4-Methyl-N-Butylpyridinium Hexafluorophosphate: A Deep Dive

Historical Development

Chemistry doesn’t stand still. Over the last few decades, ionic liquids have shifted theories and practices across laboratories. Among them, 4-Methyl-N-Butylpyridinium Hexafluorophosphate found its place as scientists hunted for more efficient and less volatile alternatives to traditional molecular solvents. Early studies from the late 1990s and early 2000s highlighted the need for stable, non-flammable electrolytes. The pyridinium-based ionic liquids, especially those incorporating hexafluorophosphate anions, began to attract attention because they tackled volatility and enhanced conductivity. Research groups across Europe and Asia started publishing work that compared pyridinium variants to widely-used imidazolium-based room-temperature ionic liquids. As more labs reported high chemical and thermal stability, companies finally recognized that these compounds could drive breakthroughs in chemical engineering, catalysis, and green technology.

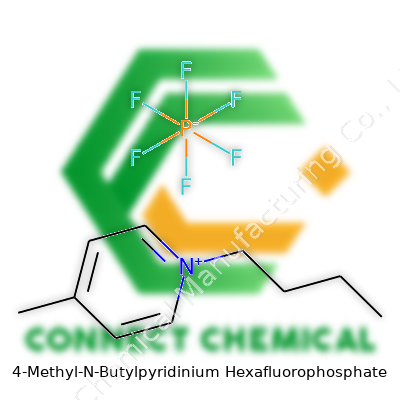

Product Overview

4-Methyl-N-Butylpyridinium Hexafluorophosphate usually presents as a pale, viscous liquid or sometimes a waxy solid, depending on purity and ambient temperature. Its makings favor chemical industries demanding less evaporative losses and extended lifespans for reagents. Folks working in battery research, electroplating, and material synthesis often keep a bottle of this compound handy, not only for its ionic conductivity but for remarkable viscosity that lets reactions run cleaner and with better separation. Markets list this compound under specialty chemical supplies, and it doesn’t pop up for general public use. Only research facilities and specialty processors make practical use of it because of its high cost and specialized nature.

Physical & Chemical Properties

This compound resists easy classification because it bridges the gap between liquid salts and organic solvents. It carries a melting point around 35-45°C and resists decomposition until approximately 250°C. Its density exceeds that of water, floating near 1.2-1.3 g/cm³, and large cations combine with bulky hexafluorophosphate anions to grant low volatility and negligible vapor pressure at room temperature. It won’t mix easily with water but blends smoothly with polar aprotic solvents. The hexafluorophosphate anion stabilizes the cation, curbing hydrolysis and sustaining ionic strength. Electric conductivity checks in moderately high, enough to act as electrolyte in several energy storage systems. Common impurities, especially from raw synthesis, include residual pyridine or unreacted starting materials, which can be tracked by NMR and handled with vacuum drying and recrystallization.

Technical Specifications & Labeling

On the shelf, the technical data sheets show purity levels rarely dropping below 98%. Moisture content receives close attention, often maintained below 0.1% to prevent unwanted hydrolysis of the PF₆⁻ anion. Bottle labels list the chemical formula as C₁₀H₁₇NPF₆ and display the CAS number 393929-37-2. Packaging comes in amber glass or Teflon-sealed bottles to avoid light or moisture degradation. Transport regulations class the compound as hazardous due to its fluorinated anion content. Most suppliers also provide spectral data—proton NMR, carbon-13 NMR, and IR spectra—so labs can verify batch consistency before running sensitive experiments. Storage temperatures favor cool conditions, away from acids and bases, to keep the structural integrity of both cation and anion. Safety datasheets warn against storing it near oxidizers or open flames.

Preparation Method

Lab-scale synthesis follows a well-trodden route. The process begins with alkylation of 4-methylpyridine using butyl bromide, usually under reflux with a polar aprotic solvent such as acetonitrile. After the reaction, the quaternized salt forms as a viscous liquid or crystalline mass, which is then washed to remove excess reactant. The crucial step involves anion exchange, where the bromide salt is dissolved in water and treated with potassium hexafluorophosphate. Double displacement forces PF₆⁻ into place while sparing the valuable pyridinium cation. The resulting product separates, often as a denser lower layer, then undergoes repeated washing with water to chase off potassium and residual halide. Drying under reduced pressure removes traces of water, essential for reliable performance in sensitive applications.

