5-Chlorovaleryl Chloride: A Closer Look at an Influential Chemical

Historical Development

The emergence of 5-Chlorovaleryl Chloride traces back to mid-20th century chemical innovation, as researchers began harnessing halogenated compounds for advanced synthesis in pharmaceuticals and agricultural products. Early curiosity about scandium-catalyzed chlorination led chemists to valorize specific chain-length acid chlorides, with 5-chlorovaleryl chloride evolving from needs in drug development and material science. Changes in regulatory landscapes and industry demand drove systematic improvement of synthesis protocols, safety practices, and documentation standards. Over decades, increased applications in intermediates, specialty polymers, and even some insecticides have steered continued investment and research.

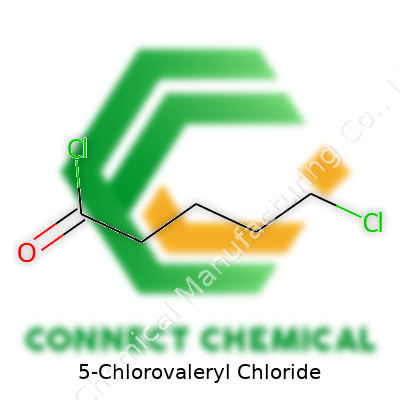

Product Overview

5-Chlorovaleryl chloride belongs to the acyl chloride family, containing five carbons and a terminal chlorine substituent. This molecular arrangement endears the compound to organic synthesis laboratories and large-scale industrial processes. Its reactivity enables introductions of long-chain, chlorinated functional groups, making it valuable for tailoring molecules to specific uses. Those on the production side know its distinct biting odor and the biting hazard it poses to eyes and skin, so it doesn’t slip under anyone’s radar in the storeroom.

Physical & Chemical Properties

This compound presents as a colorless to pale yellow liquid, with a pungency in its aroma that alerts you long before you open the bottle. Its boiling point hovers around 108-111 °C at atmospheric pressure, though anyone working in synthesis tends to keep it under a fume hood due to its irritating fumes. It reacts vigorously with water, sending hydrochloric acid vapors straight up, so dry environments and airtight containers matter. Its density generally lands between 1.15-1.18 g/cm³, and it retains a low viscosity that makes transfers rapid but also a little messy if safety slips.

Technical Specifications & Labeling

Specification sheets for 5-chlorovaleryl chloride often highlight purity exceeding 98% for analytical or synthesis-grade product. Common contaminants, like the corresponding carboxylic acid, must be kept minimal; these affect downstream transformations and final product yields. Labels must clearly indicate the UN number (UN 3265), hazard symbols for corrosives and lacrimators, and detailed storage requirements. Only glass or PTFE containers meet the standard for longer-term storage, due to the tendency for acid chlorides to corrode metals and leach contaminants. Labels on commercial containers always spell out the need to protect from moisture and exposure.

Preparation Method

Most synthesis routes draw on the reaction between 5-chlorovaleric acid and thionyl chloride (SOCl₂), with the acid chloride forming as thionyl chloride strips out water elements and forms sulfur dioxide and hydrochloric acid as gaseous byproducts. Laboratories running this reaction typically use chilled, inert atmospheres and slow addition to control exotherms. The product requires vacuum distillation or careful liquid-liquid extraction for purification. Safety teams I’ve worked with never let you forget to manage the evolved gases and perform these steps inside properly functioning fume hoods, underscoring the need for careful infrastructure.

Chemical Reactions & Modifications

5-Chlorovaleryl chloride acts as a powerful acylating agent. It makes quick work of transforming amines into amides for pharmaceutical intermediates. Alcohols react with it to generate the corresponding esters, often as building blocks in specialty polymers or agrochemicals. Nucleophilic substitution on the terminal chlorinated carbon opens the door to more elaborate functionalities, like azido derivatives in organic synthesis or sulfonamides in experimental medicine. Chemists rely on its reactive backbone repeatedly in iterative synthetic strategies, given the controlled and predictable transformation of the carbonyl-chloride group. Working with this compound, I’ve seen its power to either accelerate reactions or grind them to a halt if any traces of moisture sneak in.

