8-Bromooctanoic Acid: Exploring its Story, Substance, and Significance

Historical Development

Chemistry continues to evolve through decades of trial and curiosity. 8-Bromooctanoic acid owes its discovery to the steady march of organic synthesis. In classic lab notebooks from mid-twentieth century research, chemists mapped out long-chain halogenated carboxylic acids with meticulous care. The story around this molecule started with fundamental studies on fatty acid derivatives and the push for more versatile synthons. Researchers found themselves chasing tweaks that could add reactivity or enhance certain properties. Bromine entered the scene because it delivers a reactive handle and opens doors to downstream chemistry. Interest grew as folks realized this variant could support both academic research and the hunt for pharmaceuticals or surfactants. As large-scale organic libraries blossomed, 8-bromooctanoic acid kept finding new places on chemists’ shelves, shaped by this interplay of curiosity and need.

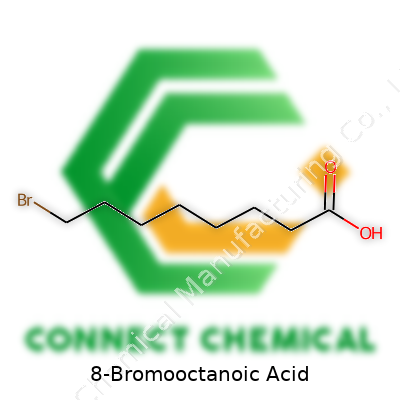

Product Overview

This compound’s name sounds intimidating, but its core structure tells a simple story: an eight-carbon chain, carboxylic acid group on one end, and bromine atom perched at position eight on the other. In the lab, it appears as a colorless to pale yellow liquid or solid, depending on the room’s temperature. Chemists know it for its haloalkane identity, bridging the world of simple fatty acids and functionalized building blocks. Unlike more generic carboxylic acids, this bromine addition gives it gravitas—it transforms a mundane molecule into a route toward further chemical creativity.

Physical & Chemical Properties

A straight chain holds predictable traits. This compound has a melting point often falling below room temperature and a boiling point in the region of 140-145°C at reduced pressure. Its slight solubility in water does not surprise anyone, but it dissolves neatly in common organic solvents like ethanol, ether, and chloroform. That bromine atom stands ready for substitution reactions or nucleophilic attack, yet its position at the far end of a hydrocarbon chain also influences its dangers and charm. Density typically hovers a notch above water, thanks to bromine’s heft.

Technical Specifications & Labeling

Quality standards matter—for reliable lab work, purity often exceeds 98%. Labels specify batch number, net weight, purity level, and storage recommendations. Attention must focus on the expiration date, as halides sometimes react with light or moisture over long storage, shifting quality over time. Suppliers stamp product numbers and standardized identifiers on every bottle: UN number for shipping, CAS registry to streamline cross-checks, and details for safe inventory handling. Even though this acid is not classified among the most hazardous chemicals, careful handling keeps accidents from making headlines.

Preparation Method

Crafting 8-bromooctanoic acid usually starts from octanoic acid or its derivatives. Bromination proceeds through a reaction with molecular bromine or sodium bromide followed by oxidation, sometimes using N-bromosuccinimide in the presence of radical initiators. Often, organic chemists lean into phase transfer catalysts to push yield higher, especially when working at industrial scales. Every step brings chance for side products, so purification—often with distillation or recrystallization—demands patience. Seasoned technicians keep close watch on reaction times and temperatures to balance productivity with safety.

Chemical Reactions & Modifications

Few molecules offer as many synthetic shortcuts as halogenated carboxylic acids. The bromine atom on this chain acts as a welcome sign for a host of nucleophilic groups—amines, thiols, and alkoxides find it irresistible. These reactions carve pathways to amides, esters, or even longer functionalized chains for medicinal chemistry projects. Beyond substitution, reductions can remove the halide, while other modifications might introduce double bonds or aromatic rings. Researchers use the compound not only for creating new materials but as an intermediate in the design of bioactive molecules, ionic liquids, or surfactants.

Synonyms & Product Names

8-Bromooctanoic acid may appear in catalogs or research as Octanoic acid, 8-bromo-, sometimes as Caprylic acid, 8-bromo- or 8-bromocaprylic acid. CAS registry 50827-98-4 brings uniform search results across regulatory documents, purchase orders, and safety datasheets. Alternative labels might include names in French, German, or local market tongues, but the fundamental carbon–bromine–carboxylic structure remains the touchstone for every bottle, no matter its sticker.

