Allyltriphenylphosphonium Chloride: A Practical Look at Its Journey and Role in Science

Historical Development

Chemists started isolating small organophosphorus compounds more than a century ago, drawn by the curious ways phosphorus bonds to carbon. Soon after triphenylphosphine hit the scene, folks explored how its reactivity could be tuned by adding different groups. Allyltriphenylphosphonium chloride came from those efforts. In the 1950s and 1960s, researchers at universities in Europe uncovered robust methods to combine allyl halides with triphenylphosphine, using mild heat and classic glassware. Papers from that era still turn up when digging for reaction protocols, showing how some foundational chemistry rarely fades entirely from view.

Product Overview

Allyltriphenylphosphonium chloride serves as a versatile intermediate in organic synthesis. The white or off-white powder usually gets delivered in tightly sealed glass or high-density polyethylene containers. Researchers gravitate toward it for the strong nucleophile-accommodating phosphonium center and the flexible allyl chain. Across labs small and large, this compound shows up on “most used” shelves, especially for folks synthesizing complex architectures or developing pharmaceuticals.

Physical & Chemical Properties

Lifting the cap on a bottle of this salt reveals a solid with a slight, pungent odor that signals the allyl group’s presence. Melting point typically sits in the 220–230°C range; it’s stable when kept dry and away from strong light. Its solubility favors polar solvents like acetonitrile and water, but less so in non-polar systems. With a triphenylphosphonium backbone, the compound holds a permanent positive charge, which helps in binding and reactivity. That charge matters, since it steers the molecule into electrophilic chemistry and makes the salt compatible with a broad set of ionic reaction conditions.

Technical Specifications & Labeling

Commercial bottles often display purity ratings north of 98%, with labeling that points out batch number, date of manufacture, and a warning about moisture uptake. Reputable suppliers tie certificates of analysis to each shipment, showing NMR and sometimes mass spectrometry data. Specification sheets focus on chloride counterion content, moisture, and the absence of related phosphonium salts. I’ve noticed that QA departments in many chemical companies now reject shipments missing this level of detail, especially if workers rely on reproducible results for FDA submissions or fine chemicals.

Preparation Method

Synthesis of allyltriphenylphosphonium chloride usually means mixing triphenylphosphine with allyl chloride under anhydrous conditions. In my own graduate work, I followed the classic Staudinger route: slightly excess allyl chloride, reflux in dry solvents such as toluene, tight exclusion of water. The reaction produces triphenylphosphine allyl salt and hydrochloric acid, which must be handled with care. Filtration and recrystallization remove unreacted reagents and side products. Many labs recycle solvents, which cuts down on waste and costs.

Chemical Reactions & Modifications

The phosphonium center gives a foothold for Wittig-type reactions—a key step for forming carbon-carbon double bonds, especially for building complex organic molecules. Chemists often pair it with strong bases to produce ylides, then react those with aldehydes and ketones. In the hands of skilled practitioners, allyltriphenylphosphonium chloride unlocks synthetic routes not accessible by other salt forms. Its structure also makes it a springboard for further modification—substituting or extending the allyl group can lead to a cascade of new molecules, some of which end up in medicinal chemistry programs or advanced materials.

Synonyms & Product Names

Shoppers in the catalog world search for names like Triphenylphosphonium, allylchloride; Allyltriphenylphosphonium chloride; or TPPA chloride. Trade names don’t drift far from IUPAC conventions, with labeling sticking close to the systematic format. This helps prevent mistaken identity—a real concern, as mix-ups between close chemical cousins have led to some memorable lab mishaps.

Safety & Operational Standards

Any phosphonium salt draws a sharp line between careful and careless lab practice. Material safety data sheets warn about eye and skin irritation. Gloves and goggles shouldn’t ever gather dust during handling, especially since contact with acids or strong bases can produce toxic gases. Proper fume hoods and well-ventilated prep stations remain standard. Waste disposal routines need attention, as phosphorus-containing compounds sometimes escape standard neutralization paths. Over the years, I’ve seen near-misses remind everyone that even routine procedures can hit a snag if safety feels optional.

Application Area

Organic chemists use allyltriphenylphosphonium chloride heavily in stereo- and regioselective synthesis. Drug discovery teams value it in strategies to lengthen or modify carbon chains, often in the late stages of making candidate molecules. I’ve spoken with material scientists who use this salt in the creation of specialty polymers and ionic liquids. Energy researchers experiment with it in the design of membranes and catalysts—especially those seeking to improve hydrogen production or fuel cell efficiency. This adaptability sparks regular collaborations across disparate fields, turning the compound into a silent partner for hundreds of different projects.

