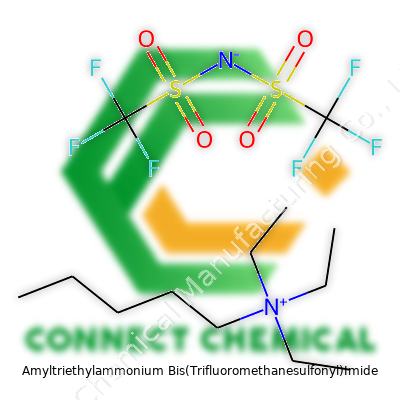

Amyltriethylammonium Bis(Trifluoromethanesulfonyl)Imide: A Ground-Level Deep Dive

Historical Development

Step back to the late 20th century. Electrochemists and materials scientists kept bumping into the same limitations in their electrolytes: flammability, volatility, and poor conductivity. The world needed salts that could keep up with growing electronics and battery technologies. Out of this period of intensive research, ionic liquids took root. The push wasn't just about finding alternatives; it was driven by safety concerns and the quest for better batteries and capacitors. Amyltriethylammonium bis(trifluoromethanesulfonyl)imide, usually called Amyltriethylammonium TFSI, marks that shift. Chemists realized that using a bulky organic cation with a TFSI anion addressed a bunch of pain points. This salt set new standards in melting point, viscosity, and especially electrochemical stability. It’s not as old as common table salt, but the innovation it brought can’t be overstated—creative chemistry that aimed for safer and better-performing products in labs and industry alike.

Product Overview

Amyltriethylammonium TFSI isn’t something that jumps off a store shelf. The product blends the qualities of a robust organic cation with a heavily fluorinated anion. It’s a salt that stays liquid at room temperature. I’ve seen plenty of researchers shocked at how such stable liquids can carry so much charge. The stress in the research community often landed on finding a material that didn’t just work on paper, but that could also be handled easily and safely. This compound raised eyebrows, in a good way, across battery and advanced material developers. The structure opens up practical use in capacitors, battery electrolytes, and pretty much anywhere a reliable, non-volatile ionic liquid shines.

Physical & Chemical Properties

Hold a bottle of this compound and you’ll notice the colorless or pale yellow liquid—usually odorless, unless you get close and know what to sniff for. Its melting point falls below room temperature, which makes it flow freely unless you keep it much colder. High thermal stability lets it stay intact up to around 300°C. Solubility tells another side of the story: it works well in many polar organic solvents, but barely dissolves in water. Its molar mass hovers around 538 g/mol. With a broad electrochemical window, chemical engineers can worry less about unwanted side reactions. Density creeps close to 1.3 g/mL, and the viscosity sits lower than expected for something so big, so ions can move quickly—paving the road for rapid charge and discharge in all kinds of devices.

Technical Specifications & Labeling

Each bottle tends to carry a label packed with details: structural formula, CAS number, chemical purity—which often exceeds 98%—and storage conditions that favor dry, ventilated spaces. Labels spell out the batch number and offer safety pictograms. I’ve seen storage instructions warn against sources of ignition and moisture. Shelf life runs several years if handled right. These standards aren’t just about compliance, they ease worries for folks mixing it into sensitive equipment and wanting clarity about what’s in their hands.

Preparation Method

Watch the synthesis process, and the value becomes clear. The salt often gets built by reacting amyltriethylamine with an alkylating agent to create the amyltriethylammonium precursor. This gets paired with lithium bis(trifluoromethanesulfonyl)imide in a metathesis reaction, floating the target salt into solution. Most chemists wash and dry the final product, then remove solvents to get a nearly pure ionic liquid. The trickiest part sits in completely getting rid of water contamination since it can play havoc with conductivity and performance in high-spec devices.

Chemical Reactions & Modifications

Chemists have tinkered with this compound through functionalization or exchanging counter-ions. Adding tweaks to the alkyl chains can sharpen or dull properties such as solubility and viscosity. In some of my collaborations, just swapping in one carbon for another shifts the working range of devices. On the flip side, mixing small amounts with additives can tailor the salt to oddball application requirements. Once, in a materials lab, even low-level impurities from synthesis delivered a surprise drop in performance, which pressed home the need for clean and consistent reactions.

