Benzyltriphenylphosphonium Chloride: Foundation, Properties, and Future Directions

Historical Development

Benzyltriphenylphosphonium chloride’s story begins with the rush to build new organic reagents in the early wave of organophosphorus chemistry. Researchers searching for better phase transfer catalysts and tools for organic synthesis landed on this compound as an answer to both needs. By the 1960s, the structure and benefits of phosphonium salts drew the eyes of both academics and industry labs. The ability of benzyltriphenylphosphonium chloride to bridge organic and aqueous phases helped refine alkylation and halide exchange reactions, offering chemists a more efficient route for certain tricky transformations. Inspiration for many came from watching how minor changes—such as swapping a methyl group for a benzyl—could send a reagent down a new functional path.

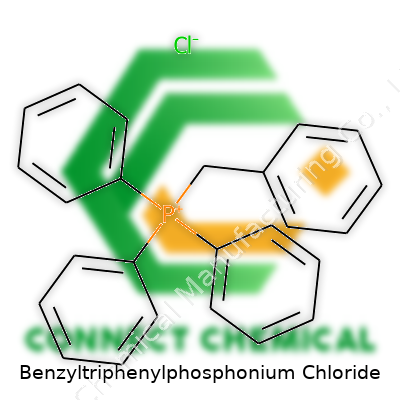

Product Overview

Benzyltriphenylphosphonium chloride stands out as a quaternary phosphonium salt with a formula of C25H22PCl. In practice, this salt works as both a phase transfer catalyst and a tool for generating ylides. Laboratories and manufacturers count on it as a workhorse for organic reactions, where it helps shuttle reactants between mismatched solvents or plays a direct part in building carbon-carbon bonds. Interest grows in its reactivity and the options it presents for customizing properties through relatively simple swaps at the molecular level. From years of working with these phosphonium salts, the biggest lesson comes from their reliability: few other catalyzing agents respond as consistently in such a range of conditions.

Physical & Chemical Properties

A crystalline solid, usually white or faintly off-white, benzyltriphenylphosphonium chloride holds its shape well under typical benchtop conditions. Melting points register near 240–243°C, signaling robust stability. The molecule carries a strong, positively charged phosphorus center flanked by three phenyl groups and a benzyl substituent, paired to a chloride anion. Its solubility favors polar solvents like water and alcohols, opening the door for its dual-phase action in many reactions. That strong ionic structure resists breakdown, supporting its reliability battering through long synthesis sequences. Its practical stability—and willingness to step into a wide variety of reaction partners—makes this salt a go-to not just for straightforward catalysis but for method development and pilot runs.

Technical Specifications & Labeling

Product datasheets typically state purity higher than 98%, sometimes hitting 99% in specialty batches. Moisture limits run under 0.5% as trace water risks clumping or activating the salt ahead of schedule. Most shipments list an assay, melting point and sometimes an NMR or HPLC trace depending on client needs. Labs expect tight tolerances for chloride content, since extra halide can tip some reactions off course. Clear labeling around storage—preferably cool, dry, light-protected conditions—serves both to maintain performance and to comply with regulations. One overlooked lesson: a clear batch history on the lot label saves hours tracking down the root of a reaction quirk.

Preparation Method

Synthesis often starts with triphenylphosphine, easy to source and versatile. Reacting this with benzyl chloride in polar solvents (acetonitrile or ethanol, for example) at modest heat typically brings the salt out of solution. Careful control of stoichiometry avoids unreacted precursor fouling the product and keeps yields robust. Bench chemists may opt for stepwise purification: precipitate, wash, and dry to bring the final salt up to analytical standard. This makes benzyltriphenylphosphonium chloride accessible even to smaller labs. Consistent yields come from close attention to mixing, temperature, and purity of starting materials—lessons hammered home through the pain of unexpected byproducts.

