4-Chlorobutyric Acid: An In-depth Commentary

Historical Development

Appreciating the uses and importance of 4-Chlorobutyric acid starts with understanding where it comes from. This compound, also known as 4-chlorobutanoic acid, has roots stretching back to the expansion of organic halides research in the 20th century. Early studies driven by the development of pharmaceuticals and agrochemicals soon found this molecule to be more than just a chemical curiosity. Chemical engineers and organic chemists included it in libraries for synthesis and testing as early as the 1950s. The real demand surge arrived with the rise of fine chemicals and specialty materials in manufacturing, highlighting its reliability for providing the butyryl backbone with a functional chlorine group for downstream modifications. Today, manufacturers keep producing tons yearly worldwide, showing just how much innovation can come from what looks like a simple chemical formula.

Product Overview

4-Chlorobutyric acid comes forward as a clear, often colorless to pale-yellow liquid at room temperature. You’ll find it in glass bottles or heavy-duty HDPE containers with tight seals. Labs and factories rely on this product as a key intermediate because it gives a good mix of reactivity and versatility. Thanks to its functional group, it opens the door to a large set of derivatives and transformation pathways. Its use is never just limited to a single sector. Academic researchers, pesticide formulators, and pharmaceutical production teams keep it on hand for many routes leading to distinct end-products. That kind of reach only comes with a compound that consistently delivers, batch after batch, without unpredictable surprises.

Physical & Chemical Properties

Digging into its structure, 4-Chlorobutyric acid—C4H7ClO2—weighs in at 122.55 g/mol. Its boiling point sits at roughly 233°C, and the melting point lingers close to -20°C, with a density near 1.19 g/cm³ at 20°C. The molecule introduces a polar carboxylic acid group and a chlorine atom attached to the terminal carbon, promoting both solubility in polar organic solvents and higher reactivity for acyl chlorides or ester conversions. That lone chlorine has a habit of jumping off in many reactions, which keeps the acid handy for organic syntheses. The liquid emits an acrid, pungent odor reminiscent of other halogenated acids, which instantly signals you to take care when handling it. It dissolves well in ethanol and ether, but only mixes with water to a moderate extent thanks to the surface tension given by the alkyl chain. These properties dictate the equipment needed and the handling routines required for both bench-top and scaled-plant operations.

Technical Specifications & Labeling

On the shelf, 4-Chlorobutyric acid carries detailed technical specs. Reputable suppliers list assay values topping 98%, GC purity profiles free of higher halogenated analogs, and benchmark maximum residual solvent content. Impurities like 3-chlorobutyric acid and heavy metals are strictly watched because they can skew reaction outcomes in downstream uses. Bottle labels stay busy with hazard temples and risk codes. UN numbers tag the containers for shipping, and GHS pictograms warn about skin irritation and aquatic toxicity. Trustworthy documentation always includes batch-specific Certificates of Analysis (CoA), which track every step from raw materials to packaging, so that any user can manage compliance reviews or trace anomalies. Material Safety Data Sheets (MSDS) ship with each carton, giving clear instructions for handling, PPE selection, and storage temps down to the specific shelving level.

Preparation Method

Synthesizing 4-Chlorobutyric acid in the lab or plant takes skill, equipment, and a solid knowledge of reaction safety. The most direct route starts with butyrolactone or butyric acid. Chlorination uses reagents like thionyl chloride, phosphorus pentachloride, or hydrochloric acid, with careful cooling and controlled addition to avoid unwanted byproducts and runaways. Industrial production streamlines the process for higher yields and purity, using continuous reactors and automation to control temperature, pressure, and reactant feed rate. Purification involves fractional distillation under vacuum to dodge decomposition and a final crystallization or solvent wash to hit target purity. Waste is not tossed aside—side products and spent acids are recovered, recycled, or neutralized to prevent environmental trouble. These well-tuned steps cement 4-Chlorobutyric acid’s place as a reliable intermediate in demanding sectors.

