Benzyldodecyldimethylammonium Chloride Hydrate: Insight and Analysis

Historical Development

Benzyldodecyldimethylammonium chloride hydrate comes from a lively history rooted in the evolution of quaternary ammonium compounds, popularly known as quats. These compounds first appeared on the chemistry scene in the early 20th century when scientists were keen on finding new disinfectants and surfactants to handle increasing demands in both public health and industry. Early quats gained popularity during the 1930s for their ability to fight harmful microorganisms, especially at a time when hospitals and the food industry demanded rigorous sanitation. Over time, formulation improvements followed, leading to more stable, water-soluble, and effective disinfectants. Benzyldodecyldimethylammonium chloride hydrate owes its current role and effectiveness to these decades of incremental tweaks. It continues to benefit from research into its performance in varied environments, from agriculture to clinical settings.

Product Overview

Benzyldodecyldimethylammonium chloride hydrate presents as a solid or sometimes as a viscous paste, often shipped in tightly-sealed containers. This compound serves mainly as a cationic surfactant and biocide, earning spots in disinfectants, fabric softeners, and industrial cleaners. The big draw centers on its ability to disrupt bacterial cell membranes, making it valuable for cleaning protocols where the stakes are high — think surgery rooms or food processing belts. Its moderate solubility in water and compatibility with a range of solvents give it flexibility across industries. Commercial batches frequently carry labels pointing to both its purity levels and intended uses, a nod to years of lessons learned about its variable performance in the field.

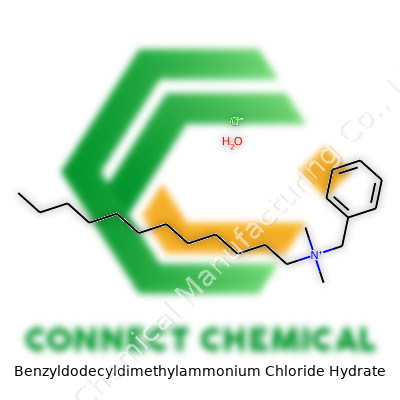

Physical & Chemical Properties

Benzyldodecyldimethylammonium chloride hydrate holds a white, crystalline or powdery look, shaped by the presence of its water of hydration. Its chemical nature as a quaternary ammonium salt equips it with a positive charge, lending itself to both cleaning and antimicrobial effects. Density ranges from around 0.95 to 1.05 g/cm³, and it melts at 45–50°C under standard conditions. Its solubility leans toward polar solvents, it handles moderate heat without breaking down quickly, and its characteristic quaternary structure fends off rapid degradation from sunlight or air. Stability and user-friendliness have made it a go-to for many cleaning and hygiene applications.

Technical Specifications & Labeling

Product standards tie closely to end use. Concentrations declared on labels can run from 50% active content in raw chemical supply to just a few percent in ready-use cleaning products. Key identifiers on labels consistently list warnings about skin and eye irritation, corrosion risk, and environmental hazards. Reference numbers from regulatory bodies, risk phrases, and guidance for proper storage and disposal mark good manufacturing practice. Technical bulletins often list pH (typically neutral to slightly alkaline), recommended dilution rates for different jobs, and shelf-life, which usually reaches two years under proper conditions.

Preparation Method

Large-scale synthesis brings together dodecylamine and benzyl chloride in alkylation reactions, using solvents and catalysts suited for high-yield operations. The quaternization step locks in the ammonium head with methyl groups before incoming chloride ions balance the whole mixture. Hydration adjusts water content to specification, sometimes through careful drying or deliberate addition of water. Manufacturers invest in minimizing impurities at each step, often using multiple purification phases, from filtering to adsorption columns. By the time the product leaves the plant, quality testing focuses on residual byproducts, chloride level, and consistency of the hydrate.

Chemical Reactions & Modifications

This compound reacts predictably owing to its simple quat backbone. The quaternary nitrogen resists most reduction and oxidation agents but can undergo ion exchange if stronger halides enter the scene. Modifications, like shortening or lengthening the alkyl chains or swapping the benzyl group, influence both biocidal power and solubility. Researchers have explored pairing it with nonionic surfactants, organic acids, or chelators to improve efficiency and stability. In my lab days, mixing it with ethylenediaminetetraacetic acid (EDTA) boosted antimicrobial action through synergistic effects, demonstrating its utility in custom blends.

