5-Bromopentyl Acetate: Chemical, History, Application, and Forward-Thinking Insights

Historical Development

Chemists, for decades, have hunted for flexible intermediates to tie together the world of industrial synthesis and specialty chemicals. 5-Bromopentyl acetate found attention in the postwar years as organic synthesis expanded in scope. Lab notebooks from mid-20th-century researchers outline brominated alkyl acetates being explored as bridges between halogen chemistry and ester formation. As laboratories searched for molecules with both functional group reactivity and straightforward preparation, this compound became a proven workhorse. Patent literature from the sixties and seventies listed this compound for its role in pharmaceutical building-block assembly, especially for new tranquilizers and perfumery bases. The history of 5-bromopentyl acetate shows how chemical curiosity leads into full-scale industry interest, moving from glassware to process vessels in response to demand in fragrance, pharmaceutical, and polymer sectors.

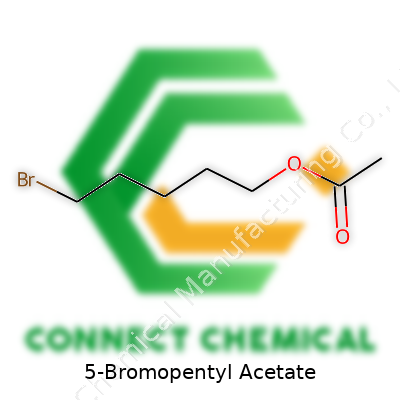

Product Overview

5-Bromopentyl acetate belongs to the haloalkyl ester group. It combines the structural elements of a five-carbon acetate ester and a terminal bromine. Producers use this compound as a starting point for synthesizing surfactants, fragrances, and pharmaceutical intermediates. The structure supplies both a latent alcohol function and a reactive bromo group, which opens up substitution or elimination avenues in the lab. Companies sell it under several trade names, but the backbone remains the same: the molecule acts like a utility knife for research chemists, providing routes into more complex targets with a stable, storable molecular foundation.

Physical & Chemical Properties

5-Bromopentyl acetate appears as a clear or pale yellow liquid, with a faint sweet and pungent aroma. This chemical carries a molecular formula of C7H13BrO2 and a molecular weight of 209.08 g/mol. The density hovers around 1.29 g/cm³ at room temperature. Laboratories measure boiling points between 235 and 240°C, which give it a stable enough character for routine extractions and heating. Solubility comes mostly in organic solvents—ethanol, ether, and chloroform—while water solubility stays low because of the hydrophobic alkyl chain. The acetate ester portion can hydrolyze in strong acid or base. The bromo terminus readily swaps for various nucleophiles, a feature that grants technical flexibility in downstream reactions.

Technical Specifications & Labeling

Producers stamp their barrels and bottles with product grades, typically stating purity over 97%. Impurities often show as free acids or unreacted brominated alcohols, which proper distillation or chromatography can drop to below detection limits. Labels must reflect hazardous components per international chemical legislation—GHS pictograms for irritants and environmental hazards commonly appear. Safety Data Sheets (SDS) detail chemical identifiers, recommended storage temperatures (usually between 2°C and 8°C), and shelf-life assessments. Compliance with labeling standards, such as REACH or OSHA, steers safe handling in commercial and academic inventories.

Preparation Method

Manufacturers synthesize 5-bromopentyl acetate through a two-step sequence from 1,5-pentanediol. The diol reacts first with acetic anhydride under acidic conditions to yield the mono-acetate, then treats the unmapped alcohol end with phosphorus tribromide or thionyl bromide, swapping the hydroxyl group for a bromine. Small modifications allow for even higher yields by controlling water content or by using phase transfer catalysts. In the laboratory, the process requires careful temperature control and reagent handling to reduce byproducts, while for industry, continuous flow setups with in-line purification systems boost output and reduce waste streams. The chemical route attracts those seeking more sustainable chemistry, since it lines up with greener protocols when using recyclable solvents or low-toxicity brominating agents.