Synonyms & Product Names

Reading a stack of papers and safety sheets can make the head spin, since this salt goes by several handles. Chemists write it out as N-Amyl-N,N,N-triethylammonium TFSI, or toss around abbreviations like [N2225][TFSI] or TEAA-TFSI. Commercial catalogs might list it as Amyltriethylammonium bis(triflylimide). The sprawl of names slows down even experienced researchers, risking confusion or even mixing up materials in a tight project timeline.

Safety & Operational Standards

In a busy lab, the rules boil down to minimizing contact and reducing unnecessary risks. Though this salt scores lower on acute toxicity compared to older solvents, gloves and goggles really matter. Spills need to be wiped quickly—any hit of moisture, and the salt starts to break down. Fire safety measures lean heavy, since organic components can still burn under the wrong conditions. The bigger risk comes from improper disposal. Ionic liquids don’t just vanish in the environment—they can build up, and their toxicity to aquatic life stays under heavy study. Waste barrels labeled specifically for ionic liquids keep accidents and costly mix-ups at bay.

Application Area

This salt’s strongest pull shows up in electrochemistry labs and high-end batteries. I’ve talked with battery engineers who value stable electrolytes that don’t break down when charging runs hard and fast. Supercapacitors gain an edge in energy density and reliability. Beyond power storage, some environmental labs explore its use as a solvent for tough-to-dissolve reactants or even as an extractant for rare metals. In the classroom, budding chemists use it to run advanced electrochemical demonstrations safely and efficiently. The growing field of green chemistry keeps coming back to this class of materials as it tries to dial back flammable and corrosive solvents.

Research & Development

Innovation doesn’t stand still here. Today’s research tracks focus on tuning the salt’s physical properties for new battery chemistries. I’ve seen projects test mixtures with other ionic liquids or explore additives that stretch conductivity and lower costs. Analytical chemists keep pushing for lower impurity levels to get more out of every drop. In biochemistry, a few groups now test these salts for stabilizing enzymes or separating fine particles, broadening the reach far beyond electrochemistry. Each year brings fresh papers claiming new uses, especially centered on making electronics safer and more powerful.

Toxicity Research

The gold standard comes from clear-headed toxicity data. Early tests made clear that these compounds don’t act like water or table salt inside living systems. Some studies flagged acute toxicity in fish and invertebrates when spills run unchecked. Researchers have clocked low-level irritation in skin and eyes in animal studies. Chronic hazard data still carries big question marks, which means companies tend to handle these with the same caution reserved for more notorious laboratory chemicals. I’ve been in meetings where lab managers push for better data and smarter handling guidelines before scaling up for larger production runs. This caution comes from experience; even small mistakes in disposal or exposure can snowball when scaled up.

Future Prospects

Energy storage, green chemistry, and next-gen materials development keep this compound in the spotlight. Big battery makers now hunt for even safer, longer-lasting, and lower-cost electrolytes, and this ionic liquid stands out in the lineup. Research keeps pulling it toward cleaner processing as people demand solutions that work without bigger environmental trade-offs. Demand in recycling and advanced manufacturing likely grows, since so many future technologies need salts that can hold up to extreme conditions. Efforts to improve the molecule’s environmental footprint and lower production costs already spark fresh patents and university projects. As new regulations reshape what happens inside labs and factories, the push to improve both safety data and large-scale production methods grows stronger each year.

A Real Piece of the Modern Chemistry Puzzle

Chemistry gets a little wild with names, and amyltriethylammonium bis(trifluoromethanesulfonyl)imide, or ATEATFSI, has a name that fills half a notebook. But dig past the mouthful, and this stuff turns out to play a small but mighty role in batteries and electronics—fields that impact everybody’s daily life, whether or not we ever set foot in a chemistry lab.

The Role in Batteries and Electronics

ATEATFSI belongs to the family of ionic liquids. Unlike table salt, which melts at over 800°C, these materials flow as a liquid just past room temperature. Chemists found that this class of chemical, known for low volatility and strong stability, could be a real workhorse. Big industries started mixing them into advanced batteries and supercapacitors, the stuff that keeps your phone running and electric cars rolling. Because ATEATFSI offers a good balance of ion movement and long-term stability, researchers often use it for electrolytes in lithium-ion and other high-performance batteries.

Ionic liquids like this aren’t flammable, which means devices don’t go up in flames as easily compared to classic liquid electrolytes. Every time I heard about a laptop or phone catching fire, I remembered why safer substitutes like this one matter. The push for safer electronics makes ATEATFSI a quiet contributor to the tech we trust every day.