Synonyms & Product Names

Over the years, this compound has gone by a handful of names. Common synonyms include "Lauryl dimethyl benzyl ammonium chloride" and "Benzalkonium C12." On safety sheets, you may see abbreviations like 'BDDAB', referencing its structure. Different suppliers market blends or derivatives under brand names targeting sectors from textile processing to swimming pool disinfection. Don’t expect standardized naming, which can cause headaches in research or purchasing; reading full product specs remains more reliable than chasing synonyms.

Safety & Operational Standards

Chemicals in this family demand strict respect for safety. Direct skin contact can cause irritation — some workers report dermatitis after frequent use, especially in dilute solutions applied by hand. Vapor isn’t a big issue due to low volatility, yet splashes and spills demand prompt cleanup. Storage rules call for tight containment, away from acids that may liberate toxic fumes. Regulatory agencies like OSHA and the European Chemicals Agency classify it as hazardous, setting occupational exposure limits and requiring personal protection gear for frequent handlers. Disposal follows wastewater guidelines, often needing pre-treatment to break down active residues.

Application Area

You find benzyldodecyldimethylammonium chloride hydrate not only in hospital disinfectants but also in veterinary clinics, dairies, and agricultural wash-down routines. Its surfactant role turns up in personal care items, from shampoos to hand washes, though some countries keep a close eye on allowable concentrations. Textile manufacturers value its antistatic and softening effects, while water treatment facilities use it to help control biofilm in pipes. Growing concern about microbial resistance has brought calls for balanced use, making stewardship programs in hospitals and food processing plants more important than ever.

Research & Development

Researchers have been busy testing new formulations and delivery systems for these types of surfactants and antimicrobials. Increased attention has gone into time-release systems, layering benzyldodecyldimethylammonium chloride hydrate with other actives, and even encapsulating it in nano-carriers to guide it toward biofilms. Scientists test alternative alkyl chain lengths, ratios of hydrophobic to hydrophilic character, and compatibility with green solvents. Many labs also focus on breaking down the entire substance quickly in wastewater to limit environmental impact while keeping costs workable for hospitals and city water departments. In recent consortiums, combining this compound with newer enzymes draws interest for potential use in problem areas like chronic wound care.

Toxicity Research

Toxicity data show its main risks revolve around acute skin and eye irritation, with dry, scaly patches arising in workers lacking consistent use of gloves. Animal studies point to low-to-moderate systemic toxicity, but high environmental persistence sparks attention from regulators. Aquatic organisms show sensitivity at low micromolar levels, making wastewater discharge a major regulatory focus. Studies in the past 10 years investigate chronic exposure, potential for endocrine disruption, and non-target microbial shifts in soil and water systems. My own experience in aquatic ecotoxicology highlights the long shadow these compounds cast on filter feeders in downstream rivers.

Future Prospects

Moving forward, industry and regulators both drive changes. Calls for higher sustainability mean research leans toward rapid degradation in the environment without losing cleaning punch. Chemical engineers look for tweakable structures: adjusting chain length, branching, or functional groups, so wastewater plants can degrade final residues after use. Healthcare settings pursue surface coatings that last longer between cleanings and cut down on chemicals, while agriculture explores blends that protect crops but break down into harmless byproducts just as fast. The next chapter for benzyldodecyldimethylammonium chloride hydrate depends on striking the right balance between antimicrobial effectiveness, safety to people, and responsible handling of its residue.

Not Just a Tongue Twister—Why You Might Care

Benzyldodecyldimethylammonium chloride hydrate doesn’t exactly roll off the tongue, but the stuff shows up in places that matter to real people. A lot of folks have wiped down grocery store carts during a pandemic, handled disinfecting wipes while trying to keep a household running, or watched cleaning staff at work in schools and offices. That fresh smell and peace of mind can owe a lot to chemicals like this one—sometimes shortened to BDDA or BDDAC in scientific paperwork. What matters is that this compound gets called up for heavy-duty cleaning and sanitation.

Straightforward Cleaning Power and Disinfecting Uses

This compound fits into a group often called quaternary ammonium compounds, or simply “quats.” Picture hospital floors getting mopped, cafeteria counters wiped down, and kitchen prep tables scrubbed daily—quats sit at the core of products used for those jobs. In my experience working evenings for a property management company, warehouses lined with supplies had labels listing these chemicals front-and-center. Disinfecting surfaces means keeping viruses and bacteria out of the equation. Without effective compounds, infections can spread fast. During public health emergencies, demand for strong, reliable surface disinfectants shoots up. The presence of BDDA in wipes and sprays isn’t a random choice. It gets tested for real-world threats, including bacteria like Staph and viruses like norovirus and influenza.