Chemical Reactions & Modifications

Benzyltriphenylphosphonium chloride’s true value glows in its reactivity. It serves as a clean route to triphenylphosphonium ylides following treatment with strong bases, key precursors in Wittig reactions. These ylides let chemists build alkenes from carbonyls with precision. That same core structure can host a variety of modifications: swapping benzyl for allyl or different substituted phenyls, tweaking reactivity for other needs. In phase transfer catalysis, it helps drive nucleophilic substitutions, pairing aqueous and organic components with improved efficiency. Experience shows this salt rarely delivers surprises—reactions happen as planned, and byproducts stay under control if reaction parameters stay tight.

Synonyms & Product Names

Common names often read as benzyl(triphenyl)phosphonium chloride, BTPPC, or simply Benzyltriphenylphosphonium salt. In the marketplace, suppliers sometimes bracket it as a Wittig reaction agent or a phase transfer agent. Brand names vary, but the structure stands out on any technical data sheet, helping chemists verify identity regardless of vendor. Synonyms may blur across international borders, adding a layer of confusion for new researchers picking up the reagent for the first time, but close focus on molecular formula always clears things up.

Safety & Operational Standards

Handling calls for routine precautions. Skin and eye contact risk irritation; best to use gloves and eye protection even for brief tasks. Benzyltriphenylphosphonium chloride lacks the acute toxicity of less selective alkylating agents, but dust inhalation and ingestion should be avoided at all costs. Good ventilation and correct PPE remain mandatory at every step. Safety data sheets warn against heating to decomposition, which could release hazardous fumes including hydrochloric acid or phosphine. Waste management follows normal paths for organic salts—sealed disposal drums, solvent-compatible bins, and clear labeling keep the workspace safe and compliant. After years of bench work, the value of solid safety culture reads in every smooth, incident-free run.

Application Area

Its reach stretches through organic synthesis, polymer chemistry, medicinal chemistry, and pilot process development. Benzyltriphenylphosphonium chloride holds a favored role in preparing ylides for Wittig and related reactions, giving scientists a lever to push or pull on double bond geometry. Academics and industry workers alike choose it for teaching and scale-up, since its predictable behavior bridges small scale and industrial batch without headache. The phase transfer properties open up faster, more efficient reactions between solvents that otherwise would not mix, broadening the landscape for complex molecule construction. In pharmaceutical routes, it supports the synthesis of intermediates where purity and yield can make or break a synthetic pathway. Anyone who has struggled with hard-to-mix systems sees immediate value.

Research & Development

Research in recent years targets new versions of this reagent, swapping groups or tuning solubility for greener processes. Teams explore ways to recycle spent salts, minimize environmental impact, and attach benzyltriphenylphosphonium chloride units to hybrid inorganic frameworks. Some efforts focus on using this salt in tandem with new catalysts or supports, seeking out new reactivity profiles. A major driver for ongoing study comes from the push toward sustainable chemistry, where reusability and minimal waste become key selection criteria. Chemists in the lab draw from years of shared troubleshooting; each experiment with these salts brings lessons—sometimes tough, sometimes clever, often subtle—about what makes reactivity tick.

Toxicity Research

Toxicological data show the compound generally does not present major hazards with ordinary use, but repeated exposure can irritate tissues or present issues after ingestion. The debate about chronic effects remains open; some studies suggest a low bioaccumulation risk given the salt’s moderate water solubility. Animal studies place the acute oral LD50 relatively high, lowering the immediate danger but not removing the need for care. Disposal always follows legal guidelines to keep downstream wastewater clear of phosphonium residues. My own experience handling related salts taught me never to shortcut routine PPE, since irritation from powder contact feels surprisingly harsh for such a routine-looking substance.

