Benzyltrimethylammonium Chloride: A Deep Dive

Historical Development

Benzyltrimethylammonium chloride first caught chemists’ attention in the early twentieth century when researchers searched for chemical compounds to help shuttle reactants across immiscible phases. Before synthetic surfactants came onto the scene, organic chemists struggled with inefficient reactions. This compound, which pairs a benzyl group with a quaternary ammonium center, grew popular as solvent technology advanced. By the 1950s and 60s, the world saw not only an uptick in phase-transfer catalysis but also a broader use in industrial and analytical chemistry. Patents and academic publications from that era reflect just how much excitement there was around its unique abilities to boost yields and enable reactions that older processes made far too slow or difficult.

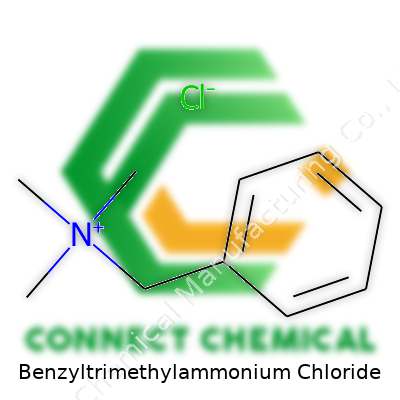

Product Overview

Benzyltrimethylammonium chloride is a white or off-white crystalline compound, known in many labs as BTMAC or TMBAC for short. This salt belongs to the family of quaternary ammonium compounds, which means it’s made up of a central nitrogen atom bonded to four organic groups and paired with a chloride ion. Its structure, featuring the influential benzyl group, drives many of its distinctive properties. Today, you can find BTMAC in powder or granule form, often packed in moisture-proof bottles or drums. Large suppliers ship it with quality paperwork and certificates of analysis, making sure users get consistent, high-purity material batch after batch.

Physical & Chemical Properties

The melting point of benzyltrimethylammonium chloride usually falls near 240°C. It dissolves quickly in water and polar organic solvents. This solubility matters in both lab research and industrial processes, especially because water-insoluble reactants need a little help moving between phases. The compound stays fairly stable under ordinary storage—but humidity and high heat can damage its appearance and performance. Chemically, BTMAC behaves as a strong electrolyte in aqueous solution and holds up against moderate acids and bases. Its cationic surfactant behavior makes it useful in emulsifiers, bactericides, and certain cleaning products. From my own experience in an organic synthesis lab, I’ve seen BTMAC help speed up reactions between alkyl halides and aqueous reagents far better than trying to stir the two layers alone.

Technical Specifications & Labeling

Suppliers tend to grade benzyltrimethylammonium chloride for analytical or industrial uses, listing purity levels that run between 98% to above 99%. Good labeling practices give the CAS number (56-93-9), batch numbers, production and expiry dates, recommended storage conditions, and any hazard statements. Phthalate levels, moisture content, and endpoint titrations show up in the technical sheets for labs focused on highly precise work. Material safety data sheets usually warn of skin and eye irritation, and that’s not to be glossed over—good ventilation and hand protection go a long way, especially when scaling up processes or making repeated transfers over a workday.

Preparation Method

Chemical suppliers manufacture benzyltrimethylammonium chloride through a straightforward alkylation. Reacting benzyl chloride with excess trimethylamine under controlled temperatures and solvent conditions, then stripping solvents and washing, yields crystalline product. My time in scale-up production lines taught me that careful control of temperature and stoichiometry helps maximize yield, while minimizing unreacted amine or unwanted side products. Once the organic layer converts, filtration and recrystallization in suitable solvents help manufacturers secure high purity. For small-scale labs, I’ve seen this prep condensed into less equipment-heavy glassware columns and rotary evaporators, though waste disposal always requires close attention.