Chemical Reactions & Modifications

Chemists value the bromo group on 5-bromopentyl acetate for its ability to serve as a launching point for substitution chemistry. Nucleophiles—amines, thiols, or carboxylates—replace the bromine smoothly to generate wide classes of derivatives, from quaternary ammonium surfactants to custom pharmaceuticals. The acetate ester can undergo hydrolysis to free the pentanol, which itself can then act as a flexible intermediate. Researchers tweak conditions to promote elimination, crafting alkenes from the bromo-acetate, or to introduce more elaborate side-chains in multi-step sequences. With access to palladium catalysis, cross-coupling with aryl boronic acids sets the stage for complex aromatic systems with custom-tailored spacers. The molecule’s modifiability keeps it relevant for both current research and scale-up experimentation, as chemists constantly seek new access points for creativity.

Synonyms & Product Names

Industry sellers and catalogues list 5-bromopentyl acetate under a handful of names: 1-acetoxy-5-bromopentane, pentyl acetate-5-bromo, and 5-bromoamyl acetate rank among the most common. Some pharmaceutical and specialty chemical suppliers develop their own codes or brand names, though the chemical registry data confirms the shared identity. Researchers rely on the consistent naming to track down reliable safety data and eliminate any confusion about chemical identity, supporting both regulatory compliance and communicative clarity.

Safety & Operational Standards

Handling 5-bromopentyl acetate calls for vigilance. Even trace vapor can irritate eyes or the respiratory tract. In my own teaching lab, gloves, splash goggles, and local fume extraction became nonnegotiable whenever brominated esters entered an experiment. Chemical companies and universities store these containers away from strong bases, acids, and oxidizers to prevent accidental decompositions or eruptions. Workers need training on spill response and storage—no open flames, careful bottle labeling, and routine visual inspections for leaks or swelling. Standard procedures require meticulous SDS review before use and waste disposal through authorized hazardous channels. Regulatory agencies also require detailed documentation from import to finished product, allowing traceability back to every batch and lot number.

Application Area

The most active commercial outlets for 5-bromopentyl acetate land in the pharmaceutical, fragrance, and surfactant sectors. Teams developing custom drugs use this acetate to ready bromoalkyl intermediates for heterocycle construction or linker technology, which ties small molecules to larger proteins or polymers. In flavors and fragrances, skilled blenders exploit the volatility and latent alcohol features to craft unique scent profiles or to act as a fixative, locking more volatile top notes into compositions. Specialty polymer makers tap the acetate for controlled functionalization along chains, seeking to adjust surface energies or attachment points on plastic surfaces. Experience shows that improvisation with such building blocks often leads to accidental discovery—one graduate student’s attempt to make a new ionophore gave rise to an antimicrobial agent still under investigation. This ability to “engineer” new endpoints from a time-tested intermediate speaks to its place in creative chemistry.

Research & Development

Recent years pulled 5-bromopentyl acetate into new research directions. Large institutes have looked for greener bromination and acetylation protocols not just for cost, but to meet internal sustainability benchmarks. Work on flow chemistry has reduced side products and created safer, more reproducible syntheses. Medicinal chemists have used the acetate route to develop targeted delivery agents for oncology, where attaching a bromoalkyl moiety provides a “handle” for subsequent drug conjugation—a tactic that makes logistics and scale-up less daunting. Academic-industrial partnerships pen articles year after year about new uses, including in advanced materials like smart polymers tuned for biomedical sensing. The R&D landscape revolves around both finding new reactivity and meeting regulatory challenges with transparent documentation, experimental reproducibility, and respect for worker safety.

Toxicity Research

Toxicological testing paints a clear picture of responsibility. Rats exposed to high concentrations of 5-bromopentyl acetate develop symptoms typical of organic halide intoxication: central nervous system depression, mild liver stress, and, with repeated doses, delayed recovery. In cell cultures, brominated esters like this show low-to-moderate cytotoxicity, with the acetate group making metabolism easier than in some longer-chain analogues. Human data remains patchy, since direct consumer exposure stays rare, but occupational physicians urge prudent handling and regular health monitoring for those in daily contact. Aquatic toxicity, like many halogenated organics, cannot be brushed aside. Laboratory assays reveal moderate bioaccumulation risk and fish LC50 values in the low ppm range, enough to trigger aquatic hazard warnings in chemical safety briefs. These hard numbers inform company risk management and compliance with environmental law, which now demands lifecycle tracking from cradle to grave.