Chemical Reactions & Modifications

Chemists value the cation’s ability to accommodate various substitutions on the pyridine ring, which tweaks solubility, viscosity, and stability. Adding more bulk or polarity—say, by attaching ether or hydroxyl groups—alters everything from miscibility with solvents to suitability in catalytic reactions. In energy research, swapping the hexafluorophosphate anion for alternatives like bis(trifluoromethylsulfonyl)imide (TFSI) produces ionic liquids with higher thermal stability and lower viscosity, which can enhance battery performance. The compound handles mild base or acid without rapid breakdown, but concentrated acid conditions can cleave the cation or hydrolyze the PF₆⁻ anion, releasing hazardous HF gas. Given its relatively sturdy ionic structure and broad potential for cationic modification, researchers keep finding new derivatives for highly specific applications, pushing boundaries on electrochemical windows and solvent properties.

Synonyms & Product Names

Naming in this field does more than fill catalog space. Besides its full designation, the compound goes by 4-Methyl-n-butylpyridinium hexafluorophosphate, or simply [4MBP][PF₆] in shorthand. Some databases list it as N-Butyl-4-methylpyridinium Hexafluorophosphate, which highlights the importance of the two major substituent groups anchoring the molecular structure. In international marketplaces and academic literature, alternative spellings pop up—you’ll see “n-butyl” and “butyl” swapped, and the hexafluorophosphate sometimes spelled with a Greek phi or as PF6. CAS 393929-37-2 locks it down globally, streamlining procurement and research communication.

Safety & Operational Standards

Dealing with ionic liquids like this one means following stringent lab protocols—no exceptions. The hexafluorophosphate anion brings risks, especially in the presence of water and acid. Any chance of hydrolysis raises the prospect of hydrofluoric acid formation, which poses a real danger for skin and respiratory exposure and corrodes glassware. Full PPE is non-negotiable: gloves, eye protection, and dedicated fume tents for open transfers. Spills need immediate cleanup with appropriate neutralization agents, never just a cloth or bare hand. Waste management follows hazardous material guidelines, with no shortcutting disposal regulations. Manufacturers supply batch documentation tracking moisture, residual chloride, and heavy metal content, reinforcing safe handling across manufacturing and research settings. Anyone handling this compound for more than a few minutes soon learns respect for its potential hazards.

Application Area

4-Methyl-N-Butylpyridinium Hexafluorophosphate shows up most in high-end research and technology prototypes rather than consumer goods. Electrochemistry labs rely on its ionic conductivity and chemical inertness to study new battery and capacitor prototypes. In electrodeposition and fine-metal separation, it acts as both a solvent and stabilizer, supporting processes under high voltages that would destroy regular organic media. Catalysis researchers experiment with its solvent properties to speed up reaction cycles or make selectivity more predictable. Some pharmaceutical chemists try it in green synthesis campaigns to reduce reliance on volatile organic solvents. Its moisture tolerance and stable ion pair formation also make it a strong candidate for membrane science, where selective transport of ions can define the success of an entire process.

Research & Development

R&D teams focusing on ionic liquid applications scrutinize this compound’s physical and chemical landscape. Their priorities extend to cost reduction, moisture resistance, and improved synthesis routes. Several universities and tech institutes publish studies on optimizing yield by tweaking reaction times and using greener solvents. The industry continues to fund research into electrochemical window expansion and improving environmental safety, because the presence of fluorine-containing anions raises environmental and health questions. The balance between maximizing ionic liquid properties and reducing environmental impact stirs debate around the choice of supporting anions and possible alternatives. Cross-discipline research also flourishes—synthetic chemists team up with environmental scientists to study longevity and eventual breakdown products, looking for sustainable design principles that will keep this material relevant beyond niche markets.

