7-Bromoheptanoic Acid: A Commentary on Its Significance and Future

Historical Development

7-Bromoheptanoic acid has carved out its own space in the world of fine chemicals. Back in the early-to-mid 20th century, researchers began exploring longer-chain haloacids for their unique reactivity. Before the industry had a reliable supply, labs often synthesized short runs for use as alkylating agents and intermediates. This compound grabbed attention thanks to its straightforward backbone—a seven-carbon chain capped with a carboxylic acid on one end and a reactive bromine atom on the other. As organic synthesis matured, chemists realized 7-bromoheptanoic acid allowed them to introduce functionality several atoms removed from the terminal group, which opened doors in industrial and lab-scale projects. You won’t find splashy stories about it in textbooks, but its impact trickled quietly into the world of pharmaceuticals and polymers. In my experience working with specialty reagents, the compound’s reputation grew largely through word-of-mouth as scientists realized its ability to serve as a building block, not just a curiosity.

Product Overview

This chemical wears many hats. People use 7-bromoheptanoic acid in the construction of heterocyclic rings, as a tether for polymer modifications, and in the streamlined manufacture of complex molecules. Researchers often need a bromo acid that’s neither too short (prone to volatility) nor too bulky (leading to steric hindrance). Seven carbons strike a balance: flexible enough to thread into molecular frameworks, sturdy enough to resist decomposition. Over the last decade, suppliers have scaled up, offering it as either a research-grade reagent or a starting material for contract synthesis. These days it shows up more often in the literature—especially in patent filings or custom molecule production.

Physical & Chemical Properties

Look at a fresh sample, and you'll see a colorless to pale yellow liquid or solid, melting just above room temperature. Molecular weight clocks in at 223.07 g/mol. Its faintly acidic odor reflects its structure. On the chemical side, it offers a polar carboxyl group opposite a reactive alkyl bromide—giving plenty of options for nucleophilic substitution or further transformation. You’ll get a density around 1.41 g/cm³ and a boiling point in the 280–290 °C range, although it decomposes before reaching high vapor pressures. It dissolves better in polar organic solvents than in water, which lines up with hands-on lab experience: it blends readily with DMF, DMSO, and ether, making it convenient for organic synthesis and scale-up procedures.

Technical Specifications & Labeling

Purchase orders often focus on purity—most suppliers guarantee ≥97% and provide HPLC diagrams on request. Acid number and bromine content back up purity claims. Container labels highlight proper handling, displaying the CAS number (629-04-9) and illustrating hazard diamonds for both corrosivity and environmental risk. On our bench, we always demand tightly sealed, light-protected, and inert-gas-purged bottles, since daylight, air, or moisture can all nudge it toward slow degradation. Transport paperwork flags it as a hazardous material—brominated organics rarely escape regulatory scrutiny.

Preparation Method

Making 7-bromoheptanoic acid starts on the practical side. The standard route involves bromination of heptanoic acid or its derivatives, often triggered by phosphorus tribromide or a similar activating agent. Sodium bromide and sulfuric acid can also play a role, especially in industrial settings where cost and byproduct management matter. The key lies in controlling temperature and stoichiometry to avoid overbromination or unwanted side reactions. After extraction and purification, distillation or crystallization yields the clean product. For anyone who’s spent time in a synthesis lab, the persistent, sharp scent of alkyl bromides always serves as a warning to step carefully and wear proper gloves.

Chemical Reactions & Modifications

7-Bromoheptanoic acid serves as a ready entry point for a variety of organic reactions. Its bromo group attracts nucleophiles, so I've seen colleagues use it in straightforward SN2 substitutions: treating it with azide, amine, or thiol converts it into heptanoic acid derivatives in a snap. In coupling reactions, it acts as an alkylating agent, linking biomolecules or building the skeletons of custom surfactants and ligands. People use the free acid for amidation—they’ll first activate it, then hook it into peptides or polymers. The possibilities aren’t just academic; they underpin pilot-scale processes from drug development to advanced coatings. Every step demands attention: the bromo group gives high yield but also asks for strict temperature management and care to avoid side products.