Synonyms & Product Names

The world of chemical commerce knows this substance under several monikers, such as 5-Chloropentanoyl chloride, 5-Chlorovaleroyl chloride, and Valeric acid, 5-chloro-, chloride. Catalogs list product codes and supplier branding alongside the standardized IUPAC name, which helps reduce confusion across borders and regulatory environments. Trade references sometimes abbreviate it as C5H8Cl2O or point to specific batch numbers to ensure traceability and safety compliance, especially in GMP-audited environments.

Safety & Operational Standards

Handling 5-chlorovaleryl chloride requires vigilance. The irritant and corrosive properties cannot be downplayed; direct contact with skin or inhalation of vapors can leave lasting damage, an ever-present reminder to never skip gloves or goggles. Storage needs a cool, dry environment, preferably with ventilation and compatible shelving. Emergency protocols for acid chloride spills include neutralization with carbonate slurries and immediate evacuation for larger incidents. Transport adheres to both UN and DOT regulations. Personnel receive annual refresher training, emphasizing the consequences of short cuts. Documentation, traceability, and segregated handling zones keep operations safe and liability in check.

Application Area

Pharmaceutical chemists turn to 5-chlorovaleryl chloride for building complex molecules, inserting the acyl segment in preparative routes to anti-infectives and neurologically active agents. Material scientists explore its use in custom intermediate production for high-performance polymers. Agricultural research groups focus on its utility in synthesizing herbicide and insecticide candidates, especially where chlorinated functional groups boost stability or selectivity against pests. In recent years, growing attention from specialty chemical markets has spurred renewed interest in scalable, less hazardous processes, prompting partnerships between suppliers and end users determined to achieve both efficiency and regulatory alignment.

Research & Development

Academic teams, particularly in synthetic organic chemistry, probe the reactivity landscape of 5-chlorovaleryl chloride, aiming to broaden its functional group compatibility and lower byproduct profiles. Recent work showcases tandem catalysis techniques, letting chemists couple reactions and slash solvent use. Industrial R&D departments run pilot campaigns to optimize batch sizes, temperature profiles, and isolation techniques, sharing findings across consortia to address process bottlenecks. Some labs invest in “greener” pathways, replacing traditional chlorinating agents with more benign reagents, though transitioning from bench to plant scale remains a real-world hurdle. Raw data from these efforts shape regulatory reviews, especially as chemical stewardship takes center stage in global markets.

Toxicity Research

Toxicologists trace acute responses to short-term exposure: respiratory tract irritation, skin burns, and ocular damage are frequent. Chronic occupational studies remain limited, but concern about cumulative low-level exposure persists, especially as regulatory thresholds evolve with new data. Animal models suggest systemic toxicity at higher doses, with signs of inflammation and even reversible liver effects in rodent trials. Research into breakdown products, especially unreacted thionyl chloride or hydrochloric acid, spots risks not just from the main molecule but from plausible real-world scenarios during large-scale handling or accidental releases. Transparency in safety data sheets and open reporting structures help companies improve protocols and protect employees.

Future Prospects

Demand for 5-chlorovaleryl chloride will track advancements in both drug discovery and advanced materials. New applications in fine chemicals and bespoke intermediates, paired with stricter environmental controls, push producers to pursue safer, less wasteful synthetic routes. Digitalization of process monitoring and data analysis speeds up troubleshooting and lets teams catch anomalies before incidents escalate. I expect growth in custom derivatives, as end users look for building blocks tailored to their performance specs while staying compliant with regional chemical safety laws. As stewardship gains priority, companies adopting closed-loop systems and real-time emissions monitoring will set new operational standards, reflecting not just a push for efficiency but a cultural commitment to worker well-being and environmental responsibility.

