4-Bromobutyryl Chloride: Examining its Legacy, Science, and Applications

Historical Development

The story of 4-Bromobutyryl chloride stretches across decades of organic chemistry research, woven into developments where halogenated compounds took off as molecular building blocks. Through the twentieth century, synthetic chemists turned their attention to chain-elongated acyl halides, including 4-Bromobutyryl chloride, for their role in functional group transformations. These innovations made a mark in both laboratory and industrial spaces, offering chemists a new way to introduce bromine atoms and acid chloride functions into organic structures. Over time, as the demand for specialty chemicals in the pharmaceutical and agrochemical worlds pushed for greater diversity in molecular scaffolds, 4-Bromobutyryl chloride found its own place as a favored intermediate, championed for its manageable reactivity and rich transformation potential.

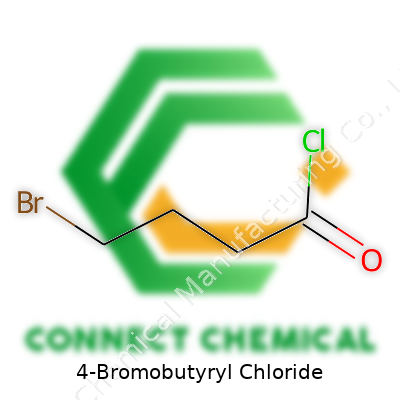

Product Overview

4-Bromobutyryl chloride stands as a versatile compound for both small-scale research and industrial production. The molecule packs a bromine atom and a reactive acid chloride group onto a four-carbon backbone, creating a dual-reactive site handy for various chemical modifications. This compound wins over researchers who need precision and selectivity in functional group installation for medicinal chemistry, given how both its halide and chloride moieties drive key steps in organic synthesis. Producers often ship it as a colorless or pale yellow liquid, stored in glass bottles or specialty containers to keep out light and moisture. Its commercial popularity reflects how it bridges practical lab needs with new technology-driving research.

Physical & Chemical Properties

This compound’s physical traits showcase the hallmarks of small-molecule acid chlorides mixed with halogenated chains. It appears as a clear to pale yellow liquid, with a sharp, acrid odor—the kind that signals caution in anyone handling it. The molecular formula C4H6BrClO yields a molar mass near 185.45 g/mol, and its boiling point sits around 115°C at reduced pressure, which helps with distillation and purification efforts. Water decomposes the molecule violently, funneling off hydrogen chloride fumes and pitching the need for strict moisture control. Its density lands just above 1.5 g/cm³ at room temperature, and it dissolves well in less polar solvents like diethyl ether and dichloromethane. The distinctive blend of a reactive acid chloride and a terminal bromine sets it apart in reactivity profiles, with both groups inviting nucleophilic attack in a way that’s controlled yet energetic.

Technical Specifications & Labeling

Manufacturers supply 4-Bromobutyryl chloride with clear certificate of analysis documentation, detailing isomeric purity—often upward of 98%—and GC/MS traceability. Each bottle arrives with bold hazard labeling: “Corrosive,” “Harmful if inhaled or swallowed,” “Reacts violently with water.” Custom orders from major suppliers often guarantee less than 0.5% impurities and may include batch-specific NMR or titration data. Handling instructions focus on chemical-resistant gloves, eye protection, and working inside an efficient chemical fume hood. The labeling goes beyond regulatory requirements, reflecting both industry standards and the hard-learned lessons of past laboratory accidents. It’s common to see emergency response procedures printed right on the outer carton, emphasizing readiness for spill or exposure scenarios.

Preparation Method

Chemists usually synthesize 4-Bromobutyryl chloride by starting from 4-bromobutyric acid, itself accessible via bromination of butyric acid or through various substitution strategies on gamma-butyrolactone. The common route involves treating 4-bromobutyric acid with excess thionyl chloride (SOCl₂), yielding the acid chloride and venting off sulfur dioxide and hydrogen chloride gases. Careful temperature control and anhydrous conditions prevent side-product formation and preserve yield. Some labs swap SOCl₂ for oxalyl chloride, depending on scale and equipment, but the motivation stays constant: produce a clean acid chloride ready for downstream applications. In my own experience, achieving dryness throughout the system spells the difference between a robust synthesis and a disappointing, impurity-laden batch.

