Benzyltriethylammonium Chloride: More Than Just a Phase-Transfer Catalyst

Historical Development

Benzyltriethylammonium chloride began to make waves in organic synthesis labs during the mid-twentieth century, a time when chemists were desperate to bridge the stubborn gap between water and organic solvents. This compound, classified as a quaternary ammonium salt, moved past being another chemical name on the shelf after researchers found it could coax reluctant reactants from separate liquid phases into finally reacting together. The surge in phase-transfer catalysis from the 1960s left a visible trail in scientific literature, with benzyltriethylammonium chloride earning a reputation for its flexible use in both industry and academic experiments. Old organic textbooks mention its popularity, not just for its strong ability to shuttle ions across phases, but also for how reliably it sped up transfers in classic reactions.

Product Overview

Anyone working in a chemical industry knows benzyltriethylammonium chloride by its unmistakable odor and crystalline powder appearance. It’s offered by many of the major chemical suppliers, from bulk in large drums for scale-up to tidy bottles for the benchtop. Synthesizing it doesn’t break any new ground for experienced process chemists, but its prominent role as a phase-transfer catalyst keeps it in business. You’ll catch the name popping up in projects ranging from pharmaceutical manufacturing, personal care formulations, to the long aisle of lab-scale green chemistry developments. The accessibility and consistent performance ensure it stays in the toolkit of people trying to cut energy costs or reduce the use of toxic solvents.

Physical & Chemical Properties

Benzyltriethylammonium chloride catches the eye with its white crystalline look and a tangy, almost fish-like smell. Unlike some of its fellow quats, it shows solid solubility in water and a broad range of organic solvents, making it truly versatile. Its melting point, which usually falls around 162°C, makes it robust enough for standard lab conditions while not being so high that it’s annoying to handle. Stability in both acidic and basic media helps during those messy, multi-step reaction sequences. It resists decomposition even when things heat up—yet it’s not so stubborn as to resist eventual breakdown in the environment, which can be a relief to compliance managers.

Technical Specifications & Labeling

Specifications for benzyltriethylammonium chloride usually sit around 98–99% purity for research and industry. Suppliers label bottles with detailed hazard statements, batch numbers, traceability data, and storage instructions, since moisture and strong acids can degrade the product if you’re not careful. The solid is typically packed in tightly sealed, opaque containers to protect it from light and damp, reflecting a combination of regulatory rules and the practical wisdom passed through generations of lab techs. Certificates of analysis almost always tag along, providing purity, physical form, melting point, and sometimes details like IR spectrum or HPLC traces for advanced users.

Preparation Method

Those who’ve run the synthesis know it demands a straightforward alkylation process—reacting triethylamine with benzyl chloride. The reaction usually takes place in an inert organic solvent under controlled temperature, using a stoichiometric approach that limits byproducts. After the reaction, the product precipitates out, gets washed, and then dried. No exotic equipment needed, just careful temperature control and patience. Plenty of graduate students have watched white crystals form and filter out the raw benzyltriethylammonium chloride before chasing down that slight chemical smell left in the fume hood.

Chemical Reactions & Modifications

Getting creative with benzyltriethylammonium chloride goes beyond straightforward use—chemists often test its skills in nucleophilic substitution, alkylation, or as a support for base-promoted reactions. Its main trick is handing over anions smoothly between aqueous and organic layers, but people have tweaked its benzyl or alkyl groups to tune its hydrophobicity or bulk. By changing substituents, the molecule can serve as a starting point for preparing tailored catalysts and surfactants used in very specific processes, stretching its influence from detergent chemistry to complex drug synthesis. The starting chloride can also swap places with other halides or pseudohalides, allowing researchers to sculpt new reactivity profiles for specialized challenges.

Synonyms & Product Names

You won’t just see “benzyltriethylammonium chloride” on the label. The chemical goes by several tags, including TEBA, BTEAC, benzyltriethylammonium chloride, and sometimes just “phase-transfer catalyst” in old texts. Chemical catalogs from Sigma-Aldrich, Fluka, and TCI are flush with alternate spellings and product codes created for convenient inventory tracking. In industry settings, it’s usually the CAS number—56-37-1—that helps resolve any lingering confusion, especially during audits or custom synthesis negotiations.

Safety & Operational Standards

Working with benzyltriethylammonium chloride means watching for irritation, especially to the skin and eyes; good gloves and goggles matter more than ever with this stuff. Inhalation risks rise in busy labs or plant settings, and the safety data sheets spell out the importance of proper ventilation. The chemical can be a mild irritant, but like other quats, it poses an environmental hazard if dumped into waterways. Most responsible facilities send the waste stream through treatment to break down the compound before releasing water. Handling procedures have become much tighter over the years, especially as green chemistry principles creep into mainstream practice. Your average lab or factory has locked away stories of careless contact because modern rules close the gaps that once led to nasty surprises.