Safety & Operational Standards

Safety work in chemistry never feels optional. This acid earns respect not only from its carboxylic group’s tendency to irritate skin or mucous membranes but also from the risk bromine introduces. Inhalation, ingestion, or skin contact invites trouble ranging from rashes to burns. Users dress the part—lab coats, gloves, goggles—in well-ventilated spaces or fume hoods. Waste management practices treat halogenated acids apart from simpler fatty acids due to the potential for environmental impact. Safety data sheets set exposure limits, emergency response steps, and first aid instructions. Consistent training in handling both the liquid and any vapor above open containers shields workers from harm.

Application Area

Industries—fine chemicals, pharmaceuticals, materials science—put this compound to work in several significant ways. Medicinal chemists reach for it to introduce flexibility into drug candidates or build prodrugs that can be further elaborated. As a linker or spacer, it connects functional units in advanced surfactants or helps in the assembly of molecular sensors. The food and cosmetics sectors might explore octanoic acid derivatives for specialty formulation, but the presence of bromine alters regulatory pathways. Some companies focus on laboratory reagents, leveraging the acid to seed synthesis for dyes, ionic liquids, or specialty lubricants. Each jar on a shelf gets used up by researchers chasing new reactions, not rote process chemistry.

Research & Development

Think-tanks and R&D labs keep finding clever ways to upgrade this acid. The presence of a reactive bromine atom encourages new strategies in green chemistry—some groups look for alternatives to classical radical initiators, aiming for less hazardous or more sustainable protocols. The race for improved yields, higher selectivity, and milder conditions draws inspiration from both organocatalysis and enzymatic tools. For every successful step forward, publication of reaction optimization, kinetic profiles, and application case studies keeps the knowledge growing. My own time in academic labs involved running dozens of reactions with similar halo acids—chasing that clean product and learning the quirks of each step. These bench-level experiences shape safer, faster, and more creative use each year.

Toxicity Research

No discussion can ignore the risks. 8-Bromooctanoic acid produces low-to-moderate acute toxicity, with skin and eye irritation among the most reported incidents in lab logs. In animal studies, ingestion or inhalation over a range of doses led to reversible inflammation or lung irritation, but chronic effects remain underexplored. Bromine itself sits higher on the hazard scale compared to its chlorine cousin, so researchers flag every experiment for proper waste treatment and personal protection. Assessment of mutagenicity and carcinogenicity continues, mostly driven by regulatory bodies comparing halogenated and non-halogenated chains. Environmental fate studies focus on biodegradability and the spread of organobromine compounds in surface water, aiming to minimize contamination as use grows.

Future Prospects

Where does the story go from here? With chemistry, answers rarely come easy or in tidy packages. Green alternatives to classic halogenation, new catalytic methods, and smart engineering for safer handling will push the boundaries of what this compound accomplishes. Pharmaceutical routes looking for innovative fatty acid analogues will keep it on the map, especially as precision medicine calls for tailor-made building blocks. Regulatory frameworks may tighten over time, especially around bromine’s impact, nudging inventors to rethink synthesis, waste, and application. There’s momentum in computational chemistry, too, as models predict new derivatives faster than ever. My own outlook comes from years of watching chemicals move from glassware to real-world impacts: the future always holds challenge, uncertainty, and excitement for anyone digging deep into the story of 8-bromooctanoic acid.

Getting to Know 8-Bromooctanoic Acid

8-Bromooctanoic acid isn’t a name that pops up at family dinners or in TV commercials. Still, folks in a chemistry lab know it by sight and smell. With a simple structure—an eight-carbon chain capped with a bromine on one end and a carboxylic acid group on the other—this compound opens doors for experiments that touch drug research, surfactants, and new materials.

A Toolbox for Synthesis

My own time working in research introduced me to chemicals like 8-bromooctanoic acid. In the early years, my desk overflowed with solvents and reagents for trial-and-error projects. I quickly learned that having a versatile compound like this in stock saved days of work. A primary use springs up in organic synthesis, especially in making building blocks for other molecules. The bromine reacts easily and gives chemists a way to stick new pieces onto the carbon chain. That’s crucial if you want to build more complicated molecules without losing your starting material to side reactions.

