Butyltriphenylphosphonium Bromide: A Ground-Level Look at a Workhorse Chemical

Historical Development

Butyltriphenylphosphonium bromide has roots going back to the expansion of organophosphorus chemistry in the mid-twentieth century. Interest first spiked as chemists hunted for stable, versatile reagents to drive reactions that would open new doors in organic synthesis. The earliest papers pointed out the impressive stability of phosphonium salts and how they unlocked new possibilities for Wittig and related transformations. Through the 1970s and 1980s, researchers in both academic labs and chemical companies sharpened methods for making a clean, consistent product. Along the way, it started showing up as a reliable backbone in methods for building carbon-carbon bonds. Technological improvements pumped out purer samples, with better yield and less waste, and laid the groundwork for today's scale-up production and expanded use throughout industry and research.

Product Overview

Butyltriphenylphosphonium bromide stands out as a quarternary phosphonium salt with a reputation for handling well in the lab. Usually sold as an off-white to slightly yellow crystalline powder, it lands squarely in chemical inventories for academic research and industry R&D. Chemists know this compound by multiple names—sometimes shortened to BTPPB or BTTPB—which speaks to its cross-discipline adoption. Commercial sources now supply it in several grades, including higher-purity options to meet regulatory or pharmaceutical needs. In my own experience in organic synthesis, this salt has offered straightforward handling, solid stability under ambient conditions, and shelf lives stretching for years if kept dry.

Physical & Chemical Properties

Butyltriphenylphosphonium bromide comes with a molecular formula of C22H24BrP and a molar mass right around 399.3 grams per mole. The physical form—those fine white to pale yellow crystals—makes dispensing easy, provided moisture levels stay low. Melting points tend to land near 270°C, which means most reactions involving this salt won’t worry about decomposition from a little heat. Its solubility profile leans towards polar organic solvents; acetonitrile, DMF, and DMSO all bring it into solution much faster than water or alcohols. Structurally, the cationic phosphonium core sticks to triphenyl and n-butyl groups, offering bulk and electron richness that helps drive nucleophilic substitutions and phase-transfer processes. In chemical terms, this salt stays pretty stable under regular working conditions, resisting hydrolysis and oxidation barring aggressive reagents. Practically speaking, it’s the sort of reagent you keep handy for its predictability in the reaction flask.

Technical Specifications & Labeling

Suppliers list Butyltriphenylphosphonium bromide with clear technical data. Purity grades reach over 98% as standard, with some pharmaceutical listings hitting 99% or above. Labels carry hazard markings by GHS or local authorities—look out for skin and respiratory warnings, as heavy exposure in dust form can irritate. Labs enforce specific storage protocols, such as dry cabinets and containers that block UV light. Shipping labels account for bromide content and phosphonium core, with all relevant UN and CAS numbers—CAS 2751-90-8 being common. I have always checked batch certificates for melting point, moisture content (using Karl Fischer titration if feasible), and heavy-metal residues. Because scrutiny has increased on chemical sourcing practices, reputable vendors back up shipments with safety data and technical bulletins.

Preparation Method

Synthesis of Butyltriphenylphosphonium bromide relies on a direct alkylation step. Most routes use triphenylphosphine as the foundation, reacting it with butyl bromide—usually under reflux in acetonitrile, toluene, or even dichloromethane. Stirring carries on till the reaction pushes out the full conversion, with the product sometimes crashing out as the solvent cools. In small-batch labs, simple filtration and washing yields a product ready for use. Scale-up facilities might use continuous stir tanks and tailor solvents for both cost and waste minimization. At each step, chemists test for purity by TLC or HPLC, and drying gets done over vacuum or low heat to suck out residual solvents. Raw yields hover around 80%, but careful work often brings that up. This synthetic route reflects the classic, direct approach still favored for many quaternary phosphonium salts.

