7-Chloroheptanoic Acid: A Deep Dive into a Chemical Cornerstone

Historical Development

Exploring the background of 7-chloroheptanoic acid, stories of organic synthesis labs in the mid-20th century come to mind. Chemists searching for new links between halogenated chains and carboxylic acids gradually mapped out the synthetic routes that brought this compound to the bench. It emerged as researchers investigated longer-chain haloalkanoic acids for their potential to build specialty polymers, fine chemicals, and agrochemical intermediates. I remember the excitement I felt reading case studies involving adaptations of the Hell-Volhard-Zelinsky reaction, leading to an explosion of interest in tailored fatty acid derivatives. The pathway to 7-chloroheptanoic acid became a testament to how patient, detailed laboratory work can give rise to a staple for synthesis.

Product Overview

Today, 7-chloroheptanoic acid stands as a valuable intermediate in both academic and industrial labs. Its molecular formula C7H13ClO2 defines a simple structure: a seven-carbon chain capped with a carboxylic acid and bearing a chlorine at the terminal position. That chlorine, by design, opens doors to further transformations, making it a popular choice for chemists wanting flexibility in alkyl chain modification. I’ve seen it requested in kilo quantities for pharmaceutical syntheses, thanks to its ability to introduce chain length with reactive functionality intact. This mix of manageable size and strong reactivity puts 7-chloroheptanoic acid in a league where it supports innovation across chemistry-driven fields.

Physical & Chemical Properties

7-chloroheptanoic acid presents itself as a colorless to pale yellow liquid, usually offering a faint, acidic odor typical of carboxylic acids fused with the sharpness of a halide. Its melting point hovers just above room temperature, while the boiling point sits much higher due to the long carbon chain and polar acid group. I’m always struck by its modest solubility in water but good compatibility with ethers, alcohols, and other polar aprotic solvents. This unique balance guides its handling in synthesis labs. It resists room-temperature decomposition, but I never store it in daylight or moisture-rich environments, as the carboxylic acid eagerly soaks up water and the chlorine may drift into unwanted side reactions under the wrong conditions.

Technical Specifications & Labeling

Cultural norms in chemical supply chains demand careful labeling and reliable specifications. Reputable suppliers often guarantee a purity exceeding 97%, typically verified by gas chromatography and NMR spectroscopy. From my experience, the best labels always include hazard warnings (irritant, corrosive), batch number, and storage instructions (under nitrogen, cool temperature, away from light). Density measurement rests around 1.1 g/cm³, with spectral data confirming the structure. Consistency between bottles matters more than price for quality control—standards borrowed from the pharmaceutical sector have permanently raised the bar for specialty acid intermediates like this one.

Preparation Method

Sourcing pure 7-chloroheptanoic acid calls for a well-controlled synthesis, often starting from heptanoic acid. The transformation usually involves halogenation, targeting the omega (terminal) position through a process like the Hell-Volhard-Zelinsky reaction. In practice, phosphorus trichloride and chlorine gas drive substitution of a terminal hydrogen with chlorine, while reaction temperature and timing decide the yield and purity. Sometimes, alternative routes using photochemical chlorination or thionyl chloride modifications come into play, depending on available equipment and safety constraints. I learned the value of precise stoichiometry and slow addition in these reactions—the cost of a ruined batch due to runaway exotherms still stings years later.

Chemical Reactions & Modifications

Carrying a terminal chlorine, 7-chloroheptanoic acid adapts well to a range of substitutions and couplings. Nucleophilic attack on the carbon bearing the chlorine lays the groundwork for ether, ester, or amine introduction, providing a way to tune bioactivity or solubility. I’ve watched synthetic chemists exploit this trait to stitch together more complex molecules, feeding the acid into sequential alkylation and amidation reactions. The carboxyl group allows activation for peptide bond formation, while oxidation-reduction manipulations extend its reach even further. It always helps to have a molecule like this—a functional handle ready for innovation, responsive to creative strategy and practical constraint alike.

Synonyms & Product Names

Names pile up for 7-chloroheptanoic acid, especially across language and regulatory borders. Some call it 7-chloro-n-heptanoic acid or heptanoic acid, 7-chloro-, also picking up designations like ω-chloroheptanoic acid or 7-chlorocaproic acid. Laboratories might use trade brands or catalog numbers designed for tracking inventory, but structural clarity always sits at the center. In my dealings with suppliers and customs agents, I’ve learned not to take shortcuts with naming conventions—a mismatched synonym on paperwork often brings an order to a frustrating halt.