Research & Development

Recent years brought steady investment into better and greener ways to prepare and use phosphonium salts. Groups working with flow chemistry report higher yields with reduced solvents and fewer side-products. Pharmaceutical researchers check for chiral purity and scalability, trying to balance technical ambition with the grind of regulatory documentation. Deeper dives into the mechanism of Wittig reactions still turn up surprises, including alternate ylide forms and new byproduct management techniques. Having spent long hours chasing optimal conditions, I see the benefit every time a cleaner or more efficient protocol turns up, especially if it ends a run of frustrating failed reactions.

Toxicity Research

Studies on allyltriphenylphosphonium chloride toxicity sit near the intersection of industrial hygiene and green chemistry. Tests show the compound can cause irritation but rarely meets criteria for acute toxicity at common lab concentrations. Chronic exposure gets less attention, but chemically similar salts display mild cytotoxicity in certain cell cultures. Regulatory bodies in Europe and Asia keep a watchful eye, nudging university and industry labs to document any health risks tied to chronic inhalation or skin contact. From personal experience, the sharp scent and mild tingling after accidental contact are enough to prompt a second look at work habits—even without dramatic published case reports.

Future Prospects

Allyltriphenylphosphonium chloride has staying power, riding on its reliable chemistry and role in creative reaction design. Momentum builds for greener synthesis and applications in next-generation materials. The search continues for alternatives that balance safety, cost, and effectiveness, but labs keep circling back to this classic salt when others fall short. Training new chemists in proper handling and creative application remains essential. As legal and regulatory scrutiny on rare and hazardous materials grows, the compound’s straightforward behavior and decades of documentation make it a resilient choice. Looking ahead, its best innovations may come from cross-pollination between fields that once worked in silos, each finding a new trick for an old reagent.

Everyday Science Behind an Unfamiliar Name

Most people have never heard of allyltriphenylphosphonium chloride, but researchers and chemists know it has chops. In most labs, this compound works behind the scenes. You see it in synthetic chemistry where small tweaks to a molecule can make or break a whole chain of reactions. It’s not the kind of thing most folks ever touch, yet without it, we’d see fewer advances in fields like medicine, materials, and energy.

Giving Chemists More Room to Work

Allyltriphenylphosphonium chloride isn’t flashy. It often takes on the job of a reagent or intermediate, helping to build or modify other chemical compounds. The real power here comes down to building molecular complexity. Take the Wittig reaction—one of the most useful tools for making carbon-carbon double bonds. This chloride lets chemists swap atoms around, add just the right piece to a skeleton, and create new structures that wouldn’t exist otherwise. It’s like giving a builder access to new kinds of beams and joints: suddenly, new possibilities open up.

If you look at drug development, burning through dozens or hundreds of chemical variants to find something that sticks can turn up new treatments. Every single addition or swap changes things, sometimes leading to breakthroughs. The process can sound slow and clunky, but it’s powered by compounds like allyltriphenylphosphonium chloride, which give labs more versatility.

Used Beyond the Lab Bench

The reach isn’t just limited to pharmaceuticals. Materials science takes chemistry from the flask and puts it into everyday products or high-tech prototypes. When scientists push to make more efficient solar panels or new polymers, the reactions made possible by this compound matter. Fire-retardant coatings, stronger plastics, or clever light-absorbing films often come out of countless chemical tests and rebuilds. Allyltriphenylphosphonium chloride is one of those quiet helpers along the way, making new options that builders and designers can turn into products.

From my own university days, seeing reactions go right or wrong because of the tiniest shift in molecular structure sparked a respect for how crucial these tools are. We’d run reactions, scribble down notes, study yields, and sometimes end up with nothing more than a cloudy flask. Other times, a single substitution, tweaked by a compound like allyltriphenylphosphonium chloride, would produce the missing breakthrough. Working hands-on drives home how useful these “invisible” compounds get in the real world.

Care and Responsibility

With any useful tool comes responsibility. Not every chemical should be handled lightly, and the same applies here. Proper research and lab safety make sure the risks get managed. Accidents in chemistry often come from rushing or cutting corners, so making safety an everyday habit ranks just as high as curiosity and ambition. Products traveling from lab to shelf should always clear strict quality checks to avoid unintended harm.