Application Area

The reach of benzyltriethylammonium chloride is hard to overstate. It has made a real name in the world of phase-transfer catalysis, allowing reactions like alkylation, oxidation, and esterification to run smoother and faster. Drug makers, for example, have adopted it for greener synthesis routes. It’s not just for high-end applications either; formulators in water treatment use it to remove contaminants, cleaning product manufacturers blend it in for its surfactant properties, and materials scientists sneak it into the process of making specialty polymers. As a university researcher, I’ve seen benzyltriethylammonium chloride transform slow, unreliable reactions into robust, scalable processes, saving weeks of troubleshooting and resources.

Research & Development

Research into benzyltriethylammonium chloride keeps unearthing practical insight, especially as labs push toward sustainability. Papers in the last decade describe tweaks that wring more efficiency or reduce side products in traditional organic syntheses. Scientists are probing hybrid catalysts that combine this molecule with ionic liquids or supported platforms to boost selectivity or make separation easier. Development interests now focus on greener synthesis and recovery processes, with funding bodies rewarding efforts that replace toxic or expensive alternatives with robust phase-transfer protocols involving this classic ammonium salt. Startups and public-private partnerships boost the pace, aiming to scale up greener technologies for everything from agrochemicals to renewable energy storage.

Toxicity Research

Efforts to unravel the toxicity profile of benzyltriethylammonium chloride point to moderate human hazards at chronic exposure and significant toxicity for aquatic life. Animal studies flag irritating effects at high doses, affecting liver and kidney function. Regulatory agencies in Europe and North America have flagged the chemical for close observation, with disposal and spill management rules steadily tightening. Long-term exposure through drinking water or dermal contact remains a worry, pushing research into safer alternatives and more efficient containment. Data collected in recent years provide baseline thresholds that regulators rely on, showing a clear move toward lower safe workplace concentrations and enhanced personal protection guidelines.

Future Prospects

The future of benzyltriethylammonium chloride depends on collaborations between chemists, engineers, and environmental scientists. Demand for sustainable manufacturing pushes the search for catalysts that minimize energy use and waste, putting phase-transfer agents front and center. The molecule’s adaptability means it won’t fade quickly, but industry looks for ways to recover and recycle it with lower energy costs. Synthetic chemists keep experimenting with modifications to tune performance or biodegradability. Regulatory pressure is likely to keep rising, so the pace of research into greener alternatives will keep accelerating. As more companies aim for net-zero targets and regulatory landscapes tighten, benzyltriethylammonium chloride stands at a crossroads—facing both strong demand and strong scrutiny.

Looking Beneath the Surface in Everyday Chemistry

Benzyltriethylammonium chloride doesn’t show up in the mainstream news, but folks working with chemicals know its value well. This compound feels almost like an old friend in industrial settings and research labs. Its main job? Helping reactions happen when water and oil-based substances would rather ignore each other. Technically, that’s called a phase-transfer catalyst. The trusted nickname is “TEBAC.”

Real-World Uses: Why It Matters

Factories turn to TEBAC to make medicines, herbicides, and specialty plastics. This compound helps chemical raw materials mix and react more smoothly. For example, drug companies rely on it when synthesizing active ingredients, saving both time and money. It streamlines the process, so factories can keep up with demand without cutting corners.

Agrochemical producers also work with it. Pesticides and growth hormones start out as complex molecules that need careful, controlled environments to form. Benzyltriethylammonium chloride ensures the building blocks meet and combine the right way. Biodegradable plastics wouldn’t hit the shelves as quickly without it making production faster and more reliable.

Familiar Challenges

Like many chemicals, using TEBAC responsibly calls for a watchful eye. If I think back to my own college days in the lab, there was always a healthy respect for these kinds of compounds. No one wanted careless mistakes that could send something down the drain or into the air without proper filtering. In industry, large-scale operations generate waste. Here’s where the focus shifts to tightening up practices so nothing dangerous slips through.

Research by the National Institute for Occupational Safety and Health highlights the importance of gloves and goggles. Accidental contact can irritate skin and eyes. It doesn’t take much to lose focus, especially on a long shift. Companies who train their workers, provide the right gear, and build a safety culture see fewer accidents and lower long-term risks.