Helping Push Renewable Energy Forward

As renewables grow, demand for better storage rises. Solar panels and wind turbines need batteries that hold energy when the sun sets or the wind stops. The right electrolyte makes a battery work years longer and stay safer. Research in journals such as the Journal of Power Sources highlights how ionic liquids, including ATEATFSI, push supercapacitor performance, which means improved storage for everything from grid backup to electric bikes. The fact is, if you want longer life and safer batteries, you start with better chemistry inside—that’s exactly where ATEATFSI comes into play.

Use in Industrial Lubrication

ATEATFSI isn’t just about powering gadgets. Industrial labs have been testing it as a base for special lubricants. Heavy machinery, aerospace, and robotics need lubricants that won’t break down under tough conditions—think crazy temperatures or demanding loads. Ionic liquids resist wear, don’t corrode metal parts, and endure long cycles. Industrial engineers working with this compound see fewer machine breakdowns and longer intervals between maintenance, which translates to more uptime and less wasted money.

The Environmental Factor

Electronics and industry often put pressure on people and planet. Regular solvents and electrolytes evaporate or break down, leaving hazards behind. Ionic liquids like ATEATFSI have much lower vapor pressure, so they release fewer toxins into the air. While not a silver bullet—nothing ever is—they help chip away at emissions that plague big cities and industrial zones. Researchers at universities such as MIT have flagged ionic liquids as promising options for greener manufacturing, even though proper disposal and sourcing still require attention.

Challenges and Solutions

ATEATFSI doesn’t come cheap or easy. It demands specialized equipment, and purity matters. Some labs find cost a hurdle in early research. To improve access, it makes sense for both government and private industry to ramp up support for manufacturing at scale and invest in recycling methods. Cheaper access to safe ionic liquids could spark innovation far beyond current use, including new types of batteries, fuel cells, or environmentally friendly lubricants.

Down at street level, people expect safer, longer-lasting tech. Inside the lab, chemists and engineers know every component counts. ATEATFSI is just one piece of the puzzle but, as with lots of science, sometimes the small things change the biggest stories.

Understanding the Risks

Working with chemicals in the lab or industry isn’t something to take lightly. No matter the experience level, each compound holds its own quirks and hazards. Missteps can lead to skin burns, fires, or even worse, so care deserves top priority. From my own time doing research, one oversight led to skin irritation that lasted for days, and that taught me to never skip the basics. Before going near any substance, the first rule—know what you’re working with. Read the safety data sheet, get familiar with hazard symbols, and ask questions if something makes you uneasy.

Personal Protection Always Matters

Gloves, goggles, and lab coats are the frontline defenders. Latex gloves work for routine spills, but for corrosive or volatile chemicals, nitrile or neoprene options protect a lot better. Regular glasses won’t shield your eyes from splashes, so goggles should never be optional. That small barrier saved me more than once from stray droplets. A simple cotton lab coat keeps toxic dust and accidental splashes from soaking into your regular clothes and reaching your skin.

Addressing Airborne Hazards

Some chemicals give off fumes that can damage your lungs or irritate your nose and throat. Fume hoods belong in any setup dealing with volatile or noxious materials. Good ventilation isn’t an extra—it’s a basic safeguard. Years ago, a forgotten container led to headaches for days before anyone noticed the smell. Proper labels, sealed containers, and setting up work away from food or drink help keep accidents to a minimum.

Proper Storage Makes a Difference

Certain compounds react with moisture or other chemicals. Keep acids far from bases, store flammable solvents in flame-proof lockers, and never pile chemicals on an open shelf. I once saw a bottle of strong acid melt its way through a cardboard box, warning everyone how fast things can go wrong. Always store reactive substances in containers with clear labels and away from direct sunlight or heat sources.

Preparation and Cleanup Go Hand-in-Hand

No job starts until all tools and containers are clean, and everything you need is within reach. Spills tend to happen when people fumble around looking for paper towels or neutralizer. Sand, spill kits, or baking soda for acids, and plenty of water nearby can keep a problem from spreading. Dispose of waste in labeled bins, not the sink or trash. Experienced professionals never throw caution to the wind, because they’ve seen how fast carelessness comes back to bite.

Cultivating a Safety Culture

Every lab or workplace should lean into safety as a shared value. Open communication makes it easy for anyone to speak out if they spot a hazard or unsafe habit. Regular training, drills, and updates remind everyone of the risks and the right steps to take. It helps to tell newcomers personal stories involving past mistakes, so lessons stick in their minds. Safety becomes a habit when everyone looks out for each other.