Everyday Settings: From Hospitals to Your Kitchen Counter

Think about the variety. Hospitals, schools, gyms, restaurants, even cruise ships all aim to beat back germs. Whiteboards in schools, hospital bed rails, trays in diners—these are high-touch places that carry risk for spreading illness. BDDA is used in the wipes that nurses carry in pockets, as well as the sprays used on kitchen islands at home. A lot of businesses and institutions use it not just for killing germs, but also for dealing with mold and mildew in damp spots. It can even turn up in some personal care items like hand sanitizers and shampoos, where low concentrations help keep bottles from growing mold after opening.

Food Safety and Farm Use

The food industry relies heavily on this cleaning power. I've seen produce facilities cycle through buckets of sanitizer mixed with BDDA to rinse cutting boards, equipment, even conveyor belts. USDA and FDA regulations push for strong sanitation to avoid outbreaks of things like E. coli. That's why meats, cheeses, and packaged salads have to be processed in squeaky-clean environments. Even on farms, this kind of chemical finds a job disinfecting animal housing, equipment, and boots—anywhere bacteria could jump from surface to animal or person. It brings some peace of mind to people buying groceries, knowing standards get followed in the background.

Health and Environmental Questions

Trust grows when people see clear safety standards followed. Of course, every chemical with disinfectant power carries concerns about health and environmental effects. It pays to pay attention to proper use—wearing gloves, mixing at the right strength, and rinsing when required. Some scientific studies point to possible buildup in water supplies or harm to aquatic life if wastewater isn’t handled well. For homes, that means not dumping extra disinfectant down the drain. For industry, it means more rigorous wastewater treatment and better alternatives where possible. We need safer, greener cleaning solutions, but we still depend on powerful products like BDDA today—especially in the toughest jobs keeping bugs and outbreaks from getting out of hand.

What Is Benzyldodecyldimethylammonium Chloride Hydrate?

Benzyldodecyldimethylammonium chloride hydrate pops up in a lot of cleaning supplies and disinfectants. Hospitals, schools, salons—you’ll see it listed in quite a few products advertised to kill germs. It belongs to a group called quaternary ammonium compounds. Chemists trust these compounds for wiping out bacteria and viruses on hard surfaces. People outside of the lab start to wonder, though, if a chemical tough enough to clean surgical instruments should get anywhere near human skin.

How Skin Reacts to This Compound

Most folks running a search for this chemical want to know if their disinfectant wipes or sprays are safe to use by hand. Simple skin contact with diluted forms tends to pass without trouble for many people. Problems usually pop up after using strong concentrations, frequent exposure, or if someone already wrestles with sensitive skin or eczema. Reports from the American Contact Dermatitis Society highlight cases of redness, stinging, and sometimes painful rashes. In rare cases, people get allergic reactions that need medical care.

I remember once cleaning tables for a school function using a spray with a similar "quat." I didn’t wear gloves. My knuckles felt rough for two days. I didn’t think a single cleaning session would matter, but it made me more careful, especially after reading research from the National Institute for Occupational Safety and Health. Their studies tie repeated exposure at workplaces to higher reports of dermatitis among cleaning staff. Research reviews in journals like "Contact Dermatitis" point out that these reactions come more often in cleaning crews than in casual users at home.

Looking at the Evidence

Scientists routinely run skin tests with typical product strength to spot problems. Studies usually find that diluted forms, as sold in most consumer products, don’t harm most people if used as intended. Dangerous reactions follow after folks work with industrial strength solutions or fail to rinse the chemical properly. The U.S. Environmental Protection Agency classifies quaternary ammonium compounds as “skin irritants” in higher concentrations. A quick look at the Centers for Disease Control and Prevention guidelines shows a clear warning: always avoid prolonged contact, don’t use undiluted "quats," and rinse skin after accidental exposure.

What Actually Matters for Everyday Use

Safety depends on how much and how often you use it. Hand wipes in public spaces have much lower concentrations than hospital disinfectants. Most product instructions stress letting your hands dry after use and avoiding any direct contact with broken skin. Don’t trust a "gentle" label without reading the tiny print or following instructions. Rinsing hands with water and using a plain moisturizer afterward keeps skin barriers healthy—something my dermatologist backed up after my cleaning job experience.

If redness, itching, or swelling show up—even after only a few uses—switch to a different product. Healthcare workers or cleaning crews with frequent contact might push for alternatives or ask employers for gloves. Relying on soap and water for regular hand washing still beats any chemical for safety, especially for kids or anyone with skin allergies.