Smarter Solutions for a Safer Industry

Switching to closed systems and updating filtration equipment helps a lot. Chemistry companies already invest in improvement, but there’s always room for more. Regulatory bodies like the Environmental Protection Agency encourage clean-up measures that go beyond the basics. By taking these extra steps, professionals protect not only themselves, but also neighborhoods and water supplies.

Transparency matters too. Researchers publish best practices and share accident reports so mistakes aren’t repeated elsewhere. Open conversations help set expectations for everyone involved, whether on the factory floor or in the boardroom. Digital training programs and real-time monitoring have made it easier to spot problems early without overloading staff.

Balancing Progress and Responsibility

Benzyltriethylammonium chloride’s reputation rests on its ability to make chemistry work better for industry. But with great power comes real responsibility. Clear guidelines, ongoing investment in safety, and an open culture keep workers, communities, and the environment out of harm’s way. That’s the kind of progress worth standing behind.

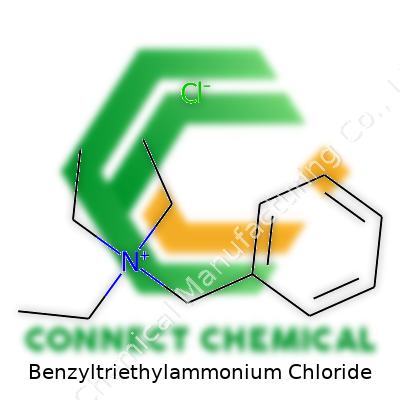

Chemical Formula Up Close

Benzyltriethylammonium chloride has the formula C13H22ClN. That’s thirteen carbons, twenty-two hydrogens, one chlorine, and a nitrogen atom. The structure might not look significant at first glance, but it tells plenty about what this compound can do in real-world labs and industries. Seeing it on a label always leads back to this structure, with a benzyl group, three ethyl groups, and a chloride balancing things out. This combination creates a molecule ready to move ions around, react with a wide set of chemicals, and serve more than just one role.

Real-World Applications Rooted in the Formula

I came across benzyltriethylammonium chloride during a summer internship in a synthetic chemistry lab. It showed up as a phase-transfer catalyst. This fancy title meant its unique structure helped pull ionic compounds from water into organic solvents, putting the right ingredients in the right place for a reaction to happen. Without a structure like C13H22ClN, reactions just stalled.

Chemists use it beyond laboratories. In the pharmaceutical world, it speeds up reactions that could drag on for hours otherwise. People cleaning up old pollution at industrial sites sometimes rely on this compound to shift stubborn ions in water treatment. Without knowing this chemical inside and out, engineers and scientists would be left guessing about compatibility and safety, which only leads to mistakes.

Health and Safety Questions

Working with chemicals that include nitrogen and chlorine always raises questions. The fact that benzyltriethylammonium chloride has a chloride ion means it shares some qualities with common salts, but its organic backbone changes the game. Safety sheets point to possible skin irritation or respiratory problems if it isn’t handled properly. Direct experience counts for a lot — in our lab, gloves and good airflow were non-negotiable. A clear chemical formula means safety teams can dive straight into databases like the EPA’s or OSHA’s and know if this compound will react with acids, bases, or other lab chemicals.

Supporting Responsible Practices

Knowing a compound’s formula isn’t about chemistry trivia. Clear identification keeps supply streams honest. I’ve seen cases where a mislabeled drum at a warehouse brought production lines to a halt because there wasn’t certainty about what was really inside. Proper tracking based on exact formulas like C13H22ClN keeps industries aligned with regulations and customer expectations.

Companies committed to best practices make use of structure-based databases, linking the right material to the right use case. If regulations shift, accurate records mean proactive changes happen faster. Transparency rooted in chemistry keeps workers and neighborhoods safer, and helps researchers find alternatives if a certain compound proves risky.

Paths Forward

Accurate identification and communication form the backbone of chemistry-driven industries. Teaching students the value of full chemical structures, not just trade names, encourages curiosity and accountability. Labs and factories benefit from open databases and smart labeling. People who understand why compounds like benzyltriethylammonium chloride matter help build safer, more innovative workplaces, and maintain public trust in chemicals that make modern life work.

Looking Beyond the Label

Benzyltriethylammonium chloride, known as BTEAC, often gets filed under “ordinary lab chemicals,” but that doesn’t make it harmless. This compound plays a part in a wide range of chemical processes, from pharmaceuticals to plastics and even water treatment. Few folks outside specialized labs have direct contact with BTEAC, but anyone working with it should take its risks seriously.

