Allyltriphenylphosphonium Bromide: A Detailed Exploration

Historical Development of Allyltriphenylphosphonium Bromide

Chemistry often builds on practical need, and the roots of allyltriphenylphosphonium bromide stem from classic research in organophosphorus chemistry during the mid-twentieth century. Back then, scientists looked for better ways to construct carbon–carbon bonds, especially in molecules where controlled reactivity and stability made all the difference in yield. The Wittig reaction turned heads, and researchers gravitated toward phosphonium salts as both intermediates and reagents. Over time, labs recognized that the unique properties of the allyl group paired with the sturdy triphenylphosphonium cation made this compound useful beyond its original niche. I remember my own early graduate days, mixing phosphorus(V) reagents and watching them shape projects headed for pharmaceutical or agrochemical pipelines. The discovery and steady improvement of production methods for compounds like allyltriphenylphosphonium bromide point to a culture where chemists expected hands-on, reliable results—something that still matters today.

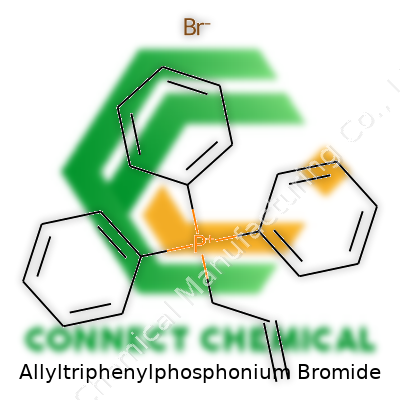

Product Overview

Among specialty chemicals, this salt stands out for its versatility. Workers in synthetic organic chemistry keep allyltriphenylphosphonium bromide stocked in their cabinets alongside more familiar salts. Its structure combines the nucleophilic character of an allyl group with the stability of triphenylphosphonium, making it a reliable platform for research and industry applications. Its CAS number is 2741-28-6. It's not just an intermediate; it brings unique reactivity for carbon skeleton building, which matters when you're planning multi-step syntheses or coupling transformations. Triple-checking for batch purity, those who source this compound turn to it out of habit, seeing how it plugs into numerous reaction schemes.

Physical & Chemical Properties

As a white to off-white crystalline solid, its appearance rarely surprises. Its melting point usually falls between 200°C and 205°C, helping users spot contamination or mislabeling early in a project. The substance dissolves best in polar solvents like dimethyl sulfoxide and acetonitrile, reflecting its ionic character. It doesn't give off much odor or vapor, so problems like inhalation are less common than with volatile organics. The molecule itself carries a hefty triphenylphosphonium backbone, so storage rarely needs anything unusual—just a dry, tightly sealed container away from direct sunlight. From experience, compounds like this handle well in glove boxes, letting you weigh and mix without worrying about sudden reactivity with air or moisture.

Technical Specifications & Labeling

Reliable suppliers provide details like a minimum purity of 97% by weight, alongside batch numbers and expiry dates. Labels often come with hazard pictograms and warnings about skin and eye contact. Packages, usually amber glass or double-layered polymer, prevent chemical degradation. I've seen researchers ignore the fine print, leading to confusion about solubility or unexpected batch-to-batch variations. It's important to scan for the typical spectrum—NMR, IR, and MS data—so you know exactly what you're working with. Transport rules for this material aren't as strict as they are for more reactive organophosphorus compounds, but shippers follow UN classification details just in case.

Preparation Method

Classic routes use triphenylphosphine and allyl bromide, combined under controlled temperature and inert atmosphere to avoid side reactions. Stirred together in polar solvents, the reactants yield the desired salt after a few hours. Washing and recrystallizing the product in ether or ethyl acetate kicks out much of the byproduct, especially excess halide. Scaling up for industry, operators adjust temperature and mixing rates to avoid local overheating or incomplete conversion. In my experience on the bench, this synthesis rarely fails when you control the rates and keep moisture out of the system. Any shortcuts—like cutting corners on drying glassware—usually invite trouble, from impure product to poor yields.

