6-Chlorohexanoic Acid: A Down-to-Earth Look at Its Journey and Potential

Historical Development

Scientific curiosity often finds itself locked on molecules like 6-chlorohexanoic acid. This compound didn't appear in a vacuum. It traces its origins back to mid-20th century organic synthesis research. Back then, chemists searched for ways to modify fatty acids to unlock new possibilities in surfactants and pharmaceuticals. My own introductions to this compound came during an undergraduate lab, where learning to chlorinate aliphatic chains pushed home just how much careful planning goes into creating something that seems simple on paper. Sometimes the methods felt outdated against today’s green chemistry landscape, but those early days set the tone. Chemists improved purity and yield step by step, always facing questions about downstream use, storage, and transport.

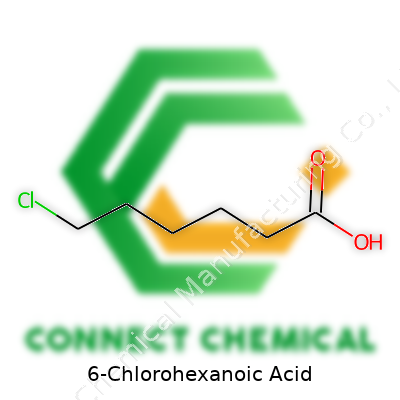

Product Overview

6-Chlorohexanoic acid falls among specialty intermediates—it doesn’t jump to mind like aspirin, but its role in synthesis spans a wide field. Manufacturers offer it as a colorless to pale yellow liquid or solid, depending on the grade and temperature. My experience working with small samples showed a faint odor and stubborn oily residue that clung to glassware. Its molecular formula is C6H11ClO2, placing it in the family of haloalkanoic acids. You can spot bottles labeled with synonyms like 6-chlorohexanoic acid, 6-chlorocaproic acid, or even hexanoic acid, 6-chloro-. On invoices and shipping manifests, you’ll sometimes see C6H11ClO2 to avoid confusion.

Physical & Chemical Properties

Handling 6-chlorohexanoic acid means dealing with an oily, sometimes crystalline substance. Its melting point hovers near 27–30°C, and on warm days you watch solid gently melt to liquid in the palm of your hand if you’re not careful. The boiling point reaches around 140–145°C at reduced pressure—lab colleagues used rotary evaporators to strip solvents and always kept an eye out for stubborn residues. Solubility in water registers as low, but it blends nicely into organic solvents like diethyl ether, chloroform, or methanol. Acidity sits in the moderate range for carboxylic acids, and once you taste hydrogen chloride on the air when working up a batch, that memory stays with you.

Technical Specifications & Labeling

Few things bother a chemist more than unreliable specifications. Producers issue certificates of analysis for every batch, listing assay (often >98%), water content, color, acid value, and residual solvents. Labels call out hazard statements for skin irritation, eye damage, and aquatic toxicity, in line with global harmonized system requirements. My time managing a chemical storehouse meant reviewing lot numbers, shelf-life, and supplier documentation. With compounds like this, wrong labeling or expired stock leads to headaches and unnecessary risk. Reliable sources confirm batch consistency—not just to keep regulators satisfied but to guard workers and downstream products.

Preparation Method

Getting hands-on with synthesis usually involves starting from 6-bromohexanoic acid or hexanoic acid, running a free-radical chlorination, or using thionyl chloride with catalysts. Friends in academic labs recount nerve-wracking moments due to exothermic reactions and noxious fumes. Small-scale preparation at the bench level means good ventilation and patience, as even small chloride leaks rapidly permeate the workspace. Careful quenching and precise temperature control shape the purity and yield. Waste disposal becomes an immediate concern—dealing with leftover acid chlorides demands respect for both safety and environmental rules.

