Benzylcetyldimethylammonium Chloride: Tracing Its Path from Discovery to Future Use

Historical Development

Benzylcetyldimethylammonium chloride first showed up in industrial circles in the early twentieth century as part of the big push for better disinfectants. Chemists, spurred by disease outbreaks and hygiene demands, started experimenting with modified ammonium compounds to see if they could knock out bacteria and fungi more efficiently. This particular quaternary ammonium salt quickly gained a reputation for doing just that. Hospitals, food processors, and water treatment plants picked it up early because of its broad-spectrum antimicrobial edge. The rise of urbanization, public health campaigns, and the spread of industrial-scale cleaning brought benzylcetyldimethylammonium chloride out of the chemical journals and into mainstream applications. I've seen older documentation where early users praised its stability and effectiveness compared to predecessors like phenolic disinfectants, which lost potency under tough conditions.

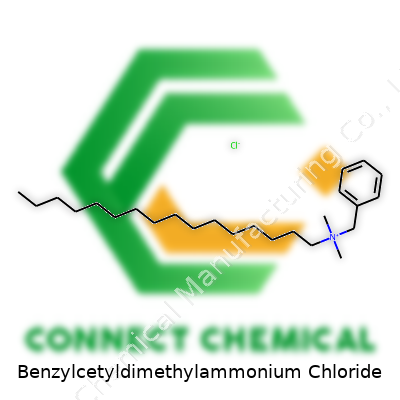

Product Overview

Looking at benzylcetyldimethylammonium chloride, one finds a product designed for tough jobs. It's typically delivered as an oily, viscous liquid or as a crystalline powder, each batch tailored for the job at hand. The molecule itself is a quaternary ammonium compound, meaning it sports a nitrogen atom in the middle, attached to four bulky groups, including a benzyl ring and a long cetyl chain. This structure lets it disrupt microbial cell walls and membranes, giving it power in both healthcare and industrial cleaning. Companies often bottle it as concentrated solutions, ready for dilution, or embed it in wipes, detergents, hand sanitizers, and industrial cleaners.

Physical and Chemical Properties

Benzylcetyldimethylammonium chloride carries a molecular formula of C25H46ClN, with a molar mass hovering around 396.1 g/mol. At room conditions, you’ll find it as a colorless to pale yellow thick liquid, sometimes as a solid with a faint amine-like odor. It melts above 40°C, and dissolves easily in water, alcohol, and many polar organic solvents. The structure, featuring both a hefty hydrophobic tail (the cetyl group) and a charged head (the ammonium moiety), means it can break apart lipid membranes, which translates directly to its antimicrobial punch. The chloride ion sitting beside the quaternary ammonium core affects its solubility and shelf life, something storage managers keep an eye on with temperature and humidity controls.

Technical Specifications and Labeling

Suppliers set technical specifications based on active content, purity, and contaminant thresholds. Typical commercial products offer purity greater than 98%. The content of active quaternary ammonium compound gets measured against standards like titration or chromatography, with strict threshold limits for related by-products, free amines, and heavy metals. Labels list the IUPAC name, CAS number, lot number, manufacturing and expiry dates, and the percentage of active ingredient. Regulatory compliance—like EPA registration in the US or REACH in Europe—means labels also carry warnings about toxicity and restrictions for use around food or potable water.

Preparation Method

Synthetic routes for benzylcetyldimethylammonium chloride build on the classic quaternization reaction. Starting with cetyl bromide or cetyl chloride, chemists react it with dimethylbenzylamine under controlled conditions. They drive the process in solvents like alcohol or acetonitrile, managing reaction temperature and time to minimize side products. Once the main reaction completes, purification comes next—filtration, solvent evaporation, and washing steps isolate the desired salt. Care with reagent quality and equipment cleanliness matters at every stage, since even trace impurities could impair antimicrobial function or raise safety questions down the line.

Chemical Reactions and Modifications

In the lab, benzylcetyldimethylammonium chloride does more than just sit on a shelf. It goes through further synthesis when tailored products are needed—say, swapping out the benzyl group or modifying the alkyl chain to tweak solubility or efficacy. On its own, the compound stays fairly stable under normal conditions but reacts with strong oxidizers or anionic detergents, losing both function and structural integrity. Some researchers modify the molecule with functional dyes or delivery matrices to boost tracking and bioavailability in targeted applications, such as surface coatings or wound dressings.