Chemical Reactions & Modifications

Allyltriphenylphosphonium bromide finds its main use in Wittig-type reactions, where it helps researchers stitch together new carbon–carbon bonds. With a handy phosphorus ylide, chemists can attack aldehydes or ketones, forming substituted alkenes with precise placement of double bonds. The allyl group introduces extra flexibility, often letting you install vinyl or homoallylic fragments into bigger molecules. Beyond basic C–C bond formation, the salt enters roles as a phase-transfer catalyst or the starting point for further functional group manipulations. Strong bases—potassium tert-butoxide or sodium hydride—pull out the acidic hydrogen, letting the phosphorus ylide form in situ. I've run these reactions under both academic and industrial conditions, finding their reliability a big selling point for scaled-up synthesis.

Synonyms & Product Names

Depending on the catalog or country, this compound shows up as (Allyl)triphenylphosphonium bromide, Triphenyl(allyl)phosphonium bromide, or its IUPAC name: allyl(triphenyl)phosphanium bromide. International suppliers each put their own spin on the trade name, but chemists worldwide recognize the structure from the core elements—triphenylphosphine, allyl, and bromide anion. In the literature, search engines spot synonyms like Ph3PCH2CH=CH2 Br or even the German style names favored by some European vendors.

Safety & Operational Standards

Lab workers learn the importance of gloves, goggles, and fume hoods early in their careers. Material safety data sheets mark this salt as an irritant, warning against eye and prolonged skin contact. Inhalation risk is low, though dust formation in poorly ventilated spaces still deserves respect. I recall a mishap where oil from an impure batch spread a small amount on a glove—prompt handwashing avoided allergic or inflammatory reaction. Disposing of excess or contaminated allyltriphenylphosphonium bromide takes careful attention to local hazardous waste rules, as both phosphorus and bromide residues pose challenges for water treatment systems. Automated storage cabinets help reduce exposure and lower the risk of mixing with strong oxidizers or reducing agents by mistake.

Application Area

Outside the textbook, allyltriphenylphosphonium bromide brings value to people working on natural product synthesis, medicinal chemistry, and materials research. In academia, it stars in multistep reaction routes where introducing an allyl group at just the right position unlocks a pathway to complex targets like macrolides or alkaloids. Pharma companies might use it to decorate drug candidates or tailor molecules for better metabolic stability. In polymer science, it serves as a linker or precursor in specialty materials with tunable double bond placement. Year after year, patents name this compound in procedures for new drugs, dyes, or fine chemicals, showing that its reputation keeps pace with changing trends in synthesis technology.

Research & Development

Labs around the world keep pushing the boundaries of what allyltriphenylphosphonium bromide can do. Researchers explore green chemistry variations, swapping traditional solvents or bases for less toxic options. Some projects screen renewable or biobased sources for the triphenylphosphine core, seeking ways to lower the environmental footprint. Instrumental advancements make high-throughput screening of Wittig reactions faster and more reliable. Collaborations between universities and industry partners investigate analogs with new functional groups, fine-tuning reactivity to open doors in drug discovery or agrochemical development. My own work with automated reactors and data logging has shown how process intensification and digital control sharpen the yields and purity profile, saving time and money at scale.

Toxicity Research

Allyltriphenylphosphonium bromide remains a low-moderate toxicity risk according to animal studies. Direct ingestion or high-dose exposure irritates digestive systems, while repeated skin or eye contact causes inflammation or sensitization in both researchers and animal models. Phosphonium ions tend to interfere with cell membranes and block normal enzyme activity, a fact that draws the attention of toxicologists in regulatory bodies worldwide. Environmental monitoring shows that wastewater carrying triphenyl derivatives builds up slowly in aquatic systems, with minimal but persistent threats to small organisms. I've noticed more emphasis on closed-system handling and proper waste neutralization, especially for large-scale operations near urban water tables.