Chemical Reactions & Modifications

This acid plays well with both nucleophilic substitution and condensation reactions. The terminal chlorine paves the way for all sorts of transformations. Swapping out the chlorine with nucleophiles brings esters, amines, or ethers within reach after a few straight shots in the right conditions. Turning it into an acid chloride brings another level, letting the chemist forge strong amide or ester bonds. Direct reductions create 4-chlorobutanol or even tetrahydrofuran derivatives. Each functional group opens doors to entire classes of new molecules, especially for fine chemical and pharma research. Some methods even exploit the carboxyl’s acidity, building up salts for further stability or safety in transport. Skilled chemists leverage the position of the chlorine to perform selective cyclizations, building structural diversity for synthetic routes. These reactions keep proving that even a simple molecule, given the right tweaks, sparks innovation across entire industries.

Synonyms & Product Names

4-Chlorobutyric acid answers to a few other names, which pop up on procurement sites and in literature. CAS number 928-51-8 tracks shipments and references across journals with pinpoint accuracy. Names like 4-chlorobutanoic acid, gamma-chlorobutyric acid, and butanoic acid, 4-chloro- all point back to the same compound. Suppliers might list it under these or plain “4-CBA” as an abbreviation. Sometimes, chemical registries fold it into a broader group of halogenated butyric acids, but the position of the chloro group—never mistaken—keeps things clear. These synonyms can trip up new researchers, but for those keeping an eye on purity and specs, they act as useful cues while sourcing or comparing literature.

Safety & Operational Standards

Working with 4-Chlorobutyric acid demands respect for both the chemical and those around it. The liquid, with its sharp odor, can burn skin or eyes quickly. Airborne droplets make masks or organic vapor cartridges necessary, at least in bench settings and especially at the drum scale. Spill containment and eyewash stations should never be out of arm’s reach. Chlorinated acids carry risk if heated or mixed the wrong way—pressure buildup, strong fumes, or exothermic surges aren’t just chemistry trivia. Disposal involves more than just dilution; waste streams move through licensed destruction or neutralization steps to keep chlorinated organic residues out of waterways and soil. Shift managers and technicians stay up to date on training around chemical hygiene, ventilation requirements, and personal protection routines. Even in a research setting, regular audits and inventory tracking catch lapses before they snowball. All these standards come from hard-earned lessons, tested by past accidents and the tight regulations governing hazardous organics.

Application Area

Industry insiders recognize the reach of 4-Chlorobutyric acid. Pharmaceutical groups use it to build anticonvulsant and muscle-relaxant drugs, linking it to GABA analogues in neurological research. Making agricultural chemicals taps its ability to introduce chlorine handles onto molecules, often as side chains or prodrug moieties. Specialty polymer manufacturers tweak its backbone for new plasticizers or tailored resins, banking on the flexibility and response of the acid to thermal or catalytic steps. Research groups, both public and private, test its transformation ability in everything from green chemistry to specialty surfactants. Diagnostic toolmakers eye it as a starting point for tagged markers or intermediates in biosensor development. Each of these sectors relies on a compound that shows up where it matters, routes well into complex molecules, and doesn’t let unexpected byproducts ruin key processes.

Research & Development

Ongoing research with 4-Chlorobutyric acid spins out new ideas faster than the textbooks can keep up. Synthetic chemists keep exploring less toxic, more predictable chlorination routes. Academic papers keep rolling in, investigating its role as a building block in medicinal chemistry, green manufacturing, and advanced materials. Teams in Japan, Europe, and North America aim for optimization—higher yields, safer conditions, and reduced waste. Some groups already report successes using benign catalysts or flow reactors, which tackle both safety and environmental concerns. The basic acid sits at the root of new GABA analogues for neuroscience, and forms the heart of next-gen crop protection agents. These new pathways not only widen the product’s reach but show a willingness among researchers to ask tough questions about sustainability, toxicity, and access to starting materials. The pipeline from curiosity-driven work to scalable industry process stays in motion thanks to these relentless R&D efforts.