Chemical Reactions & Modifications

4-Bromobutyryl chloride excels as a bifunctional platform in organic synthesis. Its acyl chloride group marks it as a top pick for acylating amines to form amides, or alcohols to form esters; these transformations find use in pharmaceutical lead development and in polymer synthesis. The bromine atom, perched at the terminal end of the butyl chain, readily undergoes displacement by nucleophiles. This makes it a springboard for building more complex molecules: think of quaternary ammonium salts, substituted butyramides, or even cyclization reactions leading to pyrrolidines and related heterocycles. I’ve watched research groups exploit both the acylating power and halogen-reactivity, scoring two modifications for one reagent—a real tactical advantage in multistep synthesis. Cross-coupling reactions, like Suzuki or Heck reactions, bring further flavor, highlighting just how tuneable this compound becomes in expert hands.

Synonyms & Product Names

Over the years, suppliers and research communities have tagged 4-Bromobutyryl chloride with a range of chemical names. Some catalogs list it as γ-Bromobutyryl chloride or 4-Bromo-butyryl chloride, emphasizing its placement on the carbon chain. In older literature, references pop up for 4-Bromobutanoyl chloride, but most international suppliers stick to the condensed “4-Bromobutyryl chloride.” Trivial names like “butyryl chloride, 4-bromo-” sometimes show up, but they rarely appear on formal documentation or product labels. CAS number 927-53-1 offers the most unambiguous identifier, anchoring procurement and regulatory search queries, and avoiding the confusion that synonym drift sometimes brings.

Safety & Operational Standards

Workplace safety stands front and center with this chemical. The acid chloride kicks up hydrochloric acid fumes if exposed to air or any trace of water, so tight handling protocols make a difference in both labs and on production lines. Facilities outfit chemical fume hoods with acid-rated filters and run regular training sessions on PPE use: goggles, thick nitrile or neoprene gloves, and chemically resistant coats. Its corrosive nature can burn unprotected skin in seconds, so swift neutralization with sodium bicarbonate solutions sits on every bench. Any kind of scale-up demands closed reactor systems or glove box handling, reducing the chance of airborne exposure. Disposal routes channel waste into neutralization tanks before dilution and treatment—anything else risks regulatory action and environmental harm. Looking at industry best practices, repeated drills, real-time spill-response kits, and automated sensor alarms earn their keep, especially as workers run larger or parallel syntheses.

Application Area

Use cases stretch across several industries but drill down strongest in pharmaceuticals, agrochemicals, and specialty polymers. Medicinal chemists appreciate how 4-Bromobutyryl chloride enables tailored sidechain attachments onto drug candidates, supporting structure-activity relationship studies that underpin modern drug discovery. Agrochemical researchers lean on its dual reactivity to design next-generation herbicides and fungicides, adding specific acyl or halogen functions to core molecules. Recent years have seen chemists harness it in surface engineering, applying it to anchor initiators onto polymers or nanoparticles for advanced coatings and controlled-release materials. Even battery chemistry sees some curiosity, as modified molecules bearing the 4-bromobutyryl moiety sometimes enhance electrolyte formulations. In every case, its popularity stems not just from reactivity, but from how it opens new doors for creative synthesis—giving teams the ability to answer problems that plain butyryl chloride or generic bromoalkanes just can’t touch.

Research & Development

Labs keep coming back to this molecule as synthetic methods and product needs evolve. In my time collaborating with medicinal chemistry groups, I watched how analog design sprints would call for dozens of structurally related amides, all conveniently accessed via this chloride. Catalysis researchers aim to streamline transformations and trim waste, testing new catalysts for milder, greener reactions involving 4-Bromobutyryl chloride. Polymer scientists keep iterating on post-polymerization functionalization, making use of its predictable modification chemistry for smart materials. Electronic materials researchers push its use into organic dyes and photoactive layers—each year brings a handful of new publications that claim some niche, valuable twist. This steady stream of investigative work points to a future where accessibility and transformation reliability keep this molecule front-of-mind for innovators chasing speed, precision, and environmental compliance.

Toxicity Research

Studies on toxicity paint a picture that demands respect. Animal models indicate corrosive damage on exposure to skin, eyes, or inhaled vapors. Acute exposure brings respiratory tract irritation and chemical burns—a story familiar to anyone who’s worked with acid chlorides. Chronic effects remain less well documented, but concerns center on repeated low-level exposures and sensitization. Wastewater treatment studies find accelerated hydrolysis but warn against uncontrolled release, given the resulting acids and halides harm aquatic organisms. Regulators require explicit training for anyone handling drums or bulk containers, and modern toxicology screens now search for effects on cellular models, flagging oxidative stress or DNA damage as risks in unchecked environments. Regular monitoring, medical checks, and process enclosure serve to keep these hazards contained, but the demands for ever-safer processes reflect how even seasoned chemists continue to treat this compound with caution born of experience.