Toxicity Research

Safety data for 4-Methyl-N-Butylpyridinium Hexafluorophosphate remains incompletely mapped, especially for long-term exposure and environmental persistence. Acute toxicity studies show limited skin irritation but caution grows in handling due to its hexafluorophosphate content. Short-term animal trials suggest low to moderate cytotoxicity when compared to other ionic liquids, but concerns about chronic fluorine exposure and breakdown into persistent pollutants can’t be ignored. Research teams continue to test cellular uptake, mutagenicity, and aquatic toxicity, with some evidence showing that both cation and anion can become bioactive under certain conditions. Regulatory agencies watch closely, and new studies often seek ways to recover and recycle the material after end-of-life to prevent environmental accumulation. As the field grows, more comprehensive toxicity maps will support safe scaling.

Future Prospects

Looking ahead, opportunities and challenges entwine tightly. Advances in synthetic chemistry promise not only to cut costs but to use eco-friendlier reagents, potentially solving some environmental issues at the source. As battery technology and green catalysis race ahead, the demand for stable, high-conductivity solvents like this one rises. Innovations in anion design and recycling schemes hold potential to satisfy stricter regulations and open mass-market applications. At the same time, questions about toxicity and lifecycle remain unsettled. Researchers continue to chase ionic liquids with even broader electrochemical windows and lower environmental impact, but the properties of 4-Methyl-N-Butylpyridinium Hexafluorophosphate keep it firmly in the rotation for high-stakes R&D. Once toxicity hurdles clear and greener synthetic pathways prove scalable, the compound could drive transformation in energy storage, separation technology, and sustainable chemical manufacturing.

Understanding Its Purpose

4-Methyl-N-Butylpyridinium Hexafluorophosphate doesn’t show up in headlines or television commercials. Anyone who has worked in a materials science lab or dabbled in battery research probably recognizes the tongue-twisting name, though. This compound belongs to the growing family of ionic liquids, a group of salts known for staying liquid at much lower temperatures than table salt or baking soda ever could. That trait makes these substances interesting for many clever uses across technology and chemistry.

How This Compound Powers Innovation

Ionic liquids like 4-Methyl-N-Butylpyridinium Hexafluorophosphate have serious staying power in modern science. Electrochemistry labs use compounds like this in batteries and supercapacitors. Unlike older liquid electrolytes, which sometimes catch fire or leak, this liquid barely evaporates and stands up to heat. It doesn’t break down and leak dangerous fumes as quickly, either. With so many reports of consumer devices catching fire from battery failures, researchers pay attention to safer, more stable ingredients.

This particular compound finds its place in the search for next-generation lithium-ion batteries. The mobility of ions—that is, the way charged particles shuffle around within these liquids—can be tuned by chemists for just the right performance. A few years ago, I watched a graduate student carefully layer ionic liquids in a test cell, trying to boost how much energy the battery could store in a single charge. That hands-on approach puts compounds like this right at the center of efforts to make phones, electric cars, and solar-powered gadgets both longer-lasting and safer.

The World of Green Chemistry

Beyond batteries, some scientists reach for 4-Methyl-N-Butylpyridinium Hexafluorophosphate as a replacement for harsh organic solvents in chemical processes. Petroleum-based solvents pollute air and water and cause safety headaches. In comparison, ionic liquids tend not to create vapor, lowering the risk of inhaling or igniting fumes. Large chemical plants need safer methods for cleaning, separating, or recycling materials, and ionic liquids come up in those conversations more often these days.

Lab workers choose this particular salt for its chemical stability and low natural reactivity. It rarely reacts with the chemicals being processed, so unwanted side products stay out of the mix. That’s a big deal in pharmaceuticals, electronics, and even in metal plating, where every trace impurity counts. In one of my own collaborations, we found that ionic liquids helped pull out precious metals from electronic waste streams without creating noxious side reactions. The goal is cleaner processes and fewer accidents.

Possible Concerns and Next Steps

Some concerns shadow ionic liquids, including 4-Methyl-N-Butylpyridinium Hexafluorophosphate. Disposal and recycling create challenges because these are manufactured, persistent chemicals—they can hang around in soil or water. Companies and labs want greener credentials and cleaner processes, but they have to balance those gains with possible long-term impacts. More studies about toxicity and breakdown pathways will clarify the road ahead. Until then, safety gear and responsible handling matter just as much as innovation.

Breakthroughs in materials science depend on compounds like this: working behind the scenes, hidden in battery cells, and green chemistry labs. Each project adds another data point that nudges industry and academia toward safer, smarter solutions. The search for a better battery, a safer solvent, or a tougher electronic coating makes these chemicals more important with every passing year.