Chemical Reactions & Modifications

Butyltriphenylphosphonium bromide finds its place as a precursor and phase-transfer catalyst. In organic synthesis, its most famous role links to the Wittig reaction, where it forms ylides that build alkenes out of simple precursors. Once you deprotonate the methylene group attached to the phosphonium, it can step into carbon-carbon bond-forming reactions, reliably producing trans-alkenes favored in pharmaceutical targets. Beyond that, this salt comes in handy for SN2 substitutions, with the butyl group showing decent leaving characteristics for further transformations. In the world of modifications, chemists sometimes swap out the butyl chain or couple in alternative anions—chloride or iodide—to tune solubility or reactivity just a little. Electrosynthesis researchers push modifications to the phosphorus center, hoping to design new catalysts for greener manufacturing. Having used this compound in both undergraduate labs and company pilot runs, I've always found it tolerant of different conditions, flexible for new methods as skills or technology advance.

Synonyms & Product Names

In catalogs and journals, Butyltriphenylphosphonium bromide answers to several aliases, reflecting global supply and different naming customs. Common synonyms include BTPPB, butyl(triphenyl)phosphanium bromide, and n-butyltriphenylphosphonium bromide. Some sources abbreviate to TPB-Butyl Br. International language differences sometimes pop up in imported documentation. Purchasers should scan all possible synonyms to avoid order errors, especially when cross-referencing regulatory lists or customs documents. For researchers, exploring chemical databases—Reaxys, SciFinder, or PubChem—under different names helps round up reaction precedents and safety notes. Whenever I browse suppliers, keeping an updated list of the most-used aliases avoids shipment mix-ups or stockroom confusion.

Safety & Operational Standards

Butyltriphenylphosphonium bromide ranks as a chemical requiring care, but not panic. Inhalation and skin contact call for gloves and effective extraction, since its powder form can prompt irritation and occasional sensitization. MSDS documentation flags risks of eye exposure and notes that prolonged handling without protection may worsen skin reactions. Lab protocol requires running reactions in ventilated hoods, washing up after spills, and labeling waste appropriately as brominated organics. In my own lab work, I found it straightforward to handle with nitrile gloves and goggles; incidents traced to carelessness—splashing during weighing or transfer—taught my teams the value of simple precautions. Disposal rules look at both the phosphonium and bromide components, sometimes necessitating halogen waste bins under institutional guidelines.

Application Area

Chemists reach for Butyltriphenylphosphonium bromide every time they need efficient ylide generation for the Wittig reaction or robust phase-transfer catalysis. Pharmaceutical process design leans on it for late-stage modification of active ingredients or scale-up syntheses of alkene intermediates that feed into antihypertensive or antipsychotic drugs. Materials development uses it in building specialty polymers or functionalized surfaces, especially where electron-rich scaffolds matter. Agrochemical research and dye chemistry also dip into this salt to streamline multi-step synthesis, cut out laborious purification steps, and ensure good product consistency. My own graduate research often involved setting up time-intensive Wittig reactions—having a solid supply of this particular phosphonium salt made a world of difference in scheduling and yield management.

Research & Development

Ongoing research continues to stretch Butyltriphenylphosphonium bromide’s reach. Teams at leading universities and companies now play with structured modifications, aiming to find new reactivity, boost selectivity in asymmetric synthesis, or boost catalytic turnover for industrial-scale reactions. Green chemistry projects eye its role in shifting processes away from hazardous solvents and minimizing by-products. Analytical labs have begun exploring its potential as a matrix in certain mass spectrometry protocols, hunting for performance boosts in peptide or polymer analysis. Working in process development, I have seen how a trusted, predictable reagent enables teams to scale promising reactions from flask to pilot plant, connecting supply chain reliability and IP generation. No forecast is perfect, but the steady pace of application patents and conference presentations tells me this salt should see wider uses as related technologies mature.

Toxicity Research

Toxicological studies on Butyltriphenylphosphonium bromide provide reassurance for general laboratory practice, but vigilance remains key. Acute toxicity sits lower than for many metals or aromatics, with published LD50 values in rodents above conventional danger zones, but lingering brominated organics in waste streams raise long-term environmental questions. Chronic studies have flagged no significant carcinogenic potential, but mucous membrane irritation shows up in both animal tests and the occasional accident report in industry. Systematic inhalation or ingestion will trigger headaches, skin conditions, or gastrointestinal upset, mainly through the bromide counter-ion effect. Risk assessments and new computational toxicology models suggest vigilance in bio-pharma settings, with periodic reviews of occupational exposure limits. From a practical standpoint, I have dealt with headaches from phosphonium dust—the lesson has stuck ever since to weigh out this compound with a steady hand and a well-fitted mask.