Future Prospects

4-Bromobutyryl chloride shows little sign of being phased out, given the trends in chemical innovation and the march toward greener, more selective transformations. Research pushes toward flow chemistry—closed, automated systems that minimize operator exposure and waste—with novel catalysts handling the molecule at lower temperatures and pressures. Synthesis groups probe biocatalytic or alternative halogenation methods that could yield precursors from renewable resources, nudging the whole supply chain closer to sustainability targets. The growth of combinatorial chemistry in drug and material design keeps up demand for clean, modular reagents like this one, and improvements in PPE, process control, and remote monitoring will only deepen its penetration into industry. Facing stricter environmental and safety regulations, producers already invest in developing derivatives tuned for less toxicity or easier downstream neutralization. I expect the next decades will see safer handling protocols, digital process oversight, and fresh applications that keep pulling on the flexibility and dependability this compound shows in practice.

The Nuts and Bolts: Chemical Formula and Weight

People in the lab world know the shorthand for 4-Bromobutyryl chloride: C4H6BrClO. This compound blends four carbons, six hydrogens, a single bromine, a chlorine, and an oxygen atom. Tackling the math for molecular weight, each part stacks up like this—carbon hits at 12.01, hydrogen at 1.01, bromine at 79.90, chlorine at 35.45, and oxygen pulls in at 16.00 grams per mole. Add it up: (4 × 12.01) + (6 × 1.01) + 79.90 + 35.45 + 16.00. The answer lands around 197.45 grams per mole, which makes this compound noticeable, especially in synthetic chemistry where every fractional gram shifts outcomes. Much like building a recipe, accuracy changes everything in the lab.

Why 4-Bromobutyryl Chloride Deserves Attention

The chemical impacts reach far beyond formulas on paper. My own experience in university labs taught me how each component plays a role—just like salt in cooking, a single atom can tip a reaction’s balance. 4-Bromobutyryl chloride steps up as a reliable intermediate for making pharmaceuticals and agrochemicals. Picture a chemist fine-tuning a painkiller or protecting crops; they rely on intermediates like this to create bonds, introduce new functions, or add stability.

The industry’s appetite for precision makes formula accuracy vital. Without it, production lines stall and costs soar. In my early research, incorrect molecular weights led to wasted batches and re-runs—a headache for budgets and timelines. Even something as straightforward as bromine can add layers of complexity, especially with safety rules and storage. Its presence in the formula often means more precautions—proper gloves, a working hood, and extra steps to minimize spills or exposure, since brominated chemicals have known hazards if managed carelessly.

Supporting Safe and Sustainable Use

Tackling safety means more than just gloves and goggles. Regular briefings, updated material safety data sheets, and keeping emergency showers up to date mean that mistakes rarely become disasters. When we handled materials like 4-Bromobutyryl chloride, stories of mishandled chemicals traveled faster than the compounds themselves. Risk grows in places without strict routines.

Disposal and environmental questions need careful answers. Lab managers sort through regulations from EPA and local agencies to stop compounds from slipping into water or soil. Many facilities invest in capture systems and trained staff who understand both the science and the law. Steps like these protect communities and ecosystems—and help avoid hefty fines that cripple projects. 4-Bromobutyryl chloride’s molecular weight isn’t just a number; it determines how to handle waste, transport the chemical, and treat exposures. In the wrong hands, something measured in grams can cause problems counted in years.

Looking Ahead: Smarter Chemistry in Practice

Supporting innovation grows simpler as chemists share best practices. Green chemistry projects now target intermediates like 4-Bromobutyryl chloride, aiming to swap in less hazardous reagents or develop recycling routines for byproducts. Open collaboration across industries leads to swaps that save both cash and the planet. More people demand records for every material in the chain, from test tubes to warehouse shipping docks. Lessons learned from handling intermediates shape the next steps for safer workplaces and cleaner surroundings.

Knowing the true formula and weight for a compound like 4-Bromobutyryl chloride goes well beyond a textbook answer—it shapes safety, efficiency, and responsibility across every part of the chemical industry. Teams that keep these numbers front and center run tighter labs, protect their own, and build trust that outlasts any single project or batch.