Future Prospects

Benzyltriphenylphosphonium chloride will stick around, not due to flashy breakthroughs but its steady capacity to adapt with changing methods. Emerging green chemistry approaches may soon shrink the environmental footprint of both its manufacture and disposal. More sustainable solvents, new reaction partners, and modified salts promise to push this scaffold into areas once dominated by more wasteful or hazardous reagents. In a world racing to do more with less environmental cost, versatility like this earns its place at the bench. From here, expect not just iterations on the chemistry, but deeper collaborations between disciplines—organic, materials, and environmental—driven by the lessons of past and the clear demand for smarter, cleaner reactions. Those with years on the bench say these incremental improvements make the real difference.

The Hidden Workhorse in the Lab

Walk into a synthetic chemistry lab, and you find rows of bottles with names long enough to fill half a notepad. One name you might spot is Benzyltriphenylphosphonium chloride. Not exactly a household staple, but for chemists, this salt plays a steady role. I remember my early days running reactions in grad school; our group leaned on this compound for some of our more creative syntheses.

The Chemistry in Action

Benzyltriphenylphosphonium chloride provides a key ingredient for certain transformations. Most often, its calling card comes through the Wittig reaction—a powerful method for building carbon–carbon double bonds. If you're new to organics, this means it helps bring together smaller building blocks into bigger, more complex molecules. Drug developers value this process because making carbon chains and rings the right way matters in designing medicines.

I’ve seen how quickly a project's progress depends on the availability of trusted reagents. In my experience, the Wittig route delivers reliable control, especially with aromatic systems. Its use doesn’t end there, though. This salt also finds use in making other phosphonium ylides, pushing boundaries in reaction scope. Some chemists dig even deeper, using it to prep ionic liquids or tune catalyst properties for specialty reactions.

Why Its Reliability Matters

Plenty of reactions look great on paper but struggle in practice. Benzyltriphenylphosphonium chloride stands out because it brings consistency. Researchers value time and reliability, and a failed reaction wastes both. For example, a pharmaceutical lab can’t afford to miss deadlines making a candidate molecule for clinical studies. A synthesis built around a dependable reagent cuts down trial-and-error, which means money saved and new drugs delivered faster.

Costs also influence chemical choices. Cheaper alternatives exist for some reactions, yet they introduce more complexity, or their waste might be tougher to manage. Tuning a process around this phosphonium compound often simplifies the workup and isolation, which then steers companies toward greener, safer procedures. Some suppliers offer it in high purity, so chemists spend less time on purification steps. From my time in industry, these small advantages often tip the scale toward an old favorite.

Risks and Responsible Handling

No conversation about lab chemicals feels complete without touching on safety. Benzyltriphenylphosphonium chloride, like many organophosphorus compounds, needs careful storage and handling. Accidental spills or skin contact can pose health risks. I’ve seen mentorship make a difference here—new chemists learn the ropes quicker when supervised by those with hands-on experience. Facility safety training stresses containment, proper labeling, and disposal. This builds habits that protect people and the environment.

Where Progress Leads Next

Green chemistry trends nudge the field toward lower-impact processes. Benzyltriphenylphosphonium chloride still pulls its weight, especially with better recycling strategies for phosphorus-based waste. Forward-thinking groups develop analogs that work under milder conditions or leave behind less residue. Some academic labs keep looking for catalysts that outperform traditional reagents in speed, selectivity, and safety.

As technology in chemistry evolves, the quiet reliability of time-tested compounds—like Benzyltriphenylphosphonium chloride—helps the community push boundaries without losing sight of practical progress. My experience teaches that a trusted workhorse, paired with smart stewardship, carries research and industry forward, molecule by molecule.

The Formula Behind the Name

Benzyltriphenylphosphonium chloride doesn’t exactly roll off the tongue, but its chemical formula pulls back the curtain on a compound that pops up in laboratories everywhere. Chemists write this compound as C25H22PCl. That formula speaks volumes about what’s inside: 25 carbon atoms, 22 hydrogens, one phosphorus atom tucked at the center, and a single chlorine playing its distinct part.

