turning a stable compound into an unpredictable hazard. Heat does the same. Based on data from safety data sheets and firsthand lab experience, a cool, dark spot like a dedicated chemical storage fridge works best. You don’t want it below freezing, but room temperature or slightly under ensures a steady environment. No part of safe chemical practice welcomes direct sunlight or temperature spikes, especially for organobromine compounds that break down and release fumes fast.

Labeling and Chemical Segregation

It’s tempting to treat all small amber bottles the same, but sloppy labeling can catch up with anyone. I once borrowed a solvent bottle mislabeled in a rush, only to realize the contents didn’t match. We caught it in time, but it’s not always a safe bet. Detailed labeling with names, concentrations, hazard symbols, and opening dates helps everyone in the lab stay on track and avoid nasty surprises. Incompatible chemicals should never share a shelf. Mixing acids with bases or oxidizers, even by accident, can lead to violent reactions and toxic clouds.

Stock Control and Inventory Checks

Oversized stockpiles of reactive chemicals gather dust and risk. I’ve seen corners of storage cabinets with ten-year-old reagent jars, their contents long questionable. Keeping just enough 4-bromobutyric acid for ongoing projects fits smarter lab management. It reduces waste, trim costs, and limits risk in emergencies. Regular audits keep surprises to a minimum and catch leaks before they become major problems.

PPE and Emergency Readiness

In my early days, I underestimated how fast a spill could get out of control. With a compound like this, having gloves, goggles, and lab coats isn’t just busywork—it shields you from skin burns and lung damage. Spill kits and eyewash stations belong near where acids like this sit. Lab safety isn’t just for audits; it’s the difference between a small accident and lasting injuries. Training new staff and reminding veterans to follow the same habits helps everyone walk away safe at the end of the day.

Turning Knowledge Into Habits

Safe storage practices don’t just protect chemicals—they protect people. Every procedural step reflects what’s learned by accident and routine. With 4-bromobutyric acid, precaution and consistency make the work possible, letting the science advance minus unnecessary risks. The payoff comes in fewer emergencies and more reliable results, every time someone reaches for that bottle on the shelf.

Understanding the Substance

People working in labs or industries often ask whether 4-bromobutyric acid raises safety concerns. This chemical belongs to a family of compounds that often catch the attention of safety specialists. It's known for its use in organic synthesis and as a building block for more complicated chemicals. While it’s not a common household name, its presence in research and development settings can’t be ignored.

What Science Says About Exposure

From my time around chemical research, very few folks took chances around substances related to haloalkanoic acids. 4-bromobutyric acid isn’t different. There’s clear evidence from data sheets and scientific reports that this substance causes irritation when it comes into contact with skin or eyes. The safety sheets highlight warnings about contact, inhalation, and ingestion. While the exact toxicity to humans lacks widespread study (not every chemical earns in-depth research), animal studies flag risks with moderate acute toxicity if swallowed or inhaled.

Real-World Risks

Jobs that bring people closer to 4-bromobutyric acid usually involve weighing, mixing, or transferring it in small quantities. The biggest concerns, in my experience, come from spillage and splashing. Gloves, goggles, and fume hoods are standard because direct contact can burn or deeply irritate. Inhalation can produce coughing or breathing discomfort, and accidental swallowing often brings stomach upset and tissue damage. The chemical’s nature means that, even if it’s not as dangerous as some cousins like acrolein, it’s no vinegar either.

Why It Matters

Chemistry labs see a steady stream of new workers every year. Not everyone walks in ready to respect the risks, especially with compounds that don’t look dramatic at first glance. Without treating 4-bromobutyric acid with caution, it’s easy to imagine an accident leading to emergency care. The National Institute for Occupational Safety and Health and the European Chemical Agency list its hazards to prevent exactly that.

Solutions and Safer Practices

Good habits are the first defense. I remember seasoned technicians always pairing bright orange gloves with eye protection and keeping spill absorbent handy. Training new team members on hazard signs and on-the-spot spill clean-up really made a difference. Having a chemical-resistant tray under containers, labeling every bottle clearly, and knowing the location of the nearest eyewash station can prevent serious incidents.

Storage also becomes critical. 4-bromobutyric acid belongs in a cool spot away from incompatible chemicals, especially alkalis and strong oxidizers. Supervisors often push for regular audits and run-throughs of safety drills to stop complacency from settling in. By investing in ongoing education and strict housekeeping, labs keep both new and experienced staff in better shape.

Looking Forward

Some labs test greener alternatives whenever possible, searching for reagents that deliver similar results without the same risks. Regulatory agencies encourage the shift to safer chemicals, where possible, through regular bulletins. Until scientists and manufacturers find those substitutes, treating 4-bromobutyric acid with a respect that matches the facts stands as the best strategy. It’s not about fear, but a practical approach that recognizes the realities of chemical work.

Looking Beyond the Certificate of Analysis

Anytime someone asks about the purity specification for a chemical like 4-Bromobutyric Acid, they’re usually looking for a number that sets expectations—maybe 98% or more. Suppliers often list purity as “98% minimum,” sometimes pushing that to 99%, confirmed by methods like GC or HPLC. It sounds straightforward, but that single number carries real weight for research labs, manufacturing teams, and end-users who count on consistent results, safe handling, and product reliability.

Why Purity Matters in Practice

Anyone who has ever tried to repeat a synthetic route with impure chemicals knows what it means when that figure drops, even just a fraction. Sometimes, a 1% contaminant can clog reactors, throw off yields, or introduce byproducts that sideline an entire experiment. I remember a project that veered off course because a supplier’s 95% grade shipped with a small amount of an unknown impurity; nothing was working as planned until testing uncovered a stubborn halide byproduct. The team spent a week chasing down a problem that might have vanished if the chemical clocked even 99% real purity from the start.

What’s Hiding in the Extra Percent?

A purity spec must mean more than just passing a test. For 4-Bromobutyric Acid, analysts usually look out for moisture, unreacted starting material, and side-chain impurities. Left unchecked, these can shift analytical results and even alter safety risks. Researchers sometimes get tunnel vision staring at the main assay, forgetting that residual solvents or trace metals from synthesis can stick around unless careful clean-up steps and verification are standard procedure.

Analytical labs lean on GC, HPLC, or even NMR to confirm those purity benchmarks. A sharp GC peak is reassuring, but broad humps or extra spikes around the target signal should ring alarm bells. Reliable suppliers will back up certificates with details on trace impurities—customers get uneasy when only one number is printed on the paperwork with no sign of what was checked or found. For meaningful E-E-A-T in the chemical trade, transparency matters more than minimum thresholds.

Checking Quality—Not Just Quantity

It helps to probe suppliers on more than the top-line percentage. Any lab asking about 4-Bromobutyric Acid can also check specifications for water content, color, and storage conditions. Stability after opening the bottle matters; this acid can absorb moisture pretty quickly, which chips away at both purity and shelf life. Some operations push to re-test after receiving material, checking not just the number but how the lot matches previous experience.

Building Trust Through Consistency

No one likes surprises in the middle of a critical experiment. Reliable purity calls for robust verification at the source, frequent batch testing, and honest paperwork. The real-world impact shows up not just in sparkling GC traces, but in the day-to-day rhythm of synthetic routines, scale-up runs, and downstream applications that depend on clean starting material. Chemistry doesn’t forgive shortcuts; purity can make all the difference between a productive afternoon and a week lost to troubleshooting. That’s why real answers about purity matter, well beyond the label on the bottle.