Fueling Pharmaceutical Innovation

4-Bromobutyryl chloride pops up quite often in pharmaceutical research labs. Medicinal chemists count on it for building blocks in the hunt for new drugs, especially those exploring central nervous system activity. This compound lets researchers make molecules with a bromine atom in just the right spot, which helps tweak how a potential drug behaves inside the body. Sometimes that single bromine atom shapes the effectiveness or safety of a new treatment, and 4-bromobutyryl chloride keeps the process running smoothly.

Anticonvulsant drugs and certain pain medications owe part of their chemical structure to intermediates made possible by this molecule. A research article in The Journal of Medicinal Chemistry explains how swapping one functional group for a bromine using this chloride can supercharge a compound’s biological effect. Lots of chemical routes would get blocked or grow clumsy and expensive without 4-bromobutyryl chloride bringing bromine to the table.

Helping Chemical Synthesis Happen

Lab folks who craft specialty chemicals and polymers regularly reach for 4-bromobutyryl chloride. Adding it to a reaction lets someone insert a four-carbon chain with a reactive bromine onto another molecule, which opens up new doors for further chemical changes down the line. Organic chemists talk about “handles”—parts of a molecule you can grab to bolt on something new. This chloride gives a short chain linked to bromine, which then lets scientists customize complex molecules.

In the world of industrial chemistry, this capability keeps product development on pace. Textile dyes, for instance, use structures made possible by the modifications this compound enables. The ability to build out molecules step by step, by adding, swapping, or trimming sections, gives manufacturers flexibility when scaling up for new customers or changing regulations.

Making Research Tools for Biology

Scientific discovery often runs through the lab bench, and tools made using 4-bromobutyryl chloride pop up all over modern biology. Affinity labels and fluorescent tags, key for tracking proteins or DNA, use structures where this compound played a background role. When researchers need to follow a molecule’s trail in a cell, sticking on a dye or another marker gives them a line of sight. That sticky connection comes from linking pre-assembled building blocks, and 4-bromobutyryl chloride can play the crucial role of setting up those connections.

Biotech companies leverage this in antibody-drug conjugates—one way cancer therapies get their punch is by latching a toxin onto a targeting antibody. The chemistry behind this link sometimes relies on the unique properties of 4-bromobutyryl chloride to give the connection both strength and precision.

Keeping Safety Front and Center

Getting results from this compound takes more than skill; it requires careful handling because of its reactivity and strong fumes. The safety data sheets warn that direct contact can trigger nasty reactions on skin or lungs, demanding gloves, goggles, and chemical hoods. Chemical producers must treat waste streams containing this material with respect, using scrubbers and neutralization tanks.

Regulators and industrial safety officers have stepped in to keep workers safe, and companies who take this seriously help avoid nasty surprises. Following strict safety protocols doesn’t just protect people—it also helps avoid supply chain headaches and keeps research on schedule. Responsible handling goes hand in hand with the benefits this compound brings to the lab and industry floor.

Looking for Greener Solutions

Chemists have begun pressing for replacements or safer derivatives, especially in academic settings and smaller startups, considering both safety and environmental impact. Some projects switch out this chloride for less toxic alternatives, but they lose the same flexibility and performance that has kept 4-bromobutyryl chloride in demand. Chemical engineers and green chemists search for ways to recycle byproducts or use milder conditions, often inspired by the principles of green chemistry.

With new safety tech and smarter processes, the industry keeps moving toward solutions that balance performance and responsibility. The push comes from inside the lab and out—by focusing on safer workflows, supply chain resilience, and environmental stewardship, the chemical field aims to retain the benefits of tools like 4-bromobutyryl chloride without leaving heavy costs for people or the planet.

Know What You’re Dealing With

4-Bromobutyryl chloride isn’t just another bottle on the chemical shelf. People working in research and manufacturing often don’t get enough reminders about just how reactive and hazardous acyl chlorides can be. They want to hydrolyze, release corrosive fumes if left exposed to air, and cause burns faster than you expect. I’ve seen both new and experienced chemists run into trouble by underestimating these risks.

Simple Rules Make the Difference

I always keep this compound in tightly sealed containers made of strong glass or compatible plastic, with the original supplier’s labels firmly attached. The container shouldn’t just go anywhere—

- Store it in a cool, dry place, away from sunlight and heat sources.

