6-Bromohexanoyl Chloride: A Down-to-Earth Look at an Unsung Chemical

Historical Development

Chemistry likes to keep secrets in plain sight, and 6-Bromohexanoyl chloride stands out as one of those names you don’t stumble on reading the daily paper. The real surge in interest came alongside the birth of modern organic synthesis and pharmaceutical development. Chemists started digging into halogenated aliphatic compounds back in the middle of the 20th century, hunting tools for new drugs, functional materials, and molecular modifications. Researchers chasing ever-more precise reactions discovered that attaching a bromine atom and an acid chloride group to a hexane backbone unlocked a playground of reactivity, especially for building next-generation drugs and probes. From the earliest days, the compound carved out a niche in medicinal chemistry for its clean halogenation and the ability to wear new hats in the hands of a skilled synthetic chemist.

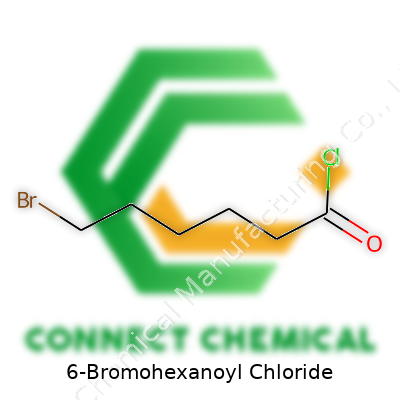

Product Overview

Talk to anyone who’s handled reactive intermediates, and they’ll say 6-Bromohexanoyl chloride isn’t just a bottle on the shelf. It stands as a versatile acylating agent packing a bromine atom at the sixth position away from a carbonyl chloride group. The six-carbon chain strikes a balance: not too short to act as a simple halo-acyl chloride, not too long to drift into specialty polymer territory. Industrial supply houses and research labs carry it for this exact reason. Unlike the common acyl chlorides, the bromine handle turns it into a powerful platform for stepwise, modular synthesis—kind of like having a Swiss Army knife tucked in your chemical toolkit.

Physical & Chemical Properties

If you pop open a bottle in the lab, you’ll see a clear to pale yellow liquid, with a sharp, distinctive odor you learn to respect quickly. Boiling kicks in around 110-112°C at 15 mmHg, and the liquid’s density sits near 1.4 g/cm³ at room temperature. Its reactivity reflects every trait you’d expect from an acid chloride: moisture in the air draws rapid hydrolysis, releasing pungent hydrochloric acid. The bromine atom on a flexible hexyl chain makes the compound eager for nucleophilic attack or substitution reactions, yet it’s not so unstable you can’t manipulate it with steady hands and proper ventilation. Before you set up a reaction, double-check that your gloves and goggles are up to the task—the compound won’t forgive shortcuts.

Technical Specifications & Labeling

Buyers want more than purity—they want clarity. For synthetic work, reputable suppliers report purity above 97%, often confirmed by proton and carbon NMR, plus gas chromatography. Labels spell out hazard statements, shelf-life (usually best stored cold, away from moisture), and the CAS number: 136690-46-9. Shipping comes in amber glass with watertight seals, always under a nitrogen blanket to keep the dicey chlorides from drawing in water. SDS sheets go with every shipment, warning about corrosivity, toxicity, and flammability. It’s not our parents’ hardware-store solvent, and the paperwork shows it.

Preparation Method

The usual laboratory prep starts with 6-bromohexanoic acid, either purchased or made by brominating hexanoic acid under controlled conditions. Convert to the acid chloride by reacting with thionyl chloride or oxalyl chloride, typically in a well-ventilated fume hood, at room temperature or with mild heating. The reaction kicks out sulfur dioxide and hydrogen chloride, so gas scrubbers belong just as much as the round-bottom flask. Some scale-up processes swap in alternative chlorinating agents to tighten control over side reactions, but for most researchers, thionyl chloride gets the nod for availability and robust yields. Purification hinges on vacuum distillation or careful liquid-liquid separation, but purity always comes down to steady handling and careful monitoring.

Chemical Reactions & Modifications

Here’s where 6-Bromohexanoyl chloride shows its colors. The acyl chloride grabs onto amines, alcohols, and other nucleophiles, forging amides or esters with ease—but the bromine several carbons away brings new options. Chemists exploit the bromine for Suzuki, Heck, or nucleophilic substitution reactions, letting the molecule stretch out into more elaborate chains, cyclize, or link up with aromatic systems. The two reactive handles rarely play nice together in one pot—you need order and protection strategies. Many researchers use the chloride end to set the backbone, then tweak the bromine with palladium catalysts or organic bases to carve out advanced targets for pharmaceuticals, agrochemicals, or molecular tools. Each synthetic detour borrows from the bones of this modest compound.