Getting To Know The Formula: More Than Just Letters and Numbers

4-Methyl-N-butylpyridinium hexafluorophosphate carries the chemical formula C10H16NPF6. Its molecular weight lands at approximately 289.21 grams per mole. This isn’t just trivia for chemists. Knowing a substance down to the formula means you’re digging up its story—the building blocks, the kind of bonds holding the atoms together, and what might happen when the material meets other chemicals, heat, or even water vapor in the lab.

What Difference Does The Formula Make?

Whether you’re crafting better batteries, hunting for safer solvents, or trying to keep a chemical process under control, formula and weight play huge roles. The details reveal the ratios for mixing, the quantities needed for experiments, and they help spot safety issues. For 4-methyl-N-butylpyridinium hexafluorophosphate, used in ionic liquids, its exact makeup shapes how easily it dissolves, how it interacts with electricity, and even how much heat it handles before breaking down.

Real Risk and Smart Handling

Safety always needs a hard look in chemistry. Too many folks simply skim over the basics, but understanding the formula gives clues about its hazards. The phosphorus and the six fluorine atoms in this compound raise concerns in handling and waste. Chemicals with hexafluorophosphate can spill corrosive hydrogen fluoride under the wrong conditions—one of those “invisible dangers” in the lab. Getting the formula right guides training, storage, and emergency measures.

Bringing Experience Into The Lab

I’ve spent time weighing out salts that look similar, grabbed scoops that left powders floating in the air, and read datasheets that barely scratched the surface of safety. More than once, a mix-up got caught early because someone double-checked the numbers and formula. Complacency doesn’t mix well with unfamiliar chemicals. Reading and understanding labels and documentation slows you down, but it’s miles cheaper than cleaning up after an accident. The lessons from earlier mishaps always linger: trust but verify, and don’t let the routine blindside you.

Supporting Claims: Industry Evidence

The world of ionic liquids keeps growing. In lithium-ion battery research, ionic liquids like this one bring better thermal stability and wider voltage windows. According to studies from the American Chemical Society, the precise balance of pyridinium and hexafluorophosphate affects ion mobility and battery durability. Getting the structure wrong means starting over in lengthy, expensive tests. On the scale of a production plant, these details translate to safety margins and cost calculations that shape the business bottom line.

Better Practices and Possible Solutions

There’s always a way forward. Training lab workers with hands-on examples of mixing and calculating can stick far better than dry diagrams on a projector. Encouraging double-checks on every chemical pulled from a shelf sets a culture of diligence. And for anyone bringing a new material into workflow, carving out time for risk assessment, even on a tight deadline, keeps everyone safer in the long run. Digital logbooks and barcodes now help track lots and verify formulas, recent advances making it almost painless to avoid costly mistakes.

Why It’s Important To Get This Right

This isn’t only a theory lesson. A sound understanding of chemical formula and molecular weight makes every glove, ventilator, and lab bench safer—and it cuts surprises in process and product testing. In an age filled with new compounds and creative chemistry, the chemistry basics still shape breakthroughs and personal safety, every single day.

Why Storage Conditions Matter More Than Most Realize

Keeping chemicals like 4-Methyl-N-Butylpyridinium Hexafluorophosphate safe isn’t just a lab rule—it’s an everyday responsibility. I’ve worked with ionic liquids before, and it doesn’t take long to notice problems that pop up from carelessness. If you’ve ever opened a bottle only to catch a whiff of something “off,” you know how quickly these compounds let you know they’re unhappy.

The Trouble With Air and Moisture in Storage

4-Methyl-N-Butylpyridinium Hexafluorophosphate doesn’t react well to water or damp air. The hexafluorophosphate anion breaks down under moisture, and you end up with nasty byproducts like hydrofluoric acid. That stuff eats through glass, skin, and any comfort level you once had. People think tossing the bottle on a cool shelf is enough, but humidity sneaks in faster than you’d expect.

The key is using airtight containers—preferably high-grade glass or heavy-duty plastic—stored in a desiccator. Silica gel packs or molecular sieves help pull out every bit of stray moisture. I remember more than once opening a container that someone thought was closed tight, only to find the contents had gone gritty or clumpy from a few bad days in a humid storeroom.