Chemical Reactions & Modifications

Reactivity pivots around the carboxylic acid and chloroalkyl functions. Acid chloride formation, esterification, and amidation open doors to custom surfactants or pharmaceutical intermediates. In the right hands, that chloro group undergoes nucleophilic substitution, letting chemists build more complex molecules. One research project I joined linked 6-chlorohexanoic acid to peptides, using it as an anchor to site-specific modifications—turns out the chlorine acted as a useful leaving group without over-reactivity in water. Catalyzed hydrogenation and oxidation further broaden the scope, making this compound a reliable building block for those ready to tinker.

Synonyms & Product Names

Confusion over trivial names trips up even seasoned professionals. Common synonyms include 6-chlorocaproic acid and hexanoic acid, 6-chloro-. Official listings show it under registry numbers such as CAS 4735-83-1. Not every supplier sticks to a single name, and regional variations can muddy the search. My own lessons came after wasting hours looking for hexanoic acid derivatives, only to discover a catalog entry under a less-used synonym. Precise nomenclature becomes more than a paperwork issue—it keeps projects on track and matches regulatory records to product movement.

Safety & Operational Standards

Working with chlorinated carboxylic acids like this one brings home the importance of safety data sheets and regular training. Contact with skin causes irritation, so Nitrile gloves and goggles see daily use. Long sleeves and fume hoods become second nature in labs handling bulk quantities. The acid vapor can shorten your day unless good local exhaust ventilation is in place. In my warehouse years, regular audits checked containers for leaks or pressure buildup. Emergencies, like accidental spills, demand prompt cleanup with hepa-filtered vacuums and neutralizers. Regulatory agencies call for careful tracking from sourcing to disposal, and those on the ground need to take ownership—not as a paper exercise, but because the health consequences of exposure can be long-lasting.

Application Area

6-chlorohexanoic acid finds its most common home as an intermediate, not a finished product. In the realm of pharmaceuticals, it acts as a chain-builder, bridging simpler fatty acids to more complex drug candidates. Agrochemical researchers leverage it to develop new herbicides and plant growth regulators. In polymer chemistry, its carboxyl group links into condensation polymers, lending chlorine substituents for post-polymerization conversion. I once spent weeks trialing this acid in surfactant synthesis—finding that trace impurities could wreck performance in emulsifiers and detergents. Ultimately, small tweaks in purity and reactivity shape whether the compound serves biotechnology, agriculture, or high-end industrial needs.

Research & Development

Research circles treat 6-chlorohexanoic acid as a flexible platform for exploring new derivatives. My own curiosity led to attempts anchoring this acid on solid supports, testing its ability to initiate ring-opening polymerizations in water. Published articles push into greener synthesis methods, using enzymes or milder catalysts to cut hazardous byproducts. Technical journals report ongoing progress in using flow chemistry and microreactors, aiming to scale up production without runaway reactions. Innovations in chemical recycling also eye this molecule, looking to recover high-value chlorinated acids from waste streams or spent products, closing the loop for more sustainable processes.

Toxicity Research

Questions about toxicity surface quickly once field trials or larger-scale manufacturing start. Animal studies and environmental screening suggest moderate acute toxicity, with the potential for longer-term effects if exposure goes unchecked. Laboratory experience hammered home the need for air quality monitoring and skin checks after repeated handling. Some colleagues developed mild dermatitis from spill mishaps, a stark reminder that safety recommendations exist for solid reasons. . Environmental testing flags concerns for aquatic organisms, so waste streams require full treatment before discharge. Regulatory testing fills in the gaps, but personal vigilance trumps assumptions—especially with new blends or untested formulations containing this acid.

Future Prospects

The future for 6-chlorohexanoic acid lies in sharper synthetic pathways, smarter regulations, and careful stewardship of downstream impacts. Newer labs work on cutting chlorinated byproducts, shifting toward more precise halogenation techniques. Biotechnology outfits aim to tailor fatty acid chains for custom properties, with this acid acting as a backbone. Larger producers keep one eye on environmental rules and another on emerging green chemistry protocols, staying nimble so shifts in policy or demand don’t leave them behind. My hope sits with researchers pressing into clean manufacturing, tighter exposure controls, and recycling pathways. The next generation inherits both promise and responsibility with compounds like 6-chlorohexanoic acid, aiming for balance between utility, safety, and stewardship.