Synonyms & Product Names

Round every corner in chemical catalogs, you’ll find shorthand like 6-Bromohexanoyl chloride, 6-Bromohexanoic acid chloride, and Hexanoyl chloride, 6-bromo-. Some suppliers throw in trade jargon, but the CAS number sorts out confusion across borders. For researchers building technical files, these synonyms matter—the last thing anyone wants is a paperwork jam because two departments use different names. Double-checking product codes and batch numbers always saves headaches on audits and collaboration.

Safety & Operational Standards

Safety talks aren’t just legal padding—anyone who’s worked with acid chlorides has stories about hissing spills, burning skin, and ruined gloves. The compound cuts through latex, so nitrile or butyl gloves become the bare minimum. You’ll want to run all work in a functioning fume hood. Accidental contact burns and inhalation hazards show up even with microgram quantities. The safest labs store it in sealed glass under dry nitrogen, label it with skull-and-crossbones pictograms, and hammer home protocols for respirator use and spill controls. Many shops lock away their reactive chlorides behind access controls and require secondary containment—because one lazy habit can snowball into a full lab shutdown.

Application Area

The usefulness of 6-Bromohexanoyl chloride cuts straight through the world of medicinal chemistry, materials science, and chemical biology. I watched colleagues in bioconjugation develop new links to proteins, peptides, or molecular probes using the twin reactivities of the chain. The pharmaceutical world mines the compound’s diversity to attach complex side chains onto drug candidates, tuning their uptake and stability. Surface chemists build self-assembled monolayers or specialized anchors for sensors, while polymer researchers graft functionalized segments for custom materials. Every application draws from the same playbook—start with a well-designed intermediate, and the options expand quickly.

Research & Development

R&D teams dive deep into the mechanistic murk of 6-Bromohexanoyl chloride reactions, testing alternative catalysts, greener chlorinating agents, and faster purification steps. One emerging trend brings in continuous flow reactors, tackling scalability without sacrificing safety. Smaller startups experiment with biocompatible modifications, stretching the reach into diagnostics and imaging. Each new report in the journals brings ideas home—how a brominated backbone opens doors to molecules that wouldn’t stick together otherwise. I’ve seen new analytical methods sharpen batch-to-batch reproducibility, a must for tight regulatory settings. The race isn’t just academic—faster, cleaner, and safer synthesis means real patients get help quicker.

Toxicity Research

The harshness of acid chlorides is old news to anyone with a chemistry background. Animal studies, if you plow through the literature, show corrosive effects on skin and eyes and significant risk if inhaled. Chronic exposure doesn’t sneak by unnoticed—there’s ample data linking repeated handling to respiratory sensitization and longer-term organ stress. Like many halogenated organics, improper disposal and spills raise the potential for environmental harm. Waste streams need tight control, incineration, and regular monitoring to avoid leaving a footprint. The need for rigorous PPE, ventilation, and employee training goes without saying, but it’s these studies that push regulatory updates. I know labs that saw real improvements after swapping in less toxic analogs or green chemistry alternatives—yet for certain applications, the unique reactivity profile still gives 6-Bromohexanoyl chloride an edge.

Future Prospects

Looking ahead, I see the spotlight swinging back to 6-Bromohexanoyl chloride as synthetic techniques evolve. Researchers keep finding clever routes to minimize its hazardous footprint—new solvent systems, catalyst recycling, and in-line monitoring all boost safety without giving up the chemical’s versatility. AI-driven retrosynthesis tools flag this compound as a key stepping-stone for building precision medicines and advanced functional materials. Sustainable chemistry circles talk up methods to swap in bio-based precursors or run lower-energy processes. More sectors are adopting closed-loop systems, sharply reducing human exposure. If the push for safer, greener labs keeps pace, 6-Bromohexanoyl chloride may become a teaching example for balancing old-school reactivity with modern responsibility. There’s a lesson waiting in every bottle, for those patient enough to combine solid protocols, fresh technology, and just the right dash of curiosity.

What Drives Interest in 6-Bromohexanoyl Chloride

Anyone reading up on organic chemistry or industrial chemistry in recent years will notice 6-Bromohexanoyl chloride popping up more often. This compound draws the attention of pharmaceutical labs and academic researchers thanks to its unique structure—a six-carbon chain with both a bromo and an acid chloride group. Most people outside chemistry circles probably don’t recognize the name, but this molecule does a lot of heavy lifting behind the scenes.

