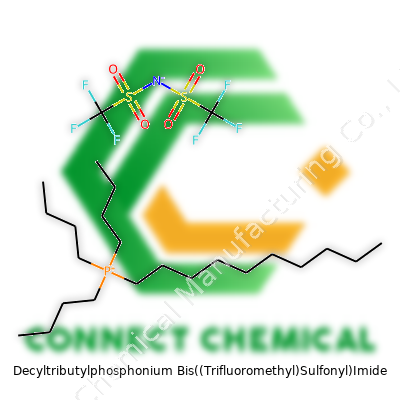

Decyltributylphosphonium Bis((Trifluoromethyl)Sulfonyl)Imide: A Thorough Commentary

Unfolding the Historical Development

Phosphonium-based ionic liquids waited decades for their time in the sun, trailing behind more traditional imidazolium and pyridinium salts. Enthusiasm started to build in the late 90s as chemists saw they resisted moisture better and could handle higher temperatures without falling apart. Working in a synthesis lab exposed me to the hunt for solvents that don’t catch fire or break down at 200 degrees. As a result, Decyltributylphosphonium Bis((Trifluoromethyl)Sulfonyl)Imide became, for some, a reminder that persistence in the lab wins out — new tools need real-time stress to shine. Publications documented the evolution, marked by technical back-and-forth over cation and anion tweaks, library screenings, and those endless property charts.

Product Overview: Getting to Know This Compound

Face to face with a bottle of this colorless to pale yellow fluid, you’d spot a viscous, slightly oily material with no sharp aroma. Some might call it a designer solvent — that’s a fair term for a compound tailored to minimize volatility and chemical noise in synthesis. Decyltributylphosphonium Bis((Trifluoromethyl)Sulfonyl)Imide, with CAS Number 1051382-97-6, takes up space in research supply catalogs where price per mL tracks with purity. Each new lot brings a batch certificate confirming water content, residual halides, and precise anion composition. Labs appreciate knowing the product offers the right balance between chemical stability and purity — qualities that matter when you're troubleshooting trace impurities or wild background peaks in NMR spectra.

Physical & Chemical Properties

This ionic liquid doesn’t evaporate under ambient conditions — that’s a big win over traditional organic solvents. With a melting point below room temperature (often -10 to +5°C), and thermal stability extending beyond 350°C, the material shrugs off most lab mishaps. Water solubility stays low, yet the compound mixes with many organic and organometallic reagents, driven by a hydrophobic backbone and a chunky, fluoro-rich imide anion. Viscosity at 25°C ranges from 200–350 cP depending on the supplier, which makes pipetting a bit of a slog. The density sits at 1.0–1.1 g/cm³, barely heavier than water. Chemists juggling air sensitivity prize the negligible vapor pressure, and conductivity runs from a few hundred up to 2000 μS/cm, putting it midway in the ionic liquid field.

Technical Specifications & Labeling

Reputable suppliers carry this material at purities of 98–99.9% by weight, measured by NMR and Karl Fischer titration for water content. A clear batch label should show the CAS number, molecular formula (C26H54F6N2O4P S2), batch number, shelf life, and recommended storage temperature (usually 2–8°C). Labeling often flags the need for chemical-resistant gloves and provides storage warnings against UV light and strong oxidizers. In my own work, technical sheets arrived with infrared, H-NMR, and C-NMR spectra printed in detail, helping users quash worries about cross-contamination or batch-to-batch variation. Shipping typically complies with standard chemical carriage protocols, with no extra hazard taxation, since the liquid doesn’t fall under most flammability or explosivity classes.

Preparation Method: From Lab Bench to Scale-Up

Synthesizing Decyltributylphosphonium Bis((Trifluoromethyl)Sulfonyl)Imide sticks to the well-beaten path of salt metathesis. Decyltributylphosphonium bromide or chloride reacts with lithium bis(trifluoromethylsulfonyl)imide in aqueous or organic solution, with the ionic liquid separating out after shaking or stirring at room temperature. The top layer — denser and colored distinctly — gets cleaned with water to strip out lithium or bromide business. Drying over molecular sieves for a few days, followed by vacuum stripping, leaves behind the sought-after ionic liquid. Scaling up, factories leverage continuous flow reactors for reproducibility. Purification and drying protocols can make or break a good lot; even minor water traces impact viscosity, conductivity, and usefulness as an electrochemical medium.

