Dodecylbis(2-Hydroxyethyl)Methylammonium Chloride: The Workhorse Quaternary Ammonium Compound

Historical Development

Dodecylbis(2-Hydroxyethyl)Methylammonium Chloride has its roots in the rapid growth of surfactant chemistry during the last century. As the twentieth century unfolded, researchers chased compounds that could do more than just lower surface tension. This particular quaternary ammonium salt caught attention because of its unique structure: a long hydrophobic tail paired with two hydroxyethyl arms and a methyl group clinging to a nitrogen core. The compound began making waves as both industrial research and household cleaning standards grew more demanding. Manufacturers in the late 1960s and early 1970s launched lines of quaternary ammonium products, seeking alternatives that didn’t just push dirt around but actually broke it apart and sanitized at the same time. Personal anecdotes from university days come to mind, where chemistry professors often cited this compound as a landmark for its balance between performance and safety compared to harsher, older quats or pure alkylammonium choices. Lessons learned in those labs and pilot plants mirror how this material managed to outcompete some of its peers in both versatility and economic synthesis.

Product Overview

Few chemical names trip off the tongue like Dodecylbis(2-Hydroxyethyl)Methylammonium Chloride, but don’t let that fool you; the trouble you face pronouncing it often belies how easy it is to use. Today, this compound finds its way into a long list of products, from textile softeners and disinfectants to personal care products. The structure acts both as a surfactant and an antimicrobial, making one bottle pull double duty in a cleaning closet or a shampoo formulation. For anyone who has ever worked in laundry chemistry or who has spent a morning testing disinfectants in a microbiology lab, its pronounced effect on greasy stains and bacterial cultures makes it stand out among quaternary ammonium compounds. Companies gravitated toward it not just for the cleaning punch, but for the way it could be fine-tuned for mildness—a balance my own hands have felt when comparing with hand-abrading alternatives.

Physical & Chemical Properties

In the jar, Dodecylbis(2-Hydroxyethyl)Methylammonium Chloride appears as a colorless to pale yellow liquid or sometimes a waxy solid depending on the purity and hydration state. Its defining feature—a dodecyl (C12) tail—makes it oil-loving, yet the hydroxyethyl arms tethered to the nitrogen help it dissolve in water. This gives the compound its edge when formulating products for both hard and soft surfaces. Melting points hover around 40°C when pure, but real-world batches often include enough water to stay fluid at room temperature. In my own lab experience, pouring the syrupy concentrate into a beaker led to quick clarification upon dilution, and I learned early how humidity could alter its handling properties.

Technical Specifications & Labeling

Producers often deliver this material with purity ranging from 65% to 80%, sometimes higher for specialty applications. Technical datasheets list major things like molecular weight (307.94 g/mol), CAS number 68391-01-5, and standard solution concentrations. Manufacturers detail the pH of a 1% solution (usually near neutral), coloring (max APHA 50 or so), and chloride content, all crucial for regulatory compliance and ensuring product consistency batch after batch. Labels call out the main hazards associated with skin and eye contact, referencing both the Globally Harmonized System (GHS) and local workplace safety standards. Personally, finding clear labeling keeps mistakes low during product formulation and reduces guesswork during toxicological review. I also notice increased focus today on including shelf life and trace allergen content, something demanded more by the cosmetics and personal care sector.

Preparation Method

Synthesizing Dodecylbis(2-Hydroxyethyl)Methylammonium Chloride starts with the common building block dodecylamine. Chemical manufacturers add ethylene oxide under controlled conditions, tacking on the two hydroxyethyl groups with care to avoid overalkylation, then quaternize the amine using methyl chloride or dimethyl sulfate to produce the ammonium chloride salt. This process requires close control to avoid unwanted byproducts such as unreacted amine or too much alkylation. Here, hands-on experience with batch reactors proves invaluable—small temperature shifts can mean off-color or impure batches. In pilot plant settings, process engineers use phase separation and solvent extraction to clean up the product, with final analyses validating absence of free amine.

Chemical Reactions & Modifications

In the hands of a skilled formulator, Dodecylbis(2-Hydroxyethyl)Methylammonium Chloride can play several roles beyond simple surfactancy. The hydroxyethyl groups on the molecule offer free hydroxyls for potential further derivatization, such as etherification or esterification, letting researchers expand the compound’s application window. In the 1980s, innovative modifications aimed at boosting antimicrobial efficacy led to blends with other surfactants or polymers, while modern studies focus on improving biodegradability or tweaking chain length to re-balance softness and germ-killing strength. In my own research, small tweaks in the substitution pattern often led to big changes in foaming and soil removal; small pilot batches underline just how much trial and error precedes a market-ready formulation.

Synonyms & Product Names

Having worked among procurement teams and specialty chemical distributors, I’ve had to navigate a sea of names. Alongside the full IUPAC handle, you find aliases such as Laurylbis(2-Hydroxyethyl)Methylammonium Chloride, and trade names ranging from Dehyquart to Quat-12-2. The confusion among new lab techs underscores the need for unambiguous CAS numbers and supplier-specific codes. Not every supplier uses the same shorthand, either. That challenge remains in documentation and compliance, as changing a supplier sometimes means changing a database or updating safety datasheets throughout the supply chain.

Safety & Operational Standards

Worker safety always dominates discussions around quaternary ammonium compounds—this one included. Direct skin or eye contact triggers irritation, especially with concentrated solutions, demanding gloves and splash protection for anyone working at the bench or filling a tank. In my own experience, projects at detergent makers involve repeated reference to SDS guidance, backing up personal anecdotes with solid data from repeated exposure tests and periodic air sampling in blending rooms. Modern regulatory standards require clear labeling for toxicity and environmental impact, pushing companies to re-train teams and install more robust ventilation or closed-system handling. Wastewater discharges draw closer scrutiny now, a marked change from older practices where effluents left the plant with minimal checks.