Smart Solutions Start with Respect

It’s easy to rush, especially with deadlines looming. But no project is more important than staying healthy. Design workspaces for quick exits, post up-to-date emergency contacts, and keep eye-wash stations clear. If something feels off, slow down and double-check. Safety starts with respect, both for the substance and for everyone around.

Why Proper Storage of Chemicals Like Amyltriethylammonium Bis(Trifluoromethanesulfonyl)Imide Matters

Anyone who’s worked in a research lab, a quality-control warehouse, or even a university classroom knows how quickly a chemical mishap can disrupt everything. Amyltriethylammonium bis(trifluoromethanesulfonyl)imide (often called an ionic liquid) isn’t something you can treat like table salt or vinegar. The unique structure of this ionic liquid means it’s popular for batteries, electroplating, and a few niche sorts of chemical syntheses, but with that popularity comes real responsibility.

Leaving chemicals on a shelf from habit, trusting a generic white label, or storing them just like any other solvent invites accidents and destroys your investment. I’ve seen well-equipped labs lose thousands because someone shrugged at safe storage, not realizing that exposure to air or moisture ruined a pricey bottle of reagent. That experience sticks. You start looking at each bottle’s label, its documentation, and where it lands on the shelf, because you see the chain of events a single careless step can start.

Moisture and Oxygen: The Real Enemies

With amyltriethylammonium bis(trifluoromethanesulfonyl)imide, water is not a friend. This chemical pulls in moisture from the air — it’s hygroscopic. If moisture sneaks in, purity suffers. Reactions get inconsistent, and results you trusted yesterday start wobbling. Keep the container sealed tight. Glass works for most, especially if it has a PTFE (that’s Teflon) lined cap. Double-check the fit after every use.

Oxygen can sometimes react with chemicals in ways you won’t see until much later. Even if the risk isn’t dramatic — no loud explosions — you end up losing money and ending experiments with confusing surprises. Nitrogen or argon atmospheres, once limited to specialized labs, now show up wherever scientists want accuracy and stability. Flushing a chemical’s container with dry nitrogen before resealing makes a real difference. Some labs even set up a glove box system for sensitive reagents, and ask anyone handling them to get familiar before they start their work.

Temperature: Not Too Cold, Not Too Hot

Temperature swings pose their own problems. Many solvents get stored at room temperature, but not every room stays consistent. Direct sun, even through a window, will break down sensitive chemicals faster than you think. Store amyltriethylammonium bis(trifluoromethanesulfonyl)imide in a dry storage cabinet away from sunlight, as close to a steady 20–25°C as possible. Refrigerators sometimes seem like a safer bet, but condensation risks go up if humidity gets in during retrieval. Dry cabinets do the job much better for ionic liquids.

Exposure and Handling: Small Steps for Big Safety

Labeling each bottle with the date of receipt and first use takes moments but tracks how long that container stays active. Anyone who’s poured from an old mystery bottle knows the gamble. Always use clean, dry syringes or pipettes. Pouring from bottle to bottle without precautions sets up cross-contamination, which is harder to catch in ionic liquids than in water-clear solvents.

Chemicals form the backbone of discovery and creation, though they demand respect in return. By keeping amyltriethylammonium bis(trifluoromethanesulfonyl)imide dry, sealed, steady in temperature, and protected from careless handling, you’ll get the reliability and accuracy you expect — and make sure the next person does, too. In my own lab, these habits keep budgets tight and surprises few, which is the way good science happens.

Looking Past the Technical Jargon

Most products we use daily—from over-the-counter remedies to basic cleaners—trace their effectiveness back to chemistry. Knowing the chemical structure and molecular weight of a product builds trust between companies and people. It’s not just an abstract request tossed around in the lab. Shoppers look at the back of a bottle, searching for answers, and scientists and regulators want proof that a product is what it claims. These details allow everyone to check for quality, verify safety, and test compatibility with existing systems or the human body.

Getting Clarity

The chemical structure spells out the arrangement of atoms. Someone scanning a formula might see hexagons, lines, and sometimes odd letters, but those shapes tell a real story. They describe how the product will behave under different conditions—Will it dissolve in water? Can it handle heat? Does it interact with other ingredients? The molecular weight, on the other hand, puts a number on the size of a molecule, offering a shortcut to predict dosing and absorption rates.