Pharmaceutical Synthesis: Where Precision Matters

Drug discovery today leans heavily on smart, targeted synthesis. 6-Bromohexanoyl chloride brings a reactive site for attaching to various amines, alcohols, and aromatic groups. Medicinal chemists turn to it to build alkyl-brominated intermediates—crucial steps toward making antiviral agents, anti-inflammatory drugs, and enzyme inhibitors. With its combination of functional groups, researchers adjust chain length and bromo substitution to tweak drug profiles and enhance absorption or binding efficiency.

This chemical often steps in during linker development. For example, in antibody-drug conjugate research, connecting a drug payload to an antibody calls for a linker that is stable but cleavable under certain conditions. 6-Bromohexanoyl chloride’s structure supports such innovation, as its bromo group can react further and the acid chloride component links easily to a host molecule. It pushes the science forward, giving researchers the tools they need to try bold formulations and tests.

Making New Materials: Polymers and Surface Chemistry

Polymer science constantly searches for new building blocks. 6-Bromohexanoyl chloride steps into this realm by joining polymer backbones or acting as a site for further modification. The bromo atom invites substitution by other functional groups, so surface chemists use it to anchor various molecules onto polymers or nanoparticles. In coatings, adhesives, and even electronics, attaching specific sidechains often involves this compound at some stage.

Anyone working in the lab with polymer brushes or self-assembled monolayers will recognize the utility of a tailored bromo acid chloride. It’s basically a tool for precision surface tuning, letting engineers attach catalysts, lubricants, or optical markers to surfaces with reliable reproducibility.

Flavor and Fragrance: Extending Complexity

Chemists involved with specialty chemicals often use 6-Bromohexanoyl chloride during the design of molecules for flavor and fragrance. Its reactivity helps in building unique esters and amides that round out the aroma profile in a perfume or add depth to a synthetic flavoring. For instance, chemists can design new aroma molecules with a controlled fatty character or spicy note using intermediate steps based on this chemical.

Solutions and Challenges

6-Bromohexanoyl chloride isn’t always easy to handle—fumes irritate, and the acid chloride group reacts rapidly with water. Chemists working with it suit up in gloves, goggles, and use well-ventilated areas or fume hoods to prevent accidents. Proper storage matters just as much. Research suggests that greener production methods and better waste management can lower its environmental footprint, so it’s time for industry leaders to invest in process optimization and safe recycling protocols.

There’s no shortcut to mastering specialty chemistry, but staying curious and responsible pays off. 6-Bromohexanoyl chloride gives teams what they need to push boundaries in medicine, materials science, and flavors—each application backed by careful science and an eye toward safety.

Understanding the Chemical's Nature

6-Bromohexanoyl chloride finds use in specialty synthesis, and anyone handling it ought to respect the chemical’s reactive character. Exposure to moisture turns it into corrosive hydrochloric acid. Fumes from improper handling hit the throat and eyes hard, so the way it sits on the shelf matters a lot. I’ve seen small spills from poorly sealed containers turn into sticky messes that send lab techs running for showers. Its hazards do not fade with time, either; storage decisions shape everyone’s safety.

Proper Storage: No Guesswork Allowed

Strong acids and acid chlorides call for a certain discipline. Temperature and humidity rule the list of concerns. 6-Bromohexanoyl chloride stays most stable locked up in a cool, dry spot, out of direct sun and far from any source of water. Sweat on the outside of a bottle matters; even a tiny amount of water in the cap can trigger a reaction. I keep acid chlorides in a ventilated, fire-resistant cabinet dedicated only to corrosives. Gloves and goggles are not optional gear around this territory, since one splash can cause deep burns.

Container Choice Makes a Real Difference

Glass stoppers with Teflon liners win every time for airtight storage. Polyethylene bottles do not stand up as well unless designed for corrosive acids. Metal closures are out of the question, since the chemical chews through most metals. Labels deserve some respect, too: fading could cause confusion, so I check them regularly. My earliest training hammered this in — mark every bottle, keep things organized, and inspect caps for cracks or loose seals.

Segregation: Stopping Chain Reactions Before They Start

Acid chlorides react with just about anything containing an –OH group or water. Flammable solvents, acids, bases, oxidizers, or reducing agents should never sit on the same shelf. I once heard about an accident in a teaching lab where a misplaced jug of ethanol got mixed with an acid chloride in a spill. Flames shot up before anyone could reach the extinguisher. Keeping incompatible chemicals apart saves more than just paperwork; it prevents fires, burns, and toxic gas clouds.