Future Prospects

Prospects for Butyltriphenylphosphonium bromide look strong due to ongoing advances in catalysis, green chemistry, and pharmaceutical innovation. As synthesis gears up for more selective, environment-friendly methods, this salt stands ready to form the backbone of phase-transfer reactions with less hazardous waste. Digital tools and high-throughput screening keep expanding its chemical footprint, letting researchers prototype new drugs or polymers without constant reinvention. Regulation may squeeze out less-predictable catalysts in favor of salts like this, which come with decades of accident-free handling and robust toxicology records. As a participant in both academic and industrial camps, I see reliable reagents like Butyltriphenylphosphonium bromide continuing to unlock creativity and safer, faster progress for a new crop of chemists entering the field.

What Makes Butyltriphenylphosphonium Bromide Useful?

No one grabs a bottle labeled "Butyltriphenylphosphonium Bromide" off the shelf for a kitchen experiment. This compound steps into the picture mostly in chemical labs and industrial production facilities. For folks like me who spent hours hunched over glassware in grad school, the name means something quite specific: it’s a quaternary phosphonium salt that helps drive reactions, especially in making new molecules for specialty products.

The Catalyst Edge

Ask any synthetic chemist about tricky chemical transformations—they usually mention phase-transfer catalysis. Butyltriphenylphosphonium Bromide enables certain reactants, which usually would not mix, to talk to each other. For example, the compound helps water-loving molecules play nice with oil-loving molecules in the same flask. This trick unlocks all sorts of new routes to pharmaceuticals, agrochemicals, and even flavor molecules for food.

Back in my university days, seeing phase-transfer catalysts in action felt a bit like magic. They cut down reaction times and often gave higher yields. For commercial chemical companies, this benefit means fewer wasted resources and less environmental impact. That matters to all of us.

A Key Piece in Organic Synthesis

Researchers use Butyltriphenylphosphonium Bromide to help build carbon-carbon bonds, which basically means stringing smaller molecules together to make bigger, more complex ones. Anyone who's followed the rise of new medicines has seen how finely tuned these processes must be. Good data from peer-reviewed work—like studies shared in journals such as Synthetic Communications—supports how crucial this compound is for making ylide intermediates, an essential step in Wittig-type reactions. Wittig reactions create double bonds, which show up in everything from vitamins to strong plasticizers.

Scaling Up: From Lab to Industry

On the production floor, Butyltriphenylphosphonium Bromide helps keep chemical runs consistent and dependable. Many factories want reliable input chemicals that don’t introduce extra waste or slow down the process. Mixing up pharmaceutical starting materials without unneeded by-products keeps costs down and safety up—a win for companies and for patients.

Environmental impact gets a lot of attention these days. This catalyst supports “greener” chemistry by cutting down on solvents and energy needed to achieve the same product. Less energy and less waste lead to a smaller carbon footprint.

Challenges and Paths Forward

Nothing’s perfect. Waste management and proper disposal matter with anything from chemical labs, including phosphonium salts. Careless handling can lead to contamination or worker risk. In my own experience, labs run better with strict training on waste streams and clear labeling—no gray areas or shortcuts. Industry regulators such as the EPA and OSHA pay close attention to best practices here.

Some new research aims to swap out classic catalysts with eco-friendlier replacements or more recyclable options. That process takes time, and many companies stick with Butyltriphenylphosphonium Bromide for its predictability. For future chemists, getting hands-on exposure to safer alternatives, understanding safety data, and discussing new regulatory guidance should be part of both their education and daily practice.

Why It All Matters

I’ve seen chemical advances shape whole industries. Butyltriphenylphosphonium Bromide, though it sounds like a mouthful, plays a real part in making life-changing products. Knowing what goes into these processes reminds us that behind every new material or medicine sits a team considering environmental, economic, and human impact. That’s a lesson future generations of chemists will build on.