Synonyms and Product Names

Benzylcetyldimethylammonium chloride appears on global markets under a handful of alternate names, complicating online searches. Common synonyms include Cetrimonium chloride, Cetyl dimethyl benzyl ammonium chloride, and BCDMAC. Trade names vary geographically, with some manufacturers marketing proprietary blends under catchy branded titles, aimed at distributors in healthcare, personal care, or institutional cleaning. Each variation reflects subtle tweaks in formulation or concentration.

Safety and Operational Standards

Handling this compound calls for real diligence. It irritates skin, eyes, and mucous membranes, so users reach for gloves, goggles, and, in concentrated forms, respirators. Ventilation matters in mixing rooms or bottling plants, both for worker comfort and for preventing the buildup of potentially harmful aerosols. Storage in cool, dry, and ventilated areas helps reduce the chance of hazardous decomposition. Disposal by dilution and treatment at licensed chemical waste processing facilities ensures run-off doesn’t contaminate groundwater supplies. Regulatory agencies, from OSHA to European chemicals regulators, routinely issue guidance and safety training for people handling quaternary ammonium compounds, driving home the point that even familiar disinfectants can become dangerous with careless use.

Application Area

Hospitals, dental clinics, and veterinary practices rely on benzylcetyldimethylammonium chloride for surface sanitation. I've worked in facilities where daily wipe-downs with “quats” form the backbone of infection control. The compound also works in food processing, dairy parlors, and beverage bottling plants, where utensils, floor drains, and tanks need thorough disinfection. Beyond hygiene, formulators add it to hair conditioners and shampoos as an antistatic agent, smoothing down frizz. You spot it further in swimming pool algaecides, industrial water treatment, and even oilfield operations for biofilm control. Its broad reach across sectors speaks to both effectiveness and versatility, but discussions about resistance and environmental impact have started shaping recent policy and product reformulation.

Research and Development

Chemists and industry partners have not stopped tinkering with benzylcetyldimethylammonium chloride. Research centers on making it work better at lower concentrations, cutting production costs, and reducing unwanted by-products. Academia and private labs both run trials with mixed formulations, combining “quats” with other biocides, enzymes, or surfactants to broaden spectra or slow resistance. I’ve seen an uptick in interest in biodegradable derivatives, reflecting rising pressure to lower the environmental impact of persistent chemicals. Researchers also track breakdown and persistence in soils and waterways, monitoring how metabolites behave outside controlled settings. Cosmetic chemists dig into structure-function relationships, figuring out ways to prevent buildup on hair while maintaining antistatic performance.

Toxicity Research

Recent toxicity studies keep a close watch on acute and chronic risks. Exposure to concentrated benzylcetyldimethylammonium chloride burns skin and eyes, and ingesting even small amounts poses poisoning risks. Regulatory authorities base occupational exposure limits on animal and epidemiological studies, showing effects ranging from respiratory irritation to organ toxicity if misused chronically. Aquatic ecotoxicology has gotten more attention—runoff from cleaning sites can hurt fish and disrupt aquatic food webs, which puts pressure on industry to improve waste controls and invest in less persistent alternatives. Some researchers look at emerging data hinting at bacterial resistance driven by overuse, drawing lessons from antibiotic stewardship programs. Until safer replacements appear, cautious handling and tighter controls form the backbone of risk management.

Future Prospects

As hygiene norms tighten worldwide, demand won’t disappear. But market watchers are betting on a two-track evolution: reformulated “quat” products for hospitals and food production, and new biodegradable options as sustainable alternatives grow in appeal. Researchers look for synthesis routes that use green chemistry principles—renewable feedstocks, lower energy inputs, and minimal hazardous by-products. Wider collaboration between manufacturers, regulators, and environmental experts has already shaped the roll-out of safer, lower-impact cleaning agents in key markets. The history of benzylcetyldimethylammonium chloride points to a product that adapts, learning from both its own successes and the concerns it raises in a changing world.

Everyday Contact with a Complex Ingredient

Walk into a hospital or a clinic and notice how clean everything appears. Underneath that shine, there’s a battle happening against germs. Benzylcetyldimethylammonium chloride works as one of the go-to weapons in this fight. I’ve stood in labs and watched how the cleaning staff prepares solutions using this compound. It’s more than a mouthful to pronounce—people sometimes call it a quaternary ammonium compound. It kills bacteria by busting up their cell membranes. Surfaces where hands land often, like bed rails and tray tables, commonly get treated with diluted solutions. Cleaning with these allows for confidence that bacteria, and even some viruses, don’t stand much of a chance.