Understanding 5-Chlorovaleryl Chloride

5-Chlorovaleryl chloride sounds like a mouthful, but it plays a big role in the world of chemical manufacturing. With its structure combining a chlorinated carbon chain and an acid chloride group, it acts as a building block for more complex molecules. In my experience researching specialty chemicals, having a reliable intermediate like this can make or break a project, especially when consistency matters.

Where It Shows Up in the Real World

Companies use 5-chlorovaleryl chloride mainly as an intermediate during the production of pharmaceuticals, agrochemicals, and fine chemicals. In pharma, it helps create molecules that eventually become treatments for infections, heart conditions, and even some forms of cancer. Drug development calls for strict control, and intermediates like this one allow scientists to build molecules with precise features.

Chemical plants also rely on it to make specialty pesticides and herbicides. The chloride group easily reacts with other chemicals, allowing for the addition of unique functional groups that influence a product’s action in the field. Farmers and agronomists want better yields, and access to improved crop protection tools starts with solid, predictable chemical intermediates.

Laboratory researchers sometimes need 5-chlorovaleryl chloride during organic synthesis, helping them explore new materials for batteries or plastics. Small tweaks to a molecule—a different chain length here, a chlorine atom there—can enable a whole world of new properties in the lab. In the end, these innovations push industries forward, from electronics to energy.

Safety, Supply, and Responsibility

Handling compounds like 5-chlorovaleryl chloride means tracking safety closely. It reacts easily with water and creates corrosive hydrogen chloride gas, which can burn skin and eyes. I’ve watched experienced chemists suit up in gloves and goggles just to uncap a bottle. That’s because mistakes can lead to nasty burns or worse, long-term health problems. Facilities using the compound follow strict protocols—dedicated storage, strong ventilation, and emergency showers nearby.

Supply chains for specialty chemicals look fragile sometimes, especially during global disruptions. If one link fails, manufacturers up and down the line can face delays. For those working in procurement, it means building relationships with several suppliers in different regions. That way, if a factory in one location shuts down, production can continue using material from another source.

Regulations keep changing, too. Producers must watch for updates on how to ship, store, or dispose of chlorinated chemicals. Waste must be neutralized before sending it to the drain. Local water agencies and environmental authorities monitor discharges, since even low concentrations threaten aquatic life and soil health. In my research, I’ve seen companies succeed not just through product quality, but by making sustainability part of their daily routine.

Room for Better Practices

More companies now invest in greener chemistry by developing alternatives to harsh reagents. Some explore biocatalysis, where enzymes help assemble similar structures under milder conditions. That reduces dangerous byproducts and keeps workers safer. In the meantime, everyone who touches 5-chlorovaleryl chloride—scientists, engineers, farmers, regulators—plays a part in using this tool wisely and looking for smarter solutions where possible.

Every chemical has a story, and how we manage 5-chlorovaleryl chloride tells us plenty about what’s possible in manufacturing when skill, safety, and responsibility meet real-world challenges.

Seeing Beyond the Symbols

Chemicals in a laboratory can look pretty much alike until you break down their names and formulas. Take 5-Chlorovaleryl Chloride, for example. At first glance, it sounds complicated, but digging into what its formula really means shows how clear lab work depends on more than memorization. In this case, the formula is C5H8Cl2O. Each letter and number stands for something real—carbons, hydrogens, chlorines, oxygen. Getting that wrong can mean wasted resources, failed experiments, or even safety risks in the lab.

Understanding the Structure: Not Just Letters and Numbers

Looking at 5-Chlorovaleryl Chloride, you have a five-carbon backbone, one chlorine attached at the fifth carbon, and a second chlorine as part of the acyl chloride group at the end of the chain. This matters because chemists rely on these formulas to plan reactions, predict outcomes, and troubleshoot when things go sideways. A single misplaced atom changes everything; it turns a useful reagent into an unexpected byproduct or a hazardous contaminant. Working with organochlorine compounds like this today, reading labels closely and double-checking structural diagrams is part of everyday lab routine for anyone who wants clean results.