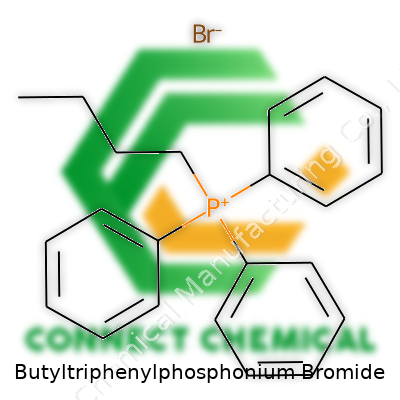

Getting to Know the Compound

Butyltriphenylphosphonium bromide stands as an intriguing chemical often seen in laboratories dealing with organic synthesis. The chemical formula, C22H24BrP, packs together a butyl group, three benzene rings, a phosphorus atom, and a bromine atom. Chemists trust it for its capacity to help shuttle ions as a reagent or a phase transfer catalyst. My years in the field have shown this compound helps bridge the worlds of organic and inorganic chemistry.

What the Structure Looks Like

At its core, the molecule consists of a phosphorus atom, which connects to one straight butyl group and three bulky phenyl groups. These phenyl groups are essentially benzene rings, each holding six carbons in a hexagonal shape. The phosphorus sits snug at the center, binding these four groups tightly.

The bromide ion, floating nearby, keeps the whole molecule electrically balanced. This sort of arrangement—a big, positively charged ion paired with a bromide—lets butyltriphenylphosphonium bromide dissolve in a mix of solvents, including those both polar and nonpolar. That versatility leads to fewer headaches in the lab, especially during tricky reactions.

Why It Matters in the Real World

Butyltriphenylphosphonium bromide shows up in more research projects than many expect. Organic chemists regularly choose it as a phase transfer catalyst, a role where it moves ions between water-based and oil-based layers. I’ve run plenty of reactions trying to keep different compounds together, and this chemical gets things moving faster and cleaner.

Researchers lean on phase transfer catalysis for tasks ranging from pharmaceuticals to specialty polymers. Clean reactions mean less waste, safer working conditions, and simpler cleanup. For years, finding ways to lower the environmental footprint in chemistry has shaped how I approach most projects. When bulky, stable ions like those in butyltriphenylphosphonium bromide come into play, reactions can run at lower temperatures and with less energy.

Potential Risks and Solutions

No chemical stays risk-free. Handling butyltriphenylphosphonium bromide needs care, especially because many phosphonium compounds can irritate skin and eyes. Long hours in the lab have taught me to rely on gloves, goggles, and well-ventilated hoods for safety. While this might seem basic, real issues often crop up from small lapses.

Disposal creates its own set of headaches. Chromium, lead, and other toxins grab headlines, but phosphorus byproducts deserve attention, too. Instead of treating disposal as an afterthought, labs benefit by setting up take-back schemes or partnerships with chemical waste handlers. Solvent recovery systems, which collect and clean up after reactions, cut down on what ends up in the waste stream.

Looking Ahead

Materials like butyltriphenylphosphonium bromide play a bigger role in progress than most realize. Their versatility in research, especially in sustainable synthesis, highlights why understanding the chemistry matters. The formula and structure guide how chemists use the compound safely and efficiently, joining the push for smarter, greener labs.

Picking the Right Storage Spot

Plenty of chemicals ask for a cool, dry spot away from sunlight, and Butyltriphenylphosphonium Bromide fits that group. Even if it does not draw much moisture from the air, keeping moisture out helps maintain purity and keeps the compound from clumping up or changing character. No one wants strange surprises in the bottle after a few months. Tuck it away in a tightly sealed container, one with a clear label to steer anyone clear who should not be near it. I’ve watched accidents happen because someone missed a faded label, thinking a white powder was simple salt.

Shelves in the chemical cabinet should sit away from direct sunlight — heat can speed up unwanted reactions. Too many mishaps spark up in busy labs because boxes stack too high or lean against each other. Sometimes, a simple slip means the wrong chemical lands in the wrong hands. Separate hazardous substances from anything flammable or acidic. A clear layout stops the frantic search for spill kits if anything tips over.