Safety & Operational Standards

Working with 7-chloroheptanoic acid means knowing the hazards and respecting the right controls. Corrosivity presents the biggest risk—skin and eye contact lead to strong irritation or even lasting damage. It burns on the nose and throat, pushing for well-fitted gloves and goggles, plus local exhaust ventilation. I remember spending an afternoon in an occupational safety review, where each spill response plan included neutralizing agents, emergency showers, and protocols for disposing of halogenated acids. The addition of clear, easy-to-read Safety Data Sheets (SDS) helps level the playing field for chemists at every experience level. Emergency numbers hang up in every entryway—a culture of caution that earned its place over decades of lessons, both easy and hard.

Application Area

Demand for 7-chloroheptanoic acid rises in sectors where tailored molecules bring competitive advantage. The pharmaceutical world leans on it as a building block for crafting active intermediates with tunable side chains and functional diversity. Pesticide designers look to this acid when engineering molecules aimed at selective plant or pest activity. I’ve seen it appear in research programs focused on polymer crosslinking, surfactant modification, and specialty lubricant additives. The value comes not only from the molecule itself but from the ease it offers at the intersection of reactivity and chain length—a boost for anyone fashioning next-generation products from base chemistry.

Research & Development

Curiosity keeps pushing researchers to reinvent how 7-chloroheptanoic acid fits into the future chemical landscape. Lab groups test novel coupling partners, exploring new transformations that tap into the bias of the terminal chlorine. Technicians tweak synthetic approaches for cleaner, energy-saving halogenation. In my academic years, I saw firsthand how funding decisions rewarded those who could prove a method saved time or reduced waste, sometimes transforming bench science into scalable, green processes. Current R&D often focuses on integrating 7-chloroheptanoic acid precursors with next-generation catalysts or flow reactors, creating safer and more reliable pathways for industrial adoption.

Toxicity Research

No discussion feels complete without addressing how exposure to this compound impacts health and the environment. Documented cases show that ingestion or prolonged contact risks tissue corrosion, while leaks into waterways pose a threat to aquatic organisms. Local regulatory bodies count on updated toxicity data to guide disposal requirements and workplace exposure limits. Modern laboratories carry out in vitro assays and animal studies to pin down safe handling thresholds. I learned early to approach waste streams from halogenated acid workups with caution, consulting environmental officers and following best practice disposal protocols. Industry-wide push for green chemistry now shapes safer alternatives and improved containment systems.

Future Prospects

The story of 7-chloroheptanoic acid hasn’t ended; momentum buoys it forward. Specialty chemical producers and pharmaceutical innovators continue to harness its dual reactivity. Modern synthetic biology hints at biocatalytic options to introduce halogens with higher selectivity or reduce harsher reagents. Academic and industrial partnerships hold promise for new product families launched from this humble molecule. In my mind, its future depends on blending high-reactivity utility with stringent safety and sustainability standards—an approach that means greater rewards for those shaping the new face of specialty chemicals over the coming decades.

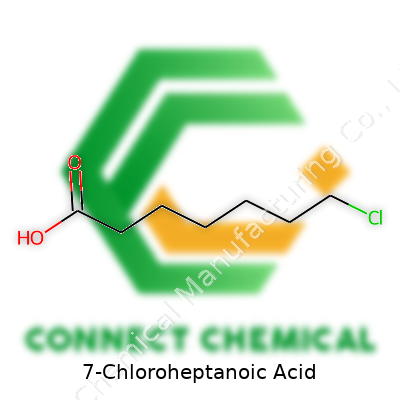

Looking at the Molecule Itself

7-Chloroheptanoic acid feels pretty straightforward if you break down the name. You start with heptanoic acid—a seven-carbon chain with a carboxylic acid group at the end. Toss in a chlorine atom on the seventh carbon, and you’re looking at a carboxylic acid (COOH) with a straight alkyl chain where the farthest carbon gets a chlorine tag. Chemically, the formula looks like this: Cl-(CH2)6-COOH.

Why Care About a Chloroalkanoic Acid?

This molecule’s structure makes it more than just a line of carbon atoms. As an organic acid, it combines the reactivity of a carboxyl group and a halogen. In my undergrad organic chemistry course, molecules like this often ended up as stepping stones in the production of more complex chemicals—real workhorses for building everything from surfactants to drugs. The chlorine atom tacked onto the tail changes everything. It can turn a regular fatty acid into a precursor for specialty compounds. Reactivity goes through the roof when you trade out a hydrogen for a chlorine on the terminal carbon, since that halogen becomes an ideal target for substitution or elimination reactions. Chlorinated acids can serve as intermediates for anything from pharmaceuticals to specialty polymers.