Synonyms & Product Names

Chemists searching catalogs may find a handful of alternative names: 7-bromocaprylic acid, heptanoic acid, 7-bromo-, or 6-carboxyhexyl bromide. Synonyms often reflect supplier preference, legacy naming, or subtle shifts in chemical focus. Occasionally, safety databases surface translations, like ácido 7-bromoheptanoico, highlighting global supply and research. On purchasing paperwork and customs forms, precise nomenclature matters; more than once, a shipment faced hold-ups thanks to inconsistent labeling or paperwork typos.

Safety & Operational Standards

No one handles 7-bromoheptanoic acid lightly. The bromo group poses respiratory and skin risks, plus the acid is irritating on contact. In the lab, I always reached for nitrile gloves, splash-proof goggles, and performed manipulations inside a ventilated hood. Spills need immediate clean-up to prevent fume exposure. Safety sheets demand storage at room temperature, away from oxidants, and in labeled secondary containers. Disposal routes it through halogenated waste collection, as environmental regulations clamp down on bromine release. For industry, process engineers stick to closed systems and require air monitoring when scaling up—leaks, even minor, can spark workplace health issues. Best practices come straight from collective experience: those who cut corners in handling typically pay with accidents or failed syntheses.

Application Area

Demand springs up most often in pharmaceuticals, custom organic synthesis, and materials research. Medicinal chemists value its chain length and leaving group ability, allowing them to create prodrugs or build side chains for lead compounds. Polymer researchers employ it to tether new chemical features onto backbones, extending chain flexibility or adding reactive sites. Specialty surfactant design taps in for the same reasons. Academics use it in undergraduate and graduate training, since it demonstrates classic substitution chemistry. When I supervised research students, I leaned on brominated acids to show real consequences of substitution: yields rise, purity stays high, but disposal and exposure hazards remain part of the lesson plan.

Research & Development

Research teams push the limits of what can be built from simple building blocks. 7-Bromoheptanoic acid now sees use in making biomedical linkers and more robust anti-fouling surfaces. Patent filings show rising interest in tailoring it for controlled-release systems—building in or out desired molecular features. Some universities, spurred by new grant funding, test novel synthetic sequences where a single switch of chain length shifts solubility or activity. My industry contacts track supplier sources closely, since competition drives both innovation and price swings. The challenge focuses less on discovery and more on scaling laboratory success into reliable, repeatable, and cost-effective bulk production.

Toxicity Research

Studies of 7-bromoheptanoic acid highlight both acute toxicity and chronic effects. Like most aliphatic bromides, ingestion or significant exposure induces nervous system depression, respiratory irritation, and possible liver strain. Animal studies reveal the danger of high doses, particularly in cumulative experiments, so regulatory agencies require careful documentation. Water-based toxicity brings another angle: brominated acids don’t biodegrade quickly, raising alarm about persistent organic pollutants. For chemists like me, these findings shaped lab routines—always assuming the worst-case exposure and keeping quantities small, minimizing open handling, and running regular air quality tests during pilot project scale-up.

Future Prospects

Looking forward, I see expanding roles for 7-bromoheptanoic acid in both established industries and experimental science. The steady march of medicinal chemistry and green polymers calls for versatile intermediates, pushing demand upwards. As sustainability pressures rise, next-generation syntheses will need safer reagents and more efficient waste management. Researchers already hunt for tailored modifications: new bromo acid analogues get synthesized and assessed for physical, biological, and environmental tradeoffs. My gut tells me the greatest advances will come when small- and mid-scale suppliers invest in cleaner, well-documented syntheses—delivering high purity, but without the hangover of hazardous byproducts. Educators and lab directors need to balance curiosity-driven research with the realities of risk, which means the legacy of 7-bromoheptanoic acid will blend respect for its power with a commitment to safe, responsible innovation in chemistry.