Future Prospects

Demand for robust, multi-role reagents stands strong as chemists chase sustainability, efficiency, and lower costs. Allyltriphenylphosphonium bromide checks boxes for reactivity, shelf life, and clear outcome control. Future work likely focuses on greener synthesis routes—perhaps flow chemistry setups where exposure to hazardous intermediates drops and energy input shrinks. Recycling steps for byproducts and solvent recovery gather steam, driven by stronger government rules and higher raw material costs. In my view, expect more crossover into electrosynthesis and photochemistry, where the unique charge and bond structure of this compound unlocks new reactivity. As software-driven tools grow in labs, rapid virtual screening blends with hands-on chemistry, promising new modifications and faster routes to market for everything from pharmaceuticals to next-generation plastics.

Why Chemists Pay Attention to Allyltriphenylphosphonium Bromide

Digging into specialty chemicals, some names don’t pop up much outside labs, but mean a lot behind research doors. Allyltriphenylphosphonium bromide landed on my radar during a stint in a university organic synthesis group. Most folks outside chemistry don’t realize compounds like this serve as tools, bridges, and stepping stones for making bigger, more useful molecules. This chemical doesn’t grab big headlines, but those working in fields like medicinal chemistry or materials research know its value.

Used in Core Chemical Reactions

Allyltriphenylphosphonium bromide’s main claim to fame comes in the form of the Wittig reaction. That reaction forms carbon-carbon double bonds—essential for building everything from pharmaceuticals to plastics. By bringing together phosphonium salts like this one with aldehydes or ketones, chemists can create alkenes that show up as building blocks in countless modern innovations. Looking around the lab, shelves often hold triphenylphosphine and its derivatives, because they often lead to high purity, predictable results in synthesis.

Helping Medicinal Research Break New Ground

During my own research, the focus was often on constructing molecules with biological activity. Synthesizing a specific segment of a hormone or inhibitor, for example, meant starting with available pieces. Allyltriphenylphosphonium bromide’s unique structure helps push these puzzle pieces together, enabling targeted modifications without too much scrambling of sensitive parts. For teams chasing a new drug molecule, this chemical gives a reliable shortcut, reducing the time and cost that usually comes with trial-and-error methods.

Facilitating Advanced Materials Science

Outside the pharmaceutical sprint, material scientists appreciate this compound for similar reasons. Developing a new polymer or exploring novel nanomaterials often means assembling complex structures from the bottom up. The ability to introduce a double bond exactly where it’s needed, thanks to this phosphonium salt, means fewer steps and less waste. Over years in the lab, I saw that flexibility ripple out into quicker prototype development and, for some, new patent filings.

Safety and Environmental Questions

Like many specialty chemicals, Allyltriphenylphosphonium bromide isn’t something to handle carelessly. Phosphonium salts can present toxicity concerns, both for those making them and for lab techs using them daily. Proper ventilation, gloves, and safe disposal processes stay at the forefront. Industry moves toward greener chemistry have started pushing for alternatives—safer reagents, or ways to recycle these catalysts. Anyone involved with their use keeps up with changing guidelines from regulatory agencies and keeps an eye out for less harmful options that don’t sacrifice quality.

Looking Toward Better Solutions

Inspired by my own mentors and the push for safer lab spaces, I see the field changing. Researchers hunt for substitutes that keep reactions efficient but lower risk for humans and the planet. Whether by shifting to phosphine-free processes or engineering new flow-chemistry methods, this drive keeps shaping lab life and industry standards. Faster knowledge sharing means improvements spread quickly, letting modern chemistry do more with less harm and expense. Allyltriphenylphosphonium bromide may seem obscure outside academic circles, but its story shows how chemical innovation underpins progress in science, medicine, and tech.

Looking Closely at Allyltriphenylphosphonium Bromide

Allyltriphenylphosphonium bromide stands out in the laboratory for its usefulness in organic synthesis, especially when working on Wittig reactions. The name might sound heavy, but its core is based on solid chemistry. This compound’s chemical formula is C21H20PBr, which breaks down as 21 carbons, 20 hydrogens, one phosphorus, and one bromine atom. Its formula truly tells the story about how the molecular structure holds together: an allyl group attached to a triphenylphosphonium center balanced by a bromide anion.