Simple Protocols Prevent Trouble

People sometimes overlook the small fixes that save entire days. Desiccators with drying agents hold the line against ambient moisture, especially in humid climates. Regular cleaning of storage areas catches leaks before they turn into health emergencies. I always keep a spill kit nearby—neutralizing powders, absorbent pads, gloves—because no one ever regrets being over-prepared. These steps cost little but pay out the moment someone fumbles a jar or forgets to close a cap tight.

Disposal and Inventory Habits Matter, Too

Expired or degraded chemicals belong nowhere near active supplies. I track purchase dates and order just enough for each project. Waste goes out through licensed hazmat services, not down the drain—one time’s laziness can linger as a major safety hazard years later. Changing this culture starts with everyday diligence, not just compliance for inspections.

Ownership of Chemical Safety

Storing 6-Bromohexanoyl chloride goes far beyond following a checklist. It calls for real ownership over safety, knowing your storage habits shape the well-being of everyone in the building. I learned from long hours watching more senior colleagues fuss over every screw cap and storage note, and that example stuck. Safe storage forms the backbone of responsible chemistry, and it starts with the simple act of doing the basics well—every single time.

Why Handling This Compound Takes Real Care

I’ve spent enough time around chemical labs to know that nobody earns their stripes ignoring safety with organochlorides. 6-Bromohexanoyl chloride stands out because of its reactivity and the pain it can cause to your skin, eyes, or lungs. Anywhere this stuff lands, it does damage – I’ve seen a colleague leave the lab with bright red welts just because some splashed above his glove. Simple exposure teaches that hazards here aren’t theory; they’re fact.

Air, Skin, and Eyes: All Need Protection

Even a brief encounter with its vapor or a splash can ruin your day. Wear a fitted lab coat; always go for goggles instead of regular glasses. Good nitrile gloves make a difference, since latex breaks down faster when chlorides are involved. I check for pinholes every time, after watching a friend go home early from a spill that could have been stopped by five seconds of attention. Respirators are smart if you’re transferring it in an open system, especially if the fume hood’s airflow rating isn’t up to speed.

Fume Hoods Aren’t Optional

This chemical loves to bite back with its vapor. Proper ventilation shouldn’t ever be a backup plan – it’s the baseline. Every time I need to open a bottle or transfer between containers, I use the fume hood, because a single whiff can trigger a coughing fit or worse. Poor airflow means those vapors linger and settle where you least expect. I’ve noticed headaches last for hours after forgetting to close a sash in one run; that lesson stuck.

Water Reactivity and Spills

Water isn’t just useless here; it actually turns 6-bromohexanoyl chloride into something even uglier. That hydrolysis reaction kicks up clouds of corrosive acid gas. Think twice before mopping up with a wet rag. Absorb spills with an inert material, then sweep it up into a sealed container. On one bad morning, wetting down a bench left me gagging on fumes. Experience like that has made me slow down and keep proper cleanup kits at arm’s reach.

Planning for Emergencies

Nothing tests a team like an accident. I know the value of a shower and eyewash station because I’ve watched people bolt for them in a panic. Every second counts. Practice your route and check these stations work every week. Make sure the MSDS sheet isn’t buried in a filing cabinet. Emergency numbers should hang on the wall. Quick decisions have saved eyes and skin more than once.

Waste and Storage: No Shortcuts

Leave it on the bench long enough, and leaks or hydrolysis follow. Store it cool, dry, and upright. Label every bottle with clear warnings. Mix-ups and mystery bottles have no place in a safe workspace. I never store it near water-based solutions. Waste disposal means going through your institution’s hazardous program, not down the drain or trash.

Safety Habits Build Trust

Handling 6-bromohexanoyl chloride without shortcuts keeps everyone safe, not just the person with the bottle in hand. Every time I see proper technique from a new lab member, I know our training sticks. Everyone goes home healthy. That’s the point of doing this right.

Why Purity Matters in Real Life

Ask anyone in a lab or a growing business relying on raw materials: the difference between “pure” and “pure enough” can be huge. A label on a container isn’t just for show — that percentage means something real for the work on your hands or the safety you count on. Purity benchmarks aren’t just traces on a data sheet. If that bottle says 99.95%, you’re trusting that nothing unexpected will react, spoil your results, or throw off sensitive machines. It’s real trust — backed by testing, not wishes.

What These Grades Really Mean

No magic, just science. Chemists use words like “technical grade,” “reagent grade,” “ACS grade,” or “pharmaceutical grade” to flag how clean a substance is. Technical grade often covers tasks that don’t sweat the small stuff, like certain industrial cleaners or construction work. Reagent and ACS grades step it up, fitting classroom, research, and quality control demands. Pharmaceutical grade tops the chart — medicine and food go nowhere without it. Every small contaminant is checked, listed, and measured because one impurity can change a batch’s entire behavior.