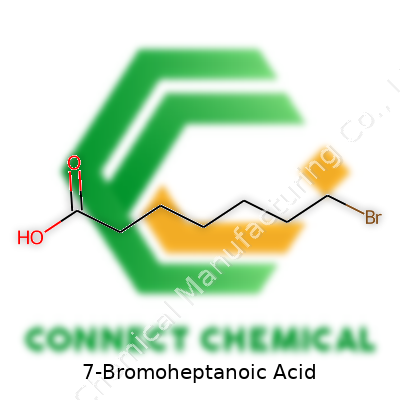

Understanding the Backbone: Atoms and Bonds

7-Bromoheptanoic acid comes across at first glance like the product of a tongue-twister, but behind that name sits a simple lineup of carbon atoms. It’s a seven-carbon, straight chain molecule where a bromine atom grabs the seventh spot, and a carboxylic acid group plants itself at the other end. Chemists often talk about it in shorthand: Br-(CH2)6-COOH. That paints a picture of six methylene groups in a row, capped on one end by bromine, on the other by carboxylic acid. It's not just academic detail — each small tweak in structure changes how a molecule behaves in a lab or out in the world.

What Sets It Apart

My own work in undergraduate chemistry labs brought a real appreciation for how a single atom, swapped or shifted, turns a docile molecule into a powerful tool or a hazardous compound. Bromine doesn’t just ride along quietly. Sitting at the end of this long-chain acid, it transforms reactivity. Lab techs and researchers reach for this compound because that bromine lets them swap in other groups by nucleophilic substitution. Its location at the terminal end means you don’t get tangled up with other parts of the molecule; you get clean, targeted reactions.

Part of running a reliable synthesis involves understanding not only what’s on paper, but how a reagent might react in the flask. By placing bromine far from the acid group, 7-bromoheptanoic acid avoids unwanted side-reactions. I’ve handled similar haloacids while prepping intermediates for pharmaceutical candidates, and I learned quickly that purity and predictability mean fewer failed experiments and less waste. The real-world result: fewer headaches, smaller budgets, tighter timelines.

Industrial and Research Significance

A lot of organic synthesis hinges on having a carbon chain pre-loaded with an easy exit. This molecule serves as a linchpin in building longer, more complex molecules. Many labs use it to add seven-carbon spacers, anchoring side chains or modifying natural compounds. The carboxylic acid end-binding pulls water molecules through hydrogen bonding, making it behave differently from a non-acidic, non-brominated cousin.

One example from a project I worked on—building non-natural amino acids—relied on these bromoacids as starting materials. The results you get hinge on how willing the terminal bromine is to let another group in. This straightforward willingness comes right out of the molecule’s chemical structure. Published research supports this, noting that bromoacids with longer carbon chains such as this one have lower toxicity compared to shorter analogs and give better yields in industrial applications, from polymers to intermediates in agrochemical synthesis.

Risk, Responsibility, and Safer Synthesis

No story of a halogenated acid is complete without a word on safety. Adding bromine can boost reactivity, but that means extra respect in the lab. I’ve personally faced mishaps from underestimating the reactivity of bromide compounds. Common practice demands gloves, goggles, and a fume hood, but I encourage newcomers to add extra care. Global best practices track handling and disposal, with regulatory frameworks like REACH in Europe and TSCA in the US. Labs and companies meet these standards by tracking every step chemicals take—storage, use, and waste. Transparency about sourcing and purity continues to improve laboratory safety and product quality, keeping accidental releases and exposures down.

Future Pathways

Chemical building blocks like 7-bromoheptanoic acid will keep finding new uses. Researchers look for greener, safer transformations—pivoting away from heavy metals and toward milder, more sustainable reagents. It’s inspiring to see academic and industrial scientists pushing to make synthesis both high-yielding and environmentally friendly, so every new route builds on a base of smart chemistry and responsible stewardship.