Future Prospects

Chemists working in synthesis always keep an eye open for reliable intermediates that “just work,” and 5-bromopentyl acetate keeps its spot in that toolbox. Industry is pushing for methods that ditch harsh reagents and reduce byproduct hazards. Better catalysts—heterogeneous instead of heavy-metal—feel closer than ever. In academia, fresh minds take this sturdy building block and generate new classes of biologically active molecules, flavor compounds, and surface modifiers for biomaterials. Digitization of chemistry opens up combinatorial searches for derivatives that could outperform long-known homologs. Regulatory moves continue to drive safer, less polluting methods; green chemistry circles view halogenated intermediates with both caution and creative opportunity. The molecule’s blend of reliability, reactivity, and modifiability sets the stage for ongoing evolution, as global priorities demand both innovation and accountability.

What's Going On With This Compound?

Most folks reading about 5-Bromopentyl Acetate for the first time probably glaze over. The name trips off the tongue like a science quiz, and it doesn’t ring bells like household names such as aspirin or acetone. Yet, this colorless liquid plays a part in some interesting corners of chemistry and industry that touch everyday life in strange ways.

The Scent Behind the Science

Think about the world of perfumes and flavors. Many of the subtle smells and tastes filling up a supermarket aisle start their life in a lab, as raw materials like 5-Bromopentyl Acetate. This compound acts as a chemical building block. Synthetic chemists reach for it when they need something that can carry an “acetate” group linked to a carbon chain—exactly the sort of thing that’s handy for brewing up new fragrance notes or specialty flavors.

A lot of people don’t realize that the backbone of the fragrance trade depends on these kinds of stable, easy-to-handle compounds. I spent some time around flavorists who explained that without reliable intermediates, their work would grind to a halt. They want parts they can trust, and this compound gives them several possibilities for designing all sorts of molecules found in packaged foods, baked goods, personal care products, and even cleaning supplies.

Bigger Picture: Pharmaceuticals and Lab Work

5-Bromopentyl Acetate holds a more serious hat, too. Researchers often use it when they're creating advanced medicines. The bromine atom within its structure works like a hook, letting other pieces attach easily during organic synthesis. Chemists use these molecules as stepping stones when engineering drugs, including antivirals, painkillers, or drugs aimed at the central nervous system.

Back when I studied chemistry, my group handled compounds like this during pharmaceutical research projects. These so-called intermediates tend to lurk in the shadows, but without them, none of the blockbuster medicines on pharmacy shelves could exist. Each new chemical needs a stable starting point—a reliable place to attach or swap groups, carve shortcuts, or protect certain parts until the final medicine is finished.

Handling and Environmental Considerations

Not all is rosy in the world of lab work. 5-Bromopentyl Acetate, like many industrial chemicals, can irritate the skin and eyes. Direct contact isn’t a joke. In a shared lab, I learned fast that handling brominated compounds meant gloves, goggles, and decent ventilation. Spills triggered big reactions from safety officers. Some of these compounds can persist in the environment, and waste rules don’t offer much wiggle room. This raises the issue: how do you use useful chemicals without piling up environmental baggage?

Companies dealing with this acetate need to build strong safety cultures and robust waste treatment routines. Regulatory bodies aren’t forgiving. Proper disposal turns into a major cost, and skipping steps can shut a factory down and land leaders in court. In my experience, the best labs put real money behind auditor training and traceable inventory. That structure protects workers and the neighborhoods around these facilities.

The Role of Trustworthy Suppliers

Quality matters. Faulty intermediates spell disaster, so suppliers who cut corners on purity or documentation lose trust fast. Supply chain scandals in pharmaceuticals often trace back to lax standards. Reputable factories back up every batch with certificates and track every sale. In food and fragrance work, a tainted shipment can lead to mass product recalls, public embarrassment, and lawsuits that sink small operations.

