Benzyldimethylstearylammonium Chloride: Commentary on Its Evolution, Applications, and Outlook

Historical Development

Benzyldimethylstearylammonium Chloride started making a mark in the early twentieth century as scientists explored quaternary ammonium compounds for their uses in disinfection and sanitation. Confidence in this compound grew side by side with public health improvements, as more research confirmed its role in fighting microbes across hospitals and food plants. Its roots can be traced to a period when simple soap no longer met demands for sanitation, and researchers sought molecules capable of breaking through biofilms and stubborn contamination. This chemical became a solid fixture during waves of hospital-acquired infections and industry-driven cleanroom expansions. Even now, memories of those breakthroughs influence how we use and trust it.

Product Overview

Manufacturers rely on Benzyldimethylstearylammonium Chloride for its power as a surfactant, boasting a strong cationic charge that attacks germ membranes. In my years working alongside cleaning supply chains, I’ve seen how simple shifts in this chemical’s grade or concentration turn it from a household disinfectant component into a critical ingredient for industrial machinery wash systems. The product fits a range of forms—usually found as an off-white solid or clear solution depending on dilution—and finds its way into detergents, algaecides, and anti-static agents. The molecule’s molecular backbone lends it a capacity for both surface adhesion and disruption of microbial life, which encouraged product developers to push its use into ever more specialized corners of sanitation and processing.

Physical & Chemical Properties

Benzyldimethylstearylammonium Chloride forms a white crystalline powder, often dissolving in water to make a clear, viscous liquid. Lab techs remember the whiff of its faint amine odor, a telltale sign of its presence. These physical clues matter for safety—improper handling can irritate the nose and skin. Its melting point reaches just above room temperature and it demonstrates solid thermal stability in most urban environments. The cationic head and lipophilic tail mean this compound readily aligns at surfaces, lowering surface tension to help lift grime and oil. Once mixed in solution, the chloride salt drives ion-exchange processes that can break down charged contaminants on fabrics and machinery.

Technical Specifications & Labeling

Professional-grade containers show concentrations usually hovering between 50-80%. Labels highlight CAS numbers, lot codes, purity level, and manufacturer contact details. In my fieldwork, technicians paid careful attention to these technical documents—minor deviations in concentration or pH strongly altered sanitation cycles, a result that could cost hours in hospitals or water treatment plants. Regulatory agencies keep a tight watch, requiring rigorous documentation to ensure safety and repeatability. SDS information, hazard pictograms, handling instructions, and expiration dates mark each batch for easy tracking and safe use, which forms the backbone of chemical compliance.

Preparation Method

Benzyldimethylstearylammonium Chloride comes from alkylation of tertiary amines—specifically, reacting stearyl-dimethylamine with benzyl chloride under controlled conditions. Heat, stirring, and precise pH adjustment keep the process stable, avoiding impurity buildup or color changes. In industry, batch reactors manage scaling up, but I’ve seen small-scale laboratories producing sample runs for research, where control over reaction time and moisture content gets crucial. This synthesis demands accurate control to achieve the long alkyl chain’s proper insertion, as side-products can decrease both yield and effectiveness.

Chemical Reactions & Modifications

The molecule stands out for its highly reactive quaternary ammonium group, opening doors to a suite of derivative compounds and reaction products. Research teams frequently test alkyl chain substitutions, examining how small changes impact antimicrobial power and compatibility with various polymers. In wastewater treatment, combinations with non-ionic surfactants can enhance dirt-carrying strength, while simple alkaline hydrolysis can modify the compound for less persistent environmental footprints. The route to new blends leans heavily on in-lab performance testing, as any tweak to the molecule often translates to a real change in foaming or cleaning results in industry settings.

Synonyms & Product Names

Walking through a storage warehouse, you’ll hear Benzyldimethylstearylammonium Chloride referred to by many names: Stearyl dimethyl benzyl ammonium chloride, Cetrimide S, or sometimes by off-brand trade names that change with supplier. This patchwork of synonyms springs from decades of regional branding and regulatory overlap—something procurement managers wrestle with as they check inventory for compliance. I’ve seen confusion arise with similar-sounding compounds, which underscores the value in strict batch record-keeping and up-to-date product indexes.

Safety & Operational Standards

Handling this chemical calls for vigilance—goggles, gloves, proper ventilation, and strict separation from incompatible substances. Direct exposure can cause skin burns, eye irritation, or respiratory distress, an all-too-common lesson for new workers in the field. Cleaning crews run through training drills to internalize hazard pictograms and emergency measures. Storage tanks require robust labeling and regular integrity checks, as accidental spills risk rapid release of airborne vapors. Fire departments near industrial sites keep specialized foam on hand, given that chemical fires require more than water. OSHA and the EPA both track workplace incidents, recommending tight oversight and clear procedures. Safety standards keep pace with research, periodically updating as fresh toxicity data or improved formulations hit the market.