How the Structure Matters

Sitting in the flask, this salt looks like a handful of other phosphonium compounds. The phosphorus atom in benzyltriphenylphosphonium chloride wears three hefty phenyl rings, plus a benzyl group. Chemistry fans might picture three hexagonal rings joined by phosphorus, then a little tail at the end — that’s the benzyl group. Chloride sits close, balancing out the charge. This structure turns out to matter a lot to how this compound gets used in real work.

Why Chemists Care About Benzyltriphenylphosphonium Chloride

Working as a building block goes hand-in-hand with unique properties. Take phase-transfer catalysis, a method that lets chemicals from two different layers actually meet up and react. This stubborn separation often drags down reactions, wasting time and money. The phosphonium salt steps in as a sort of chaperone. Its bulky, oily structure crosses boundaries, pulling molecules from water into oil so a reaction finally kicks off.

I’ve handled it myself during some of my research. When dealing with stubborn reactions, adding this salt sped up sluggish benchwork. Instead of spending all day wrestling with layers that refuse to mix, this compound lets things progress faster. For many, that little trick translates into better yields and happier research groups.

The Health and Safety Side

Chemical formulas don’t always spotlight the risks, but it’s worth noting. With 25 carbons and a hefty aromatic ring count, benzyltriphenylphosphonium chloride means business. It won’t dissolve in every solvent, and it can irritate the skin or lungs if handled carelessly. Gloves, goggles, and proper ventilation serve as non-negotiables. Safety culture in labs draws heavily from respecting compounds like this.

Solutions: Rethinking and Handling Chemical Use

Many researchers, especially newcomers, sometimes overlook proper storage. I’ve seen expired bottles tucked in forgotten corners, their labels faded. This calls for real discipline: regular checks, proper waste disposal, and up-to-date handling procedures. Management of chemical stocks isn’t just about staying organized — it keeps the working environment safe.

On top of that, sustainable chemistry pushes the field to rethink options. Some labs swap out traditional solvents for greener alternatives, or hunt for less toxic phase-transfer agents. The pressure comes not only from regulation but from a sense of responsibility. Every time someone cracks open a bottle of benzyltriphenylphosphonium chloride, they should think about its whole life cycle: where it comes from, how it’s used, and what happens after it leaves the bench.

Closing Thoughts

Understanding the formula C25H22PCl isn’t just an exercise in memorization. It shapes how we use, handle, and respect what chemicals can do. Knowledge, practical habits, and a little forethought go a long way in putting that formula to good use.

Understanding the Chemistry

Benzyltriphenylphosphonium chloride. The name alone hints at its complexity. This compound, commonly found in chemical research and organic synthesis labs, brings both utility and challenges. It’s a white, fine crystalline powder, not something you want wafting around unrestricted. One key fact: this material absorbs moisture from the air. Walk through any busy laboratory, and you’ll spot why loose lids and ambient humidity clash with such a sensitive salt.

Keeping It Dry and Cool

Most organic reagents fare better in dry, stable conditions. No secret—moisture means trouble, especially for compounds like this one that turn clumpy or even degrade. Storing it in a tightly sealed container becomes routine fast. I once watched an entire batch of phosphonium salt ruined after a student left the cap ajar over the weekend. It formed sticky lumps; we had to discard the lot. Desiccators, or at the very least, storage boxes packed with silica gel, give some peace of mind. They keep the relative humidity low, warding off the slow creep of water vapor.

Temperature swings can also spell disaster. Ambient room temperature works, as long as it doesn’t spike beyond normal lab levels. An office with reliable cooling shields against the worst summer heat waves. I learned to avoid corners near radiators or windowsills. Direct sunlight and warmer spots in the lab tend to reduce shelf life, sometimes sparking unexpected reactions or color changes.

Why Chemical Compatibility Counts

You’ll rarely see benzyltriphenylphosphonium chloride stored next to acids, strong bases, or oxidizers for good reason. Accidents in shared labs sometimes come from overlooked shelf neighbors. I once had to explain to a new assistant that mixing incompatible chemicals, even by storage, can trigger corrosion or lead to cross-contamination. The compound stays safest in a dedicated section, away from troublemakers.