Digging Into Industrial Chemistry

6-Chlorohexanoic acid doesn’t turn many heads in daily conversation, but its role in laboratories and factories feels surprisingly broad. Many products people enjoy trace their existence to chemicals like this one. Personally, I’ve always been more interested in where things begin before they reach store shelves, and this is one of those backbone molecules you rarely hear about unless you read ingredient lists backward.

A Backbone for Synthesizing Complex Molecules

It’s easy to overlook intermediate chemicals. 6-Chlorohexanoic acid stands out in organic synthesis, where chemists build more complex compounds step by step. Its structure—with a six-carbon chain, a chlorine atom, and a carboxylic acid group—makes it perfect for making other useful chemicals. Factories often use this acid as a starting block to create specialty chemicals used in pharmaceuticals, agrochemicals, and even unique flavors or fragrances.

One notable application centers on producing caprolactam, a monomer necessary for nylon-6 production. The global textile and plastics world counts on this connection. Without dependable sources of intermediates like this one, the supply chains risk unpredictable disruptions. Nylon-6 brings strength and flexibility needed for fabric, carpeting, and tough plastics. The carboxylic acid in the molecule gives chemists something to latch onto chemically—helping them chain these pieces together to fit specific needs.

Role in Custom Synthesis

Research chemists hunt for building blocks to explore new therapeutic options. Medicinal chemists exploit its reactivity to try tweaking candidate molecules. Sometimes a simple chlorine atom at a particular spot changes the biological activity of a potential drug. Here, compounds built with 6-chlorohexanoic acid could meet the next antibiotic trial or crop-protection test. The idea isn’t just academic; the pharmaceutical industry pours money and effort into identifying unusual acids or halogenated molecules for patentable outcomes.

The Environmental Conversation

People concerned about environmental exposure need to ask about chemicals like this. Any molecule with a chlorine atom asks for careful management—chlorinated organics sometimes linger longer than expected in water or soil. Industry must take pains to avoid accidental releases. I grew up near a river that occasionally suffered chemical spills, and I know how important real-world safety plans and honest transparency are. Manufacturers handle 6-chlorohexanoic acid while following rules designed to keep people and wildlife out of harm’s way. Waste treatment and containment during production go a long way toward reducing risks.

Paving a Way Forward

Every intermediate chemical offers both opportunity and responsibility. Chemists continue looking for ways to swap out hazardous or persistent compounds—sometimes by designing alternatives with less environmental impact. Some firms now explore greener synthesis, using renewable feedstocks, and recapturing byproducts instead of dumping them. I think consumers and researchers both benefit from this trend. The big challenge today lies in scaling alternatives so industry won’t sacrifice reliability or cost just to improve a safety margin.

In the end, 6-chlorohexanoic acid plays a supporting role that’s tough to replace overnight. Its chemistry enables inventions people depend on, but every step of its life cycle deserves thoughtful oversight and honest innovation.

The Chemical Formula Behind Everyday Chemistry

Ask anyone who works in a lab with organic compounds, the journey usually starts with the nuts and bolts: chemical formulas and weights. 6-Chlorohexanoic acid, a basic building block in organic synthesis, carries the formula C6H11ClO2. That means it has six carbon atoms, eleven hydrogens, a single chlorine atom, and two oxygens—straightforward enough for anyone familiar with carboxylic acids. Swap a hydrogen out for a chlorine on the sixth carbon, and you've got it.