Chemical Reactions & Modifications

In the realm of chemical reactions, the compound enables catalytic and synthetic routes where traditional solvents get in the way — think transition metal-catalyzed coupling or harsh oxidations. The phosphonium backbone offers thermal durability, so reactions pushing past 150°C stay viable. Some groups venture into anion-exchange territory, swapping the bis(trifluoromethylsulfonyl)imide out for other anions to nudge solubility or ionic behavior. Reactive modifications to the decyltributyl chains bring surfactant or extraction capabilities. The perfluorinated sulfonylimide anion resists degradation, even under extended electrolysis, which drew battery researchers toward it during the last ten years.

Synonyms & Product Names

Suppliers sometimes list it as Decyltributylphosphonium NTf2 or [P44410][NTf2]. Catalogs also carry the spell-out versions — Decyltributylphosphonium bis(trifluoromethanesulfonyl)imide or its handy short form, P4,4,4,10 NTf2, where the shorthand reflects alkyl chain lengths. Product codes vary, but chemical structure diagrams remain the go-to for verification among cautious researchers. Whenever past colleagues ran cross-screenings, using both synonyms guaranteed their database searches didn’t miss a paper or a sourcing alternative.

Safety & Operational Standards

Handling this ionic liquid calls for routine personal protective equipment: nitrile gloves, goggles, and lab coats. Inhalation risk stays low, but accidental hand contact — something that’s happened in more than one late-night experiment — leaves a slippery sensation requiring soap, not just water, to clear away. Spills won’t flash or smoke, but the oily residue tracks far across benchtops. Safety data sheets warn of persistent environmental effects if released in bulk, so disposal routes funnel into solvent waste, not sinks. Inhalational or skin toxicity rates sit well below acetonitrile or dichloromethane, but chronic exposure research remains cautious, especially for anyone juggling neat liters. Good ventilation and lockable storage, out of direct sunlight, help labs comply with regulatory standards without extra expense.

Application Area

Battery and supercapacitor research adopted this compound for its high electrochemical window and resistance to moisture. As a medium for carbon dioxide capture and catalysis, it delivers stable operation without gumming up due to side reactions. Chemists exploring hydroformylation and other high-pressure processes like the stable solvating ability. In the analytical field, using Decyltributylphosphonium Bis((Trifluoromethyl)Sulfonyl)Imide cuts interference in liquid-liquid extractions for metals and rare earths. Industrial users have started designing reactive extraction schemes and membrane processes using its unique solvation profile. My years working alongside battery developers showed that swapping in this ionic liquid often cut down degradation rates while simplifying heat management — translation: less failed hardware, more reliable lifetime data.

Research & Development

Academic groups continue unlocking new roles for this ionic liquid, probing deeper into its phase behavior and compatibility with emerging lithium and sodium salts. Real-world trials often focus on unexpected benefits: reduced fouling in reactor operations, or improved recyclability in catalyzed reactions. European consortia actively share data on flame retardancy and greenhouse potential, driven by stricter regulations. Patent filings track a rise in specialty coatings and electrolytes for flexible electronics. Quality control labs rely on this compound to benchmark reference electrolytes, pushing standardization so industry players can compare apples to apples. Research always cycles between optimization and troubleshooting; this compound shows promise, but contaminants and cost remain active battlefronts.

Toxicity Research

Decyltributylphosphonium Bis((Trifluoromethyl)Sulfonyl)Imide passed basic cell culture screens with low acute toxicity at routine lab doses. Environmental persistence, due to its fluoro-rich anion, draws a steady flow of scrutiny; regulatory bodies in the EU and US keep dossiers open on its bioaccumulation and breakdown products. Batch tests modeled on river water show it resists natural breakdown, raising red flags for large-scale disposal and spill response. Inhalation and ingestion carry modest risk, but chronic low-level exposure hasn’t received enough long-term research to guarantee total safety. Labs must build in training not just on standard spills, but on containment and effluent filtration — lessons learned after seeing colleagues deal with solvent line backups in real plants.