Health, Safety, and the Importance of Understanding Structure

Working with synthetic chemicals like this one taught me about risk and regulation. Halogenated organic acids carry extra baggage into the lab, and not just in the way they react. The presence of chlorine brings up both safety and environmental questions. Accidental exposure or improper disposal can spell trouble for people or the ecosystem. Manufacturers and researchers who deal with these chemicals rely on detailed knowledge of chemical structure to choose safe processes. According to the International Agency for Research on Cancer, a handful of chlorinated acids show potential for bioaccumulation or toxicity, especially if they build up in water or soil. The design of containment and disposal methods depends on knowing just how polar and reactive a compound gets with that chlorine atom in place, which affects solubility, volatility, and persistence in the environment.

What Science Can Do to Improve the Picture

There’s room for progress in the way society handles organic compounds like 7-chloroheptanoic acid. Researchers have been developing greener synthesis strategies that use less toxic reagents and generate less hazardous waste. I’ve come across enzymatic and catalytic processes that look promising for halogenation, which could decrease pollution from synthetic routes. Also, advances in molecule tracking allow better monitoring and detection in soil and water, leading to safer manufacturing and disposal decisions. Detailed knowledge of structure helps chemists design molecules that break down after use instead of hanging around for decades. That applies to 7-chloroheptanoic acid and a long list of similar specialty chemicals.

Final Thoughts on Chemistry in the Real World

Understanding the structure of 7-chloroheptanoic acid goes beyond the textbook. Such knowledge helps keep research, production, and the environment safer and more predictable. Developers who work with these building blocks face the challenge of balancing performance, safety, and sustainability. Chemical structure offers more than a diagram—it’s a toolbox for designing better futures, whether you’re after new polymers or planning safer clean-ups.

Not Just Another Chemical

In the landscape of organic chemistry, 7-chloroheptanoic acid stands out as a tool with a niche presence. A lot of folks see chemical compounds as abstract ideas tucked away in textbooks, but the story of this one links straight back to things that shape industries like pharmaceuticals, materials science, and synthetic chemistry. If someone handed me a vial of 7-chloroheptanoic acid years ago and said it would help build more effective medications, I would have called it a stretch. But the small changes these building blocks bring can echo throughout an entire system.

Fueling Pharmaceutical Discovery

Drug development rides on small tweaks and clever combinations. Researchers use the ‘chloro’ group found in 7-chloroheptanoic acid to build in selectivity or boost potency. The acid backbone plays well in peptide synthesis, helping chemists anchor or extend molecular chains. Some pharmaceutical teams rely on modified heptanoic acids as scaffolds for new medicines, especially when they're searching for molecules that work on challenging targets — like enzymes tied to neurological disorders or metabolic diseases. One story from a research group in Germany showed that swapping a hydrogen out for a chlorine atom let them zero in on a new antibiotic candidate, simply because the chlorine added stability in the right spot.

Steps Toward Greener Chemistry

Environmental pressure keeps growing on manufacturers — waste and harsh processing sit poorly with both regulators and communities. Many modern syntheses look for intermediates like 7-chloroheptanoic acid for this reason. It steps in during the production of biodegradable surfactants and specialty chemicals, such as tailored lubricants for machinery or cleaner gasoline additives. The placement of the chlorine atom opens options for further transformation. In one facility I toured, engineers explained how 7-chloroheptanoic acid’s reactivity reduced the number of chemical steps, so the production floor saw less waste and workers used fewer toxic reagents. This made a difference for both environmental output and their bottom line.

Materials and Polymers

The plastics space doesn't grab headlines like pharma, but almost every item on a modern desk involves polymers built by linking together various chemical feedstocks. Some polymer scientists turn to 7-chloroheptanoic acid when designing plastics that need flexibility or controlled degradation. The acid's structure lets it slip smoothly into reaction chains. The chlorine atom, never just an afterthought, allows for later tweaking of the polymer’s toughness or solubility. There’s ongoing research into biodegradable plastics where such acids add just the right amount of “give” — not brittle like some bioplastics, but sturdy enough for everyday use.

Challenges and Looking Ahead

A compound this useful doesn’t escape safety scrutiny. Any time you bring chlorine into the equation, risks follow. People working with 7-chloroheptanoic acid need solid training and proper protection. Some regions keep tight controls on chlorinated chemicals because of their persistence in ecosystems. This puts pressure on scientists to design better waste recovery and reduce emissions from manufacturing plants. More companies embrace green chemistry principles, swapping harsh conditions for milder processes, or setting up closed-loop systems that recycle leftovers. It’s a change that takes effort, but as demand for such compounds grows, responsible sourcing and stewardship mean more today than ever before.