Better Choices and Solutions

Safer habits start with reading labels, following directions, and respecting skin limitations. Strong disinfectants have their place, no doubt, but using them as a go-to skin cleanser doesn’t lead to healthier hands. Workplaces need to train employees, supply proper gloves, and provide access to safer skin care products. At home, sticking with soap and water covers most routine needs—and avoids skin problems from chemicals meant for more heavy-duty jobs.

Why This Chemical Matters in Everyday Spaces

Benzyldodecyldimethylammonium chloride hydrate finds its way into a surprising number of homes, hospitals, and labs as a powerful disinfectant and sanitizer. Many have probably used a cleaning product with this chemical and never thought twice about what happens if it isn’t stored the right way. Safety doesn’t start with wearing gloves—it starts with what you do the minute that container arrives on your shelf.

Controlling the Environment: Temperature and Placement

Temperature swings create trouble. Heat breaks down the effectiveness of this ammonium compound, and cold can lead to unwanted clumping that changes the consistency. In my experience working in both community clinics and university labs, keeping chemicals like this at room temperature, far from direct sunlight or heater blasts, guarantees reliability. A stable 20 to 25°C works well in most climates. Placement matters, too. Try to store it up high on a sturdy shelf, tucked away from children, pets, or foot traffic. Even well-organized clinics have seen unfortunate spills from a misplaced bottle or a distracted employee.

Securing the Container: Moisture and Air Exposure

This compound draws moisture like a magnet, risking spoilage and dangerous fumes. Humid environments shorten shelf-life quick. An airtight, original container seals out both humidity and excess air. My old lab manager drilled into our heads: the tighter the cap, the longer the chemical stays potent. Using a glass bottle with a screw cap works well if the product arrived that way, but never repackage unless the label says it’s safe. Every label carries a unique batch number, which really helps track problems if anything ever goes wrong.

Chemical Compatibility: No Mixing, No Drama

Benzyldodecyldimethylammonium chloride hydrate has a strong personality in the chemical world. Acids, oxidizers, and many household cleaners don’t play well with it. Keeping this compound away from bleach, for instance, stops the risk of forming toxic gases. In settings like hospitals, color-coded storage bins help prevent accidental mix-ups. I’ve seen messy supply closets with mysterious containers next to janitorial carts—a recipe for confusion. Clear separation and good labeling beat guesswork every time.

Labeling and Documentation: Taking Out the Guesswork

Handwritten labels fade or fall off. Barcodes or pre-printed industrial labels hold up through lots of handling. Digital inventories bring a more reliable system. One facility I visited introduced a digital sign-in for every chemical that entered their storage area. That meant a quick scan could tell who checked the bottle out, when, and for what purpose. If someone ever asked, "Where did that go?" the answer was in the records, not up for debate.

Emergency Preparation: Just in Case

The best plans account for mistakes. Every shelf with strong disinfectants should have easy-to-read emergency instructions taped nearby—think wash stations, spill kits, emergency contacts. In real emergencies, fumbling through paperwork wastes precious minutes. Every facility should walk through their spill or exposure response at least once a year. This simple drill helped our small team stay calm when a bottle cracked open—no panic, just action.

Final Thoughts on Staying Ahead

Benzyldodecyldimethylammonium chloride hydrate rewards proper storage with a long shelf life and safe results. Well-lit, dry, clearly labeled shelves set up everyone—chemists, custodians, and homeowners—for safety and peace of mind. Relying on experience, not just instructions, keeps this potent chemical working for the right reasons.

Finding the Sweet Spot in Disinfection

Disinfectants step in when people hope to keep germs under control, whether in hospitals, schools, or their own kitchens. Plenty of folks eyeball a splash of bleach or cleaner and hope for the best. If concentration lands too low, bacteria survive and multiply, defeating the point. If it goes too high, risk creeps in—surfaces get damaged, airways burn, and helpful organisms get wiped out alongside the bad. Each chemical brings its own story, and using past experience or guesswork never delivers reliable safety.

What Real-World Practice Shows

Take household bleach. For many surfaces, mixing one part bleach with nine parts water (so about a 0.5% sodium hypochlorite solution) knocks out viruses and bacteria efficiently. Higher doses burn skin and corrode metal, fast. Healthcare workers sharing tricks of the trade always stress careful dilution. In a busy hospital, using too strong a solution can set off asthma in staff, damage floors, and even trigger fire alarms with chlorine fumes. Cleaning professionals get used to reading tiny print on disinfectant bottles, following instructions, and keeping logbooks to show inspectors they’re not just winging it. Regular training beats any shortcut, especially when safety sits on the line.