Application Area

From hospital disinfectants to swimming pool algaecides, Benzyldimethylstearylammonium Chloride claims a spot in dozens of key operations. During my visits to textile mills, the compound appeared as an anti-static and softening agent, lowering the likelihood of static charge buildup on synthetic fibers. Food processing plants tap its disinfectant power to sanitize surfaces in high-throughput environments, maximizing yield and minimizing the risk of contamination. Municipal water authorities reach for it during treatment of pipelines and tanks, breaking down slime and microbial deposits that threaten flow efficiency. Even dairy farmers understood the value, dosing it in wash cycles between milking sessions. Each field discovers unique benefits, but the core features—a strong cationic presence, antimicrobial activity, and surfactant properties—run as threads across these diverse applications.

Research & Development

Research labs, both private and academic, continue probing the compound’s limits—searching for ways to extend effectiveness against drug-resistant bacteria or enhance biodegradability. Environmental engineers focus on how to dial back persistence and toxicity in aquatic systems, looking for tweaks that maintain cleaning power without lingering aftereffects. Collaborative groups test the molecule in new blends, attempting to create formulations that hold up under harsher processing or require gentler disposal methods. When I talk with chemists at trade expos, enthusiasm bubbles up around ongoing efforts to understand nano-scale interactions and the potential for pairing this compound with emerging green chemistry protocols. Advances in analytics let development teams track by-products with unprecedented detail, shaping the next generation of safe, sustainable products.

Toxicity Research

Toxicologists have tracked the health impacts, running standardized chronic and acute exposure tests in lab animals and through workplace epidemiology. At low concentrations, the chemical breaks down in water and soil, but high doses kill aquatic life and linger on biological surfaces. Some studies flag its potential for cumulative skin damage with frequent contact, so industrial users rotate personnel and introduce periodic health monitoring. Environmental groups laid pressure on regulatory agencies to tighten wastewater discharge limits, urging more in-depth longitudinal studies. I remember cases where outbreaks traced back to improper dosages, serving as reminders for why regular risk assessment and updated educational programs matter so much.

Future Prospects

Demand shows no sign of slowing as public health crises, water shortages, and food safety requirements all reinforce the need for improved disinfection and cleaning solutions. Green chemistry advocates press for versions that perform under leaner environmental rules—less persistent, more biodegradable, with reduced aquatic toxicity. Startups eye formulations based on renewable feedstocks, attempting to edge out fossil-fuel-based synthesis routes. Researchers keep testing new delivery modes, from encapsulation in polymer beads to controlled release sprays, all in the pursuit of cutting waste and boosting efficacy. In my experience, transparent sourcing and full-spectrum safety testing have emerged as industry must-haves, shaping not only what goes in each barrel but also how consumers and regulators look at labels. More honest communication—about risks and improvements—boosts confidence, guides safe use, and ensures this compound’s future in modern cleaning, processing, and health protection.

Trying to Stay Clean in a Messy World

Take a walk through the aisles of any supermarket and the shelves shine with bottles promising “99.9% germ kill.” That power comes from chemicals, and benzyldimethylstearylammonium chloride—let’s call it BDSAC for short—ranks among the workhorses. You’ll find it included in disinfectant sprays, surface wipes, and even some liquid soaps. Its job is simple: attack bacteria, viruses, and fungi before they can multiply. That matters not only at hospitals or industrial kitchens, but also in homes where the smallest germ can upend a family’s week.

My time cleaning up after two curious kids (and an accident-prone dog) has proven just how quickly messes happen. People want disinfectants they trust. BDSAC doesn’t just wipe dirt away—the chemical bonds tear apart bacteria cell walls and scramble their functions. The U.S. Environmental Protection Agency and regulators around the world require strict testing, so users know it works against key pathogens, from Salmonella to the stubborn norovirus.

Where Hygiene Gets Serious

Hospitals, animal shelters, food-processing plants—none have the luxury to gamble with germs. BDSAC shines because it works even in hard water, sticks on surfaces, and keeps killing long after the first spray. In clinics, surfaces get wiped down several times daily. Disinfectants with BDSAC prove reliable when speed matters and workloads run high.