- A dedicated, well-ventilated chemical cabinet with corrosion-resistant lining works best.

- Keep acids and bases far away, since accidents with reactive spills escalate quickly.

If you handle 4-bromobutyryl chloride in a room with regular air, you risk inhaling toxic vapors or damaging electronics. Strong ventilation solves this. I always use a fume hood—never the open bench, no matter how small the task.

Personal Protection Builds Confidence

Anyone handling this compound benefits from simple protective gear. I wear splash-proof goggles, nitrile gloves with sleeve protection, a lab coat, and sometimes a face shield for larger amounts. Skin contact brings severe burns, and even a quick splash can leave scars.

After an incident early in my career involving a similar compound splashing onto unprotected hands, I stopped taking shortcuts in safety. Proper gloves, regular checks for holes, and prompt washing after every session feel like muscle memory now.

Preparation Saves the Day in Emergencies

Spills and surprises happen in every lab, and clear steps matter. Absorbent pads designed for acids, access to calcium carbonate or soda ash for neutralization, and an eyewash station within arm’s reach turn a scary moment into a solvable one.

If the liquid touches your skin, flush immediately with running water for at least 15 minutes, then ask for medical attention. Vapors in the eyes or lungs demand a fast move to fresh air, with a phone ready for emergency help.

Respect Goes Further Than Rules

Some folks might see storing a reactive chloride as just a chore, but experience changes your view. Every label, every double-check, every glove is a show of respect for everyone in the room. People bring that mindset home, too—accidents can lead to lifelong injuries.

Training sessions shouldn’t just cover what the compound does. Hands-on practice with opening, measuring, and disposing of it builds real understanding. No one should feel embarrassed to ask questions or raise concerns.

Smart Disposal Keeps Everyone Safe

Waste with this type of chemical can’t go in the sink or trash. Neutralize solutions in a controlled way—outside the hood, the fumes harm air quality and health. Dispose of both the neutralized liquid and empty containers through authorized waste streams, never regular garbage.

Proper records and regular checks of storage areas, even for old bottles you may have forgotten, help everyone avoid unwanted surprises.

Hazards That Demand Respect

The smell of 4-Bromobutyryl Chloride gives an early warning—something pungent, like acid biting at the air. I’ve learned over the years that chemicals carrying that sting need more respect in the lab and warehouse. This compound brings together a tricky combination: corrosiveness, strong reactivity, and harmful fumes. Those who handle it every day know accidents don’t always come from dramatic spills—just a bit of negligence, a splash, or fumes escaping a faulty seal can send someone to the emergency room.

Contact causes burning pain. Liquid or vapor eats through gloves, clothing, and skin, leaving behind severe irritation or even serious burns. Eyes react even faster. Losing sight or walking around with damaged corneas isn’t worth skipping a face shield. Once, a co-worker opened a bottle without checking the fume hood flow and ended up wheezing and dizzy—chloride vapors don’t play fair with lungs or throats. I’ve seen shortness of breath and choking within seconds in closed spaces.

Water brings another layer of risk. Add 4-Bromobutyryl Chloride to anything moist, and you get a quick reaction, sending out hydrogen chloride gas. That’s not just uncomfortable—it’s toxic, tears up airways and eyes, and corrodes metal fixtures around the building. Mismanagement can turn a minor leak into an emergency.

Handling and Safety Starts with Awareness

All it takes is one skipped step for this chemical to create chaos, so I never shortcut. Wearing proper gear isn’t optional—long sleeves, nitrile gloves, splash goggles, and a lab coat that resists acid. Airflow matters. I always check that the fume hood works before opening a bottle, no matter how many times I’ve handled it. Not every lab worker gets a second chance if fumes spread in the wrong place.

Storing it far from water sources and incompatible materials like strong bases or alcohols stays at the top of my checklists. Double-sealing the container adds peace of mind. I make it routine to label everything with clear hazard warnings—even if I pour into a temporary flask. People borrow and share equipment, and one missed warning causes trouble for the whole team.

Spill kits specifically designed for acid chlorides have saved more than a few labs. I’ve used them: powdered absorbents swallow up the liquid, keeping reactions under control. Training drills keep me sharp, so my hands know where the nearest eye wash, shower, and respirator sit. Fire risk sticks in the back of my mind, too, since many chemicals that react with it can heat up fast or flame out unexpectedly.