Moving Forward

Chemistry never stands still. Each new building block, like allyltriphenylphosphonium chloride, chips away at tough challenges. Cleaning up the waste, working with greener processes, and pushing to recycle reagents should stay at the front of every lab’s priorities. We owe the next breakthrough to sharp minds and careful hands—something that gets shaped as much by the tools we use as the questions we ask.

Understanding Allyltriphenylphosphonium Chloride

In the world of organic synthesis, sometimes a reagent slips into view that quietly keeps chemists’ reactions moving forward. Allyltriphenylphosphonium chloride stands as one of those workhorse compounds—appearing often enough in Wittig-type protocols for building new carbon-carbon bonds. Talking about its formula and structure isn't just a matter of reciting numbers or letters. Getting comfortable with its layout can help researchers avoid headaches later down the bench.

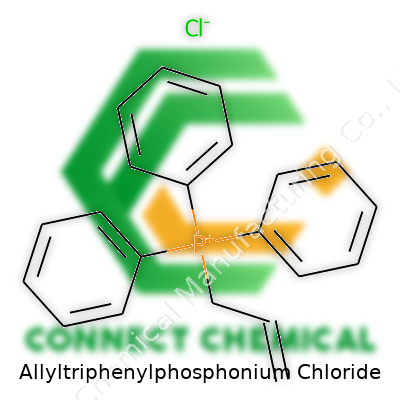

Chemical Formula: C21H20PCl

This salt features a triphenylphosphine backbone attached to an allyl group, with a chloride hanging out to balance the charge. The chemical formula reads C21H20PCl. That means you get twenty-one carbons, twenty hydrogens, one phosphorus, and one chlorine packed together in a tidy ionic package. Every atom has a job to do; phosphorus anchors the molecule, the three phenyl rings provide bulk and stability, and the allyl group offers that reactive twist synthetically valuable for carbon coupling.

Structure and Key Features

Drawing this molecule on paper (or picturing it in 3D) reminds me a bit of molecular Tinker Toys. Start with phosphorus at the center. Three phenyl rings fan out around it—each shaped by a benzene hexagon. On the fourth arm, you find the allyl group: a three-carbon chain, ending in a gentle double bond. Ionic charge gets the job done—phosphonium bearing a positive charge on the phosphorus atom, which gets counterbalanced by a chloride ion somewhere nearby, often locked together by crystalline forces during purification.

It helps to describe the structural formula for newcomers: the central phosphorus atom connects to three benzene rings and to a –CH2–CH=CH2 segment, forming what’s called the allyl substituent. So, the molecular ion itself is (C6H5)3P+–CH2CH=CH2 Cl−.

Why the Structure Matters

Some readers may look at phosphonium salts as just another reagent. Here’s where it gets interesting: The city-block size of the triphenylphosphine group helps control selectivity in reactions like the Wittig or similar coupling steps. The allyl group stands ready for nucleophilic addition, setting the stage for careful construction of bigger, more complex molecules. Graduate students working late in the lab care about these details—how easy a salt dissolves, whether crystals are stable, or if an unexpected side reaction blows up an afternoon’s work.

Textbook diagrams sometimes miss the reality that bulkier reagents like allyltriphenylphosphonium chloride can tune yields, provide safety advantages, and influence what side products show up. Lab experience shows that handling this compound safely matters; it isn't particularly toxic, but phosphorus compounds call for gloves, goggles, and proper ventilation—each step informed by decades of empirical wisdom.

Opportunities for Safer Handling and Use

Manufacturers and researchers have choices to make in storage and application. Dry bottles and argon lines help protect the reagent from damp air, since many phosphonium salts can draw in water and degrade before anyone notices. Direct sunlight breaks down the organic scaffold, so storing in amber glass makes sense. Sharing wisdom in the lab about safe weighing, minimal exposure, and proper disposal cuts down on accidents and waste, always welcome in any modern workspace.

Reflections from Organic Synthesis

Allyltriphenylphosphonium chloride may not get splashy headlines. Still, from my experience, understanding its formula, structure, and quirks lets chemists design cleaner protocols, speed up synthesis, and build molecules that change how drugs, dyes, and new materials are made. Simple details—right down to the way the phosphonium group meets the allyl chain—keep chemistry moving forward, one carbon bond at a time.

Recognizing Real Risks

Anyone who spends time around fine chemicals knows the importance of knowing and respecting the hazards that come with each bottle in the cabinet. Allyltriphenylphosphonium chloride is no different. This compound is strong-willed. Its structure—part phosphonium salt and part reactive allyl group—means it’s got a mind of its own both in terms of the reactions it participates in and the potential harm it can cause if handled without thought.