Personal Experience in Chemical Choices

I once watched a friend’s biotech project hit a wall because a single batch of low-grade buffer salt let in traces of metal. For weeks, every result looked wrong. After tracking every step, the real culprit wasn’t the team’s skill — it was the hidden “dirty” chemistry inside what seemed like an ordinary white powder. They switched to a guaranteed ACS-grade product, and things snapped back into focus. Stories like this turn “purity” from textbook talk into a lesson you feel deep in your gut.

How Purity is Measured

Laboratories don’t just guess. They push samples through machines — gas chromatographs, mass spectrometers, titrations — and chase down every stray molecule. Test results include both “percent pure” and a list of the leftovers, called impurities. These details end up on Certificates of Analysis, which should ship with anything serious. Whether you’re buying for research, making pharmaceuticals, or running a school, you don’t want mystery extras. Scanning that certificate becomes part of the job, not just paperwork.

The Risks Behind Cheap, Unlabeled Chemicals

Cost cuts look tempting, especially for startups strapped for cash. Skipping on stated grade might save a few dollars today, but the risk is real: unknown side effects, busted equipment, wasted effort, or–in the worst cases–health hazards. History holds plenty of painful lessons. Unmarked industrial supplies have caused product recalls, injuries, and losses. One missed impurity can flow downstream, tainting what seemed safe or reliable.

What Helps Make Better Decisions

Buyers and lab teams can get smarter about sourcing. Pick suppliers with clear, public data. Ask direct questions about purity, and press for those test certificates. If answers come slow or vague, walk away. It’s not worth the gamble. Groups like USP, ACS, and ISO set public standards anyone can check, giving everyone a yardstick. Skipping the steps to cut corners only leads to more trouble.

The Real Risk with Chemical Waste

Working in a chemistry lab for years, I saw too many folks underestimate the leftovers. Some bottles would gather dust until someone threw them out “the usual way.” With 6-Bromohexanoyl Chloride, that shortcut can cause far bigger headaches. This compound doesn’t just look intimidating on a label. It reacts forcefully with moisture, releasing toxic fumes. If it touches skin, it can burn. Pouring it down the drain or tossing it in the trash brings real risks – both for people and for the neighborhood outside the lab.

Why Tossing It Isn’t an Option

The U.S. Environmental Protection Agency and local authorities make it clear: improper disposal of halogenated acid chlorides breaks rules and endangers public health. Sewer systems were never made to handle corrosive, volatile chemicals. Once these compounds hit water, they transform, and the byproducts – think hydrogen chloride gas – can damage lungs or corrode metal. Municipal waste removal workers might not expect a cloud of acid poisoning their workday. Putting landfill or water quality at risk over a bottle of chemical waste never seemed fair to me.

Safe Paths Forward

After a big experiment, clearing out leftover reagents always ran through one channel: the institution’s hazardous waste program. Every reputable lab, whether at a university or a company, runs this type of service. Waste gets collected, labeled, and stored in special containers, and nothing leaves the site without paperwork. While this process can feel slow, it’s built on missed lessons from earlier decades when shortcuts poisoned rivers and left communities fighting cancer clusters.

6-Bromohexanoyl Chloride demands attention to details. Waste cans with secondary containment, good ventilation, and clear signs blocking off access — those steps kept me and my colleagues from getting complacent. We never poured anything containing acid chlorides or bromine down the sink, not even diluted. One time, a senior chemist wore a splash to the forearm while separating waste; he staggered straight to the safety shower. The memory sticks because no exam tests or training video drives home the lesson like a real emergency.

Turning Waste Over to the Pros

Outsourcing to certified chemical waste handlers costs more than tossing a bottle, but it pays dividends in peace of mind. Specialists use neutralization tanks, chemical scrubbing systems, and careful monitoring. They convert hazardous acid chlorides into stable salts and track every drum’s journey until incineration or long-term storage. Professional oversight drops accident rates and makes sure rules get followed.

Building a Culture of Responsibility

Having everyone on the team informed and proactive matters as much as the best lab equipment. Training needs to go beyond reading safety data sheets. Chemists should walk through actual waste storage points, see the warning signs, and know who to call for emergencies. If in doubt, never guess—ask an environmental health office or a waste contractor approved by the lab. Holding each other accountable creates safer labs and less impact on neighbors.

No chemical should leave the lab unless it’s been made harmless by professionals who know the risks. My old professor always reminded us: safety isn’t the last step in an experiment — it is the backbone that lets real science happen.