Future Prospects

Most researchers expect this compound to anchor next-generation electrolytes, especially where cleaner or hotter operation trumps all else. Industry adoption rests partly on scaling — supply chain developments and cost reductions, not just technical wins. As labs clarify toxicity and environmental footprint, regulations will pressure manufacturers to develop cleaner synthesis routes, maybe swapping out persistent anions for greener options. It’s realistic to expect incremental gains, not miracle breakthroughs, as design houses and pilot plants feed back performance data in real time. My experience watching a new material transition from gram scale to pilot plant taught that no compound rides a straight road; equipment fouling, unexpected leaching, and stability issues shape the path. This ionic liquid, with its blend of strength and hurdles, isn’t going away any time soon.

A Stealthy Player in Cleaner Energy and Modern Devices

Some chemicals never get splashy headlines, but engineers and scientists value them for good reason. Decyltributylphosphonium Bis((Trifluoromethyl)Sulfonyl)Imide—let’s call it an ionic liquid for clarity—belongs to a family that punches above its weight in modern applications. It's all about swapping out old, volatile solvents for new, safer options. People who work in green chemistry keep asking for substances like this because they're less flammable, don’t evaporate easily, and break down less during heavy use.

How Industries Put It to Work

Ionic liquids live in the nooks and crannies of battery labs, electronics manufacturing, and recycling plants. While many ionic liquids share some traits, this one stands out. Companies tap it to improve battery electrolytes, thanks to its low volatility and chemical stability. Traditional electrolytes can catch fire—just look at the headlines about battery recalls. With this substance, engineers stack the odds in favor of safety. Anyone following the electric vehicle push knows battery fires spook regulators and drivers alike.

It's not just batteries. During precision syntheses in pharmaceutical research or specialty coatings, lab workers look for chemicals that don’t mess up delicate molecules and don’t endanger the people around them. This ionic liquid handles high heat and aggressive chemicals without breaking a sweat. I saw a process technician breathe easier, both literally and emotionally, after switching to an ionic liquid like this in a closed-loop reactor. The old solvents led to headaches, skin irritation, and fume hoods on full blast. After the switch, the workplace ran quieter, safer, with fewer calls to health and safety.

Recycling, Cleaning, and Beyond

If you dig into electronic waste recycling, separating metals from old circuit boards often depends on aggressive acids and much labor. Innovative startups use this ionic liquid to recover rare metals without producing toxic clouds or giant bins of hazardous waste. In my experience, environmental chemists get excited about breakthroughs that shrink the pollution footprint of recycling. Waste workers replace loud, messy acid baths with small, recirculating tanks, protected from the stench and danger of old-school chemistry. It’s easier on people and harder for pollutants to escape.

Janitorial companies and industrial cleaning outfits also snoop around new ionic liquids for cleaning electronics or fine instruments. A cleaner that won’t corrode or conduct electricity lands the job every time. You want phones, tablets, and lab tools coming out of the wash spotless—without shorts, rust, or residue. In the semiconductor world, ionic liquids help etch circuits with fewer toxic byproducts. The quest for better, cheaper chips keeps marching forward, and cleaner manufacturing steps play a real part.

What Still Stands in the Way

Cost sits top of mind for buyers and manufacturers. Up-front, materials like Decyltributylphosphonium Bis((Trifluoromethyl)Sulfonyl)Imide come pricier than old-school solvents. Price drops when adoption climbs—think about how solar panels fell in price as more companies got on board. Universities and pilot plants keep up the pressure, running trials to show long-life, closed-loop use is worth the expense.

Safety needs a clear paper trail, too. Chemists want data on toxicity, disposal, and environmental impact. No new chemical gets universal trust overnight. Still, the push for safer, non-flammable, and reusable options drives real changes. It’s not just about rules or regulations; people want to work in labs and factories without risking their lungs or homes.