Choices That Shield Health and Safety

Everyday gloves offer nothing against specialty chemical powders. Nitrile gloves, safety specs, and a proper coat keep skin and eyes safe from splashes and dust. I once watched a colleague ignore a splash and thought rinsing their hands would solve things. A rash broke out by the end of the day. It’s easy to forget how quickly powders can enter through small cuts or get carried home on clothes and skin.

Work in a fume hood or well-ventilated area. A tiny bit of dust in the air can set off coughing fits or worse — no chemical, no matter how stable it seems, should get inhaled. Standard dust masks do little in lab settings; always use certified respirators if any fine powder becomes airborne. Clean up spills with wet methods, never dry sweeping. Dry dust moves quickly and ends up on the next person’s skin or the lab notebook.

Why Documentation and Training Matter

Safety data sheets exist for a reason. Each time a new supply arrives or a new team member joins in, go over the sheet with the group. A quick skim can save hours of regret later. Butyltriphenylphosphonium Bromide is used in many synthesis routes, not just research, and experienced teams lose track without regular reminders.

Disposal must follow local regulations. Pouring leftovers down the drain contaminates water supplies and can break waste systems. Set up a regular check of storage dates to keep outdated stocks from gathering dust until they're forgotten. I've seen labs spend weeks dealing with decades-old supplies that would have cost cents to dispose of earlier.

Culture of Safety Saves Resources

Safe storage and handling start well before the bottle gets opened. Open conversation between coworkers builds good habits — nobody should feel awkward pointing out a messy shelf or asking about a mystery powder. Accidents can derail months of work and put health on the line. Ownership of safety beats rigid checklists every time.

Investment in training, clear labeling, and accessible spill kits pays back down the line — not just in compliance, but in keeping everyone healthy and focused on the work at hand. For workers, researchers, or anyone handling Butyltriphenylphosphonium Bromide, making these steps part of the daily routine protects not only individual safety but the integrity of the entire workspace.

Unpacking Its Multifunctional Role

In any lab focused on organic synthesis, you’re bound to come across a shelf lined with all sorts of reagents—some classic, some niche. Among them, butyltriphenylphosphonium bromide gets a spot not simply for its interesting name, but for the jobs it can handle. My years working alongside synthetic chemists have shown just how often a chemical like this can save time in a complicated reaction sequence.

Phase Transfer Catalysis: Speeding Up Reactions That Struggle

If you have ever worked on a reaction between a water-based mixture and an organic solution, you know how slow things can get. It feels like watching paint dry. By adding butyltriphenylphosphonium bromide, you bridge that stubborn gap. The compound acts as what's called a phase transfer catalyst. In action, it picks up negatively charged species—like anions—from the water phase and carries them into the organic phase, where the real reaction starts to happen. The process goes from crawling to racing.

Industries working with pharmaceuticals, agrochemicals, or polymer science lean on phase transfer catalysis because it simplifies ambitious reactions. A report in *Organic Process Research & Development* emphasized that these catalysts help cut down the number of purification steps, waste, and time—three things everyone wants to minimize.

Building Blocks for Ylides and Wittig Reactions

Dig deeper into organic transformations and you’ll run into the Wittig reaction. This process creates those ever-important double bonds, helping chemists make everything from vitamin A analogs to drug intermediates. Butyltriphenylphosphonium bromide acts as a precursor to phosphonium ylides. What does this mean in the real world? A chemist throws this salt into a flask, treats it with a strong base, and forms the ylide needed for the Wittig reaction. It’s quick, and the compound’s stability offers reliability no one overlooks in research or industrial labs.

I’ve watched junior chemists get excited the first time they pull off a smooth Wittig reaction using this reagent. It means they can skip certain tricky steps, and that boosts productivity. This phosphonium salt’s straightforward handling and relatively benign nature also help in educational labs, where safety remains a serious concern.

Supporting Functional Group Transformations

The journey from starting material to a functional drug is full of stops and starts. Butyltriphenylphosphonium bromide can also participate in other transformation strategies. Need to convert an alcohol group to a better leaving group for nucleophilic substitution? This reagent’s structure lends itself to various modifications, giving scientists a leg up when developing creative synthetic routes. Its role assisting with selective alkylations or acting as a mediator for uncommon coupling reactions isn’t something you’ll always find in the textbooks, but it's become a practical trick in many labs.