Toxicity Research

Scientists and planners both pause when assessing toxicity. 4-Chlorobutyric acid doesn’t casually break down in open air or water; the chlorine raises questions about long-term environmental fate and bioaccumulation. Rodent models show central nervous system effects and possible organ irritation at higher exposure levels. Skin contact stories remind everyone in the lab that gloves are not optional, even on a quick transfer. Wastewater teams test regularly for halogenated residues, and standards require double containment for any large-scale use. Regulatory frameworks keep labeling and handling requirements front and center, especially in places with strict chemical management rules. As with many organohalogens, even trace amounts over time build up questions around reproductive health or ecosystem risks, so regular reviews of safety data and exposure limits show the industry’s serious approach to risk management.

Future Prospects

Looking forward, 4-Chlorobutyric acid stands at the intersection of innovation and responsibility. As green chemistry takes a firmer hold, new synthesis methods cut out hazardous reagents or reduce waste by reusing spent materials. Regulatory climates keep tightening, asking for higher safety in manufacturing and stricter end-use tracking. The growing use in drug discovery and advanced materials hints at even broader adoption, especially where custom analogues open doors for tailored treatments or adaptive polymers. On the production side, scalable and safer methodologies prepare the industry for increased demand without raising risk. Sustainability groups and forward-thinking researchers continue to refine lifecycle analyses and push toward more biodegradable derivatives. That combination of adaptability, enduring value, and constant scrutiny makes 4-Chlorobutyric acid a telling example of how chemistry can serve progress and responsibility in equal measure.

What is 4-Chlorobutyric Acid?

4-Chlorobutyric acid pops up more often than most people think, especially in research circles and industrial settings. It’s a small, colorless molecule with a sharp odor, but its reach can stretch well beyond the lab bench. The structure, simple as it seems, makes it a stepping stone in organic chemistry. I’ve seen it take on some interesting roles during project work, and it's made me curious about how chemicals like these shape bigger industries, from flavor additives to medical research.

Foundations in Chemical Synthesis

On the chemistry side, 4-Chlorobutyric acid works like a Swiss army knife for researchers. Manufacturers use it to stitch together more complex compounds, especially as a building block for drugs, pesticides, and fragrances. Chemists lean on it for constructing molecules with four-carbon backbones, which pop up in everything from muscle relaxants to anti-seizure medications. Digging into published studies, such as those catalogued in the Journal of Medicinal Chemistry, it’s clear how it gets woven into many pharmaceuticals. So a bottle of this acid in a lab storeroom could be a first step toward a new hospital treatment.

Applications in Fragrance and Flavor Creation

Anyone working in fine chemicals will bump into acyl chlorides or pyrrolidines now and then, and 4-Chlorobutyric acid plays a key part in these syntheses. In the world of fragrance and flavor, companies want unique molecules that can mimic or enhance natural tastes and scents. Through careful chemistry, this acid can get converted into specialty flavor compounds or volatile aromatics—the smells you get in perfumes or the aftertaste in artificial fruit flavor. It’s a puzzle piece, one that fits into a much bigger sensory picture, one I’ve seen come to life during flavor-testing work with food scientists. Safety remains critical here, since the starting material must be stripped away or fully reacted, so only the intended flavor compound stays behind.

Research, Regulation, and Safety

Not every story with chemicals is rosy. 4-Chlorobutyric acid has raised flags among safety professionals because it carries some risk if misused. Laboratories keep a close eye on it, requiring gloves, fume hoods, and ventilated space for handling even small amounts. The European Chemicals Agency lists it with hazard warnings about irritation and potential toxicity at higher concentrations. Researchers who work with this acid need real hands-on training, not just written procedures. I’ve watched new students get a crash course in safety before touching a bottle of this stuff—and for good reason.

Solutions and Ethical Considerations

Responsible sourcing stands out as a practical solution. Suppliers with transparent paperwork, trackability, and safety info help labs and companies keep their chains clean and workers protected. I also see promise in greener chemistry approaches—finding alternative synthesis methods or switching to less harmful analogs when possible. The research industry, especially in pharmaceuticals and flavors, faces pressure to balance innovation with environmental health, so every choice around chemicals like this one carries weight.