Stable Temperatures Keep the Chemistry Boring

Changes in temperature stress out sensitive chemicals. From my own work with ionic liquids, it’s clear that storing 4-Methyl-N-Butylpyridinium Hexafluorophosphate between 2°C and 8°C keeps things stable without freezing. Excess heat speeds up unwanted reactions; freezing can shove the salt out of solution, making for a mess in your container. Regular room temperature usually works unless your lab feels like a sauna.

Setting a consistent spot in a climate-controlled cabinet means no daily fluctuations, no ice forming on the inside, and a lot fewer accidents. It’s easy to slack off and set a bottle wherever there’s space, but it comes back to bite—either with ruined product or, worse, cleanup from a hazardous spill.

Compatibility Checks Stop the Small Disasters

We’ve all grabbed the nearest container at crunch time. Not all plastics handle strong ionic salts without warping or cracking. Teflon and certain borosilicate glasses last longer and don’t react, so I always check for that before trusting a container with expensive or hazardous material. Once, I watched a bottle dissolve from the inside—just because no one double-checked what kind of plastic it was.

Store away from acids, bases, and oxidizers. Separate shelves make cross-contamination less likely, and mishaps rarer. It’s on us to read the labels, but some workplaces toss everything together. That’s asking for trouble with a compound like this.

Labeling—It’s Not Just for Show

Mislabeling leads to confusion. Expiry dates, hazard warnings, and the date you opened the container should be easy to spot. A dry erase mark on a glass desiccator and tough lab tape never failed me. If you can guess what’s in a bottle by sight or smell, chances are someone’s forgotten the basics.

Trading Shortcuts for Consistency Pays Off

4-Methyl-N-Butylpyridinium Hexafluorophosphate isn’t a chemical you treat lightly. Keeping it dry, cool, and out of the wrong containers prevents most of the failures I’ve seen. Good habits—airtight lids, trusted containers, clear labels—mean fewer disasters and less waste. That’s something every lab and every worker can get behind.

Peeling Back the Chemical Curtain

Not every chemical grabs headlines, but 4-Methyl-N-Butylpyridinium Hexafluorophosphate stands out among ionic liquids making their way into labs and energy storage. Its long name sounds intimidating, and it probably should. I’ve watched chemists grow more cautious with these “designer” salts. This one, built from a pyridinium ring and hexafluorophosphate, isn’t as benign as some product data sheets may suggest.

Toxicity: What the Research Shows

I tend to look beyond supplier blurbs and dig into published toxicity data. With 4-Methyl-N-Butylpyridinium Hexafluorophosphate, animal studies show both acute and chronic effects. Researchers working with related pyridinium salts observed changes in liver and kidney tissues after repeated exposure, even at moderate doses. Scientists at European labs noted enzyme inhibition and impacts on fertility in small mammals. That tells me the risk isn’t just a remote concern.

Hexafluorophosphate adds another layer of trouble. If this compound breaks down or is exposed to moisture, it can release hydrofluoric acid. I once saw a young tech ignore this hazard and end up with skin burns from an “innocent” spill. Hydrofluoric acid acts fast and penetrates tissue deeply, and only professionals with solid training should handle anything that might generate it.

Environmental Risks: The Overlooked Cost

Companies sometimes market ionic liquids as “green” alternatives, pointing to low vapor pressure and low flammability. These labels overlook the main threat—persistence. Once released, 4-Methyl-N-Butylpyridinium Hexafluorophosphate sticks around in water and soil. It resists breakdown by sunlight or bacteria. Scientists studying urban waterways in Germany have found traces of similar compounds months after release, hinting at bioaccumulation in fish. If this persists, the food chain pays the price.

Why This Matters in the Lab and the Real World

Many college chemistry departments press for research experience early on. I remember my own undergraduate days when safety training lagged behind enthusiasm. Too many young researchers jump into ionic liquid use without grasping the risks. Gloves are good, but splash goggles, chemical hoods, and careful disposal matter even more for this class of chemicals.

Outside labs, some startups look at these salts for battery and solar panel development. Laboratory curiosity turns into large-scale production faster than some regulations catch up. The European Chemicals Agency labels many hexafluorophosphate salts as “hazardous to aquatic life, with long-lasting effects.” Every new application likely brings new industrial waste streams.