One thing often missed in the molecules-and-microbes talk: surface safety. Unlike bleach, which discolors or corrodes, these quats won’t ruin cloth upholstery, stainless-steel counters, or sensitive equipment. As someone who watches every penny spent on furniture, I appreciate chemicals that kill germs without destroying what they touch.

The Other Side of the Story

There’s always another angle. I’ve read reports and spoken to teachers whose classrooms smell like hand sanitizer. Overuse brings new worries. Some germs adapt. Resistant strains, like MRSA, raise warnings. This isn’t about ditching disinfectants altogether—life in a hospital would be chaos without them—but also about using them wisely.

BDSAC must be diluted correctly. Bottles carry instructions for a reason. Over-concentration leads to residue on surfaces, which can trigger allergies or asthma in sensitive groups. In my house, a little goes a long way, and airing out rooms after cleaning has improved everyone’s breathing.

What’s Next: Responsibility in Our Hands

Real solutions come down to knowledge and balance. Cleaners with BDSAC serve a purpose where cleanliness isn’t just a preference, but a lifeline. Everyday users—parents, teachers, facility managers—should stick to recommended amounts and alternate with good old soap and water where possible. Developers and chemical companies can help by making labels clear and supporting research into environmental impacts. Some brands already explore biodegradable alternatives that break down faster in wastewater.

Hygiene matters. Trust matters even more. Knowing what’s inside household chemicals makes a difference. By giving thought to their use and their role, people can stay safe without turning their homes or workplaces into chemical battlegrounds.

A Chemical Hiding in Plain Sight

Benzyldimethylstearylammonium chloride shows up more places than most people realize. Hospitals rely on it to kill germs. Factories add it to cleaning solutions, and it hangs around in some personal-care products. Whenever we hear about a chemical like this, the question pops up: what does it really do to us and to the world outside the lab?

Impact on Human Health

I remember sorting through bottles of hospital-grade disinfectants during the early pandemic chaos. Gloved, masked, hands raw from soap, I saw benzyldimethylstearylammonium chloride listed on nearly every label beside promises of germ-busting strength. On a label, it sounds promising. In real life, it’s not always so simple.

Contact with this compound can irritate skin, mouth, eyes, and breathing passages if it drifts through the air as a fine mist. There are medical reports of burns from accidental splashes or too-concentrated mixtures. While everyday users rarely hit those risky concentrations, it’s workers who really see the risks pile up. Prolonged skin exposure or breathing the vapors can trigger asthma-like problems or skin rashes. I have met hospital aides with stubborn hand rashes after months of scrubbing surfaces with these cleaners.

Research points out that ingesting even tiny amounts can threaten kids or pets. Swallowing can lead to gagging, vomiting, or much worse. So it’s not something to splash around at home without care.

What About the Environment?

Toxic chemical runoff used to sound like someone else’s problem—until I saw foamy rivers during a local waterway clean-up. Industrial cleaners, including quaternary ammonium compounds like benzyldimethylstearylammonium chloride, don’t always break down as quickly as we hope. They find their way to rivers and lakes. Just a bit can harm fish and aquatic bugs. Scientific reports highlight that some of these disinfectant residues interact with algae and fish in ways that damage fragile water systems.

Once in soil, this chemical doesn’t just vanish. It binds with particles and tends to stick around. Wastewater treatment plants remove most of it, but not all. So, it leaks out in small amounts that add up over months or years. That “low and slow” accumulation sits beneath the radar for a while, then shows up as ecosystem troubles later.

Seeking a Healthier Balance

Regulators in Europe and the US have set safety standards for workplace exposure, and manufacturers publish handling instructions. These rules matter, but I’ve found that a lot comes down to honest habits: using gloves, good ventilation, and proper dilution. Regular users—janitors, healthcare workers, custodians—benefit when employers offer real training, not just a poster on the wall.

For home use, switching to greener biodegradable products where possible reduces risks to people and the planet. Not every job calls for heavy-duty chemicals. Sometimes, soap and water truly do enough. On the larger scale, regulators should make sure companies share full data on breakdown and long-term effects, pushing for greener options. Research keeps catching up with what these chemicals do in real settings, and we need public access to those findings. Taking the time to read the fine print on ingredients isn’t just a chore—it’s part of taking care of the health of our homes and waterways.

Understanding the Real Risks

Benzyldimethylstearylammonium chloride, a cationic surfactant used in disinfectants and industrial cleaners, looks unassuming in its commercial packaging. In practice, small lapses in handling can mean big safety hazards. My early days working in a chemical stockroom taught me the value of reading the label twice—and the safety data sheet three times. Spills result in slippery floors. Those same qualities making it good at breaking down grime also mean skin and eye contact brings irritation fast.