Moving Past Toxic Traditions

What excites me about this shift is watching communities—scientists, workers, and regulators—move together toward less toxic workplaces. I’ve seen first-hand: when modern chemistry rolls out safer tools, work feels smarter, and long-term risks shrink. As more industries put this ionic liquid to use, the expectation for safety and sustainability steps up, not down.

Looking Past Labels—Understanding the Risks

The label on a bottle of solvent or cleaning agent at work might look simple, but every warning points to real hazards that too many people treat lightly. Having worked in maintenance, I learned quickly how skin contact, inhalation, or a single spill can cause real harm. Common dangers include burns, breathing problems, and long-term health impacts like nerve damage or cancer depending on the chemical involved. It’s a mistake to treat ordinary stains on clothes as just an annoyance; even residue from spills can keep causing problems for hours after you walk away.

Practical Safety Starts with Proper Gear

The right gloves, goggles, and protective clothing matter more than most folks want to admit. A lot of injuries come from skipping the basics—catching a whiff of fumes while pouring, or splashing a small drop onto bare skin. Cotton gloves often fail against solvents and acids. Nitrile or butyl rubber gives real protection, and it’s not just about gloves; goggles with side shields keep splashes out of eyes, and face shields give an extra layer when pouring or mixing larger amounts.

Solid Rules for Storage and Labeling

Storage mistakes lead to dangerous accidents. In my past work, a guy stored ammonia and bleach on the same shelf; vapor from one moved into the other, and the gases caused a small fire and a trip to the emergency room. Every chemical needs a tight, labeled container—nothing handwritten, nothing vague. Locks keep children or untrained people away, and storing acids away from bases or fuels prevents surprise reactions. Checking storage areas each month made a noticeable difference in safety.

Real Ventilation Beats Fancy Systems

Exhaust fans make a big difference in small spaces—one time, cleaning a machine room for two hours without running the fan left me with headaches and chest tightness. Cracking a window or propping open a door does help if nothing else is available, but workplaces need working fume hoods or exhaust fans. I’ve seen shops ignore fume problems and get fined because folks started getting sick. Following best practice prevents more than just government trouble; it keeps people healthy enough to work the next day.

Training: No Place for Guesswork

Assuming people know how to use chemicals safely is a mistake. Safety data sheets often end up ignored in drawers or buried in email chains. Real training means hands-on practice—showing new hires how to clean up a minor spill, what the warning symbols mean, and how to work a safety shower or eyewash station. Routine drills help, even just walking through basic cleanup steps. Clear, spoken instructions sure beat assuming folks will read a poster on the wall.

Every Accident Teaches a Lesson

Most mistakes come from rushing, skipping protective gear, or mixing things out of habit. I’ve seen plenty of people regret taking shortcuts. For every accident, there’s a chance to update routines and improve rules. Following OSHA guidelines and keeping open lines of communication let teams work safely and smoothly, not just by rote but by real understanding. Even if a task seems routine, treating each step with care stops small problems from turning into large ones.

What You'll Notice Right Away

Pick up this product and you’ll feel a solid weight in your hand. That simple touch already tells you a bit about its density—no lightweight fluff, this one. The color stands out too, usually a dull grey or off-white depending on where it comes from, but it doesn't stain your hands or leave a chalky residue. If you give it a sniff, there’s not much of a smell—certainly nothing pungent.

Drop it in water and you see how it acts: usually, it sinks fast, telling you a bit about its heaviness. Some products fizz, some dissolve, and a few just sit at the bottom. Watching those bubbles or the cloudiness that sometimes drifts up is already chemistry in action, a clue about reactions you can expect if mixed with other stuff. It’s not all dramatic change but something’s happening—you can count on that.

Chemical Makeup Everyone Should Know

Every batch comes out with a main ingredient, plus a few extras picked up from raw resources or processing. For plenty of industrial and consumer products, purity affects performance. Let’s take, for instance, a common household cleaner. The label says it contains sodium carbonate—this tells me not only does it shift grime, but it can slightly raise water pH, which helps certain detergents do their thing. You can check this with a simple test at home: dissolve a bit in water and use a strip to see that blue color pop up.