Chemical Reactions & Modifications

Beyond phase-transfer catalysis, BTMAC takes part in ion-exchange reactions, supports nucleophilic substitutions, and can transfer hydrophobic anions into aqueous environments. Some chemical engineers have modified BTMACs by swapping chloride for bromide or other halides as the counterion, searching for changes in solubility or reactivity. In my synthetic work, using BTMAC offered clear benefits compared to basic trialkylammonium salts—it handled harsher reagents without breaking down, and it helped drive reactions to completion more reliably. Labs also explore derivatizing the benzyl substituent to tune selectivity in catalysis or material synthesis. Diverse pathways open up with this kind of backbone, even letting creative teams design new surfactants for specialty use in agriculture or biomedicine.

Synonyms & Product Names

Depending on the supplier and application, you’ll find benzyltrimethylammonium chloride sold under several names: Triton B, TMBAC, BTAC, or BTMAC. Its systematic name (N,N,N-Trimethylbenzenemethanaminium chloride) pops up in high-grade catalogs and academic reports. Regulatory listings also pull in these synonyms, important when searching for compatibility or cross-referencing safety data sheets. Different languages and regions sometimes swap prefixes or emphasize the ammonium over the benzyl, but the core structure stays the same. In any procurement process, checking both chemical names and registry numbers avoids confusion and ensures shipments match exactly what your process or experiment requires.

Safety & Operational Standards

Handling BTMAC means respecting both its chemical activity and physical irritant qualities. Dust from powders can irritate respiratory tracts and skin, so decent gloves, goggles, and local fume extraction work as common-sense precautions. From personal experience, spills not cleaned up quickly can leave stubborn, greasy residues. Consistent auditing of storage (dry, well-sealed containers kept at stable temperatures) prevents clumping or yellowing. Regulations in many countries place quaternary ammonium compounds in restricted substance lists; safety audits and compliance with standards like OSHA or REACH keep both employees and downstream users protected. Training on emergency eyewash use and the right absorbents for spills makes real-world difference: a little preparation saves a lot of trouble.

Application Area

BTMAC’s reach spreads across fine chemicals, pharmaceuticals, and even the manufacture of dyes and pesticides. Its value as a phase-transfer catalyst means it gets used to make ethers, esters, and other organics that without mediation, would never form efficiently. I’ve seen it used to drive Williamson ether syntheses and SN2 alkylations, drastically reducing the time to completion. Its antimicrobial action also finds room in certain personal care and disinfectant products, though regulatory hurdles get stricter each year. In water treatment, BTMAC aids in coagulation and can even show up in analytical chemistry for the separation of ions. These uses keep demand stable and inspire further tweaks to formulation practice every year.

Research & Development

Chemists haven’t stopped tinkering with benzyltrimethylammonium chloride. University and commercial researchers look for new catalytic cycles, sometimes pairing BTMAC with metal complexes for greener syntheses, or analyzing its behavior with crazy new solvents like ionic liquids. As sustainability climbs the agenda, work also focuses on biodegradability and alternatives with lower toxicity. At innovation hubs, the compound provides a testing ground for making multi-phase operations more energy efficient, leveraging advances in process control and monitoring. It’s rewarding to see new generations of chemists push BTMAC into fields like polymer science and surface functionalization, where it still has plenty to offer and surprises to yield.

Toxicity Research

Researchers keep a keen eye on the potential hazards of chronic BTMAC exposure, especially as regulations keep tightening around persistent organic pollutants. Some animal studies, published in peer-reviewed journals, show that quaternary ammonium compounds can trigger cell membrane disruption or respiratory issues if inhaled extensively. Careful analysis of breakdown products and their environmental fate matters, especially in pharmaceuticals and water treatment where trace residues need tracking. In plant settings, responsible usage means regular environmental monitoring and investment in air quality systems, not just for regulatory reasons but for the health of those working with the product daily. Education campaigns inside organizations help workers understand both the acute and long-term effects, making compliance feel less like a checklist and more like a shared responsibility.