Practice and Policy Go Hand-in-Hand

Every mistake with 4-Bromobutyryl Chloride leaves a mark—on health, equipment, or workplace safety records. Companies that value their staff keep firm chemical hygiene policies. I’ve seen how a team that rehearses emergency responses, inspects storage, and replaces old safety gear makes labs safer places. In my experience, even minor carelessness—like failing to clean up a few grains—breeds bigger problems.

Keeping up with changing regulations and safety data isn’t a paperwork chore. It’s a chance to stay ahead of risks. I remind new team members that no shortcut or improvisation beats a habits-based approach to safety. Respect for dangerous chemicals like this earns its reward every time we walk out of the lab healthy.

Smart Steps Lead to Safer Labs

Safety doesn’t start with fear; it starts with knowledge and consistent habits. Handling 4-Bromobutyryl Chloride with well-practiced precautions, clear procedures, and the right personal gear keeps incidents rare and minor. People trust their lives to this kind of diligence every day. I’ve seen both the cost of carelessness and the reward of doing things right—staying prepared is the only way to work with peace of mind.

Taking the Technical Into the Real World

When someone talks about 4-Bromobutyryl Chloride, most folks outside the lab pause. The chemical does serious work across research, pharma, and sometimes even in making the molecules that end up in drugs or specialty materials. That doesn’t mean it arrives at your doorstep ready for anything, and quality matters as much as in any other product someone wants to trust. Purity and packaging aren’t just technical specs—they’re about trust, risk, and getting work done right.

What Purity Really Means

Labs don’t order this stuff by the truckload for no reason. People want high-purity 4-Bromobutyryl Chloride, often around 98% or higher—that’s the standard offered by suppliers who serve real markets. Some manage to push purity to 99% or even higher for specialty uses, but chasing that last percent always raises cost and complexity. Even a fraction of a percent of the wrong substance might foul a step or force someone to repeat an experiment, especially if you’re working with synthesis or pharma-grade requirements.

Lab results live and die by purity. If someone asks why we even care about decimal points, trace impurities can trigger side reactions, spoil research, or even lead to big safety trouble down the line. Some suppliers will give a breakdown—listing water, organic acids, and chloride content. Others only give the basics. Smart buyers always ask, check the COA (certificate of analysis), and push for details. No one wants to be a test case for what happens with a contaminated batch.

Packaging: A Balancing Act for Safety and Usability

A chemical like this gets grumpy pretty fast—hygroscopic, moisture-sensitive, sometimes aggressive. Thick glass bottles or amber glass ampoules are the norm, sometimes with a Teflon-lined cap and always tightly sealed. No one sends this material off in a paper sack. Even packaging has a purpose. The tight seal keeps out air and humidity, cutting the risk of hydrolysis and losing potency. Heat-sealed containers are more common for those expecting longer shelf life or global shipping.

In my own work with specialty chemicals, lighter packaging is never really an option. A cracked seal can mean the whole batch goes bad or exposes handlers to dangerous fumes. Even the color of the glass matters—clear shows off any color changes, amber keeps out the sunlight that might mess with stability during long storage. That’s one place where experience matters more than just following an SOP.

Stock Sizes—and Who Actually Buys Them

Most research and pharma operations look for sizes they can actually use. Small bottles—10 grams, 25 grams, or 100 grams—fit most needs. Trying to store a kilo bottle of this stuff isn’t anybody’s idea of safe, unless you’ve got the right hood and staff ready. On the other hand, small, consistent batches reduces risk. Scale-up jobs sometimes ask for 500 grams or up to a whole kilo, but by then you’re talking big money and likely direct-from-manufacturer protocols.

Suppliers provide material in packaging designed to make handling as easy and safe as possible. No matter the batch size, each bottle needs a robust label—chemical name, hazard warnings, CAS number, traceability for recalls. Not only does this help meet regulations, but it also keeps everyone in the supply and research chain accountable.

Quality—and Responsibility—Built In

Solid handling of 4-Bromobutyryl Chloride comes down to two things: don’t cut corners, and trust the supplier. Companies need to keep up with regulations—the European REACH standards or US OSHA guidelines—if they ship to global labs or manufacturing facilities. It’s tempting to go with a no-name source for price, but quality checks stop real problems before they start.

Simple as it sounds, what sits in that bottle is only as good as the documentation and expertise backing it up. Always push for transparency, specs, and safety. Cutting corners in purity or packaging never ends well, especially in chemistry.