Why It Matters

4-Chlorobutyric acid connects humble lab work to whole industries, including the food you eat and medicines in your cabinet. Each use ties back to real people—chemists, workers, consumers—who trust that safety, transparency, and quality haven’t slipped through the cracks. For all the advances it makes possible, oversight and responsible decision-making must keep pace with the science.

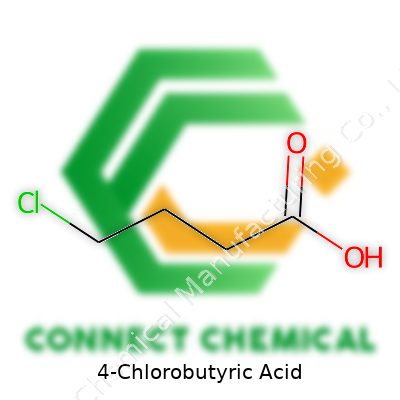

A Closer Look at the Basics

4-Chlorobutyric acid often comes up in discussions about organic synthesis, drug development, and industrial chemistry. Its structure turns heads for its simplicity and utility. Picture a four-carbon straight chain, topped with a carboxylic acid group at one end—nothing too wild for the world of organic acids. Then, a chlorine atom attaches to the fourth carbon, which stands farthest from the acid group. With the formula C4H7ClO2, this molecule gives chemists a reliable tool when building more complex compounds.

Getting into the Details

The backbone of 4-chlorobutyric acid stacks up like this:

- Carboxyl group (COOH) at position one

- Chlorine atom on the fourth carbon

- Filled in with hydrogens so each carbon makes a total of four bonds

I remember seeing the structure for the first time in college, tucked away in a section that covered halogenated acids. Its simplicity stood out. Many people might glance over the chlorinated branch and miss its quiet potential, but that little chlorine atom changes how the molecule reacts compared to plain butyric acid.

The Impact of Structure on Reactivity

That fourth-position chlorine does more than give a name: it shifts how this molecule interacts with the world. Chlorine’s presence makes that end of the molecule more reactive in substitution and elimination reactions. Synthetic chemists appreciate this—those looking to shape larger, more complicated molecules find 4-chlorobutyric acid an inviting starting point.

From what I’ve seen, labs use this acid to make drugs, plasticizers, or even as a link in the middle of a chain that ends up influencing an entirely different corner of the chemical world. The structure itself acts as a sort of Swiss Army knife. Many pharmaceutical intermediates owe their existence, at least in part, to easy access to that reactive chlorine at the far end of a carboxyl-rich acid.

Why Detail Matters: Real-World Effects

Ignoring small changes in chemical structures can spell trouble. For example, swap the chlorine to the second or third carbon instead, and the acid might react differently. In industrial settings, such mistakes can wreck a project or expose workers to higher risk. The location of every atom matters in both lab notebooks and on production floors, because those little choices decide not only what gets made, but how safe and efficient the process turns out.

Clear Facts and Considerations

Safety data for 4-chlorobutyric acid—a necessity for anyone handling it—points out notable hazards. It can destroy tissue and poses health risks if inhaled or absorbed through the skin. According to the National Institute for Occupational Safety and Health, proper protective equipment reduces these dangers. Most reputable suppliers share Safety Data Sheets that outline exactly what to do if the acid spills or if someone is exposed.

I also saw researchers focus on limiting environmental release, since chloride-containing waste sometimes harms aquatic systems. Smart management solutions include neutralization and careful disposal, guided by up-to-date safety protocols. Training laboratory teams to never overlook details helps keep accidents rare, and keeps the molecule a force for innovation, not harm.

The Real Risks of 4-Chlorobutyric Acid

Anyone who’s spent a chunk of time in a chemistry lab knows a strong chemical just by the way it lingers on the air, or bites at the skin. 4-Chlorobutyric acid brings out both those reactions. The clear, colorless liquid shows up in industry recipes as a handy building block, but the safety data always demands respect.

This stuff burns. The vapor stings noses and eyes, and direct contact deals a punch that you remember for days. People sometimes let their guard down around “routine” chemicals, figuring something that looks bland can’t cause much harm. Yet, 4-chlorobutyric acid will irritate skin and eyes faster than most expect. I’ve watched colleagues who’ll never admit their own error—splattering some across a glove, then realizing the glove wasn’t as thick as they thought.