Future Prospects

With the push for greener chemistry and more sustainable materials, benzyltrimethylammonium chloride faces both challenges and opportunities. Ongoing research looks for ways to boost its catalytic efficiency while reducing environmental impact, sometimes blending classic quaternary salts with new biodegradable analogs. Regenerative purification of BTMAC for re-use, or its application in closed-loop systems, seems likely to expand as resource-conscious companies ramp up. Markets show growing demand in high-precision syntheses, specialty coatings, and as a building block for more complex molecules in pharma. Provided suppliers and end-users remain committed to safety, compliance, and smarter process management, BTMAC will keep its relevance—continuously shaped by both scientific creativity and the evolving needs of industry.

Where It Shows Up in Real Life

Walking into a lab, you sometimes notice bottles with long, intimidating names. Benzyltrimethylammonium chloride feels like one of those. Its uses stretch beyond the lab, though. In my work with chemical processes and a few years of classroom teaching, I’ve seen this compound pop up in surprising places.

Making Chemical Reactions Work Better

Benzyltrimethylammonium chloride often finds itself on the shelf with phase transfer catalysts. Picture trying to mix oil and water—ingredients just don’t want to cooperate. Chemists run into this wall regularly. This compound steps in to act like a matchmaker, helping two very different chemicals meet and react. It speeds things up and lets reactions work at lower temperatures, which makes a big difference in cost and energy savings. In the classroom, you can actually show students how adding a small amount of this can turn a sluggish reaction into a fast one.

Water Treatment and Sanitation

This compound isn’t just for the lab bench. It plays a role in keeping water clean. Some water treatment plants use it to break down stubborn contaminants. Its surfactant qualities let it bind to fats and oils, helping remove greasy residues. From experience visiting industrial water sites, workers trust chemicals like this to make sure the stuff leaving the plant won’t pollute rivers. It remains important that wastewater gets safe before finding its way back to the environment, and Benzyltrimethylammonium chloride helps make that possible.

Antimicrobial Properties and Cleaning Products

Germs are part of life, but folks working in healthcare or food processing need a safe, clean space. This chemical brings antimicrobial power. It stops mold, bacteria, and some viruses from sticking around. I’ve seen quaternary ammonium compounds (which is the group this one belongs to) listed on industrial and even household disinfectant bottles. Hospitals look for reliable ways to kill pathogens, and this ingredient pops up more than you’d expect.

Boosting Pharmaceutical Manufacturing

Drug makers always look for ways to cut down waste and side products. Here, Benzyltrimethylammonium chloride assists in getting more accurate chemical reactions. Some medications need this kind of help to form the right structure or mix with other agents. If you talk to folks in pharmaceutical manufacturing, they’ll mention these additives in careful doses, helping guarantee product safety and save resources.

Potential Hazards and Public Health Concerns

No chemical belongs everywhere, and some come with risks if folks don’t handle them right. Benzyltrimethylammonium chloride causes skin and eye irritation in workers exposed without good gloves or goggles. If it ends up in river water above safe limits, it can harm aquatic life. Regulators keep an eye on levels in water because of this. The push for stricter rules and regular safety checks protects both public health and local ecosystems.

Chasing Safer Solutions and Sustainability

Green chemistry keeps growing. Researchers work on improving the structure of chemicals like Benzyltrimethylammonium chloride so they break down more quickly and are less likely to cause harm outside the factory. Industries now look for re-use and recycling strategies so leftover chemicals don’t go straight to the landfill or waterway. From my conversations with environmental labs, progress depends on both strict enforcement and creative science.

Getting To Know The Substance

People who work in labs have met plenty of chemical compounds that don’t get much buzz outside professional circles. Benzyltrimethylammonium chloride belongs to that category—a quaternary ammonium salt used mostly in chemical synthesis and industrial applications. You might find it in phases that promote chemical reactions, or as a part of some cleaning and disinfecting products. Even if its name sounds complicated, its impact on health is simple enough for anyone who’s spent time around chemical storage cabinets to appreciate.