Keeping It Dry and Cool

The first thing I always check is moisture. Water and allyltriphenylphosphonium chloride do not mix. Any contact lets hydrolysis kick in, which breaks the compound down and ruins a batch. Worse, it can generate byproducts that bring their own headaches. So it’s best to keep this salt in a dry, well-sealed container. Some folks go all-in and stash it in a desiccator with silica gel. Stacking the decks against humidity always pays off. Heat can also be a problem; the compound can start to decompose if left near a radiator or sunny window. Storing at room temperature in a dark place is smart, but in sweaty climates or during the summer, a touch of air conditioning or a spot in a cool cabinet makes a difference.

No Room for Sloppy Labeling

Mislabeling has a way of sneaking up on labs. I’ve seen it before: faded ink, peeling tape, or—worse—no label at all on a jar filled with something white and crystalline. The solution is simple: clear, robust labeling with both the full chemical name and the date of purchase. That’s saved me more than once when memory failed and a labmate mixed up containers.

Respect for PPE and Ventilation

A mistaken splash or a careless whiff is a sure way to turn a simple task into a crisis. Allyltriphenylphosphonium chloride is not something to get on your hands or near a cut. It’s a skin and respiratory irritant. The way to play it safe is straightforward: safety goggles, lab coat, gloves, and a bench with proper airflow. I’ve found some older labs missing fume hoods. In those cases, working with the smallest quantity possible and keeping a fan going at all times makes a difference. If granules or powder get loose, they move on air currents. Better to keep everything tidy and sealed, and wash up thoroughly after handling.

Thinking Two Steps Ahead About Incompatibles

I've heard stories from old-timers about surprise reactions in the stockroom. Allyltriphenylphosphonium chloride doesn’t belong near strong oxidizers or acids. If it starts to break down, it can release fumes and maybe more. Storing it well away from things like peroxides or nitric acid cuts out the risk of accidental contact. I organize my own shelves so there's no confusion, using dividers or even separate cabinets if space allows.

Spill Response Plans Save the Day

I’ve learned to treat every transfer or weighing as a chance for a spill. Keeping a plan and supplies ready—spill pads, neutralizing agents, and gloves—saves time and stress if something tips or scatters. It’s not dramatic until it happens, but the first time you see white powder fly across a countertop, you remember. Quick cleanup, proper disposal in line with local hazardous waste rules, and leaving no residue behind keeps everyone safe.

Training and Communication

One thing that makes a huge difference is good training for labmates, students, or newcomers. Sharing best practices—double-checking labels, storing chemicals smartly, handling spills—builds trust and keeps people protected. Communication prevents someone from walking in blind or making a guess that leads to a problem.

Responsible Stewardship

Allyltriphenylphosphonium chloride is a real workhorse in some synthesis routes, but its benefits only show up if treated with respect. Safe storage, proper PPE, smart handling, and a culture of open information keep chemicals as a tool, not a threat. That’s an approach that has served me—and many colleagues—well for years in the lab.

Understanding the Chemical’s Profile

Allyltriphenylphosphonium chloride sits among the lesser-known phosphorus-based compounds. Most people outside chemical research circles would struggle to pronounce it, let alone explain what it does. As someone who enjoys digging into safety sheets, its name popped up during a project involving organic synthesis. Not much everyday use here; it’s a specialist’s material, usually spotted in the hands of chemists working with advanced organic reactions.

Unpacking Toxicity Concerns

This isn’t some household cleaner or a common garden supply. Toxicity matters when a chemical escapes the lab or meets casual hands. According to safety data from chemical suppliers and the European Chemicals Agency, allyltriphenylphosphonium chloride demands respect. It may cause skin irritation, poses a risk of harming the eyes, and can trouble the respiratory tract if inhaled. I remember a colleague telling me about a mild rash after spilling a dilute solution — thankfully, nothing serious, but it showed how direct contact stings.

Rodents exposed in laboratory studies sometimes showed toxic responses, with symptoms like labored breathing or skin reddening. Chronic exposure data seems thin, but the general rule applies: just because a material doesn’t immediately provoke drama, doesn’t mean repeated handling stays safe.

Routes of Exposure and Proper Precautions

Chemicals like this shouldn’t pass through your kitchen. Exposure usually happens through skin, eyes, or lungs, especially during weighing and mixing. I spoke with a friend in chemical safety who pointed out how easy it becomes to forget one careless moment ends with a ruined day — or worse, a trip to occupational health. Even the average university lab sets out gloves, goggles, lab coats, fume hoods. Those aren’t overkill, they’re the base layer for working with reagents of this type.