The Role of 6-Chlorohexanoic Acid in Research and Industry

I remember my first time preparing a halogenated acid in grad school. You can spot the function right away: that chlorine atom lets chemists tweak molecules for pharmaceuticals, plastics, and even crop protection chemicals. The modification at the chain’s end helps anchor the molecule for further reactions, sometimes leading to anti-fungal agents or specialized polymers. Chloroalkanoic acids like this one help those discoveries move from bench-top flasks into the products we touch every day.

Molecular Weight: Accuracy Matters

For those tracking quantities or running reactions, accurate weights are vital. One mole of 6-chlorohexanoic acid weighs in at 166.61 g/mol. That number isn’t dusty trivia—get it wrong, and your reaction yields drop or, worse, you contaminate a sample batch. It’s a lesson fresh scientists learn quickly when they see a reaction fizzle or fail.

Safety, Handling, and Health

Working with chlorinated acids calls for respect. My own experience in a teaching lab showed me that fumes can irritate eyes and skin, and gloves plus good ventilation make a difference. Chemical catalogs flag these risks for a reason: small molecules like this can sneak through porous gloves or stick around if a spill isn’t cleaned up right. In a world where accidents happen, anyone new to the bench deserves steady training, not just a checklist.

The Need for Clear, Reliable Information

Accurate chemical data doesn’t just help chemists. I’ve worked alongside environmental consultants tracing pollutants in water samples—the wrong number in a report can skew risk assessments, hurting the communities they serve. Teachers need to explain formulas and weights without leaving out the details, letting students connect classroom theory with real-world stakes.

Building Knowledge and Trust: E-E-A-T in Chemical Information

Experience has taught me that it’s not just the chemical properties that matter. Reliable sources make all the difference when it comes to safety, progress, and public understanding. Everything—formula, weight, risk—needs a clear foundation. Peer-reviewed journals, trusted laboratory databases, and regulatory agencies keep that data up-to-date and accurate. In my own work, I cross-check new compounds with multiple references before use.

The Road Ahead: Improving Communication and Safety

Solutions for better chemistry start with education and good habits. Regular safety seminars, up-to-date chemical inventories, and easy access to reliable data help prevent mistakes and shore up trust. It’s not just about the numbers; it’s about the confidence to use them right, whether you’re running a small science project or scaling up to big industry.

Anyone handling 6-chlorohexanoic acid benefits from clear, accurate information. That’s how progress happens—one careful measurement and one honest report at a time.

The Insider’s View on Handling This Chemical

Gloves on, goggles in place, lab coat buttoned—there’s this unspoken respect for chemicals like 6-Chlorohexanoic Acid. Anyone who’s measured, poured, or even capped a bottle of it knows how quickly carelessness can turn into trouble. The risk isn’t just about personal danger. It’s about protecting the workspace, the coworkers nearby, and the investment your organization has made in safety equipment and storage solutions.

Why Reliable Storage Really Matters

6-Chlorohexanoic Acid looks mild enough in its usual white powdered state, but don’t let appearances fool you. It has a corrosive streak, especially once moisture enters the picture. Fumes? They aren’t pleasant—and can trigger coughing or worse, depending on the exposure. Keeping it sealed in a tight, clearly labeled container blocks not only bad reactions with air and water, but also keeps accidental exposure to zero. An unlabeled or loosely closed cap isn’t just lazy; it becomes a ticking liability for everyone in the room.

Direct sunlight turns storage containers brittle, which risks cracking and leaks. That kind of mistake haunts some folks, especially after years in research or manufacturing. Ultraviolet rays speed up the decomposition process. So shelving this acid in a cool, dry, shady spot makes more sense than a sunlit window or a warm water bath. Stacking it alongside incompatible substances like strong bases, oxidizers, or flammable organic craps out any safety plan built over years of good habits. Separate acid cabinets exist for a reason—ignoring that can cause fires or violent reactions.