Helping Out Beyond the Hospital

Grocery store shopping carts catch a lot more than groceries. You’ll find people spraying and wiping them before the next shopper grabs hold. Chemical wipes often feature ingredients like benzylcetyldimethylammonium chloride since this molecule takes down both odor and germs. Cleaning companies don’t just use it in public places. It fits into industrial processes, such as food processing plants and restaurants. Workers scrub down cutting boards, equipment, and even mats to keep unwanted microbes from turning up in the food chain.

Disinfecting Water and More

Swimming pools might look tempting on a hot summer day, but they also gather organic muck fast. Add to that the inevitable germs people bring in, and the water becomes risky. Pool maintenance crews sometimes use quaternary ammonium compounds like this one to deal with bacteria. The same holds for decorative fountains, spas, and other water features. Plastics, textiles, and paints can become breeding grounds for mold and mildew. This molecule keeps growth in check in those products, doubling up as both a cleaning ingredient and a preservative. So, this one molecule works behind the scenes, making certain items last a little longer and smell fresher.

What Makes This Ingredient Tricky?

Many folks get used to seeing “kills 99.9% of germs” stamped onto cleaning labels. That promise rests on chemicals like benzylcetyldimethylammonium chloride doing their job. But there’s a catch: repeated use and over-reliance on broad-spectrum disinfectants might nudge some microbes to develop resistance. I’ve read public health reports calling for rotating different disinfectants in large facilities to slow this trend. Skin irritation can also occur with direct, prolonged contact, especially if people neglect gloves or proper dilution in cleaning routines.

Seeking Better Balance and Public Understanding

People need products that keep their work and personal spaces healthy. Still, awareness about how these chemicals should be handled falls short far too often. Whenever I visit a facility for a professional training session, I emphasize reading instructions and using personal protection. Regulatory oversight in countries like the U.S. holds companies to specific standards. The Environmental Protection Agency regulates this molecule’s use, requiring evidence-based safety testing before use in products. Using the right chemical in the right way keeps buildings and public spaces safer and slows the problem of resistant germs. If more people understood what’s behind the “disinfected” sticker, we’d see fewer issues with misuse and accidental exposure, especially in schools and childcare centers. Cleaner spaces depend on more than just spraying—the wisdom behind how and when we use ingredients like benzylcetyldimethylammonium chloride matters just as much as the science behind them.

A Closer Look at Benzylcetyldimethylammonium Chloride

Benzylcetyldimethylammonium chloride turns up in a surprising number of household and industrial cleaning products. Most folks probably haven’t read the fine print on their disinfectant wipes or surface sprays, but this chemical lands on kitchen counters, pet bowls, and even floors where children crawl and dogs nap. It’s marketed for its germ-killing power, and nobody can deny how important a clean environment feels. Still, questions come up about what exactly happens after the shine fades.

What Science Says About Safety

Experts in toxicology and public health stress that exposure, dose, and frequency shape any risk. Scientists have found that benzylcetyldimethylammonium chloride breaks down skin barriers and irritates membranes, especially after repeated or high-concentration contact. Reports of red eyes, rashes, or even breathing trouble trace back to strong cleaning agents containing this ingredient. Studies in labs describe moderate toxicity if swallowed or absorbed in significant amounts, both for humans and smaller animals.

Regulatory bodies, including the European Chemicals Agency and the United States Environmental Protection Agency, highlight safe upper limits for both people and animals. Hand sanitizers and sprays often fall below these thresholds when used as directed, but accidental spills, misuse, or overzealous cleaning routines tip the balance.

Impacts on Pets: A Special Concern

Dogs and cats inspect their world with noses and tongues. Lingering residues from freshly disinfected floors or chewable objects pose more than a passing risk. Veterinary toxicologists have documented case reports of animals developing mouth ulcers, drooling, vomiting, or even seizures in severe cases linked to high-level or chronic exposure. Some pets groom themselves right after walking through a just-cleaned patch of tile, bringing the chemical straight to their bloodstream.

Puppies, kittens, and small breeds suffer faster, given their size and developing systems. Even careful owners could miss that wet floor spot where a curious animal licks up cleaner instead of water.

Balancing Clean with Safety

Everybody wants their family and pet to thrive in a tidy home. Still, it seems wise to rethink routines. Picking up toys, food bowls, and bedding before mopping helps. Cleaners should say “pet-safe,” and thorough rinsing or letting spaces dry completely before letting animals back in really makes a difference. Gloves and ventilation take the sting out for people too.

Doctors and vets encourage staying alert for early warning signs. Sticking with diluted mixes, keeping chemicals out of reach, and swapping in plain soap and water whenever possible go a long way. Some families even try plant-based disinfectants for light jobs, depending on infection risk and health needs at home.