Applications Stretch Farther Than You’d Think

Drug scientists lean on 8-bromooctanoic acid to design molecules that might show antiviral or anticancer activity. The bromine atom can be traded out for something else, or used to create branching points that turn a boring chain into a candidate for medicine. I once worked next to a team developing inhibitors for enzymes connected to neurological disorders—they needed a way to test how changing one atom in a chain affected the whole system. This acid gave them that chance.

Chemical engineers don’t just stop at medical applications. They use 8-bromooctanoic acid as a raw ingredient in creating surfactants and lubricants. These chemicals affect how substances mix, how oils break apart, and even how cleaning products spread on a surface. It feels strange to realize something cooked up in a flask could influence the way a shampoo lathers or how a machine stays clean.

Toxicity and Handling: Why Safety Matters

Sitting through lab safety briefings taught me never to take short cuts. 8-bromooctanoic acid isn’t classified among the worst offenders, but working with halogenated acids means you watch your step. Direct skin contact can irritate, and you want fume hoods for anything involving bromine. The responsible handling comes from reading studies and employer-mandated protocols, experience that taught me chemical accidents often stem from people getting complacent. Every year, industry journals talk about burned countertops or worse when someone decides to “just pour quickly.”

Room for Improvement

The chemistry crowd continues to search for less hazardous alternatives or methods that cut out bromine waste. Eco-friendly labs swap out halogenated acids where possible and hunt for recycling methods for leftover reagents. This mindset pushes companies to invest in green chemistry not just to save dollars, but to protect workers and reduce cleanup costs.

In the end, 8-bromooctanoic acid stands as more than a mouthful in a chemistry catalog. It brings opportunities and, like all reagents, calls for respect and practical solutions on the way to discovery.

Turning a Name Into a Structure You Can Picture

Ask chemists about 8-Bromooctanoic acid, and most will quickly say, “That’s an eight-carbon fatty acid chain with a bromine atom at one end.” For those tackling chemistry or curious about what goes into common laboratory reagents, this structure looks simple, but each atom brings its own purpose. The formula spells it out: Br(CH2)7COOH. If you draw it out, you’ll see a bromine stuck to the very first carbon, then a run of seven methylene (–CH2–) units, and then a familiar carboxylic acid group at the end. It’s not just a lab curiosity—this molecule teaches us how chemistry’s basic rules end up shaping entire industries.

Why This Molecule Matters

Stack up molecules like 8-Bromooctanoic acid in a university lab, and you’ll spot them at the starting line for much bigger syntheses. Their layout—long hydrocarbon tail, reactive ends—lets organic chemists tweak or modify other, much more complicated molecules. Bromooctanoic acids act as nucleophilic partners in substitution reactions. Once you’ve got that electronegative bromine in place, you can swap it for other atoms, attach different chemical groups, and build something new.

It’s not just academic tinkering. Companies and researchers use 8-Bromooctanoic acid as an intermediate for surfactants, pharmaceuticals, and even materials science. Take the bromine at the end off, or turn it into another functional group, and suddenly you’re looking at a suite of building blocks for other synthetic paths—fatty acid derivatives, specialty plastics, even antimicrobial agents. Plenty of progress in drug design, especially when exploring new antibiotics or enzyme inhibitors, builds on chains like this one.

Handling and Hazards: The Side of Chemistry That Needs Respect

Working with 8-Bromooctanoic acid in the lab means more than just memorizing its formula. The carboxylic acid group brings acid properties, so gloves and goggles land on the essential list. The long hydrocarbon tail makes it less soluble in water and more likely to stick to organic solvents. The bromine atom poses its own risks—compounds with organic bromine have a history of irritating respiratory systems or even acting as environmental hazards if not managed carefully. Reading material safety data sheets before opening a bottle remains a true ritual, especially for chemists passionate about safety.

Chemical Structure’s Role in Modern Science

I watched classmates get stuck on small details of molecules like this—some guessed wrongly about where the bromine slipped into the chain, others missed how a small structural shift changes reactivity. Once you understand where each atom sits, the next steps in reaction planning and hazard assessment flow a lot more smoothly. Countless mistakes in research or commercial projects start from not nailing down the correct structure early in the game.

Drawing and recognizing structural formulas in class or the lab helps sharpen the skills needed for synthetic research. It also reinforces the value of connecting textbook chemistry with real-world impacts: the reliability of lab tools, the safety of consumer goods, and even breakthroughs in treating disease. For anyone working with molecules, the story behind 8-Bromooctanoic acid says as much about the process of science as it does about the substance itself.