Why Purity Makes a Difference

Every time I’ve worked in a lab environment or been involved with chemical sourcing, the first question that comes up centers around purity. 7-Chloroheptanoic acid, used in specialty synthesis and pharma work, is no exception. High purity—usually 98% and above—directly affects outcomes. Even a fraction of contamination can throw off yields, introduce unknown interactions, or build in costly rework. Large chemical suppliers usually offer certificates of analysis and batch test reports. Seeing data on water content, trace solvents, and by-products isn’t a luxury. Purity verification tools like NMR and GC-MS have become baseline standards in reputable labs. From my experience overseeing routine quality control, batches below 98% purity lead to complaints and returns. Consistency from source to source helps to keep the headaches away down the line.

Packaging Isn’t Just a Box

Packaging used to feel like an afterthought. That notion disappears pretty fast after a few shipments of broken bottles or oxidized products. Glass bottles fill most orders below five kilograms. They seal tightly against moisture pick-up and fend off leaching—essential since some solvents react with plastics. HDPE drums show up for larger volumes, usually lined to guard against absorption and slow release. Skilled logistics teams know even a few extra grams of water vapor or the wrong packaging resin can turn an entire drum into waste. Vacuum-sealed sachets and aluminum-lined pouches sometimes appear, especially if the client asks for granular rather than liquid acid. Temperature control also matters if there is risk of material degradation. I once watched a project stall for days just because packaging broke during a cold snap, so good insulation and shock resistance pay off.

Addressing Safety and Handling

Mistakes in safety labeling and tamper seals have cropped up in global trade. I’ve worked through audits where even minor omissions led to customs delays and regulatory trouble. It’s never just about “getting the order out the door.” Clear hazard symbols, batch numbers, and full SDS data have to travel with every shipment. During a training session, a seasoned shipping manager shared an example where a lack of corrosion warnings damaged entire pallets of nearby goods. Rushed packaging and missing paperwork can mean months of lost supply chain trust.

Reliable Sourcing and Decision-Making

Price lists and supplier directories provide handy starting points, but actual confidence comes from verified paperwork and repeat order success. I’ve seen researchers and purchasing agents benefit from buying small batches first. It’s hard to overstate the value of batch-to-batch consistency, especially for high-purity buyers. Contract documentation of purity, storage conditions, and recertification schedules keeps everyone honest. More sources are adding QR code tracking, which cuts down on mislabeling and ensures the supply chain stays transparent from door to bench.

Room for Improvement

Upstream, more chemical producers are investing in automated filling and smart packaging lines, picking up issues human eyes miss. Digital records now allow customers to trace not just packaging but the full purity validation history. In my own experience, pushing suppliers for extra purity analysis and robust packaging pays off in fewer downstream issues. Researchers and buyers have begun asking detailed questions about primary containers, lot-specific purity, and paperwork—turning simple purchases into well-managed supply chain partnerships. The process is only as strong as the weakest point, which for many chemicals, means attention to both purity and packaging, every step of the way.

Risks Surrounding 7-Chloroheptanoic Acid

7-Chloroheptanoic acid doesn’t sound dangerous. Once you read the safety paperwork, it becomes clear that this chemical brings some clear risks. Skin and eyes don’t take kindly to its presence. Direct contact may leave burns, redness, or irritation behind. Inhaling the fumes can irritate your nose, lungs, and throat.

Many lab workers put their trust in gloves and goggles, but those don’t always block all exposure. Years of working with strong acids have shown me that surprise spills and splashes find unprotected wrists, necks, and even shoes. Overlooking a tiny leak in a glove can turn into days of discomfort. This acid’s vapors might not fill the room with a strong smell. Toxicity sneaks in quietly, boosting the danger.

Personal Protective Steps That Matter

A splash-proof face shield covers more territory than simple glasses. Lab coats mean less opportunity for a stray drop to reach bare skin. Chemical-resistant gloves like those made from nitrile or butyl deserve respect here—common latex doesn’t hold up. Fume hoods aren’t just a luxury; everyone in the room breathes easier with one humming along. Each time you open a bottle, double-check that fresh air draws any vapor away.

People often skip reading labels and safety data sheets. Yet these documents explain the exact strength and quirks of each chemical. 7-Chloroheptanoic acid can burn. Emergency showers and eyewash stations in reach make a difference if worse comes to worst. Never eat or drink near the bench—oily hands or contaminated sleeves can bring problems beyond the lab.