Why This Matters Beyond the Lab

I’ve worked projects where missing or obscure data left teams flying blind. In one case developing a food supplement, our group couldn’t confirm purity claims or match local regulatory requirements until someone inside the supply chain finally shared the complete structure and molecular weight. That single exchange cut through weeks of speculation. This isn’t just scientist talk: missing data can mean an allergy reaction goes unchecked, a prescription doesn’t work as expected, or a hobbyist ruins a batch of soap or paint. It can even impact environmental safety—knowing the chemical story helps predict breakdown in soil or water.

Providing Facts Builds Trust

The world has watched recalls and scandals unfold when chemical details stayed hidden. Stories like contaminated children’s toys or unknown food additives burned into public memory. Open data about structure and molecular weight makes it easier for watchdogs—sometimes even regular shoppers—to spot problems before they spiral. Many governments now require this level of transparency so no one gets left guessing.

Potential Solutions

Companies benefit by putting these details front and center. Clear, plain-language chemical structures—supplemented with images for non-scientists—help more people understand what’s in the bottle. Explaining molecular weight and its role also makes sense, especially since it affects safety and effectiveness, and transparency turns a risk into an asset when addressing questions from press, regulators, or parents. Investing in easy-to-read labels, free access to chemical safety databases, and third-party verification can reduce confusion and prevent harm.

Industries and educators can also bridge this gap by hosting resources explaining these chemistry basics in plain language. More information flows in both directions, making the conversation on product safety and science literacy stronger. People rarely remember the perfect chemical formula, but they do remember the companies and experts who answered honestly and put safety over shortcuts.

Why Purity Matters in Real Applications

A lab bench tests anyone’s patience, especially when contaminated chemicals throw off an experiment or a process. You see this play out in industries from battery research to pharmaceutical development. Amyltriethylammonium bis(trifluoromethanesulfonyl)imide shows up as more than just a mouthful; it’s a powerhouse in electrolytes and specialty synthesis. Whether someone is staring into a reaction flask or assembling the latest prototype battery, purity draws a hard line between success and a trip back to square one.

A friend once joked about keeping a “rogue’s gallery” of failed syntheses on the wall—each attempt’s culprit had traces of either water, metal ions, or organic residues. You never want your expensive ionic liquid to join that wall of shame just because you skimped on quality. Tiny impurities, too small for the eye, change conductivity, stability or yield surprise side reactions. Researchers often see this as an expensive lesson, but it’s one the fine chemicals market hasn’t ignored.

Industry Has Responded with Options

You can’t expect a chemical supplier to slap the same label on every bottle and call it a day. Years on both the buying and technical support side have shown me that reputable vendors answer with specialized purities. Chemistry-driven companies usually offer at least two or three grades—sometimes more, depending on demand. Walk into a trade show or scroll through a product catalog, and you’ll see terms like “analytical grade,” “battery grade,” or “anhydrous.”

Research-grade products cost less, as they tolerate a touch more impurity, perfect for teaching labs or proof-of-concept work where budgets run tight. Someone running full-scale battery production or pharmaceutical testing can’t take those risks. For them, an upscale grade delivers lower water content, fewer metallic traces, and confirmed compatibility with high-spec processes. It’s true—cost rises with purity, but so does peace of mind.

Testing Brings Accountability

Any claim about purity comes with data. A legitimate supplier provides certificates of analysis, not just a brochure’s glossy promise. I’ve seen teams demand GC-MS reports, Karl Fischer titration numbers, and ICP results before they even green-light a purchase order. Even small discrepancies show up in these documents: one batch may carry a water content below 50 ppm, another closer to 100 ppm. That difference determines whether a substance qualifies for next-generation battery work or ends up stuck in basic screening.

Suppliers also see requests for custom formulations. Those working on niche projects sometimes need salts with purity specs outside the standard lineup, driving innovation but raising cost. If your project depends on an ionic liquid that’s both ultra-dry and absolutely free of trace metals, your vendor probably produces it as a special run. Don’t expect these tailored products to come cheap; the labor and analytical work stack up.

Improving Access and Trust

Labs, universities, and start-ups juggle price and purity every day, often making tough calls. Easy access to technical support plays a big role. I’ve personally benefitted from direct emails with chemists at supplier companies—no chat bots, just straight answers on grades, shelf life, or storage issues. Building this trust keeps projects on track and communities informed.

As research pushes toward industries demanding higher consistency—from EV batteries to drug analysis—the market answers with more tightly controlled manufacturing, better testing tools, and direct customer support. Open conversations and published data move everyone forward, one synthesis at a time.