Swallowing it creates a much bigger problem. It’s corrosive enough to damage a mouth and throat, even in a small spill. Animal studies, which are often grim reading for any chemical, show negative effects on the nervous system and liver at higher doses. For workplace safety, those health facts carry weight. Even a small mistake—an ungloved finger, a missed fume hood—can flip an ordinary afternoon of lab work into a regretful medical report.

Understanding Exposure in the Workplace

There’s no way around it: inhaling the vapor or getting splashed ends badly. That acid latches on to tissues, and the body responds with inflammation. Regulators like OSHA and EPA rank 4-chlorobutyric acid as hazardous. There are strict limits on how much someone can be exposed to during a shift.

I think of friends who started in labs with rubber gloves and a splash of overconfidence. An unplanned exposure wouldn’t just irritate skin—it could trigger headaches, dizziness, or breathing trouble. Long-term, repeated low-level exposure brings up questions about cancer risk that scientists are still sorting out, using new data as it comes in. Each year brings another finding that urges more respect for the chemical in the bottle.

Practical Steps for Safety

One solution is stubborn, routine caution. Fume hoods are not an option—they’re required, every single time. Nobody pours, transfers, or cleans up any spill without goggles and gloves rated for acid resistance. If it’s on your skin, rinsing right away really matters. Machines that measure air quality in the lab or plant keep teams honest about what they’re breathing in.

Beyond gear, good training stands out. Too many stories reach back to a skipped safety meeting or the new guy not knowing why he needs double-layer gloves. I’ve seen labs build a culture where people check with each other, spot mistakes, and talk about close calls, so lessons stick with everyone.

Industry Responsibility and Environmental Concerns

Producers and employers also have to step up. Clear labeling, proper disposal, and tight inventory all lower the odds of trouble. Dumping even a small amount down the drain pollutes water and affects local wildlife. Waste teams, who handle chemical leftovers, deserve the same respect and protection as the researchers mixing the original product.

This is a chemical with benefits for manufacturing and science, but it cuts both ways. Anyone handling it can’t afford shortcuts, and everyone in the chain should hold their ground on safe practices. That’s the only way to make things right for both people and the places they work.

Why Safe Storage Matters

4-Chlorobutyric acid isn’t a substance anyone wants to mishandle. It’s a chemical that can irritate the eyes, skin, and respiratory tract. Small spills can snowball into bigger problems if the right care is not taken. Over the years, I’ve seen people underestimate simple steps and pay the price with accidental exposure or ruined product. Safety starts with storage, not with first aid after an incident.

Finding the Right Container

A high-quality, tight-sealing glass bottle works best for this chemical. Plastic sometimes reacts or lets vapor escape, which puts both the product and its handler at risk. Avoid cork stoppers or damaged lids. Every time I’ve seen a shortcut in material choice, it’s led to leaks or contamination. Metal, unless it has a compatible lining, stays out of the equation too. That little decision can save major headaches down the line.

Stable Temperature

Store it in a cool place, ideally under 25°C (77°F). Heat speeds up degradation. I once worked in a lab where poor climate control led to changes in the acid's quality, not to mention a rise in fumes. Even for short-term storage, keep it away from radiators, direct sunlight, and hot equipment. A pressure rise from heat can also pop a lid or crack a container. For longer-term storage, a dedicated chemical fridge marked for acids works wonders.

Keep Away from Incompatibles

4-Chlorobutyric acid doesn’t play nice with strong oxidizers or bases. Wrong neighbors on a shelf can mean accidental reactions. I’ve seen labels fade and mix-ups happen, with some pretty nasty close calls. Use clear, large labels and check Storage Group assignments—a small investment in extra stickers beats an emergency evacuation.

Control Moisture and Air

Exposure to humid air or open containers lets this acid absorb water or react with air, changing its structure and sometimes emitting unpleasant fumes. Every opening shortens shelf life and adds risk. My habit is to mark when a bottle is opened and to check the tightness after closing. Desiccators or dry cabinets help for high-purity stocks. Never return unused acid to the original bottle; cross-contamination is all too common and often overlooked.