Sparking Change in Organic Synthesis

7-Bromoheptanoic acid brings a practical tool to the table in organic chemistry labs. Chemists reach for it during the construction of larger, more complex molecules. Its seven-carbon backbone with a bromine sitting at the end acts as an anchor for further reactions. In the synthesis of pharmaceuticals, the compound stands out as a bridge for adding functional groups to a molecule. It opens a pathway to form carbon–carbon bonds, a building block move that comes up all over drug development and research.

Pharmaceutical Exploration and API Manufacturing

In the search for better medicines, scientists rely on intermediates that speed up the process without sacrificing safety or consistency. 7-Bromoheptanoic acid fits that bill. It pops up during the pre-clinical stages of drug discovery as well as in the production of active pharmaceutical ingredients (APIs). Its unique structure allows researchers to investigate new ways to modify chemical frameworks. For example, by swapping the bromine atom for another group, chemists experiment with new analogs that could improve the therapeutic action or cut side effects. That constant testing and adjusting keep the search for new treatments moving forward.

Stepping Stone in Agrochemical Development

Farming relies on chemicals that protect crops and boost yields. Before any of those products reach the market, their inventors run through various synthetic routes to optimize costs and effects. 7-Bromoheptanoic acid steps in as a precursor during the development of certain agrochemicals, especially in making selective herbicides or insecticides. Because of its ready reactivity, it lets scientists add longer chains to their molecules. That flexibility gives crop protection researchers extra options to tailor how a new product interacts with the environment.

Crafting New Materials and Surfactants

Research into new materials goes beyond plastics and textiles. The chemical industry looks for cleaner, more efficient surfactants to improve everything from detergents to oil recovery. Using 7-bromoheptanoic acid as a starting point, manufacturers design molecules with custom tail lengths and reactivity. The bromine acts as a target, helping link new functional ends, making the finished product perform in specific conditions. With the growing focus on green chemistry, this approach helps reduce waste and reliance on less sustainable reactants.

What Makes It Stand Out in Research Labs?

Having spent time juggling reactions in both academic and commercial labs, there’s a clear difference between a compound that complicates steps and one that smooths out bottlenecks. 7-Bromoheptanoic acid lands in the latter spot: it’s stable enough for storage on the shelf, but reactive enough to keep reaction times reasonable. Every experiment counts in tight budgets and short timelines, and flexibility speeds up progress. The relative ease of handling and predictable behavior allow students and professionals alike to focus on creative problem-solving instead of constantly troubleshooting.

Moving Toward Safer and Greener Approaches

The broader chemical world continues shifting toward methods that cut down on hazardous waste. Brominated carboxylic acids, including 7-bromoheptanoic acid, support this trend when researchers design protocols that use fewer solvents or produce less pollution. Seeking these process improvements goes beyond ticking boxes on compliance checklists—it means lower costs, better worker safety, and a lighter footprint on communities near production sites.

Supporting Reliable and Efficient Supply Chains

Reliable access to specialty chemicals lets industries react quickly to market shifts or sudden scientific breakthroughs. Many chemical distributors now stock 7-bromoheptanoic acid with strict quality checks in place to meet Good Manufacturing Practice (GMP) standards. That level of oversight helps downstream partners in pharma, agriculture, and materials science move research from the whiteboard to the pilot plant without the disruptions that can come from unknown impurities or inconsistent batches.

Why Chemical Storage Needs a Closer Look

Any researcher who’s dealt with organobromine compounds feels discomfort handling them without clear rules. 7-Bromoheptanoic acid carries both an acidic carboxyl group and a halogen, making it both reactive and potentially hazardous. Buried under technical jargon hides a key fact: a storage slip with this material wrecks experiments, drags down lab safety, and risks ruining expensive inventory. It doesn’t matter if you’re a grad student or a pro–no one wants emergencies traceable back to a lazy storage shelf.

What Chemistry Tells Us

Ask any chemist why some acids get locked away with a warning label, and they’ll point straight to their reactivity. This acid’s bromo group can ignite wild substitution reactions. Keeping it dry is vital: water can hydrolyze sensitive bonds or accidentally jumpstart decomposition. Humidity also introduces risk.