Learning from Experience

Many folks in my circle run busy households with kids, pets, and the dirt that comes with both. We all want fast cleaning, but after seeing a neighbor’s dog get sick from licking up a spill, the entire block switched to milder disinfectants or kept pets away while floors dried. Simple shifts—like swapping evening mopping for mornings, or marking freshly cleaned rooms—spare headaches later.

People turn to science and common sense, and every new report and review helps adjust habits. Paying attention to labels, understanding what’s under the sink, and watching out for changes in behavior, rashes, or coughs in both people and pets protect everyone sharing a home.

Understanding the Importance of Concentration

A bottle labeled Benzylcetyldimethylammonium chloride looks harmless on a shelf, but strength hides behind a chemical name. As a quaternary ammonium compound, people often find it in disinfectants, sanitizers, and cleaners. I remember the first time I handled a concentrated form during a summer job at a food processing plant. A mentor pointed out the burned patch on his coveralls—a tough lesson in sticking close to dilution tables.

Finding the Correct Dilution

Every task calls for a different ratio, based on what you're cleaning and the level of risk. In common settings like hospitals or kitchens, the typical dilution sits at 0.05% to 0.2%. Take a concentrate that holds 10%. To reach 0.1%, add 1 mL of this solution to 999 mL of water. If anyone starts pouring without checking the manufacturer's sheet, mistakes happen fast. High doses leave a residue and irritate skin, while too little does not kill germs. Product labels and safety data sheets clear up the numbers; each batch needs careful calculation.

Safe Practices Make the Difference

I have learned from hard experience that gloves, goggles, and clear labeling save skin and eyes. Even after dilution, don’t take shortcuts. Mix in well-ventilated areas. Add the chemical to water, not the other way, to control splashing. Mark spray bottles and buckets—never use food containers or anything likely to be mistaken for a drink. If you ever see someone transferring without a funnel, stop them. Precision at this step means fewer headaches during cleanup.

Using Benzylcetyldimethylammonium Chloride the Right Way

Once mixed, timing controls the results. On a hard surface, spray until wet and leave for at least 10 minutes before wiping. Rinsing with clean water removes any chemical leftover—nobody wants that taste on a cutting board. Public data shows that, at the right concentration and contact time, the compound stands strong against microbes like E. coli and Staph.

Disinfectant use has soared, especially after COVID-19, but higher usage rates bring higher risks. A CDC report last year tracked minor burns and poison control calls linked to improper use. That report drove home the value of regular staff training and audits. Supervisors can walk through a facility, spot-check labels, and watch for shortcuts, ensuring no diluted product sits unused beyond its shelf life.

Better Outcomes with Routine Oversight

Regulators and public health experts keep a close eye on how frequently quats show up in places they shouldn’t: rivers, lakes, even municipal water. Thoughtful disposal practices cut down on contamination. Pouring leftover solution down the drain, after heavy dilution, lets most wastewater systems handle it safely.

At the end of the day, one bottle of concentrate stretches far, but only with respect for the process. Science, safety data, and first-hand stories all point to a simple principle: measure with care, label everything, store wisely, and protect yourself. The cleanest results come not just from strong chemicals, but from strong habits around every bottle and bucket.

Understanding the Substance

Benzylcetyldimethylammonium chloride belongs in the family of quaternary ammonium compounds that clean and disinfect surfaces ranging from hospital equipment to public washrooms. Many folks working in facilities probably recognize the sharp, soapy odor and the slippery touch of concentrated solutions. Over the years, I’ve seen too many janitorial closets double as hazardous storage sites, mostly because people overlook a few simple, but crucial, steps in managing chemicals like this one.

Temperature and Environment Matter

Storing this compound in a dry, cool spot makes a big difference. Humid air or high heat can mess with its stability and lead to unexpected reactions. I’ve seen containers left in sunlit windows at storage facilities — a mistake that invites leaks, fumes, or worse, a chemical change. Industry sources, including the World Health Organization, stress that 15°C to 25°C is ideal. Direct sunlight will degrade many disinfectants, even if the bottle feels sturdy. Keeping the bottle or drum away from heat sources, like radiators or poorly insulated warehouses, helps preserve shelf life. Secure ventilation prevents vapor build-up, important in rooms without much airflow.

Packaging: Not Just Any Container

Original containers play a key role. The packaging does more than just hold the chemical in place; it stands up to the product’s corrosive tendencies. Shoddy replacement jugs or reused plastic can buckle after a few months. I still remember a near-miss at a small medical clinic where someone poured a batch into a mislabeled water jug. That jug crumbled by summer. Using manufacturer-issued containers helps avoid accidental mixing, keeps warning labels front and center, and limits surprises. If residue collects or crust forms around the cap, that usually means a slow leak or improper seal — both of which need attention before a bigger mess arises.