Why the Numbers Matter

Molecular weight isn’t just a trivia question for a chemistry exam. For Allyltriphenylphosphonium bromide, the molecular weight measures about 399.27 g/mol. That number shapes how you handle this compound in the laboratory. If you’re preparing stoichiometric calculations for a synthetic route, using an incorrect molar mass means your results will slide off course. Years ago in graduate research, a slip in weighing out a phosphonium salt threw off a reaction yield—small changes in mass made a big dent in both time wasted and lab resources spent. Accuracy starts with respecting these numbers.

Crossroads: Synthesis and Role in Organic Reactions

This chemical proves essential in the preparation of alkenes. The presence of the allyl group gives it a unique twist compared to ordinary triphenylphosphonium salts. Chemists often depend on these compounds for the Wittig reaction, where they help to connect carbon atoms and build more complex molecules. The ease of forming ylides and their reliability set this compound apart for those crafting tailored molecular architectures. Research published in Organometallics illustrates how allyltriphenylphosphonium salts expand the scope of olefination strategies, especially for difficult substrates.

Safety and Handling: Respect the Hazards

It’s not exciting to think about safety data sheets, but ignoring them leads to injury and failed experiments. Bromide salts like this one come with real risks. Mishandling phosphorus compounds usually means irritant or toxic exposure, especially if fine powders release dust. Gloves, goggles, and attentive lab habits become more than guidelines—they’re what makes sure you clock out of the lab with health intact. Data from chemical manufacturers and the European Chemicals Agency emphasize handling with care because exposure symptoms can sneak up and slow down productivity (and, more seriously, health).

Environmental Concerns

Aside from human safety, disposal is a topic that doesn’t always get enough daylight in chemistry classrooms. Brominated organics don’t just disappear with a rinse down the drain. Waste management must match regulations, or you risk leaching harmful substances into water supplies. Here, developing green chemistry alternatives or using safer, less toxic analogs can support both laboratory safety and environmental stewardship. Growing initiatives in academia, like solvent recycling and microscale synthesis, have started to chip away at these long-standing challenges, but widespread adoption remains spotty.

Where We Move Forward

In short, the formula C21H20PBr and its molecular weight drive more than abstract chemical equations. These facts affect scientific progress, personal safety, and environmental decisions. As the chemical industry leans toward responsible practices, knowledge of what’s inside each flask sets the table for creative solutions, safer protocols, and a future where innovation never comes at the cost of carelessness.

Why Proper Storage Matters

Some chemicals don’t demand much attention. Allyltriphenylphosphonium Bromide is not among the easy ones. A few years ago, after a colleague stored a similar compound too close to sunlight, the pile of clumped powder reminded me how important it is to take storage details seriously. Skipping steps with this one can turn a research routine into a headache, and actually end up risking health, wasted supplies, and lab time.

Keeping It Cool, Dry, and Dark

Moisture and heat get into so many chemical disasters. Allyltriphenylphosphonium Bromide tilts closer to the group of powders that can slip up fast with a blast of humidity or a sunbeam streaming through the window. Any lab storing this chemical usually learns fast: room temperature works, but you want dry and dark conditions. A desiccator isn’t just a luxury – it’s a need. Seal the chemical tightly, double-bag if the container feels old, and keep it far from water or steam sources. Even a damp shelf can ruin a good batch.

Labeling and Responsibility

Good labeling is more than following safety rules. Chemical shelves turn into confusing graveyards after a few weeks if things aren’t clearly marked. Nobody wants to play chemical roulette. For Allyltriphenylphosphonium Bromide, clear, dated labels with the full name and hazard warnings stay critical. In my old lab, that simple extra effort stopped mix-ups more than once, let us track shelf life, and nudged the next shift to stay on top of checks.