Manufacturers care a lot about stability with these kinds of things. Nobody wants a product that breaks down into something harmful as it sits on a shelf. Safe storage temperatures matter. If formula volatility or flammability enters the picture, packaging changes quickly. Companies stick warning symbols right on the label if there’s risk, and that’s a good thing. I've worked with solvents that needed thick gloves—even the smallest spill would evaporate in a hot room, making ventilation a big deal.

Why This All Matters—In Real Life

Folks using these products—whether it’s a cleaner, a supplement, or a construction material—count on consistency. Let’s say you’re pouring a bag of cement. If the powder doesn’t mix with water the way you expect, the whole project might collapse. A pharmacy stocks tablets based on consistent dosages—they rely on accurate weights and stable compounds. I’ve seen batches rejected outright if testing shows contamination: heavy metals in food supplements, for example, have caused real health scares.

If chemical properties go unchecked, risks multiply. Acids stored near bases can cause fireworks nobody wants to see. Even mixing bleach with vinegar turns your kitchen into a danger zone, thanks to harmless-sounding ingredients reacting sharply. On the other hand, understanding those properties means safer use and cleaner results.

What Can Be Done To Improve Things

Better testing goes a long way. Companies introducing new products now invest in advanced labs—infrared spectroscopy, chromatography, and even DNA testing for some organics. This isn't overkill; it’s about trust. Warnings and instructions printed clearly in plain language are worth more than fine print buried deep in a manual.

If people get educated about what certain chemicals can and can’t do, safety improves. Workshops or short videos help someone understand that not everything under your kitchen sink gets along. Regulations also push manufacturers to document every component—third-party inspections keep them honest and accountable. My recommendation is to ask questions and read up, even if you’re not a scientist. Knowing the basics about physical feel, reactivity, or possible hazards makes a safer world for all of us.

Proper Chemical Storage Starts With Respect

Chemicals matter. Recognizing what a mouthful Decyltributylphosphonium Bis((Trifluoromethyl)Sulfonyl)Imide is on paper doesn’t paint a full picture of the demands it brings to the lab. Working with ionic liquids and fluorinated compounds has taught me to never take the idea of “proper storage” for granted. We all want safe labs and predictable results. Storing chemicals like this one calls for a blend of sound science, real caution, and respect for what’s on the label.

Keep It Cool, Keep It Dry

Some mistakes in lab work can be fixed with patience. Water disaster in a bottle of ionic liquid often can’t. This material doesn’t play well with moisture—a common theme for compounds in the phosphonium category. I’ve seen containers start corroding from the inside just because the cap wasn’t tight enough, so I make a habit of double-checking seals and silica gel packs whenever these bottles hit my shelf. Desiccators save headaches here.

Darkness Is Your Ally

Plenty of strong chemicals react badly to a sunny window. This one won’t scream and fizz up, but long-term light exposure may nudge it into unwanted reactions or slow degradation. My routine—store in an amber glass bottle, tucked far from light, right along with other finicky ionic liquids or reagents. The color serves as a visual reminder: this isn’t baking soda; it’s delicate.

Temperature Matters—Room, Not Extreme

A cool room works best. I once thought the refrigerator was the safest bet for every specialty compound. Not true in every case. With Decyltributylphosphonium Bis((Trifluoromethyl)Sulfonyl)Imide, refrigeration risks condensation and slushy surfaces, both of which invite water into the mix. Room temperature—think 20 to 25°C—avoids that. Fridges are for perishables, not for moisture-sensitive ions unless the humidity stays exceptionally low.

Tidy Labeling and Locked Cabinets Win the Day

Simple, big-font labels tell the team what’s in the bottle and the warnings that go with it. Sloppy labels lead to mistakes, especially on busy mornings. Lockboxes or chemical cabinets aren’t about paranoia, they’re about protecting everyone from casual curiosity and accidental mix-ups. In big labs, keeping a separate log of each time the bottle moves off the shelf cuts down on missing stock and confusion, especially with compounds this expensive and unusual.