Real Risks, Real-World Impact

It’s easy for someone outside a chemistry lab to underestimate the importance of chemical formulas. But even small errors can spiral out of control. In industry, a mislabeled bottle or a typographical slip on a shipping manifest can trigger expensive recalls or hold up entire production lines. Minor mistakes can escalate into safety hazards on a scale that regulatory agencies like OSHA and EPA track closely. For students, disciples, and professors alike, accurate formulas underpin lesson plans, research, and real professional credibility. I still remember a lab partner in undergrad who once mixed reagents based on a hasty reading—what should have been a routine synthesis turned into scrambling for the spill kit.

Supporting Claims with Facts

Scientific literature and worldwide chemical databases like PubChem and ChemSpider consistently list 5-Chlorovaleryl Chloride as C5H8Cl2O. Synonyms sometimes pop up, but the structure stays consistent. That’s backed by peer-reviewed journals and official records, not just textbook glossaries. Even a quick search for safety data sheets confirms the same breakdown of atoms every time. It’s not just repetition for its own sake—the field depends on everyone reading formulas the same way and double-checking each other’s work.

Solutions and Best Practices

Getting it right all starts with building habits around active verification. Whenever someone prepares or discusses chemicals, especially at the synthesis or shipping stages, cross-referencing the written name, structure, and molecular formula can prevent costly errors. Digital tools and smart labeling systems also cut down on confusion by producing consistent, traceable records for inventory and communications. Training newcomers to prioritize accuracy pays real dividends. Experienced chemists sharing real-world stories about mistakes—what happened, what it cost—make the value of precision hit home much better than dry warnings ever could.

Why This Matters for All of Us

Even those of us who don’t work in a laboratory feel the effects of precision in chemistry every day, whether in medicine, manufacturing, or the products lining store shelves. Accurate chemical formulas aren’t just technical details—they protect people’s health, keep businesses moving, and support discoveries that change lives. That’s why remembering C5H8Cl2O for 5-Chlorovaleryl Chloride isn’t just trivia—it’s the sort of detail that builds trust between science and society, one molecule at a time.

Understanding the Risks

5-Chlorovaleryl chloride isn’t a chemical you see every day unless you work in a lab or chemical plant. This stuff brings a sharp, pungent odor—if you can smell it, you’ve already got a problem on your hands. The compound reacts harshly with water and moisture in the air, releasing hydrochloric acid fumes that sting and burn. Without careful control, you’re looking at a recipe for injury, property damage, or at the very least, some angry coworkers.

Lessons Learned from Experience

My years handling reactive chemicals made one thing clear: storage mistakes come back to bite fast. Once I watched a mismarked drum of acid-chloride rupture a week after someone stacked it in a hot, damp space. Fixing the corrosion and neutralizing the spill took days. No one wants to repeat that mess. With 5-chlorovaleryl chloride, you must treat every container as if it’s one leak away from real trouble.

Safe Storage Practices

Cool and Dry: This isn’t just a label suggestion. Even a small bump in temperature can nudge up vapor pressure, prying open seals or sending fumes into the air. Direct sunlight? Out of the question. Heat accelerates degradation faster than most realize. Basement storage often works, as long as humidity is under control and flooding isn’t a worry.

Airtight and Secure: Forget flimsy lids or old corks. Use tightly sealed, corrosion-resistant containers. Glass bottles with PTFE-lined caps or high-density polyethylene drums rated for acid chlorides get the job done. Once I saw someone reuse a salvaged tin; it cracked before the week ended. Don’t cut corners, even if the right drum costs more.

Ventilation Matters: I’ve walked into poorly ventilated chemical stores and felt an immediate burn in my nose. Install mechanical ventilation or, at a minimum, fans keeping the air moving toward an exhaust. Fumes build up quickly, and even a tiny leak will fill a small room within hours. Hydrochloric acid vapor starts damaging metal shelves and nearby supplies—never mind your lungs—almost immediately.