Storage: Keep It Contained and Controlled

Acids never belong in the open or near heat sources. This acid’s stability drops near bases or oxidizing agents, and improper mixing fuels dangerous reactions. It’s safest inside an airtight, properly labeled bottle, tucked inside a chemical storage cabinet marked for corrosive substances. Temperatures stay steady, lids remain tight, and the area—preferably well-ventilated—keeps chemical vapors from building up.

Glass containers hold up better than plastic against corrosion. For workplaces without dedicated acid cabinets, at least separate acids from other reactive chemicals. Oversights in labeling lead to mix-ups that nobody wants. Dates and batch numbers help track freshness and store managers know when to replace old inventory.

Spill Response and Waste Disposal

A little preparedness in spill response limits lasting harm. For this acid, spill kits deliver a mix of absorbent pads, neutralizing powders (often sodium bicarbonate), and the right disposal bags. Workers trained in quick, calm response avoid panic that compounds the danger. Never handle drops or puddles without gloves and eye protection already in place—no matter how small the mess. Wash away residues with plenty of water, and remember that drains may not accept chemical waste under local rules.

Waste management depends on more than tossing material in the standard trash. Secure acid containers for pickup by a qualified disposal team, following all regional and national environmental rules. Mishandling disposal can create contamination that lingers in the local water or soil, bringing community health risks.

Solutions and Improvements

Education and training pay off. Annual safety drills built into lab routines keep handling steps fresh. Teams need refresher classes that actually use the chemicals—not just generic videos. That reduces real-world accidents.

Newcomers learn fastest from mentors. Working side by side with a skilled chemist teaches more than a manual can. Everyday caution—checking labels, wiping down benches, locking bottles tight—grows into muscle memory. Over time, the whole team develops sharper instincts for safe chemical work.

Understanding the Risks and Real Needs

7-Chloroheptanoic acid comes with its own quirks. This compound, with its reactive carboxylic group and chlorine atom, asks for more care than simple acids. Most folks don’t keep bottles of this lying around—scientists, lab managers, and process engineers usually know there’s more to it than tossing it on a shelf.

Leaving bottles uncapped or exposed to air invites moisture in. Anyone who’s ever tried to salvage a chemical after too much humidity knows the gritty mess that can happen. Water from the air can cause hydrolysis, breaking the acid down, maybe producing corrosive by-products. Such risks climb if the acid sits in a damp place. Store it in a dry environment to stop all that hassle from starting.

Temperature Matters—Keep It Cool, Not Freezing

Some acids tolerate swings in temperature, but 7-chloroheptanoic acid holds up best in steady, cool spaces. Heat speeds up degradation and the shelf life drops fast in a warm storeroom. I once saw a batch go from clear crystals to an off-color, clumpy mess after a summer weekend outage at a university lab—consistent coolness could have saved that material. Store it at room temperature or bit cooler, but not below freezing. Freezing can crack glass, change the appearance of the acid, or even burst containers in rare cases.

Minimize Light and Air Exposure

Direct sunlight encourages photo-degradation, changing the chemical structure of sensitive compounds like this acid. UV from overhead bulbs can also play a part. Anyone who’s handled light-sensitive materials knows yellowing or breakdown doesn’t take long. Always reach for a brown glass bottle or, at least, keep the container tucked in a closed cupboard or storage box.

Oxygen from the air can slowly help oxidize certain acids. This isn’t the fastest process, but over months, slow changes add up. Always recap the bottle right after use, and try to clear out any air space—some labs introduce an inert gas like nitrogen, though that’s not always practical outside bigger operations.

Use the Right Containers

Storing acids in cracked or reactive containers only shortens their lifespan. Glass works well for most organic acids, especially borosilicate types that shrug off mild corrosion and don’t react the way some plastics do. Polyethylene and polypropylene often stand up to 7-chloroheptanoic acid’s bite, but thinner plastics can leach or get brittle over time. Metal caps or closures sometimes rust, so choose plastic-lined lids or glass stoppers.

Labels, Documentation, and Checks

Skipping labels or ignoring dates leads to real problems. Always mark the bottle with the receipt date and batch number. Write down storage conditions or notes about changes seen during inspections. Regular checks matter—seeing discoloration, changes in smell, or clumps can be an early warning that something’s off.

Reaching for Practical Solutions

Proper storage doesn’t need fancy tech. Basic climate monitoring, diligence in closing bottles, and using the right containers all cut down risk. Semi-annual reviews and using inventory controls stop stockpiles of expired acid from building up. Training team members pays off, especially with compounds like this where stability keeps research safe and reliable.