What We Know About The Health Hazards

Benzyltrimethylammonium chloride irritates if it meets the skin, eyes, or nasal passages. Eyes redden and water, and skin stings or breaks out. Breathing in its dust or mist can trigger coughing, chest tightness, or even asthma-like symptoms in sensitive people. Swallowing it might upset the stomach, lead to nausea, or cause more serious stomach damage.

I asked a few chemists who routinely handle specialty reagents about their own run-ins with this compound. They described spills that led to burning sensations on the skin. Some said a whiff kicked off sneezing fits or left a funny taste at the back of the throat. Not as vicious as strong acids, but nobody messes with it minus gloves or goggles anymore.

Why It Matters: Not Just An Occupational Detail

Plenty of chemicals don’t cause much trouble unless you use them the wrong way. The problem with benzyltrimethylammonium chloride crops up from either ignorance or shortcuts. Hobbyists, students, or workers new to a lab might not realize what counts as "safe handling." Even in places with safety protocols, accidents happen. I remember a time in a teaching lab, an open jar led to headaches and eye irritation for almost everyone at the next bench. The instructor called it a “teachable moment.” We called it an unnecessary one.

Research literature, including data from the European Chemicals Agency, labels it hazardous but not as catastrophic as mercury or cyanide. Its Material Safety Data Sheet reads clear warnings—wear protective gloves, keep good ventilation, flush eyes if splashed—but that only helps if someone actually reads it. Busy days in a lab often mean people take shortcuts, skip PPE, or ignore lingering chemical odors. Small mistakes, real consequences.

Reducing The Risks

Knowledge and habits stand as the first defense. Anyone using this compound needs to treat it with the same respect given to other irritants. Store it in airtight containers, never let it sit open on a bench, and always use gloves and goggles. Ventilated hoods aren’t just decorations; using them can mean the difference between a normal day and one spent at the doctor.

Supervisors in workplaces and universities need to reinforce training and spot checks. Easy-to-understand warning signs and reminders at storage locations matter more than technical data sheets locked in a binder no one reads. In my experience, regular safety briefings that draw from real incidents stick more than dense lectures or paperwork.

People underestimate the small stuff—a little spilled powder, a missed spot on the glove, a quick trip across the lab without protective glasses. Good ventilation, fresh gloves, and running water nearby save people real discomfort. Building better habits before someone gets hurt makes more sense than plugging holes after the fact.

Room For Better Practices

Clear labeling on bottles, storing it away from incompatible chemicals, and routine checks for leaks or broken seals belong in any space that deals with this substance. For anyone outside a lab who runs into it through cleaning products, keep it out of reach of children, avoid mixing with other chemicals, and stick to product label directions. Companies owe it to workers and customers to share full ingredient lists and offer real training, not just fine print.

No single chemical creates a risk-free environment. Experience, education, and plain old respect for what sits on the shelf turn potential hazards into manageable challenges.

Learning from the Lab: Keeping It Simple

Years spent sharing cramped space with flammable liquids and quirky chemicals taught me a few key lessons: forgetful storage invites trouble, and the little details matter more than the safety signs promise. Benzyltrimethylammonium chloride sounds technical, but its needs are not rocket science—just respect for its quirks and a dash of common sense.

Nothing Beats a Cool, Dry, Dark Spot

This compound attracts water like a sponge. Left open, it clumps, caking up inside bottles and sneaking into the air, making scales sticky and gloves slippery. Keeping it tightly sealed saves money and headaches; humidity ruins chemical purity, business margins, and sometimes, experiment results. In my early days, I learned the hard way—half a kilogram lost because I thought a twist cap did the trick. Now, desiccators and screw-top bottles lock in the dry, keeping the product ready for action, not accident.