Physical Contact Isn’t Trivial

Let’s start with skin: BTEAC feels oily, but it brings more than a greasy residue. The irritant properties mean it can cause redness, itching, or blistering—especially with repeated or lengthy exposure. I’ve seen careless lab staff skip gloves for quick tasks, only to end up with persistent skin irritation. Even seemingly tough skin needs protection here. Eye contact stings intensely and can leave lasting discomfort, sometimes causing corneal damage.

Breathing It In: Not Worth the Risk

Fumes may not overwhelm the senses, but inhaling BTEAC dust or mist creates problems quickly. Watery eyes, coughing, a scratchy throat, and even breathing trouble make an appearance. In my time around industrial setups, I’ve seen production workers drop their masks and try to “tough it out.” Not long after, they land in the nurse’s room with burning lungs. Prolonged exposure ups the risk of respiratory tract inflammation.

Swallowing Is An Emergency

Few would accidentally sample BTEAC, though mistakes happen. A drop in the mouth usually brings nausea, stomach pain, and vomiting. More severe effects like diarrhea or abdominal cramps show up fast, and medical help becomes non-negotiable. My own training drilled this into us: every spill, every splash near the mouth is a cause for immediate action.

Long-Term Effects and Environmental Problems

Acute effects usually fade after prompt first aid, but the bigger concern for workers is what might come from long-term exposure. Chronic contact hasn’t earned the same headlines as substances like benzene, but there are still murky areas. BTEAC can mess with cells, irritating the mucous membranes and affecting liver enzymes in animal studies. Over time, that might spell trouble, especially for those on the production line or routinely handling concentrated batches.

Environmental hazard is another layer. BTEAC sticks around in water and doesn’t break down fast. Aquatic life takes a hit, especially smaller organisms, and local waterways sometimes show the impact of run-off from careless disposal. The EU classifies BTEAC as hazardous for aquatic environments, not just people.

Better Precautions for a Safer Workplace

In my years around chemical warehouses, the difference between safe outcomes and weekly accidents boiled down to habits. Gloves, goggles, tight storage, ventilation—all went from “suggestions” to “standard survival gear.” Training staff so that safety steps come naturally helps more than any poster or dusty binder in a closet. Regular safety drills, instant access to spill kits, and clear disposal protocols spare everyone unnecessary risk.

On the regulatory front, national agencies set workplace exposure limits, but personal responsibility fills the gaps. Ventilation hoods and sealed containers stop fumes from traveling, and treating waste before landfill keeps BTEAC from seeping into water bodies. Community awareness campaigns about chemical hazards in water sources can nudge industries to clean up their acts.

BTEAC does a job in the right hands, but it demands respect all the same. Safety habits and good oversight make sure it never turns a simple shift into a medical emergency.

This Chemical Isn't Your Average Cleaner

Benzyltriethylammonium chloride crops up in organic labs around the world. Folks lean on it for phase-transfer reactions, pushing boundaries in both academic and industrial chemistry. It’s a white, crystalline powder, tempting to underestimate if you’ve spent too many hours around more hazardous substances. Yet, approach it with the same respect you’d give any reagent capable of skin irritation, respiratory discomfort, or eye damage. Years in the lab have shown me even “unthreatening” chemicals demand careful handling, especially in a cluttered storeroom or overworked undergraduate stockroom.

Real-World Storage: Keep it Cool and Dry

Labs run best on habits, not luck. Benzyltriethylammonium chloride fares badly with moisture. A leaky cap, an overfilled shelf, or a storage drawer near the autoclave leads to clumping or unwanted reactions. Best practice means sealing the container tight, labeling it clearly, and tucking it into a low-humidity, well-ventilated cabinet. I’ve seen a corner of a room go bad for weeks because someone left out organics near a sink with a slow drip. Avoid that scenario by keeping containers far from water sources, even in small spaces.

Forget the Fridge—Choose Room Temperature

Some compounds cry out for ultra-cold storage. Benzyltriethylammonium chloride sits comfortably at room temperature, and there’s no sense wasting freezer space. Extended exposure to sunlight, though, starts breaking down its chemical structure, leading to impurity drift. Darkness wins out for shelving choice. Even years back, before I understood why, my boss insisted on amber glass or thick plastic bins; that simple precaution protects both the chemical and anyone using it next semester.

Mind the Company it Keeps

One big mistake I’ve watched play out more than once: tossing incompatible chemicals onto the same shelf. Benzyltriethylammonium chloride shouldn’t share space with strong acids, oxidizing agents, or alkali metals. You won’t just spoil the chemical—you’ll upend safety protocols built to keep accidents rare. Fire, toxic fumes, or just ruined reagents all become real risks in a short lapse. Shelves organized by reactivity save far more headaches than spreadsheets ever will.