Segregation: 5-Chlorovaleryl chloride must stay far from flammable materials, water sources, and incompatible chemicals like amines or alcohols. Once, two chemicals mixed from a shelf collapse, and the result cleared the storage area for days. Color-coding shelves and sticking to strict inventory checks prevent disastrous cross-reactions.

Labeling and Emergency Response

Misplaced trust in memory doesn't work. Every drum, bottle, and sample should carry up-to-date labels with hazard symbols and handling instructions. Emergency showers, spill kits, and respirators should all sit within arm’s reach. Never underestimate how fast a situation can escalate. Quick neutralizing agents—calcium carbonate, sodium bicarbonate—allow small spills to become a cleanup, not a full-scale evacuation.

Why All This Matters

Chemical safety is not about paranoia, but respect. Shortcuts put at stake not only your safety, but also those working alongside. Every detail from container choice to ventilation comes straight from real-world lessons—companies that ignore the basics land in the headlines for all the wrong reasons. Regulatory audits look for proof of best practices because history shows where neglect leads. If you wouldn’t trust your storage with your own well-being, it’s time for a change.

Moving Toward Better Standards

The chemical industry keeps evolving, with advances in container materials, digital monitoring, and fire suppression. Embracing those improvements turns risk management from headache to habit. Root good practice in daily routine, not because it’s a regulation, but because everyone deserves a safe workspace. That’s the mark of a responsible operation—and no one builds trust in the dark.

Recognizing the Risks

5-Chlorovaleryl chloride can throw a nasty punch if handled carelessly. This chemical has a sharp bite, irritating eyes, skin, and lungs. Whenever a bottle gets cracked open, visible fumes and a sharp odor signal danger. Years in the lab teach the hard lesson—no chemical gives second chances. People think gloves and glasses are enough, but this compound chews through latex, gives off noxious gases, and burns on contact. A single splash can land someone in the emergency room. Chlorinated acyl chlorides bring particular hazards, forming hydrochloric acid when they hit water, even the humidity in the air. Overlooking basic rules turns a routine synthetic job into a mess.

Personal Protection Comes First

Simple habits play the biggest role in long-term safety. Heavy-duty nitrile or butyl gloves shield better than thin latex. A crumbling glove turns into trouble fast. Face shields protect against unpredictable splashes; standard safety glasses leave cheeks and chins exposed, so they don’t cut it here. Long sleeves, closed shoes, and acid-resistant lab coats add a layer of armor people don’t always appreciate until after things go sideways. Proper respiratory protection matters too—5-Chlorovaleryl chloride releases fumes that irritate airways and lungs. Fume hoods pull dangerous vapors away and should be non-negotiable for any handling or weighing.

Engineering Controls

After years working with hazardous chlorinated organics, nothing earns more appreciation than a well-maintained fume hood. Recirculating hoods or makeshift setups never give peace of mind. Dedicated vented chemical storage cabinets keep bottles cool and away from incompatible chemicals, such as bases, alcohols, and amines—mix-ups here have led to runaway reactions. Emergency showers and eyewash stations should sit close enough for a sprint; not having them in reach has turned minor accidents ugly, fast.

Safe Handling and Transfers

Risk never disappears, but careful planning shrinks it. Scaling up from grams to larger quantities brings new pressure. Always double-check containers for tight seals and fresh deterioration. Store only unopened amounts in dry, labeled space set aside for hazardous chemicals. Use glass or PTFE equipment because regular plastics soften and degrade from contact. Never pipette by mouth—old habits still surface in some labs but spell disaster with this chemical.

Disposal and Clean-Up

All waste should hit labeled vessels dedicated to hazardous, chlorinated, or acid-generating materials. Neutralization and quenching require expertise—dumping leftovers down the sink creates toxic fumes and environmental damage. Spills get ugly if ignored. A well-stocked spill kit should include absorbents, neutralizers, and dedicated PPE. Notify others fast—hiding a spill under paper towels only creates more pain later. Involve trained professionals for significant exposure or cleanup.