Why Hazard Labels Actually Matter

Regulators classify allyltriphenylphosphonium chloride as an irritant. Safety labels might seem like bureaucratic clutter, but they save real skin. I visited a research group where, because of one absent hazard sticker, a junior researcher reached bare-handed into what looked like salt. That slip-up landed them with a raw patch on their finger for a week. Nobody wants to feel pain just because a label went missing.

Environmental and Waste Issues

Down the sink, that’s never the right move for any organic-phosphonium compound. Few studies have mapped the full ecological fate; what is clear, it can cause harm to aquatic life. That puts it side-by-side with numerous other research chemicals which should head only into hazardous waste disposal. In my lab days, our supervisor drilled proper disposal into everyone — bottle, tag, track, no excuses.

Steps Toward Safer Labs

Substitution makes sense but rarely happens overnight. Less toxic alternatives sometimes exist but chemistry loves its niche reagents. Institutions need to keep up real risk assessments, refresh training, and lead by example. I’ve found that open communication in lab meetings about “near-misses” works — people learn from stories, not just sheets of rules.

Taking allyltriphenylphosphonium chloride for granted can cost more than it gives. Avoiding injuries remains easier than treating them. That’s where science can keep moving, and people stay healthy.

Purity Matters in Chemical Reagents

Walk into any lab that deals with organic synthesis and you’ll spot chemicals like allyltriphenylphosphonium chloride on the inventory list. Experienced chemists raise eyebrows if purity slips below a certain threshold. A reagent’s purity affects not just reaction efficiency, but also the interpretation of experimental results. For this compound, most suppliers provide material with a minimum purity of 97%. Some go a notch higher, offering up to 99%. It’s not just a formality thrown in for catalog value—those percentage points matter. Unwanted byproducts or trace contaminants in the bottle can spoil a reaction, add noise to spectra, or lead to false starts that cost both time and money. I've learned to check certificate of analysis documents thoroughly, and more than once I've caught gaps where quality controls missed hidden problems.

Certified high purity doesn’t just rest on label claims. Labs that care about repeatable results lean on suppliers who can show exacting quality management, documented batch analysis, and reliable sourcing. Several trusted brands make their chromatograms and NMR data available, and they do so for good reason. Mistakes in this area ripple through research timelines and can sideline promising projects. In drug discovery especially, reproducibility stands tall. One impurity can force costly rework down the line. Going for higher purity prevents headaches and builds trust—between supplier, scientist, and the resulting science.

Available Packaging Sizes: Small Needs and Scale-Ups

Projects move at different speeds and scales. Some teams only need milligram quantities for screening new synthetic routes or performing mechanistic studies. Others ramp up to gram or even larger batch runs. Commercial suppliers offer a range of packaging to fit both cases. Most common bottles roll off the line in 1 gram, 5 gram, and 25 gram sizes. On rare occasions, major suppliers custom-fill larger containers, but these usually require prior arrangement and a decent lead time. Single-use vials make life easy for those handling sensitive compounds, because multiple openings risk moisture exposure. Allyltriphenylphosphonium chloride can draw water if left open, and even a small shift in composition can skew a reaction.

From my own work with sensitive phosphorus compounds, I’ve learned not to buy more than I’ll realistically use in a single season. The shelf life improves when stored in tight bottles, away from direct light, and with minimal air exposure. Some of the best labs decant powder under inert gas, especially for long-term storage. In teaching labs, smaller 1 gram bottles make handling safer and minimize waste. Larger process labs can order custom bulk packaging, squeezing down per-gram costs. It’s not just about convenience; it’s built into good safety and best lab practice.

Practical Concerns and Credible Sourcing

Not all suppliers stick to the same standards, so vetting sources becomes a top priority. Chemical purchasers dig into supplier profiles, inspect quality certifications, and sometimes even talk to customer service about their handling and shipping processes. Knowing that storage conditions affect stability, I always ask about temperature control during transport. High value, high reactivity chemicals like this don’t tolerate sloppiness.

Packing options reflect real-world research needs and storage habits. Small vials fit classroom or high-throughput efforts. Bulk jars suit industry; mid-size bottles land right for steady R&D in academia. Reliable purity and packaging together protect both experiments and people behind the bench. By paying close attention to both, labs ensure data stays credible and resources aren’t wasted.