Keep It Cool, Dry, and Contained

Until you’ve seen what humidity can do, it’s easy to underestimate the importance of a dry environment. Moisture causes this chemical to clump and degrade. Room temperature storage, away from heat sources, keeps things stable. I have watched coworkers stack cleaning chemicals near steam pipes—bad move. Increased temperature impacts shelf life and sometimes sparks reactions with other compounds nearby. Benzyldimethylstearylammonium chloride handles best in tightly sealed containers, away from sunlight. Light-sensitive chemicals toughen up in the right conditions, but cut corners and purity takes a hit.

Labeling and Segregation

I learned quickly to never trust memory. Labels fade or peel off—mark every container clearly with the chemical name and concentration. Segregate this compound from acids and anionics. If you don’t, expect instability, sometimes releasing dangerous fumes. There’s a reason the Occupational Safety and Health Administration (OSHA) points out the importance of chemical compatibility charts. A row of acidic toilet bowl cleaners stacked with quaternary surfactants brings real risk. Physical distance matters as much as a closed lid.

Personal Protective Equipment: Non-Negotiable

Even veteran staff skip steps–that’s where accidents sneak in. I’ve seen contact dermatitis after a quick, ungloved cleanup. Splash goggles, chemical-resistant gloves (nitrile or neoprene), and a long-sleeved coat minimize exposure. Benzyldimethylstearylammonium chloride stings mucous membranes, so no eating, drinking, or smoking near where it gets handled. After handling, wash hands thoroughly with soap and water. PPE sometimes feels like overkill, right until the first speck gets in an eye.

Ventilation and Spills

Don’t trust a musty storeroom. Ventilation sweeps any lingering fumes away—essential if you’re measuring out powder or mixing concentrates. In my own experience, poorly ventilated areas let vapors or mists build up, giving even experienced workers headaches. For spills, absorbent wipes and chemical spill kits keep things contained. Never sweep with a dry broom; that sends particulates airborne. Disposal should follow local hazardous waste laws—pouring down the drain has consequences for water treatment down the line.

Training and Routine Inspections

Well-trained staff catch signs of problems early. During my tenure, we held short, regular safety briefings so nobody got complacent. Routine storage checks spot leaks or damaged containers before they become health issues. A quick weekly look means fewer surprises and less scrambling. No system works on trust alone—update training with changes in product or process.

Taking Responsibility for Safety

Benzyldimethylstearylammonium chloride shares hazards common to strong cleaning chemicals. Respecting its risks means staying vigilant. Practical habits—checking the storage environment, labeling, using PPE, and staying informed—cut accidents down. Responsible storage doesn’t slow the work, it prevents setbacks and injuries. Even the best procedures work only if you follow them every day.

What This Ingredient Brings to the Table

Benzyldimethylstearylammonium chloride shows up in more places than most people notice. I’ve read the back of enough cleaning bottles and cosmetics labels to spot it among a list of other tongue-twisters. It works as a quaternary ammonium compound. In plain language, it tackles microbes, fights odors, acts as an antistatic agent, and even helps creams and lotions feel the way they do on the skin. This single ingredient manages quite a bit of heavy lifting, yet many folks don’t recognize its name.

How Companies Mix It In

In the lab, chemists don’t just dump this stuff into a big vat and hope for the best. They measure out the solid or concentrated liquid and stir it into water or oil—whichever base the formula runs on. It dissolves pretty well, so proper blending usually doesn’t lead to clumps or chunks. Even the temperature of the mixture plays a role, since higher heat lets the compound spread more evenly.

Each type of product sets its own rules. In hand sanitizers and disinfectant sprays, I’ve seen this ingredient used at specific concentrations—usually one to three percent. Too little, and you won’t get enough germ-fighting. Too much, and you could run into skin irritation or even chemical burns in some cases.

Real-Life Impact on Products You Use

Benzyldimethylstearylammonium chloride does more than clean. I once worked in a small lab where we compared its use to plain soap. Adding it made fabrics less clingy in the dryer, so it pops up in fabric softeners for a good reason. I’ve tried out lotions and noticed how much smoother the cream feels. That silky glide comes from this compound working behind the scenes as a conditioning agent, giving texture without a sticky mess.

The flip side shows up if you’re not careful. I have friends with sensitive skin who react poorly to quats like this one. Some countries even regulate the maximum levels used in leave-on and rinse-off products to help protect folks with allergies.