Building a Culture of Respect

Workplaces protect people best through real training and open conversation. Rushed students, tired juniors, and even seasoned chemists get complacent. Hands-on demonstrations, updated safety data sheets, and visible signage save people from repeating mistakes that scar, sicken, or kill. Trust in the experience passed down, stay vigilant, and treat every bottle like it’s waiting for a mistake. Doing the routine steps every time has saved more lives than any high-tech gadget.

The Role of Purity in Chemical Supply

Chemists and manufacturers pay close attention to purity for a simple reason: impurities can spoil even the best laid plans. In industrial and research settings, 5-Chlorovaleryl Chloride usually turns up at a purity of 98% or higher. For most applications—especially when aiming for consistent reactions or clear downstream products—this level works. Some labs might want a higher grade, but 98% keeps the process predictable and the product safe.

Impurities sometimes bring unexpected headaches, from lower yields to toxic byproducts. With a chemical like 5-Chlorovaleryl Chloride, which reacts easily and can release unpleasant fumes, cutting out the extras isn’t a nice-to-have—it’s a must. High purity removes guesswork and keeps end-users out of trouble. It also keeps research results reproducible, a bedrock principle in any honest lab.

Packaging Sizes That Match Real-World Demand

Buyers rarely use the same quantity. Academic labs may only need a few grams, while manufacturers might use kilograms in a single day. Suppliers usually offer 5-Chlorovaleryl Chloride in bottles as small as 25 grams, which comes in handy for trial reactions or method development. Beyond that, 100 g bottles hit the sweet spot for repeated small-scale work; 500 g containers fit mid-scale projects.

Bulk buyers, often in pharmaceuticals or agrochemicals, look for drum sizes—5 kg, 25 kg, sometimes up to 200 kg. These aren't just about convenience. Proper packaging protects both the chemical and the people handling it. Small bottles keep risks manageable in the lab, but drums require more careful storage and trained staff because 5-Chlorovaleryl Chloride reacts aggressively with water and air.

Quality and Safety Aren't Afterthoughts

Quality assurance gets serious with any reactive chemical. Each batch comes with a certificate of analysis, listing not just purity but also limits for water, free acid, and other organic halides. This level of detail serves a purpose. In my own lab work, missing data on a chemical’s purity once led to ruined experiments and wasted time. Quality slips lead to real costs, both in money and student morale.

Suppliers that follow rigorous checks—using titration, chromatography, even NMR—offer more than just peace of mind. They help their customers avoid dangerous surprises. I’ve seen cases where poorly packaged chemicals leaked, corroded shelves, or even triggered emergency shutdowns. Good suppliers don’t just send the right gram weight; they use containers with proper liners and secure closure, and they clearly mark hazard warnings.

Can Supply Chains Improve?

Strong demand always strains logistics, and with chemicals like 5-Chlorovaleryl Chloride, delays or mislabeling make things worse. Smoother digital inventory systems have helped. Tracking barcodes, digital signatures, and real-time updates mean fewer missed shipments and better planning for projects.

A few suppliers even offer environmental data. Knowing the carbon footprint or waste streams makes a difference for users with green chemistry goals. While not everyone asks right now, this kind of transparency is building trust across the board.

Practical Solutions Going Forward

Successful outcomes begin long before pouring chemicals into a flask. Customers can do basic tests on incoming materials, but good practice starts upstream. Vet suppliers based on their testing standards, packaging, and after-sales support. Push for clear documentation and ask early about the packaging type and minimum order size—so you never over-order or risk unsafe storage.

For those running larger operations, set up systems to check seals and labels before acceptance. Train staff so no one mishandles the bottle or drum. Even simple steps, like staggered delivery schedules, can prevent backlogs or hazardous clutter.

Chemistry rarely forgives shortcuts, and neither does regulation. Working with the right supplier—transparent, responsive, thorough—keeps your work safe, efficient, and on track.