Heat deserves no place near this material. Excess warmth jumpstarts chemical breakdown, especially over time. Keeping bottles away from radiators, windows, or warm equipment pays off. I once discovered melted labels and clumpy remnants after a bottle spent a summer by a sunny window—lesson learned: check the placement, not just the label. Some labs tuck it away in temperature-controlled shelves to avoid such mishaps.

Avoiding Hazards, Protecting People

Storing this chemical safely prevents both workplace injuries and expensive cleanup jobs. Inhaling it causes irritation; splashed in eyes or spilled on skin, it burns. Gloves and goggles aren’t optional, and keeping storage cabinets clearly marked makes sure nobody grabs the wrong bottle in a rush. I felt safer knowing that anyone who shared my workspace could tell exactly where any risky material lived—a sharp reminder that teamwork can mean just labeling and organizing well.

Oxidizers, acids, and strong bases should stay far away. Accidental mixes will smoke, fizz, or worse. Learning to separate shelves early on meant avoiding nasty cleanup assignments later. Simple shelving plans can prevent months of drama, fines from inspectors, and even fires.

What the Rules Say—And Why They Matter

Regulations do more than tick boxes. They protect health and reduce liability. The Globally Harmonized System (GHS) points out its dangers: irritant to skin, eyes, even lungs. Local guidelines like OSHA’s or Europe’s REACH require hazard labels, secure containers, spill containment kits, and up-to-date safety data sheets close by. Anyone working with this substance should review these materials regularly. It’s a lot more than red tape—most real accidents I’ve seen could have been avoided by sticking to these basics.

No Substitute for Good Habits

Talking storage may sound dull, yet it’s where many labs—small and big—save themselves real trouble in the long run. Keeping the area organized, double-checking that bottles are sealed, and making sure new staff understand storage routines can change a workplace’s safety culture fast. Better habits mean fewer injuries, less waste, and experiments that actually deliver. At the end of the day, a little care with a bottle of benzyltrimethylammonium chloride beats scrambling to clean up a mess nobody saw coming.

A Chemical to Approach with Respect

Benzyltrimethylammonium chloride, a common quaternary ammonium salt, shows up across labs and industry. It helps as a phase transfer catalyst and finds a home in organic synthesis. From years of handling similar chemicals, I've learned respect for materials like this beats out bravado or shortcuts every time. It doesn't take a specialist to see why: the risk often hides in plain sight, and overconfidence leads to mistakes that can affect everyone in the lab.

Hazards: More Than Meets the Eye

You might notice its powdery texture or faint odor and think, “How dangerous can it be?" Toxicological data and case studies paint a clearer story. Skin or eye contact has caused irritation. In high concentrations, serious respiratory symptoms follow air exposure. Accidentally ingesting this chemical won't just upset your stomach—it brings real health risks. Even a quick search through pubmed or OSHA records turns up cases where improper handling caused issues that lingered.

Practical Steps I Rely On

No one enjoys donning extra gear, but some things can't slide. My go-to kit for working with benzyltrimethylammonium chloride covers lab coat, gloves—nitrile seems to endure better than latex here—goggles, and a properly fitted mask if I expect any dust. Not all work benches have the same protection, so I always move to a fume hood before opening any container. It only takes one gust or awkward scooping motion to send a cloud into shared air space. Whenever transport is needed, secondary containment reduces the chance of spills.

Storage and Housekeeping

I always check storage conditions before putting this chemical away. Dry, cool shelves in a locked cabinet keep out moisture and curious bystanders. Moisture won’t just clump the powder; it can trigger slow degradation or make cleanup harder down the line. I use a clear, legible label—complete with date opened—so anyone else stepping in won’t need to guess what’s inside. Cleanups follow a special set of tools. Disposable towels and a sealed bag for waste go into a hazardous container, not down the drain or regular trash.

Training Matters More Than Fancy Gear

In my experience, no substitute exists for solid, repeated safety training. Posters fade into the background with time, but hands-on demos and open discussions about close calls leave a mark. I’ve pushed for regular safety meetings as a way to keep everyone sharp and honest about what we see around us. Peer checks—just asking, “Do you have your goggles?”—help avoid absent-minded mistakes.