Potential for Safer and Greener Formulations

Safety and environmental health come up a lot in conversations about these chemical additives. Wastewater plants sometimes struggle to break down quaternary compounds. That means a portion can slip into rivers and lakes, causing harm to aquatic life. Some companies now search for biodegradable alternatives or tweak formulas to lower their environmental footprint. I’ve also seen a push for more transparent labeling, so anyone with allergies or concerns can spot this ingredient easily.

From my own perspective, a little bit of industry accountability goes a long way. Brands can share more details about their ingredient choices and educate people on how to handle their products safely. Even at home, reading labels and following directions pays off. For anyone interested in safer cleaning and personal care, checking the percentage of benzyldimethylstearylammonium chloride and understanding its job helps make more informed choices.

Diving Into the Details

Benzyldimethylstearylammonium chloride doesn’t show up in everyday conversations, but it manages to turn heads in chemistry and cleaning industries. Folks in labs and manufacturing lean on it for its antimicrobial qualities and its effectiveness in many kinds of sanitizing solutions. The name sounds like a mouthful, but this compound packs a story that’s easy to understand once you look a little closer at its structure and context in our world.

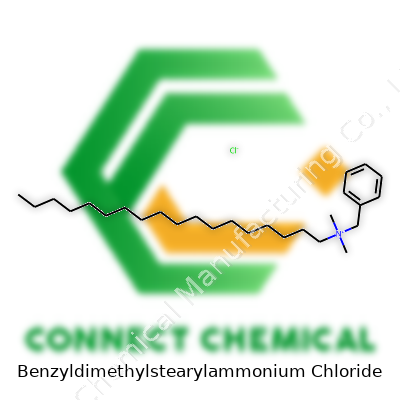

Breaking Down the Structure

Let’s not dance around: you’re looking at a quaternary ammonium compound. At its heart, it relies on a nitrogen atom that holds four groups. There’s a benzyl group, two methyl groups, and a stearyl group. Toss in a chloride ion and you’ve got the salt form used in most applications.

Chemists like to write this as C25H46ClN. If you spell it out, the formula shows one benzyl (a benzene ring with a -CH2- attached to it), two methyl (-CH3) groups, and a stearyl chain—basically an 18-carbon tail that’s fully saturated. This long fatty chain helps it stick to surfaces and disrupts bacteria and other microbes. The nitrogen sits at the center, binding it together and carrying a positive charge, which lets it attach with a negatively charged chloride.

The Official Stamp: CAS Number

Chemical Abstracts Service, or CAS, gives unique numbers for legibility and tracking. Benzyldimethylstearylammonium chloride carries the CAS number 122-19-0. This identifier ties it to a wealth of studies, handling recommendations, and manufacturing data. Pull it up in any reference book or safety sheet, and you know you’re talking about the right substance. It keeps emergencies, regulatory checks, and purchasing simple. No confusion over similar-sounding names or regional variations. Just those numbers, and the details follow.

Why Structure and Identity Matter

My own experience tinkering with surface disinfectants taught me that missing small details in a compound’s identity leads to mistakes that affect everything down the line. Properties change fast if the stearyl chain becomes another alkyl group, or if the benzyl gets replaced. Customers notice. Sometimes regulators do, too, and that brings headaches from recalls and product investigations.

Many quats share base features, but the stearyl group in this one offers strong hydrophobic interaction, making it great for binding to greasy surfaces or organic debris. Professionals need clear separation between chemical cousins; you don’t want to swap a household sanitizer ingredient with one for industrial machines. Knowing structure and accurate CAS information helps anyone—from a plant worker blending chemicals to a researcher working on safer disinfectants—keep safety and effectiveness where it ought to be.

Meeting Safety and Quality Expectations

Anyone working with benzyldimethylstearylammonium chloride needs to treat it with respect. Skin contact, inhalation, and improper disposal pose risks. Labels featuring the chemical formula and the CAS number don’t just comply with standards; they guide frontline users and warehouse teams every day. Reference guides and SDS documents use these identifiers to spell out proper handling, first aid, and disposal. This cuts down on workplace accidents and streamlines conversations between users, regulators, and suppliers.

Improving Transparency and Handling

If companies hope to avoid costly mishaps, they prioritize complete labeling and staff training on compounds like this. That means clear batch records, robust education, and easy-to-access reference materials. Digital cataloging of chemicals by CAS number works best for every scale—from neighborhood cleaning crews to big pharmaceutical plants—making audits and traceability more accurate.

Trust in any chemical product comes from consistency and clarity, which starts with understanding both structure and identity. Benzyldimethylstearylammonium chloride might not be a household name, but its precise makeup and documentation earn it a place in settings where quality and safety mean everything.