Mixing and Measuring: Keep an Eye on Dose

This disinfectant works well only if measured right. Pouring straight from the bottle into a sink or mop bucket will amplify risks, especially for skin and eye health. The Centers for Disease Control and Prevention recommend using gloves and goggles due to irritation risks. In my experience, reusable measuring cups marked for chemical use—never kitchen leftovers—help avoid confusion and accidents. People forget that dilution often means mixing into water, never the other way around, to prevent a splashing hazard. Capping bottles as soon as they’re poured stops evaporation and keeps fumes in check.

Hazards: Don’t Underestimate Exposure

Most label warnings spell out the risks: burns, breathing problems, and danger to pets and kids. Just last year, a minor spill at a local poolhouse sent two staff to urgent care with skin irritation. Quick action with water contained the issue, but it showed how easily accidents happen. Never store this chemical next to food or drink, even in cleaning closets next to break rooms. Regular checks of shelf integrity and a logbook for opening dates offer more control. Health Canada and OSHA recommend routine safety drills for staff working with any ammonium-based disinfectant.

Solutions for Safe Handling

Safety training lifts a lot of the burden off individuals by teaching the small details — like storing below eye-level to prevent spills and not stacking heavy items on weak containers. Spill kits nearby, containing absorbent granules, gloves, and eye-wash, make a practical difference. Clear labels, including hazard symbols and dilution instructions, prevent rushed mistakes. I find that dedicated shelves for quaternary compounds, separate from other cleaners, cut down on cross-contamination. Prompt cleanup, smart storage, and routine checks make accidents the exception.

Recognizing the Hazards

Benzylcetyldimethylammonium chloride pops up in plenty of cleaning products and disinfectants. My time as a science teacher reinforced how quickly folks can overlook chemical safety, especially with something that seems so common. This compound doesn’t just linger in a bottle; it can wreak havoc if not handled right. Get it on your skin, eyes, or in your lungs, and irritation strikes fast. At higher levels, this isn’t something you want in your house or workplace without thoughtful consideration.

Using the Right Protection

Simple gloves and goggles go a long way. I’ve watched countless folks try to skip these steps, thinking cleanups are quick or harmless. Then redness shows up, or someone coughs through a whole shift. Opt for nitrile gloves instead of flimsy latex, and goggles that form a seal. Factory workers, janitors, and home cleaners each face risks. Direct contact with this compound will sting and leave marks, so keep exposed skin covered, no matter how rushed things get.

Ventilation: Don’t Ignore the Air

Fumes don't play favorites. Any time I’ve worked with strong disinfectants in poorly ventilated spaces, headaches weren’t far behind. Open windows, run exhaust fans, and prop open doors. If you’re in an enclosed room, the air turns sour fast. Ventilation cuts down on fumes getting into your lungs and keeps everyone sharper and safer on the job.

No Shortcuts with Mixing

I once watched a coworker pour leftovers from two bottles together, thinking they’d cut down on waste. Chemical mixing can make things worse—sometimes releasing dangerous gas, sometimes breaking down the active ingredients. Stick to what the manufacturer prescribes. Label all containers clearly. Don’t pour unknown substances down the drain, since benzylcetyldimethylammonium chloride harms aquatic life and messes with plumbing systems.

Safe Storage

Accessibility and safety don’t always go hand-in-hand. In a school, we made sure this compound stayed locked up and far from where kids could reach. Sunlight, heat, and open flames can all boost risks. Store these products in cool, shaded spaces, and look out for leaking or damaged bottles. I once saw a cleaning supply closet flooded because one lid broke—smell and skin trouble followed close behind. No one wants a similar mess at their workplace or home.

Tackling Spills and Accidents Head-On

I’ve handled more than a few chemical spills. The first instinct some people have is to grab paper towels and wipe, but that spreads the compound around. Use absorbent materials that can handle chemicals, and bag everything before disposal. Wash affected skin straight away, rinsing for at least fifteen minutes if it splashes. Call poison control or a doctor after accidental exposure, even if things seem mild at first.

Training and Ongoing Awareness

Honest conversations about the dangers matter. We hold short workshops at work because it’s easy to forget steps as the months roll by. Read the safety data sheets. Watch for updates from health agencies. Encourage everyone to speak up about missing protective gear or unsafe storage. Experience shows that a little time spent learning prevents big headaches—sometimes literally. Safety doesn’t happen by accident; it follows good habits every time you open a bottle, spray a surface, or mop the floor.