On a broader scale, halogenated acids can give off corrosive fumes over time, so the bottle shouldn’t sit near materials sensitive to acidic vapors. Good airflow or a closed system helps prevent buildup of anything dangerous. One oversight some folks make is reliance on old glassware. Halogenated compounds, especially in an acid solution, eat away at cheap metal caps or erode ill-chosen plastics. Always check for corrosion, both at initial receipt and for long-term stock.

Best Practices from Hard Experience

I recall that time in a small academic lab, where we watched a cap start to crumble after two months. The acid’s vapor corroded metal threads, seizing the lid. Three hours later, two researchers and a hacksaw solved a problem that proper storage could have prevented. Lessons like this provide evidence: overdressing acids in the right container matters.

Most research-grade acids belong in high-quality, tightly sealed glass bottles. For 7-bromoheptanoic acid, amber glass wins over plastics, shielding from light and cutting down degradation. Store the container upright, away from sun and heat—think interior fridge, dedicated to chemicals, set between 2 and 8°C. Avoid the main kitchen fridge, where snacks mix with sensitive samples.

Labels sometimes fade or peel, especially in cold conditions or around solvents. Tough labels, waterproof pen, and regular checks save confusion during inventory. Don't ever top up an old bottle with fresh acid—proper segregation keeps chemical identity clear and prevents stray impurities from building up.

Keeping Safety Simple and Real

Many labs get lazy on safety after years of no problems. But every researcher owes something to their coworkers. Acids like 7-bromoheptanoic can splash or fume if left near bases, flammables, or even strong oxidizers. Stack these separately—and store spill-absorbent pads nearby, just in case. Always check local disposal rules. While federal guidelines say to lock hazardous chemicals away, each state and building enforces unique codes. Never toss containers in the trash or pour leftovers down the drain.

Accidents often happen to people who think they’ll see an issue coming. Good storage turns chemical danger into chemical control. For 7-bromoheptanoic acid, glass, cool, dry, and labeled wins out, every time. Commonsense beats complacency, every time, too.

Understanding Why Purity Makes a Difference

In the lab, there’s a world of difference between chemicals that just “seem fine” and ones that consistently give reliable results. 7-Bromoheptanoic acid shows this reality clearly. Chemists look for clarity in their analysis, and a solid set of purity standards keeps experiments on track and data trustworthy. Researchers can spend months, even years, hunting down why an experiment didn’t work—only to learn it was due to an impurity in a reagent. It’s no overstatement. This stuff matters, right down to the decimals.

Common Purity Specifications for 7-Bromoheptanoic Acid

Industry suppliers and research labs usually expect 7-Bromoheptanoic acid to reach at least 97% to 99% purity by GC (gas chromatography) or HPLC. That level means fewer surprises in reactions, so chemists worry less about side products or unproductive efforts. Impurities like heptanoic acid, 1-bromoheptane, water, or traces of solvents can undermine expensive research projects. Pharma and biotech teams are especially picky. They’ll push for certificates of analysis and batch-specific chromatograms before they commit. The best sources back every shipment with traceable results, sometimes verified down to the tenth of a percent—because trace impurities become a headache after scale-up.

How Purity Is Established and Measured

Reputable suppliers don’t just eyeball their products. They bring out the heavy machinery—NMR, HPLC, GC-MS—to check both organic and inorganic contaminants. Chromatography picks up unexpected guests. Spectroscopy can confirm the exact structure, so nothing sneaks by because it “looks right.” An experienced chemist always reads the certificate of analysis carefully. For 7-Bromoheptanoic acid, the standards don’t stop at purity by chromatography. Water content, usually measured by Karl Fischer titration, plays an important role, especially for moisture-sensitive work. Heavy metals and residual solvents get checked, too, since lingering palladium or TFA traces from synthesis can ruin reactions. There’s a world of difference between 99.5% and 95% quality—fail to check, and your next experiment might flop or give odd results.