The chemical industry’s future seems tied to how these intermediates are sourced, used, and discarded. As regulation grows stricter and markets get more complex, choosing the right partners and training the next wave of chemists makes all the difference. Even small compounds like 5-Bromopentyl Acetate carry bigger stories than their names suggest.

Breaking Down the Name

Labels in chemistry aren’t just for show—they give you a roadmap to the molecule’s structure. “5-Bromopentyl acetate” packs information into just a handful of words. The “5-bromo” part signals a bromine atom on the fifth carbon of a pentyl chain. “Pentyl” signals a five-carbon backbone. “Acetate” clues us in on an acetic acid-derived ester. You get a molecule shaped by those decisions.

Finding the Chemical Formula

Take pentane, C5H12. Remove a terminal hydrogen, replace it with a bromine at the fifth carbon—you've got a 5-bromopentyl group. Acetate, that familiar C2H3O2 group, bonds to the oxygen, completing the ester. Assemble the pieces: five carbons from pentyl, two from acetate, plus the bromine, stick all the hydrogens and oxygens in place, and the full chemical formula comes out as C7H13BrO2.

Why Precise Formulas Matter

I've seen projects drop months of work due to one overlooked atom. One missing bromine, a swapped methyl for ethyl, and the outcome isn’t just a different smell or a weaker solvent—it could even mean pharmaceutical activity changes or failed chemical tests. Lab work thrives or flounders on these details. Researchers rely on molecular formulas to run their reactions, confirm purity, or predict how a compound will behave.

It’s also a safety line—brominated organics need careful handling due to toxicity. Misreading a formula could result in unsafe exposure or a blown experiment budget. Good science checks and re-checks molecular details, especially with halogenated esters.

Industry Needs Clarity

On the manufacturing side, accuracy in chemical labeling impacts compliance and product quality. For anyone ordering reagents, the wrong formula on a bottle delivers setbacks that ripple down production lines and disrupt schedules. Being clear about something as simple as the molecular arrangement helps avoid headaches, whether you’re blending fragrances, designing pharmaceuticals, or producing intermediates for further synthesis. More than once, miscommunication over compound identity caused prolonged downtimes or forced batch recalls.

Strong Documentation Supports Good Decisions

Reference materials—databases like PubChem or ChemSpider—make it easy to double-check structures and formulas. Smart labs and companies encourage referencing these frequently, since it takes little time and pays off with better data and safer outcomes. I've caught mistakes that would’ve cost a company credibility and cash, all because they double-checked the documented formula. Everyone benefits from this double layer of security: fewer incidents, less confusion, higher confidence.

Building Better Habits

Teams with good training on basics like IUPAC naming or molecular structure cut their error rate and impress clients with reliability. People sometimes overlook the groundwork, thinking advanced tools or new science outpace the importance of clear, foundational data. In practice, double-checking basics like the chemical formula for 5-bromopentyl acetate, C7H13BrO2, anchors the whole operation. Simple steps win over shortcuts every time.

The Basics on 5-Bromopentyl Acetate

Looking at a bottle with a label that reads “5-Bromopentyl Acetate,” you might just see another chemical name. For researchers and anyone with lab experience, this compound means business—a colorless, sometimes faintly sweet-smelling liquid, often used in synthesis work. Once it’s on the shelf, storage becomes one of the most critical steps. The risk isn’t just about personal harm, but about lost time, contamination, and the potential expense of a ruined batch.

Why Storage Makes a Real Difference

Leaving storage up to chance in any lab never serves you well. From my days handling organic chemicals, I’ve seen firsthand how skipping a simple storage rule ruins weeks of planning. 5-Bromopentyl Acetate reacts with air and light in ways that drive up degradation. Heat cranks up the risk of unwanted reactions. Quality drops, with results nobody can trust. And if you lose track of a volatile solvent or flammable compound, you’re one loose lid away from a safety incident or a ruined workspace.