Why Ventilation Isn’t Just About Comfort

Many researchers put more faith in fume hoods for reactions, less for basic storage. Even if Allyltriphenylphosphonium Bromide sits quiet most of the time, keeping the storage spot well-ventilated makes sense. Some dust in the wrong place or spilled powder on a careless day can mean trouble, especially as some people show skin or breathing sensitivity. I always keep spill kits close, put on gloves and a dust mask—even if I only expect to open the jar for a second. That habit has saved me from annoying rashes and lots of cleanup work.

Fire Safety and Chemical Compatibility

Stashing Allyltriphenylphosphonium Bromide away from open flames or heat sources isn’t just about following rules—it’s real-world safety. It’s flammable; nobody wants a fire, especially with solvents stored nearby. Keep oxidizers, reducing agents, and strong acids off the same shelf. Quick checks and keeping inventory lists in my workspace let me spot dangerous mixes before they turn into bigger problems. Years in a busy lab taught me that a single slip with shelf order can mean disaster later.

Staying Up to Date

Keeping up with fresh information from reliable sources like chemical suppliers or Material Safety Data Sheets (MSDS) doesn’t get old. A strong safety culture builds around these habits. I don’t lean on memory or routines for changes—updated storage tips or hazard details sometimes slip through the cracks if people settle into autopilot. Anyone new to the lab, or just coming back after a few months, benefits from a 5-minute review of safe storage guides and updated shelf maps.

Conclusion: Make Safety a Habit, Not a Checklist

Careless storage decisions with Allyltriphenylphosphonium Bromide can wreck samples, shut down experiments, and put real safety at risk. Small actions—dry shelves, tight seals, clear labels, and regular reviews—work better than any big poster or safety drill. In my labs, it’s the hands-on habits that protected us and made the science work. No chemical, especially one with sensitivity like this, deserves routine treatment. Storage isn’t a back-burner detail; it’s a frontline job worth doing right every single time.

Why Safety Matters

Working in a chemistry lab for years, safety guidelines become second nature. Chemicals like allyltriphenylphosphonium bromide don’t often show up in everyday conversations, but those who handle them know you can't let your guard down. This compound pops up during organic synthesis, especially for reactions involving phase transfer catalysts. It looks harmless at first glance, but hazards don’t always shout their presence.

Hazards Lurking Behind the Formula

Allyltriphenylphosphonium bromide brings a few risks to the table. The substance can cause skin and eye irritation on contact. Breathing in the dust may prompt respiratory issues, and there’s no sense pretending people don’t sometimes skip their mask or gloves out of habit or haste. Exposure, even at low levels, eventually stacks up. Just because no alarm bells ring right away doesn’t mean the body isn’t picking up damage.

Workers sometimes trade stories about minor exposures that led to burning eyes, coughing fits, or rashes. The reality is that repeated carelessness can lead to chronic issues. That's not fear-mongering—it's the lesson from long hours spent cleaning up other people’s spills.

Recognized Risks and Official Guidance

Government agencies and chemical suppliers keep data sheets for substances known to bite back. Peer-reviewed research shows phosphonium salts like this compound can disrupt cellular processes if ingested or inhaled in large quantities. Allergic reactions sometimes occur, especially among those already prone to sensitivity.

The Environmental Protection Agency tracks chemicals such as this one for their potential to cause harm if mismanaged. Its registration as a hazardous substance isn’t based on guesswork but real lab and industrial incidents. There's a reason storage and handling protocols spell out the details for even a single gram.

Real-World Safety Practices

I’ve never met a chemist who regretted wearing goggles or gloves—just those who skipped one or the other. For this compound, full nitrile gloves and anti-fog goggles make sense. Dust mask or respirator? Only a rookie thinks they look foolish in one. A seasoned handler cares more about their lungs.

Ventilation helps a lot. Fume hoods catch particles before they get into your airway. Keeping work benches tidy and cleaning spills right away saves hours down the line and prevents that accidental contact people assume only happens to “someone else.” Containers with clear labels and chemical-resistant seals avoid accidental mixing and spills.

Dealing with Spills and Disposal

Spills, even minor ones, need immediate cleanup using absorbent materials and disposable wipes. Avoid pouring remnants down the drain, as waste management rules require hazardous substances go through special disposal routes. I watch colleagues double-bag materials before dropping them at the designated disposal centers, a routine drilled into us by workplace inspections.