Learning from Science, Not Just Labels

Some disinfectants need specific concentrations to take down certain pathogens. Chlorine works best at 1000 parts per million for most viruses—including norovirus, which often takes down cruise ships and cafeterias. Alcohol-based hand sanitizers need at least 60% alcohol to really break apart viral coatings and end the infectious cycle. Quaternary ammonium compounds, often found in disinfectant wipes, require at least a 0.1% solution to stop bacterial growth. Pseudoscience slips in when people believe “more is better.” Research shows that over-concentration doesn’t improve germ kill but can create resistant microbes.

Watching Out for Human and Environmental Costs

Overshooting the recommended dose may feel safer, like doubling down adds extra defense. A few years back, one school janitor confessed to adding extra bleach because “flu season was bad.” The result? Kids complained of headaches, teachers lost their voices, and floors peeled up from chemical damage. Environmental agencies keep warning against pouring strong mixtures down the drain, as high concentrations build up in rivers and affect aquatic life. The right dose means balancing the need for health protection with respect for the people who share the space—and the planet they call home.

Practical Steps Forward

Keeping a sheet of printed protocols near every cleaning station helps prevent accidents and confusion, especially in environments with shift work and language barriers. Suppliers owe it to customers to label products in plain language and alive font size, not microprint legalese. Staff deserve fresh gloves and eye protection when cleaning. Regular training refreshers close knowledge gaps and help head off errors. If a cleaner or caretaker notices strange smells, stains, or lingering residue, dialing back and checking instructions can help avoid bigger mishaps. In busy households, labeling spray bottles with both contents and date of mixing adds an extra layer of assurance.

Sticking to proven concentrations for disinfectants protects lives, improves trust, and keeps spaces healthy and welcoming. That precision isn’t a bureaucratic hurdle—it’s real-world wisdom born of sweat, science, and shared community spaces.

How Side Effects Show Up in Everyday Life

People crave the benefits that come with new products, yet side effects don’t always get the same attention. Whether it’s a supplement, a food, a chemical cleaner, or the latest tech gadget, unwanted effects can sneak in. Side effects often appear as headaches, rashes, stomachaches, dizziness, fatigue, or in rare cases, more severe symptoms. If you’ve ever tried a new lotion and broke out in a rash, you know the frustration. I once bought a new kitchen cleaner. On day one, my hands got red and itchy. I learned quickly that skin reactions mean there’s something in the formula that doesn’t agree with me or plenty of others. In my work, I talk to people dealing with the fallout of overlooked warnings—so I know the importance of transparency.

What Drives These Unwanted Reactions?

Ingredients tell a big part of the story. Some additives trigger mild irritation. Preservatives or fragrance compounds can lead to allergic responses. Even “natural” products cause havoc—think about peanuts or pollen. Long ingredient lists make it tough to pinpoint the troublemaker. Some products interact with medicines. Grapefruit juice, for example, blocks enzymes that break down certain drugs, which can turn a safe medicine into a risky one. In tech, poorly shielded devices emit signals that set off migraines for some users. Awareness about these connections grows only when issues pile up, and people start looking for patterns.

Problems That Repeat, but Don’t Get Enough Attention

Marketing campaigns focus on promises. Packages flash words like “safe”, “natural”, and “gentle.” Real warnings get buried in fine print or hidden on a website you’ll never visit. Sometimes, companies don’t take complaints seriously until enough noise builds up on social media. Doctors often hear from people who react badly, but product makers could do more to gather reports and share risks truthfully. Too often, warnings get added only after someone lands in the hospital or shares a story no one can ignore.

Protecting Yourself and Your Family

Reading labels closely matters. If you don’t recognize an ingredient, look it up, or ask an expert. Trusted sources like government health agencies, pharmacists, and non-profit science sites publish clear lists of substances known to cause problems. If you start using anything new—skincare, food, vitamins—introduce it gradually. If you feel off, stop using it and look for patterns. I learned to photograph ingredient lists with my phone, so I’m never guessing at the store.

Product Innovation Needs Responsibility

Companies can do better by running thorough tests long before launching a product. Safety data shouldn’t stay in the lab; people deserve to know real experiences from other users, good and bad. Honest reviews, open customer service, and quick action when reports come in all build trust. It helps everyone make smarter choices.

Toward Smarter Choices

Product safety goes beyond regulation. It includes the daily judgment calls we all make. Knowing your own body, checking in with health professionals, talking with friends, and paying attention to how you feel help avoid harm. Responsible companies open up about what went right and what didn’t. That keeps safer products on shelves and gives everyone a fair shot at making healthy decisions.