Room for Better Practices

Institutions and companies still face the challenge of updating old habits. Routine hazard reviews and peer audits catch problems before accidents happen. Switching to less hazardous alternatives saves trouble if the process allows. Some teams set up digital logs for chemical use and disposal. In facilities with high turnover, clear onboarding about chemicals like this prevents new employees from walking blind into unnecessary risk.

Respect Goes a Long Way

I learned early on that treating chemicals with casual disregard gets people hurt. Balancing productivity with safety takes extra effort, but the effort pays off. Benzyltrimethylammonium chloride, like many specialty chemicals, rewards careful, respectful handling. Habits forged now last a lifetime and set standards for everyone around you, proving that safety can walk side-by-side with good science.

Behind the Formula

Benzyltrimethylammonium chloride pops up consistently in both labs and the chemical industry. Its chemical formula C10H16ClN reflects a molecule that looks simple on paper but can punch above its weight in synthesis and processing applications. Each part of this formula carries a specific story: a benzyl group, a trimethylammonium core, and a chloride counterion. Those familiar with organic chemistry can instantly pick out several useful features—aromatic stability from the benzyl, water-solubility from the quaternary ammonium, and an easily handled solid salt form thanks to the chloride.

Physical Mass: More than Just a Number

The molecular weight of benzyltrimethylammonium chloride clocks in at 185.70 g/mol. Knowing this value goes beyond cataloguing for inventory. A chemist can calculate exact concentrations and scale reactions precisely, which means fewer wasted resources and more predictable outcomes. This is how reliable screening and reproducibility in experiments is made possible. Seasoned process engineers have often shared stories of batches spoiled simply because someone made assumptions about “just a little extra” when calculating weights and molarities. Precision matters, down to the decimal.

From Bottle to Bench: What Makes It Useful

Ask those working with organic reactions, and benzyltrimethylammonium chloride rings a bell—phase-transfer catalysis. It shuttles ions between layers that wouldn’t otherwise interact. This boost in solubility and reactivity often saves on effort, energy, and time. Instead of relying on tough conditions or obscure solvents, chemists can reach their goals cleaner and faster. People in quality control value chemicals they can trust, and a molecule with a known, stable formula and weight means less time troubleshooting and less chance for error.

Common Sense Handling in Real Life

Anyone who’s spent months in a synthesis lab knows that even reliable chemicals need respect. Benzyltrimethylammonium chloride isn’t especially toxic, but like many salts, it can irritate if mishandled. Gloves and safety goggles find daily use not out of paranoia, but because no one wants their week ruined by careless exposure. ICS guidelines and company protocols aren’t there just for show—they protect both the worker and the product. Friends in production facilities have shared their routines for cross-checking labels and double-sealing chemicals, which keeps accidents rare and ensures product consistency batch to batch.

Digging into Credentials and Trust

Every fact here matches resources from established databases—think PubChem, Merck Index, and Sigma-Aldrich. Years of benchwork, group meetings, and consulting sessions have underlined how critical it is to double-check numbers from sources valued for their accuracy. Chemists, production techs, and QA personnel often share the same sentiment during coffee breaks: trust in your numbers, or prepare for trouble. Scrutinizing the formula and molecular weight before starting out forms a habit more valuable than any background check of a supplier.

Paving the Way for Better Chemicals

While the basics of benzyltrimethylammonium chloride—C10H16ClN, and 185.70 g/mol—look settled, new students and seasoned professionals alike can’t afford to let familiarity breed mistakes. The best labs foster habits grounded in rigorous measurement, continuous verification, and a culture where accuracy supports not just good science but safe work. By valuing these details, the next time a chemist measures out this salt, they’re set up for a smoother and safer project. Accountability, hands-on know-how, and reference to reputable sources make all the difference, turning what could be just another lab staple into a trusted workhorse in chemical innovation.