Making Laboratory Life Smoother

Butyltriphenylphosphonium bromide brings dependability and versatility. Cost remains another factor. Compared with less stable or more hazardous phase transfer agents, it offers a safer profile under most handling conditions, which helped it earn trust over riskier alternatives.

Recognizing the need for scalable, reproducible, and efficient methods, chemists often return to this phosphonium salt. If the goal is greener chemistry, using fewer toxic solvents and maximizing yields, reliable helpers like butyltriphenylphosphonium bromide deserve a place on the workbench. Existing literature supports this, and years running reactions in both the classroom and commercial scale-up validate that trust.

Why Knowledge Matters in Chemical Safety

Anyone who’s ever worked in a lab or industrial setting knows that small oversights with chemicals can bring big consequences. Butyltriphenylphosphonium bromide doesn’t appear in the news as much as household cleaners or pesticides, but it shows up in research and manufacturing, especially where catalysis or ionic liquids play a role. People who handle chemicals for a living know you develop a relationship with new reagents—no matter how routine the job becomes, respect for chemical safety saves a lot of trouble. Understanding the actual hazards behind the jargon helps professionals stay safe and supports making smarter choices on the job.

What the Science Says About Hazards

This compound doesn’t top the charts for acute toxicity, but that doesn’t mean it deserves carelessness. Acute exposure brings moderate irritation to skin, eyes, and the respiratory tract. Even slight dust release or accidental splashing matters—once it lands on skin or gets in the eyes, discomfort follows. Scientific data, including the European Chemicals Agency and popular safety data sheet sources, reveal that repeated or prolonged exposure increases risks. Prolonged skin contact has the potential for dermatitis; eye exposure can lead to more severe inflammation than just a quick rinse can fix. The compound remains a solid at room temperature, but its fine powder form spreads easily into the air, raising the chance of accidental inhalation, which often doesn’t get noticed until irritation starts.

Real Workplace Practices: What Actually Helps

It’s easy to forget how common sense steps add up. As a research assistant, neglecting gloves during a late-night experiment cost me a nasty rash—one shortcut led to days of regret. Chemical goggles, lab coats, and non-permeable gloves may look excessive, but those layers keep the compound where it belongs. Mixing chemicals or preparing solutions inside a fume hood matters; even seasoned chemists who get too comfortable risk breathing fine dust. The fume hood’s exhaust or directional airflow cuts down on invisible airborne exposure.

A dry cloth never replaces running water if you get dust on your skin. A 15-minute rinse with running water can prevent discomfort and longer-term reactions. If it gets in the eyes, start rinsing immediately and head for medical attention. Workers handling large quantities need spill kits close by. Any spill, even a dusting, calls for containment, moistening to reduce airborne particles, and cleanup with proper personal protective equipment.

Disposal and Long-Term Risks

People in research and industry environments can forget that what goes down the drain doesn’t just disappear. Butyltriphenylphosphonium bromide poses environmental risks as a persistent organic compound. It can move through water systems and remain stable in the soil, affecting aquatic life. Proper disposal follows local hazardous waste protocols—never down the sink, always through engineered waste streams. This step protects not just the handler but the greater environment, especially in cities with sensitive water sources.

Cleaning up after yourself protects colleagues too. Cross-contamination is real—a few grains on a benchtop travel on sleeves, notebooks, or through shared gloves. Regular surface washing, labeling, and secure storage in tightly sealed containers cut down on surprises during future experiments.

Building Culture Beyond Rules

Safety culture grows when every person—not just lab managers—calls out unsafe practices. Open conversations based on real events, not just rule recitations, foster smarter habits. Asking questions, like “Do you know where the closest eyewash is?” or “Does this procedure need a hood?” builds trust and keeps standards high.

In the end, routine and respect must go hand in hand. Whether in a research lab or a pilot plant, controlling exposure to butyltriphenylphosphonium bromide takes the same care as any other compound: use equipment that fits, know the emergency steps, and never skip the basics. That’s how workers finish their shifts healthy—and how organizations earn reputations for safety.