Choosing the Right Storage Spot

Every lab worth its salt keeps volatile and sensitive liquids in cool, dry, and well-ventilated places. Basements stay too damp; countertops get sunlight. Keep 5-Bromopentyl Acetate in a cabinet made for storing chemicals—one marked with a flammables sign. Temperature needs to stay below room temp, but freezing turns the stuff sluggish and hard to mix. Stash bottles away from bright bulbs and direct sunlight, which speed up breakdown. In my own experience with similar compounds, a few degrees make all the difference when it comes to shelf life.

Picking the Right Container

Glass wins for storing 5-Bromopentyl Acetate, since plastics sometimes soften or leak over time. If your container closes tightly, vapor won’t seep out. A glass container with a secure cap cuts down on exposure to oxygen and keeps everything stable. Shrinking the number of air exchanges by opening bottles just for what you need keeps purity intact. Every label should include chemical name, date received, and hazard warnings. Clear, honest labeling stops mix-ups, especially if bottles look alike.

Storing Away from Incompatibilities

Pairing up chemicals in close quarters always invites trouble. 5-Bromopentyl Acetate shouldn’t sit next to strong bases, oxidizers, or acids. Storage shelves packed too tight lead to accidental spills. Separate shelves or containment bins help avoid cross-contamination. In a shared lab, color-coded bins save the day more than once.

Working Smarter, Safer

Labs with real safety culture stick with chemical inventories and regular checks. Expiry dates matter—a compound past its prime means wasted experiments or dangerous byproducts. Logging entries whenever a bottle moves keeps everyone honest.

Solutions for Peace of Mind

Setting up secondary containment below storage shelves catches leaks and spills. Spill kits with absorbent material, gloves, and proper disposal bags should always be close by. Regular staff refreshers help everyone remember why the process matters. Those simple steps let everybody focus on results, instead of cleaning up after avoidable accidents.

Making Expert Knowledge Routine

Smart storage practices reflect real commitment to safety, data quality, and cost savings. Instead of shortcuts, investing in careful routines creates a lab where risks shrink and results make sense. Anyone who’s handled chemicals for years knows—safe storage isn’t extra work, it’s essential.

No Cutting Corners: Personal Protection Always Comes First

Every time I handle chemicals, even if I have used them for years, a healthy respect keeps me from getting careless. With 5-Bromopentyl Acetate, a compound sometimes found in chemical synthesis labs, direct contact feels unforgiving on the skin and nose. Nitrile gloves, not latex, stay on my hands from opening the bottle to disposing of any waste. Nitrile offers better chemical resistance, which is easy to overlook until a glove springs a leak mid-task. Splash goggles keep fumes and drops out of my eyes, and a proper lab coat stays fastened up to my wrists. I never work with the stuff while wearing contact lenses—vapors latch onto lenses and increase the risk to eye health.

Ventilation: Don’t Underestimate the Power of Fresh Air

Odor often tricks people into thinking something is “not so bad.” Just because a chemical smells faint or sweet doesn’t mean breathing it is safe. I use a chemical fume hood with the sash down low and always check the airflow before I open any container. When fume hoods are out of commission, portable exhaust fans and wearing a respirator become necessary backups. In confined spaces, fumes linger and quickly reach unsafe levels, even if you can’t see or smell them. Neglecting proper ventilation leads to headaches and dizziness and, with repeated exposure, much worse.

Storage Habits That Prevent Accidents

No one wants a messy shelf that triggers a spill when you reach for one bottle and accidentally knock over two others. I keep 5-Bromopentyl Acetate in clearly labeled, tightly sealed glass containers, far from acids, bases, or anything it could react with. Every label lists the date received, hazard class, and emergency contact just in case something goes wrong. I keep the storage area at room temperature, away from sunlight. A small spark or a little sun-heated pressure can turn a sealed bottle into a projectile. At home, I would never store chemicals around food or drink, and I extend that same rule to the workplace.

Spill Preparedness Means Thinking Ahead

Spills catch everyone off-guard at some point. I have all the tools nearby before starting work: absorbent pads, chemical-resistant waste bags, and a bucket of sodium bicarbonate to neutralize acidic residues. If anything spills, I cover it right away, ventilate the area, and notify the right folks. Never mop with water—reactivity isn’t always obvious until you see a reaction that’s hard to control. My workspace always has an eyewash station and an emergency shower close by, because the difference between a minor burn and serious injury can come down to a few seconds.