Sticking to the Right Specification in the Real World

Many academic labs, and plenty of industrial R&D teams, have shared stories about projects derailed by trace contamination. Sometimes you see it on a TLC plate—a faint ghost of another compound. Sometimes you only discover it in the final yields or spectral data. If the purity isn’t up to par, you can waste weeks troubleshooting, convinced you made a procedural mistake. You learn, often the hard way, that cutting corners on specifications rarely pays off.

Getting the Specification That Fits the Job

It’s good practice to talk directly with the supplier and insist on a transparent purity breakdown. If a project leans on tight tolerances—like work on pharmaceutical intermediates or advanced materials—a regular check of every batch makes sense. Analytical reports, full spectra, and impurity profiling become part of your workflow. If purity dips below spec, it’s better to swap suppliers than to compromise and hope for the best. A chemist’s experience soon teaches that reliable starting materials shape the science that follows. For work that depends on reproducibility, only verified, high-purity batches get near crucial experiments.

Looking at the Hazards Up Close

Handling chemicals like 7-Bromoheptanoic acid means weighing the risks. This compound, known for its use in organic synthesis and pharmaceutical research, carries more baggage than you see on first glance. When someone picks up a bottle of 7-Bromoheptanoic acid, they're not just reaching for a routine lab reagent. Skin and eye contact cause irritation or burns, depending on exposure. Breathing in powders or vapors from this kind of substance can trigger coughing or more severe respiratory problems in some people.

Personal Experience Shapes Caution

Spending lab hours near reactive and corrosive chemicals shaped my respect for safety routines. One time, a colleague thought a similar compound was “nothing dramatic.” Days later, a careless spill led to a small chemical burn and a chain of reporting that slowed an entire project. Even seasoned researchers pay the price for letting their guard down. A clear lesson stands out: overconfidence in chemistry carries consequences.

Straight Facts on Reactivity and Toxicity

Looking at the Safety Data Sheet for 7-Bromoheptanoic acid, you'll see warnings for corrosivity and toxicity. If this liquid or powder meets skin or eyes, it can damage tissues quickly. Breathing in dust or getting splashed eyes-on brings plenty of risk. Standard labs tag this compound as hazardous, not just for its bite to tissue but for the way it reacts—halogenated organic acids don't belong in the same room with strong bases, oxidizers, or open flames. Heating these compounds can also release toxic fumes, including hydrogen bromide, which ramps up the danger.

Packed with Precautions

Chemical safety isn't a guideline—it's a must. For 7-Bromoheptanoic acid, gloves, goggles, and lab coats block splashes and dust that make trouble. Always prep your workspace with local ventilation or fume hoods. Never store it near incompatible substances or on a crowded benchtop. Bringing food and drink near spaces where this acid lives should stay off the table completely. Good lab practices start with more than labels and checklists—they rely on habits built through repetition and vigilance.

Protecting More than People

People often forget about environmental hazards when disposing of chemical waste. Pouring 7-Bromoheptanoic acid down a drain leads to groundwater contamination and risks aquatic life. Chemical waste containers, properly labeled, save custodial staff from accidental exposure and protect local ecosystems. Most facilities enforce strict waste collection, but personal responsibility still counts the most at the point of disposal.

Supporting Safe Research and Industry

Researchers keep building new pharmaceuticals and advanced materials with chemicals like 7-Bromoheptanoic acid. Knowledge about its hazards doesn’t stop progress—it powers smarter, safer experiments. I keep going back to real-life accidents as reminders: reading and following procedures may feel slow, but cleaning up after a rushed mistake takes much longer. Shared vigilance and clear communication push lab safety culture forward.

Solutions: Training, Equipment, and Mindset

Periodic safety training cements best practices. Investing in proper protective equipment pays off, even when costs feel high. Open conversation about close calls and incidents coaches new team members without shame. Everyone benefits from up-to-date material safety data and a workplace where safety takes priority over speed. With all the promise chemistry offers, mutual responsibility and skepticism about “routine” are what actually keep people safe.