Finding Solutions: Focusing on Safety and Transparency

Information saves lives in places where new compounds get tested. Material Safety Data Sheets need honest updates, not sales pitches. Students and scientists require hands-on hazard training, not just written protocols. Companies piloting new tech must measure real emissions and work with local regulators to keep effluents from reaching rivers and landfills.

Emerging research programs focus on “greener” ionic liquids—meaning salts that break down into non-toxic parts after use. Until those arrive, proven chemical skills and a bit of healthy skepticism offer protection. The story of 4-Methyl-N-Butylpyridinium Hexafluorophosphate highlights why knowing what’s in the flask, asking tough questions, and sharing data trump wishful thinking every day of the week.

Understanding Purity in Research Chemicals

Chemistry labs rely heavily on the purity of their materials. If you’re pouring hours into making progress with ionic liquids, a compound like 4-Methyl-N-Butylpyridinium Hexafluorophosphate can make or break an experiment. Most suppliers offer this compound at a purity level of 98% or higher. That means out of every hundred grams, at least 98 grams of the stuff you’re getting is the genuine ionic liquid, with any leftovers making up the “unknowns.” For sensitive applications—say, battery development, organic synthesis, or advanced materials—it’s important to pick the highest purity available. Any rogue impurities might throw off your results down the line, leaving you scratching your head with unexpected data.

There’s a world of difference between running a reaction with technical-grade chemicals and working with near-pristine material. Someone with a chemistry bench can rattle off stories about how a small impurity introduced noise into the data, mucked up cell performance, or led to questionable yields. And it’s not just about dry numbers—quality impacts safety, too. An impurity, even in small concentrations, can set off unwanted side reactions or corrode your equipment faster than you might expect. With ionic liquids like this one, folks chasing new energy solutions or greener chemistry can’t afford to gamble on subpar quality.

Packaging Sizes: Finding the Right Fit

Anyone who has ever worked in a lab knows that buying chemicals isn't a one-size-fits-all affair. 4-Methyl-N-Butylpyridinium Hexafluorophosphate usually comes in a handful of different sizes. Common options include 5-gram, 10-gram, and 25-gram bottles. Graduate students chasing a single round of reactions might only spring for the smallest bottle, easing concern about waste or chemical degradation. On the other hand, teams running pilots for industrial scale-ups usually have eyes on bigger containers, like 100-gram or even kilo sizes, to keep their workflow smooth.

Real-life stories abound: I recall a colleague who underestimated just how quickly their ionic liquid supply would vanish after a few test runs. Ordering too little forced them into an awkward scramble, delaying progress for weeks. On another project, overbuying led to poorly stored, expired material. Companies that act responsibly emphasize accurate forecasting based on planned experiments, and careful storage to protect shelf life—both help keep cost and chemical waste down.

Trust Begins with Reliable Suppliers

You need to check certificates of analysis before opening your wallet. Suppliers who take quality seriously will show off their test results and offer transparency about how each batch holds up. Reputable vendors often provide access to safety data sheets, detailed COAs, and customer support teams happy to field questions about storage tips, chemical stability, or batch-specific quirks.

You can’t build trust in scientific work without dependable materials. Groups that invest in traceable sourcing earn credibility in publications, collaborations, and industry relationships alike. In my own quests for strange fluorinated compounds, I’ve learned to dig for detailed batch analysis and open lines of communication. It saves headaches later on and builds relationships with suppliers who stand behind their products.

Tackling Access—and Waste—Through Smarter Decisions

Scientists talk often about sustainability, but the small decisions carry a big punch. Choosing the right packaging size reduces both cost and waste, which lines up with the greener goals many institutions now pursue. Accurate stock tracking and a healthy respect for chemical shelf life keep dangerous disposal down and budgets healthy. Industry pushes toward reuse, recycling, and safer storage—these initiatives matter as much in the university lab as in the corporate R&D center. Here’s the real advice: listen to your needs, study the certificate of analysis, choose packaging thoughtfully, and keep a close relationship with your supplier. The payoff arrives as cleaner experiments, better data, and a lighter footprint on the environment.