Managing Waste with Care

I transfer waste into labeled, vented containers that stand up to the same safety checks as those used for storage. Mixing waste streams is risky—organics, oxidizers, and heavy metals belong in separate containers. I always double-check the compatibility using material safety data sheets. Regular pickups by certified hazardous waste companies keep things from piling up. In my experience, skipping any step just leaves a mess for someone else or puts the whole building at risk.

Training and Staying Up-to-Date

What keeps you safe today might not be enough tomorrow. I make time for regular safety audits and encourage colleagues to share updates about better safety gear or new best practices. Reading the updated SDS and asking questions beats guessing any day. It’s one thing to work with confidence; it’s another to work with knowledge and care because a small mistake can trigger a chain of problems that’s hard to reverse.

Behind the Chemical Label

Ask any research chemist or industrial buyer about 5-Bromopentyl Acetate, and the conversation quickly turns to purity. It’s not just about “getting what’s on the label.” Different end uses — from academic research to cosmetics — pull this compound into a web of purity requirements. If you’ve ever worked in a lab, you know that those tiny differences can turn a promising experiment into a wasted afternoon or a product batch into a recall headache. The stakes change with every decimal point.

Grading Isn’t Just a Formality

Over the years, I’ve watched suppliers roll out certificates of analysis reading 95%, 98%, or “GC purity above 99%.” Those numbers mean everything, especially for researchers aiming to discover new chemical pathways. One batch of 95% won’t cut it for pharmaceutical synthesis, but it might do the job in early-stage agrochemical work. Fine chemicals don’t always demand the highest grade, but consumer products — especially anything touching food or skin — do. Contaminants sitting in those missing 1–3% can throw off toxicology, spoil flavors, ruin textures, or even spark regulatory trouble down the line.

Real World, Real Choices

My own trial with intermediate-grade chemicals showed the risks. Working on a sensory study, I needed high-purity compounds to pinpoint specific olfactory responses. Settling for a lesser grade, just to save a few dollars, introduced off-notes. That small impurity went undetected until the final blending, sending the whole project back to the starting line. In another lab, I saw how lower-purity chemicals, when used in scale-up, ended up clogging up reactors or requiring extra purification steps. Costs spiral out quickly, all from a shortcut.

Market Offers, and What Drives Them

Sourcing chemicals across suppliers in Europe, North America, and Asia, I noticed that most vendors offer at least two main grades for 5-Bromopentyl Acetate: technical and high-purity. Technical grade walks a line between function and cost. It often fits for applications where a trace impurity won’t ruin the process — maybe a solvent mixture, or as raw material for further synthesis and distillation. High-purity material, sometimes labeled “analytical” or “reagent” grade, costs more and typically ships with more thorough documentation, including specific impurity profiles. This transparency backs up safety data sheets, and in regulated industries, that’s non-negotiable.

Don’t Forget Verification

Certificates can only go so far. Labs committed to quality double-check purity with their own GC or NMR profiles. In pharmaceutical or food labs, that step stops surprises before they turn into liability. Students and small startups may skip this for cost reasons, but bigger players see the return on investment.

Smarter Sourcing and Communication

One solution that helped in my work: always ask the supplier for an up-to-date lot analysis — not just a generic data sheet. If you want to get the best match for your application, a short chat with a technical rep can clear up misunderstandings. Some suppliers also customize purification, especially if your order size justifies the extra effort. That might seem reserved for large companies, but in practice, persistent startups have managed to leverage this flexibility, especially if they show growth potential.

Looking Forward

As regulations tighten and downstream applications require greater consistency, the value of grade-specific 5-Bromopentyl Acetate will increase. Markets and labs that overlook these differences risk setbacks in efficiency, safety, and ultimately cost. The best move is staying informed, verifying every batch, and keeping the lines of communication open with suppliers who understand what’s at stake — not just today, but a few product launches down the road.