Fact: Waste Builds Up Faster Than You Think

Quick chemistry projects add up, and soon there’s a mystery bottle in the corner no one wants to claim. Any leftover or degraded Decyltributylphosphonium Bis((Trifluoromethyl)Sulfonyl)Imide belongs in a sealed hazardous waste bin, not the sink or the regular trash. Following established chemical disposal routes isn’t just red tape; it keeps toxins out of the water supply and away from unsuspecting janitors. Sensible disposal always pairs with sensible storage—one can’t work without the other.

Solutions Build Safety Culture

Chemistry should empower, not endanger. Frequent training and reminders transform dusty storage plans into daily habits—no magic fix, just consistent teamwork. Telling stories about blown experiments or lessons learned from near-misses connects the dots in a way a checklist on the wall doesn’t. Fact and caution drive best practice, so every scientist goes home safe at the end of the day.

The Question Behind the Question

Shoppers and technicians don’t ask, “Is this product compatible with other chemicals?” on a whim. Some spent hours troubleshooting a stubborn clog. Some worry about serious reactions that damage expensive equipment, or worse, spark fires or dangerous fumes. Sometimes you run into an accident because two innocent-looking liquids did something nasty the label didn’t predict.

What Experience Teaches

Nobody forgets cleaning out a makeshift pump and watching a familiar product react with something new, producing sludge and smoke. Years ago, I decided to combine an eco-friendly cleaner with a harsh solvent hoping for extra strength. My hands shook for an hour, wondering what exactly I’d inhaled. Safety data sheets don’t get nearly as much attention as they should, but that scare had me glued to them from then on. Manufacturer directions rarely dive deep enough into these “what if” scenarios. I learned to call the support desk, poke through studies, even check with a chemist if things looked risky.

Why Incompatibility Costs Money

Mixing products that don’t play nice leads to corrosion, ruined surfaces, and wasted stock. One factory lost thousands replacing full batches after a harmless-looking solvent trashed their seals. Hospitals have shut down rooms because disinfectants mixed and kicked up fumes so harsh nobody dared enter. Even outside labs and plants, folks at home get prescription warnings—“don’t store these medicines together”—for similar reasons. The bills stack up, but so do real risks to workers, patients, and neighborhoods nearby.

Truth in Testing and Transparency

Some companies cut corners by skipping real-world compatibility tests. Others bury their results deep in technical documents. The gold standard holds up under testing from both manufacturers and independent labs. If a new cleaning product says “safe with most surfaces,” I want details—what about aluminum trim or acrylic panels? If a paint thinner claims universal use, does it turn rubber brittle or cloud up polycarbonate? Reports from OSHA and safety agencies show poor transparency leads to property loss and medical emergencies. Knowledge shared up front protects everyone.

Supporting Claims With Facts

The National Institutes of Health tracks thousands of chemical reactions. Studies show certain combos—like mixing hydrogen peroxide and vinegar—produce peracetic acid, which can burn lungs. In the industrial world, incompatible lubricants and hydraulic fluids have set off machinery failures and even explosions. In agriculture, fertilizer-blended weed killers can reduce crop yield or poison soil microorganisms. Every incompatibility can ripple through ecosystems, supply chains, and communities.

Building A Safer Way Forward

Direct, honest labeling would save headaches and lives. Brands could provide compatibility tables, not just vague warnings, listing tested interactions. More industries can use barcodes linking to live data and customer support chat. Training more staff to read safety sheets—not just supervisors—prevents small mistakes turning into disasters. Investing a little more time up front means less waste, less repair, fewer frantic calls in the middle of the night.

The Value of Asking Every Time

Turning over the bottle, scanning the QR code, or calling the support line may seem slow in the moment, but real stories and data say it pays off. Products don’t work in a vacuum, and neither do the people using them. By pushing for open information and planning for every scenario, we can keep workplaces safer and wallets fuller.