Access Control and Documentation

Limit who can reach the chemical. At my previous job, only trained team members got the key to the acids cabinet. No exceptions. Accurate inventory logs catch problems early too—if you see a discrepancy, it’s easier to trace the issue when good records are in place.

Emergency Readiness

A spill kit for acids stands by the storage location. Even with the best precautions, accidents happen. Chemical splash goggles and nitrile gloves should be within arm’s reach before handling. A printed safety data sheet, rather than just an online copy, belongs near the storage area. In every lab where I’ve worked with 4-chlorobutyric acid, these basics separate routine work from regret.

Summary

4-Chlorobutyric acid asks for respect: glass storage, a cool dry spot, clear labeling, and sharp emergency prep. Small, routine efforts add up to a safer workplace and better outcomes for everyone who handles or relies on this chemical.

What You Really See in 4-Chlorobutyric Acid

Take a look at a bottle of 4-Chlorobutyric acid in the lab, and the first thing you’ll notice is its clear, colorless liquid form at room temperature. If you’ve handled many similar organic acids, you can spot the sharp, pungent odor from a distance, something reminiscent of strong vinegar but harsher, mostly thanks to the molecule’s short carbon chain and presence of chlorine. That smell clings to gloves and lingers in glassware, so nobody working with it forgets what it is.

Boiling and Melting Points: Why They Matter

The boiling point hovers around 230°C, and melting lands close to -35°C. This puts it right in line with many small-chain organic acids, and there’s no guessing here—these numbers come from real-world measurements, not just guesswork. The relatively high boiling temperature can trip up new chemists expecting something more volatile. In practical terms, heating the liquid much above the boiling point risks not just vapor but decomposition, which makes temperature control a priority for any synthesis work bunched around this molecule.

How It Handles Water and Other Liquids

4-Chlorobutyric acid dissolves pretty well in water. Not every acid with a chlorine stuck on it can claim that, and it makes a difference in the lab or large-scale processing. Beyond water, you can mix it up with alcohol, ether, or acetone, thanks to its flexible carbon backbone. That makes this acid easy to move between extraction steps or in making derivatives, especially if the end goal sits somewhere in the agrochemical or pharmaceutical world.

Density and Viscosity: More than Just Numbers

Pull up the density, and you’ll find it around 1.17 grams per cubic centimeter at room temperature. That’s heavier than water and usual for chlorinated short acids. Pour some from one container to another, and it still runs smoothly, not syrupy, so it doesn’t clog up small tubing or pipettes. Daily chemical handling goes smoother with a liquid that actually leaves the glassware quickly, as anyone tired of cleaning sticky residues will agree.

Corrosiveness and Storage

4-Chlorobutyric acid earns respect for its corrosive bite. Spill some on steel or aluminum, and you can see pitting form if it sits too long. That’s why you often see this stuff stored in glass, Teflon, or certain plastics, not the cheapest metal cans. Anyone working with it needs gloves and eye protection, plain and simple. Skin contact brings irritation right away, and the vapors aren’t any nicer in confined spaces. It pays off to set up clear spill-handling rules and good ventilation, since mistakes aren’t just a nuisance—they can end work for the day fast if left unchecked.

Opportunities and Hazards

This molecule ends up in stacks of syntheses for things like drugs, flavors, or other organochlorine compounds. At the same time, the physical properties shape every step. Water solubility helps simplify clean-up, but the low melting point and corrosive side mean cold storage and extra care during transfer. Echoing my time supervising a student doing esterification, failing to check that the fume hood worked properly turned a simple task into a multi-hour air-out session because of vapors.

Looking Toward Better Handling

In any setting, investing in airtight containers and always labeling them well cuts down on mix-ups and exposures. Training fresh lab hands on safe transfer techniques with a focus on spill response saves hassle and keeps everyone out of the emergency eyewash station. Keeping these bases covered turns a tricky, sometimes intimidating chemical into a reliable workhorse for those willing to respect its bite.