Why Safe Storage Calls for Careful Steps

8-Bromooctanoic acid might not land on people’s radar like common table salt or vinegar, but anyone involved in chemistry recognizes its real weight in research and manufacturing. My first experience handling this compound in a university lab stuck with me. One misplaced jar and the whole room filled with worrying fumes. That memory hammered home the fact that storing 8-Bromooctanoic acid is about more than just putting a bottle on a shelf. It’s about protecting everyone in and around the workspace.

Straightforward Rules for Storing 8-Bromooctanoic Acid

Clean, consistent storage safeguards lives and preserves the quality of every chemical, especially the ones like 8-Bromooctanoic acid. Temperature plays a big role. Most sources agree that cool—think between 2°C and 8°C—keeps things stable and slows any reactions that could brew trouble. Even in my stints in different labs, we’d crowd some chemicals into shared fridges, just to avoid the risk of heat and humidity.

Dry air wins every time. Moisture in the air speeds up reactions, leading to degraded material and even dangerous byproducts. A tightly sealed container, preferably with a desiccant pouch, cuts out this risk. I’ve watched humidity ruin well-sealed samples after a single hasty cap — so double-check those lids.

Light has always posed danger to light-sensitive compounds. 8-Bromooctanoic acid doesn’t top the list of photo-reactive substances, but constant sunlight or strong overhead lights set off reactions that break down the acid and ruin results. Opaque or amber-colored bottles, stored deep in a cabinet, give much better peace of mind.

Keeping Chemistry Safe: People and Process

Labeling takes hardly any time but saves worlds of confusion. Clear, permanent labels with names, concentrations, and hazard markings keep even experienced professionals out of trouble. In my own work, a missing date or faded label once led to an expensive round of waste disposal for what turned out to be a perfectly usable batch.

The spot you pick for storage should always keep acids away from bases, oxidizers, and flammables. Chemical segregation rules exist for a reason. I recall one incident—someone left a bottle of organic acid near a container of bleach. The cleanup lasted all afternoon, and the memory stuck. Stick to locked, ventilated cabinets for every bottle of 8-Bromooctanoic acid.

Routine inspections catch issues early. Containers crack, seals split open, and inventory numbers fade fast in busy spaces. Once a week, a quick check of each shelf saves thousands of dollars in lost material and even greater costs in accident claims.

Paths to Better Practices

Strict training keeps best practices alive. No new staff member ever felt ready to handle acids after a PowerPoint. Real safety comes from hands-on demonstration and supervision. Whether in a research setting, industrial site, or campus lab, a culture of sharing experience and prioritizing safety stops mistakes before they start.

Simple changes—better labels, inventory logs, reliable containers—add up. Most of the worst accidents I’ve witnessed came from rushed routines or trying to save a few minutes. In working with substances like 8-Bromooctanoic acid, a little extra care doesn’t just follow the rules. It proves respect for every person sharing that workspace.

Direct Contact Can Cause Trouble

Few people outside a lab know what 8-bromooctanoic acid looks like, but its hazards are real for anyone working with it. This chemical irritates the skin, eyes, and respiratory tract. Even small splashes to the eye can quickly turn a normal day into an emergency. Once, I watched a careful chemist rush to the eyewash after a drop hit his cheek, which started burning within seconds. It’s not a matter of bravado—nitrile gloves and face shields matter.

Why Ventilation Matters

Volatile fumes from this compound smell sharp and chemical, and inhaling them can spark coughing or worse. People sometimes cut corners and think the risk is overblown, but just one mistake can lead to headaches or labored breathing. Fume hoods aren’t just a suggestion—they’re a frontline defense. It’s worth double-checking the airflow before each use; I once saw a hood labeled “Working” sputter out after a filter clogged. That could have gone badly.

Don’t Ignore Spills—Cleanup Is Critical

Small spills might look harmless, but they spread vapors fast and soak into surfaces. Corners of research benches often turn sticky, and I’ve learned to always grab a chemical-resistant mat before opening a bottle. Spills should be covered with absorbent pads and then wiped using a detergent and plenty of water. Gloves, goggles, and a lab coat offer layered protection, but you still want to keep containers sealed tight, storied at room temperature, and away from direct sunlight.