Labeling and Tracking Prevent Mistakes

Clear labeling isn’t just bureaucracy—it keeps everyone safe. Labels with dates, hazard warnings, and exact contents stop confusion in a busy space. Adding a simple “keep dry” note often helps team members notice the risk. I keep an inventory sheet for each chemical, noting every time a container opens. This habit picked up after one too many “where did all our phosphonium chloride go?” scenarios.

Personal Experience: What Works, What Fails

Long ago, I made a rookie mistake: trusting a “resealable” plastic bag, straight off the vendor’s shelf, for a month. The crystals started to stick together. After that, glass bottles with PTFE-lined screw caps became standard. Bad packaging brings water, odors, and even tiny bits of dust. Treating this salt like table sugar on a rainy day leaves you with less reliable results. Mistakes come from cutting corners on storage and ignoring warning signs—harsh lessons for anyone hoping to use every gram efficiently.

Steps Toward Responsible Chemical Management

Labs separated for inorganic, organic, and oxidizing chemicals help reduce risk. Regular checks on stock follow best practice. Setting up simple in-house rules—never open containers outside the dry box, always return chemicals to their spot—pushes safety and consistency. I encourage regular training, especially for new faces in the lab. Every open container, every spill avoided, adds up to safer, more productive research. Responsible storage habits keep compounds like benzyltriphenylphosphonium chloride ready for use and far from causing headaches.

Looking Beyond the Chemical Name

Reading chemical names like benzyltriphenylphosphonium chloride can throw most people off. I remember coming across similar names as a chemistry student, and learning that the story behind each one winds through the labs and the manufacturing plants where safety isn’t just a preference — it’s a basic need.

The Facts on Toxicity

Benzyltriphenylphosphonium chloride often shows up in specialty chemical applications. Chemists like me recognize it as a quaternary phosphonium salt. It isn’t as widely used as something like bleach or acetone, but it’s still important to handle it with attention.

The compound raises some red flags. Lab safety sheets (SDS) highlight risks: skin and eye irritant, potential for toxic effects if swallowed or inhaled, and possible environmental harm from accidental release. Studies on similar quaternary compounds back up these warnings — they tend to disrupt cell membranes and harm aquatic organisms.

Acute exposure could cause burning sensations or coughing. Chronic exposures remain poorly studied, but that isn’t a green light for complacency. Most labs store and handle benzyltriphenylphosphonium chloride with gloves, goggles, and good ventilation. I know firsthand that rushing or cutting corners never ends well. Chemical dusts and vapors can find their way into your eyes or lungs before you realize it.

Regulation and Best Practices

Regulatory bodies such as OSHA and the European Chemicals Agency keep an eye on chemicals like this one, assigning it hazard codes and suggesting strict control measures. A material doesn’t land on those lists without reason. Companies handling it often need to keep detailed records, update risk assessments, and train employees. Neglecting these steps risks health, safety, and sometimes big environmental fines. Even a small spill in the wrong place can have outsized impact on water or soil.

Everyday Impact and Broader Lessons

Few people outside a lab or chemical plant will ever meet benzyltriphenylphosphonium chloride directly. This fact sometimes leads organizations to think about it as “someone else’s problem.” But chemicals have a way of working upstream and downstream. Waste, residues, or accidental emissions don’t stay neatly boxed in a warehouse. Local communities can get exposed in ways no one thought to predict.

Years ago, I saw a minor spill trigger a big debate inside the plant. Some workers argued over how much risk there really was, but clear heads pointed out that risk starts small and grows as people ignore warning signs. The lesson stuck. It isn’t the scale of the incident; it’s about shutting down future harm by acting early.

Solutions Start with Awareness

No single rule covers every workplace, but a few steps make a real difference. Access to reliable safety information, like updated SDSs, helps everyone make smart decisions. Simple habits work too — safe storage, labeling, using personal protective equipment, and disposal by professionals. These aren’t extras; they’re the baseline.