Regulations, Documentation, and Compliance

Any place with a chemical inventory worth its insurance premiums keeps a printed Safety Data Sheet (SDS) for 6-Chlorohexanoic Acid, even if digital backups exist. No excuse covers up for skipping the simple rule: check the SDS before storing anything new or unfamiliar. These sheets outline temperature points, chemical interactions, health effects, and emergency procedures. They’re not just paperwork—they save lives when minutes count.

No one wants a surprise inspection to reveal corrodes, leaking shelves, or worn-out PPE. Regulatory agencies may hand out warnings and fines, but the real harm falls on coworkers caught off guard by a whiff of acid in the air. Every bottle should have a legible label. Any shelf not intended for acids should stay off-limits. Regular checks for corrosion, spills, or odd odors matter as much as any end-of-year audit.

Simple Steps Bring Peace of Mind

Years in chemistry taught this: double-checking a cap never feels like wasted time. After use, containers belong back in their assigned cabinets without shortcuts. Using secondary containment trays under containers saves headaches and cleanup if a bottle tips over. Acid-absorbing mats underneath storage shelves turn a minor spill into a quick wipe-up, not a day lost to hazmat cleanup. Eye-wash stations and running water don’t collect dust if people know what they’re for, and staff refresher courses should be as regular as clockwork.

Safe chemical storage isn’t just company policy—it’s respect for the people who share the space. The cost of good habits looks small compared to what happens when carelessness and chemicals meet. 6-Chlorohexanoic Acid, like too many tricky compounds, reminds everyone to stay sharp, keep organized, and never ignore even the smallest warning sign.

Understanding What We're Dealing With

In my lab days, 6-chlorohexanoic acid sat on a shelf with a bright label. The rules never changed about it: treat with respect, or you’ll regret it. This compound acts like a lot of medium-chain acids—it burns on contact, and you can’t mistake the smell for anything pleasant. Even the most seasoned chemists can get careless when things get busy, so strong protocols always matter.

Protecting Your Skin and Eyes

Chemical burns from 6-chlorohexanoic acid don’t heal quickly. I’ve seen a coworker forget gloves for a second and end up with peeling fingers for weeks. You’ll want nitrile gloves, not the cheap latex ones that split under pressure. Face shields protect better than basic goggles—splashes happen fast and sideways when pouring from stock bottles.

Long sleeves and closed-toe shoes become non-negotiable in this situation. Lab coats seem bulky at first, but you forget that once you see what acids do to fabric and, worse, to skin. Use chemical-resistant aprons when handling larger volumes. You can scrub your hands, but it’s tough to get acid off a cotton shirt mid-spill.

Ventilation and Air Quality

No amount of caution helps if you work in a dead-air room. This stuff produces fumes that irritate the throat and eyes almost immediately. Modern labs use fume hoods for this reason, and I’d never handle 6-chlorohexanoic acid outside of one. Even at small scales, fumes build up. I learned to double-check the air flow every time—I ignored it once and spent the afternoon coughing, eyes watering.

Accurate Labeling and Storage

The worst accidents in my experience start at the storage shelf. Don’t reuse old reagent bottles, since the acid will eat through almost anything that isn’t glass or specially certified plastic. Keep the container sealed, locked away from heat sources, and far from bases or amines. Someone mixing acids and bases because of a faded label is not some distant horror story—it’s a real risk.

Label every bottle with the full chemical name and a bold corrosion warning. Date your containers. Old acid starts degrading packaging, and that minor leak can go unnoticed until you grab the bottle next week and find a sticky mess—or worse, a puddle burning through shelving and onto your shoes.

Plan for Emergencies

Everyone talks about safety showers like they’re for show. They aren’t. In my lab, we kept a clear, unobstructed path to the eyewash station and shower. Know where these are—seconds count if acid hits your face. Water can’t fix deeper burns, but flushing chemicals off quickly keeps injuries minor. Don’t trust luck or quick reactions; set your lab up for emergencies before they happen.