Training Makes the Difference

Inconsistent safety habits spark the kind of incidents that make headlines. Proper training offers a buffer between chemicals and preventable accidents. Refresher courses aren't just box-ticking exercises; they remind staff how quickly things can go wrong. Honest conversations about mistakes build a culture where people speak up if something looks off. That heads-up can be the difference between a near-miss and a hospital visit.

Building Confidence Through Precaution

Most people would never enter a construction site without a hard hat. Chemical labs deserve that same respect. This isn’t about fear—it’s about treating substances like allyltriphenylphosphonium bromide for what they are: potentially hazardous when mishandled, entirely manageable with care. From the perspective of someone who’s cleaned enough messes, prioritizing safety saves time, health, and peace of mind every day in the lab.

A Look at Purity

People working in chemistry and material science rarely get excited by a name like Allyltriphenylphosphonium Bromide, but the details of its purity demand attention. Purity affects research outcomes, product development, and even the repeatability of experiments. In my years in the lab, I’ve handled this compound more than once, and purity hovered above every project, almost like an unwritten contract between researcher and reagent.

Most commercially supplied Allyltriphenylphosphonium Bromide usually arrives at 98% or higher purity—sometimes up to 99% from reputable sources. That means impurities are down to traces, enough to avoid trouble for organic syntheses, particularly when planning a Wittig reaction or using it as a phase-transfer catalyst. What makes these numbers more honest is the batch-specific certificate of analysis attached to each shipment, something crucial for anyone comparing suppliers.

Lower purity grades can bring headaches: unwanted byproducts, poor yields, or unreliable reaction profiles. During my own research on phosphonium salts, even a one percent dip in purity threw a wrench into a multi-step synthesis, contaminating intermediates and forcing me back to the start. Contaminants like triphenylphosphine or residual starting materials can jump into reactions uninvited. They slow progress and spark doubts about results. For companies producing this compound, they use chromatography and crystallization to raise the bar on purity, checking everything with NMR, IR, and elemental analysis.

Physical Appearance: What You See Matters

Physical appearance tells plenty at a glance. Pure Allyltriphenylphosphonium Bromide forms white to off-white crystalline powder. Sometimes batches show a faint yellow tint; that usually tells you about leftover unsaturated hydrocarbons or oxidized impurities. A yellowish hue signals a quality dip, or maybe poor storage—moisture and air can slowly color the crystals. I’ve learned to reject anything clearly yellowish; the color isn’t just cosmetic, it signals potential trouble in later chemical steps.

The powder sinks in a jar, tightly packed or just slightly clumped, depending on humidity or static. Grain size gives clues about the synthesis and drying method. Granular powder often points to careful recrystallization and drying, which usually means better purity. Clumping or stickiness can happen if the compound’s been left exposed to high humidity. Keeping it in sealed containers, tucked away from light in a desiccator, worked best for me.

Unlike some compounds that show signs of degradation quickly, good Allyltriphenylphosphonium Bromide holds up well in storage if properly sealed. Nonetheless, periodic checks for color change or odd smells can keep surprises at bay.

Why Purity and Appearance Matter

If a research group or industry lab chases tight yields, precise mechanisms, or new catalysts, even minor impurities can create questions nobody wants. Batch-to-batch consistency still challenges suppliers, despite improvements in manufacturing techniques. For critical projects, ordering analytical data alongside the compound, and screening in-house with TLC or NMR, goes a long way in skipping frustration.

Quality control tools have gotten smarter. Some companies now offer blockchain tracking of their reagents. For an old hand used to hand-written labels, seeing this level of documentation brings confidence. Better traceability and openness about synthesis methods could push standards even higher.

Allyltriphenylphosphonium Bromide offers lessons beyond its chemistry: small impurities can have big impacts, and quick evaluations—by eye and by test—will save both time and money. In the end, purity and clear crystals remain essential, no matter how familiar the substance seems.