Know Your Storage Spaces

Storing 8-bromooctanoic acid on a random shelf invites trouble. It reacts with strong bases and oxidizing agents, risking heat and dangerous byproducts. Keeping it in a clearly labeled, dedicated cabinet keeps people and other chemicals safe. If a bottle starts to discolor or build pressure, it’s time for safe disposal. I’ve seen improperly stored bottles develop crusty residues—never open those. Call the hazardous waste team immediately.

Stay Prepared for Mishaps

Emergencies don’t announce themselves, but planning for them saves time and nerves. At every lab I’ve worked, a safety shower and eyewash station stand by the door. Training matters—everyone should know how to use them, where spill kits are, and whom to call for help. Regular drills keep the memory sharp and cut down on panic if something goes wrong.

Responsible Use Starts With Education

Working with chemicals demands respect, not fear. Safety Data Sheets contain information that saves lives, yet they often collect dust until a problem pops up. Take ten minutes before a new procedure to read through them. Let everyone in the lab know about risks, and never assume someone else already handled it. Team culture makes the most difference. Open discussions about safety help catch blind spots, such as an overlooked open bottle or missing glove.

Technology Is Only Part of the Solution

Personal protective equipment shields against the immediate danger, but habits and vigilance do more over the long haul. Simple routines like cleaning up each day, double-checking labels, and reviewing safety protocols make labs better for everyone. A colleague once joked that safety “slows you down,” but good habits actually speed up recovery and productivity after an incident-free year.

Practical Steps Save Lives

Respecting 8-bromooctanoic acid means treating every use like it matters. Get the right gear, stay alert, talk to your team, and make safety a non-negotiable part of the job. Lives and careers depend on it.

Real Value Behind High Purity

In chemical research and industry, you quickly learn the importance of purity in every reagent. With 8-bromooctanoic acid, purity isn’t just a checkbox. For anyone synthesizing pharmaceuticals, running precision reactions, or just trying to keep consistent project results, quality matters every single time.

In the market, the specification of 8-bromooctanoic acid can make or break your workflow. Most reputable suppliers stick to a purity of at least 98%. That leaves minimal room for contaminants and helps support reliable outcomes, especially in synthesis where odd by-products seriously mess up results. If you’ve ever experienced an unexplainable side product in your data, there’s a good chance impurities in your reagents caused it.

Digging Into Typical Specifications

8-bromooctanoic acid usually comes as a white to off-white solid, sometimes a powder or crystalline form. Melting points generally fall between 47°C and 51°C, and any deviation hints at the presence of unwanted material, often overlooked until it’s too late. Most trusted suppliers will back up their specs with an assay—like HPLC or NMR—that spells out the purity, often showing a clean 98% or better, as well as reporting on moisture content and trace metals which can skew results if left unchecked.

Water content rarely rises above 0.5%. Anyone who’s fought with hydrolysis or decomposition issues in organic chemistry knows water’s a silent problem-maker. Residual solvents get flagged and kept within very tight limits since those can trigger unforeseen side reactions in more delicate experiments. Each lot gets a certificate of analysis, and from experience, anyone skipping over this paperwork will miss major quality cues.

Why Stringent Specification Matters

Pharmaceutical research, custom synthesis, and advanced materials all benefit from confidence in their ingredients. For researchers, a single slip in purity cascades into lost time and unreliable results. Take it from someone who’s trouble-shot enough dead-end syntheses: knowing your 8-bromooctanoic acid meets published standards will save hours of wasted bench time. Details on melting point, spectral analysis, and even packaging type (amber vials to block light) come from generations of practical feedback and problem-solving on the lab floor.

Some manufacturers invest in advanced purification, like column chromatography, and ensure batches avoid cross-contamination during handling. This isn’t just hype—it’s a cornerstone for reproducibility. Lower-grade chemicals find a place in teaching labs, but for anyone pushing boundaries, high-purity reagents matter more than any flashy instrument upgrade.

How to Avoid Pitfalls

Before choosing a supplier, do more than just check the purity percentage. Ask for a recent certificate of analysis. Trust suppliers who track down and report impurities, not just the main component. Look up user experiences online, maybe even reach out to colleagues. If you spot a jump in your failed reaction rates, compare your batch certificates with a reliable one. Sometimes the tiniest difference in supplier technique explains months of irreproducible data.

As a chemist who’s seen both rushed and careful sourcing, cutting corners on specification never pays off. When teams prioritize these details, discoveries follow—and so do real industry breakthroughs that make a difference beyond lab walls.