What the Facts Tell UsThe National Institute for Occupational Safety and Health lists the effects of 6-chlorohexanoic acid exposure: burns, respiratory distress, and possible long-term tissue damage. OSHA requires personal protective equipment and specifies procedures for handling acids—it’s not busywork. Incidents still occur, with cuts corners turning into medical emergencies. Safety training saves lives. Familiarity with protocols, not overconfidence, is what keeps labs safe.

Building a Culture of Respect

Labs that avoid accidents treat safety as a daily habit. Share stories—not just data—about close calls and injuries. Don’t let time pressure push anyone to skip goggles or use the wrong gloves. Keep equipment in top shape, and refresh training for newcomers often. A safe lab means focusing just as much on people and habits as on technical details. That’s the hard-earned truth behind every chemical safety manual I’ve read or lived.

Why Purity Matters in Daily Lab Work

Anyone who has spent enough time in the lab knows the frustration of tracing back a failed reaction only to find that an impurity in a reagent played a silent, damaging role. 6-Chlorohexanoic acid isn’t immune to this issue. Variations in purity grades—ranging from technical grade right through to highly purified, research-grade material—carry real consequences in both research and industry settings. At its core, purity isn’t just a sticker slapped on a bottle. It’s often about having repeatable, trustworthy results and avoiding those sneaky contaminants that wreck more than just an experiment—they can torpedo months of work.

6-Chlorohexanoic Acid in the Real World

6-Chlorohexanoic acid pops up across organic synthesis, special polymer manufacturing, and, occasionally, specialty surfactant preparations. Based on experience, the type of purity you want depends heavily on the job. In academic contexts, researchers may prefer analytical or high-purity options to ensure side reactions stay out of the picture. When the goal is bulk synthesis for industrial intermediates or pilot-scale manufacturing, technical or commercial-grade acid often gets the nod since cost and large-volume processing outweigh the need for ultra-clean material—at least until a purity-related inconsistency shows up in the end product.

What Do the Grades Mean?

They tend to reflect two main things: the content of the acid and the profile of contaminants. Research-grade material often comes with a certificate of analysis, outlining trace metal content, water level, and sometimes residual solvents. This is the bottle you reach for when purity makes or breaks your downstream step, like synthesizing sensitive pharmaceuticals. Technical grade might contain extra bits and pieces—things like residual solvents or related alkanoic acids. Some labs can tolerate this, but not every application can weather that unknown risk.

Common Problems Linked to Impurities

One evening in the lab, a contaminated batch of 6-chlorohexanoic acid left behind a sticky mess in a reaction designed for a hydrolysis study—with just enough uninvited guests to spoil the outcome. Even a minor impurity in a carboxylic acid can cause headaches: extra peaks on the GC, unpredictable results in bioassays, or a drop in yield that triggers a week-long round of troubleshooting. The cost of a slightly cheaper, less pure chemical sometimes gets multiplied many times over in wasted man hours and missed timelines. Many researchers, even after trying to purify in-house, learn to demand a clear statement of purity before ordering.

How to Choose the Right Grade?

The process of picking a grade involves a hard look at the application. For bench chemists, reproducibility often wins over cutting costs, so the safest bet is to check for suppliers who provide batch-level analysis. In an industrial plant, technical decisions still must factor in regulatory requirements and the end-use application—medical or food-contact products almost always prompt higher scrutiny. If documentation is lacking, anyone who has ever tried to chase down the source of a bad batch knows the headaches baked into that risk.

Better Solutions for Scientists and Industry

Clear labeling, verified batch analysis, and a transparent supply chain should no longer be optional. Sometimes a supplier’s willingness to answer technical questions about their product’s profile tells more about their material than any smiling sales brochure. Companies able to keep trace impurity levels low, report those numbers, and provide reliable stock, tend to get repeat business for good reason. Investing in solid supplier relationships—and never skipping the small print on the specification sheet—remains the easiest insurance policy against a week lost to mysterious lab results.