For chemical manufacturers and laboratories, switching to safer alternatives is always worth exploring if the chemistry allows it. Safer doesn’t always mean less effective, and often opens up new business opportunities. Following local and global regulations protects individuals, communities, and brands from tragic and costly mistakes.

Trust Grows from Transparency

People want to trust the products and workplaces around them. Being clear about hazards — and how to reduce them — builds stronger teams, safer industries, and healthier communities. Trust doesn’t happen by accident; it builds with every honest safety briefing, every shared fact, and every worker who comes home healthy after a shift.

Understanding the Risks Behind the Name

Benzyltriphenylphosphonium chloride has a long, tangled name, and that’s fitting—this stuff doesn’t come without complexity. I remember my first real chemical handling experience in grad school, and I wish someone had spelled out the facts in plain language. This isn’t kitchen-table material. It can irritate your skin, eyes, and airways pretty fast. Spill some, and you start to wonder about the long-term costs. Treating all powders with respect pays off in the lab and in any production setting.

Why Personal Protection Never Feels Optional

Basic gear isn’t overkill. Gloves—nitrile, not those breakable latex ones—make sense right away. The fine dust can float up from a scoop and irritate your nose or throat long before you see anything on your hands. Goggles block any stray dust, and a long-sleeve lab coat wraps up the fundamentals. I’ve seen too many folks try shortcuts, telling themselves, “It’s just a little bit.” That line of thinking lands you in the campus health office with a chemical burn, at best.

Ventilation Always Matters

Even if the task looks simple, fumes and tiny particles can linger. Never open a bag or weigh out chemicals outside a fume hood. I learned that lesson by catching the odd headache after careless weighing by an open bench. Good air flow remains your best defense—you want those vapors and particles out of your breathing space, not hanging around for the next unsuspecting person.

Planning for Spills: Cleaning Up Without Drama

Spills happen. A quick response limits the damage. For powders like benzyltriphenylphosphonium chloride, always keep a spill kit around with absorbent materials and a sealed bag to toss the mess. Never sweep powders dry—cleanup by gentle scooping or a wet method keeps dust at bay. Afterward, wash down surfaces with water and a gentle detergent. Training everyone in these steps gives safety a real meaning. Every lab benefits from regular drills or refreshers to keep routines sharp.

Storage Choices Guide You Through the Workday

Secure, labeled containers with close-fitting lids should be non-negotiable. I’ve seen chemicals get mixed up because someone reused a generic jar or scribbled out a half-faded label. One wrong move, especially with reactive powders, can escalate. Store benzyltriphenylphosphonium chloride away from strong oxidizers or acids. Keep it in a dry spot, far from direct sun or heat. Any dampness can kickstart unwanted reactions, and sunlight degrades plenty of tricky compounds.

Training Holds It All Together

No equipment or manual beats knowledge. Every group, whether in industry or academia, benefits from hands-on instruction that covers what to do in an emergency. Watching a seasoned chemist walk through the process leaves an impression that’s tough to forget. Share near-miss stories openly. If someone catches a mistake before it turns ugly, talk about it. This drives home the idea that safety isn’t a checklist, but a process shaped by real experience.

Shaping Safer Workplaces: Practical Steps Forward

Regulations exist for a reason—OSHA and similar organizations set rules, but daily habits make the rules count. Any site working with benzyltriphenylphosphonium chloride can encourage a safer environment by structuring clear reporting systems and keeping hazard sheets visible. Up-to-date material safety data sheets (MSDS) should always be right at hand.Look into options for safer substitution if possible. Sometimes, other reagents do the same job with less risk. Review chemical inventories quarterly, and it never hurts to ask suppliers for updated safety information. Science moves, and manufacturers improve packaging or provide new data. Staying open to these updates keeps the process fresh and effective.