Label, Audit, Repeat

Mislabeling bottles remains one of the oldest hazards in any stockroom. After dealing with a mislabeled bottle during a long synthesis run, I started triple-checking labels and encouraging regular inventory audits. Dates, names, and hazard symbols out in the open stop confusion long before it starts. The University of California’s Office of Environment, Health & Safety puts this standard front and center for all hazardous substances: clear labeling heads off incident reports, cross-contamination, and a litany of headaches.

Practical Fixes for Common Mistakes

Instead of chasing new software or complicated tracking systems, I found that a printed ledger at the storage cabinet goes a long way. Train every new student or lab tech to record use, check seals, and clean up spills right away. In community college labs, that simple step did more to prevent loss and mix-ups than every digital app we trialed. Consistency improves storage not just for Benzyltriethylammonium chloride, but for any hazardous compound in rotation.

A Safer Lab Culture Starts with Storage

Benzyltriethylammonium chloride isn’t a monster, but it never pays to get casual. Cool, dry, dark, and well-documented storage delivers years of safe use and few surprises. Labs that respect these basics protect their people, keep projects running, and rarely scramble in emergencies.

Understanding This Unassuming White Powder

Many people outside the lab probably don’t run into Benzyltriethylammonium Chloride on a daily basis. Yet, in the world of organic synthesis, this salt gets pressed into service more often than you’d guess. It steps into the role of a phase-transfer catalyst, bridging the gap between substances that otherwise refuse to work together. All of this hangs on one key trait—how it dissolves. Scientists have found its unique solubility kicks open doors that would otherwise stay locked in chemistry.

Why Solubility is a Big Deal for Chemists

Pull back the curtain on most reactions and you’ll see a mess of oil and water—two layers just sitting there, not mixing. Reagents in water can’t easily attack compounds floating in an organic layer. You need something that can merge with both worlds. Benzyltriethylammonium Chloride handles this task thanks to the structure of its molecule: a positively charged nitrogen gives it water affinity, while its hydrocarbon tails keep it at ease in organics.

Drop it in water and it’ll dissolve easily—that’s expected for many salts. Yet try putting it in toluene or chloroform, and it also goes into solution pretty well. In fact, its ability to travel between polar and non-polar phases is what allows it to deliver cargo (reactants or ions) right where they’re needed, shuttling ingredients from one layer to another. This trait stands at the heart of its utility in phase-transfer catalysis.

Looking Beyond the Laboratory

Not everyone realizes that solubility underpins real-world breakthroughs. For example, greener chemistry relies on reducing harsh solvents. If you can use Benzyltriethylammonium Chloride to drive a reaction in water instead of something like benzene, you dodge a bunch of health risks. From a safety standpoint, labs and factories both benefit when reactions can shift to milder conditions. Several published reports support this shift: studies in the Journal of Organic Chemistry and Chemical Reviews spotlight how phase-transfer catalysis enables clean, efficient processes.

Environmental impact gets trimmed as well—less solvent waste and lower emissions. But this is only possible when your catalyst can play nice with the solvents at hand. After all, if the key ingredient won’t get into solution, the reaction stalls. Benzyltriethylammonium Chloride’s flexible solubility across both aqueous and organic phases isn’t a luxury; it’s what lets many industrial and pharmaceutical syntheses run at all.

Challenges and Possible Ways Forward

That versatility introduces another topic: dependency on solvent quality. If water gets too hard (loaded up with calcium or magnesium), you may see some weirdness with how much of the salt actually dissolves. Impurities can gum up the process. Keeping careful tabs on conditions improves reliability.

For folks working outside big research institutions, another point comes up: handling and cost. Benzyl-based quaternary ammonium salts fetch higher prices than some alternatives. Researchers aiming to cut costs sometimes fall back on analogs, but usually pay the price in lower efficiency or green credentials. The need for a sustainable and economical phase-transfer catalyst continues. Chemists have responded with reports of recyclable ammonium salts and more selective compounds. This direction deserves more investment and collaboration.

Personal Take: Why It Matters

Back in my graduate days, I saw entire projects stall out before someone swapped in Benzyltriethylammonium Chloride, suddenly watching a stubborn reaction spring to life. Understanding how and where things dissolve changes outcomes. It’s tempting to tune out chemical jargon, yet the direct link between solubility, safety, and sustainability runs through all of modern chemistry. Getting a handle on solutions—literally—remains a smart investment for anyone hoping to make scientific progress.