Application Area

Dodecylbis(2-Hydroxyethyl)Methylammonium Chloride carves out its largest market in cleaning and disinfectant lines, both inside institutional kitchens and sprawling automotive facilities. Laundry softeners, floor polish emulsions, and antimicrobial rinses owe much of their mild touch and reliable action to this compound. In personal care, its mildness compared to harsher disinfectants means it often ends up in “gentle” shampoos or conditioners. Industrial water treatment taps into its biocidal capacity, slowing down microbial growth in cooling towers and pipelines. Experience on factory tours often reveals stacks of intermediate drums marked with this compound destined for products that touch nearly every household. Yet, despite its scope, the compound’s true reach depends on awareness and responsible use; eco-labels and performance claims both influence how widely it can travel across global supply chains.

Research & Development

Research in this field never really slows down. In the labs I’ve visited, much of the focus falls on greener synthesis and lowering residuals, addressing mounting regulatory and consumer demands for safer, more sustainable products. Innovation teams keep exploring new combinations with other surfactants and active agents, seeking performance without skin irritation or environmental persistence. Academic partnerships often yield deeper insights about the compound’s action against resistant bacteria, but industry experiments stress real-world trials—can this molecule hold up in a thousand wash cycles, does it perform in hard water, will it biodegrade fast enough for next-generation waste guidelines. Talking with R&D teams, the message comes through: adapt or get left behind.

Toxicity Research

Toxicology stands as both a red flag and a green light for market expansion. Animal studies show low acute toxicity at the levels used in consumer goods, though common sense and regulatory controls still call for care. Skin and eye irritation at higher dosage levels requires that workers and users take precautions. Researchers keep a close watch for long-term effects on aquatic life, with recent studies sparking efforts to minimize downstream environmental traces. Lab tests and regulatory dossiers I’ve helped assemble often reinforce established use levels, but unexpected findings prompt reformulation or withdrawal of products more often than many assume. Stakeholders today press for fully transparent data, leaning on third-party reviews and continuous monitoring.

Future Prospects

The future rides on how well the industry balances performance, sustainability, and regulatory acceptance. New synthesis pathways aim to cut down on energy intensity and waste. Market trends push companies to promise biodegradable or low-irritant alternatives, but performance cannot take a back seat, especially in health or critical infrastructure. In discussions with industry partners and trade association members, there is strong interest in recycling and circular life cycles—could this compound’s hydrophobic chain come from renewable feedstocks? Broader acceptance depends not just on technical advances and green chemistry, but on shared responsibility: manufacturers, regulators, and end users all have a part to play. Only by tackling challenges in toxicity, environmental persistence, and application demand head-on can Dodecylbis(2-Hydroxyethyl)Methylammonium Chloride continue to serve as a cornerstone without running headlong into obsolescence.

Everyday Uses in Cleaning and Sanitizing

Dodecylbis(2-hydroxyethyl)methylammonium chloride doesn’t exactly roll off the tongue, but plenty of cleaning products wouldn’t work the same way without compounds like this. My own run-ins with industrial-grade disinfectants in janitorial jobs taught me that quaternary ammonium compounds—quats, as people call them—do more than just kill germs. They break the greasy film on floors and leave bathrooms smelling like someone cared. It’s not the hero everyone thinks about, but its role matters: hospitals, hotels, laundries, and even veterinarian offices rely on it to clean up messes and fight the things we can’t see.

You pour a bit of concentrate, dilute it in a bucket, and scrub down a surface—it leaves things looking clean and actually sanitized. Covid opened everyone’s eyes to how fast germs can spread, and it’s these kinds of solutions that help people keep up.

Why it Shows Up in Industrial Formulas

This chemical doesn’t only belong in mops and sprayers. It pops up in textile mills and dye houses—places you wouldn’t expect unless you’ve seen how cotton gets turned into towels or clothes. I’ve spoken with folks in manufacturing who rely on this stuff to kill off mold and bacteria, especially when humidity hangs around. Left unchecked, mildew can ruin an entire production run. Using something that breaks the surface tension of water and attacks microbes keeps the machinery and the product line running at full tilt.

How it Impacts Water Treatment and Agriculture

Municipal water treatment runs up against all sorts of contaminants. Quaternary ammonium compounds—including this one—help control algae and biofilm in cooling towers, closed water systems, and even sometimes in swimming pools. I’ve lived in towns with well-managed municipal pools and towns with algae slicks near the walls, and that difference often traces back to water treatment protocols and the quality of the sanitizing agents.

Farmers face their own headaches—barns with livestock, greenhouses, machinery exposed to the elements. Surfaces need deep cleaning, both for the health of the animals and the workers. Relying on this type of chemical isn’t about fancy technology; it’s about being able to spray down a space and get on with the day, knowing you’ve cleared out most of what could make animals or people sick.

Health and Environmental Considerations

Nobody I know enjoys handling strong chemicals day after day. Safety data sheets for this compound make it clear: skin contact and inhalation carry their risks. Wearing gloves, goggles, and proper ventilation isn’t just about rules—it’s about not ending up with rashes or coughing fits. Workers on the front lines in cleaning and manufacturing need tools, but they also need simple safety training.

Down the drain, questions start coming up about aquatic toxicity. Quats can build up in waterways, affecting fish and plants. Regulatory groups in the US and EU have begun to watch these chemicals more closely. Some companies have already shifted toward less persistent compounds or reduced concentrations in finished products. Europe’s REACH regulation pushes manufacturers to rethink older recipes. More public awareness and watchdog groups help nudge changes, but big shifts take time.

Simple Steps Forward

Companies can do more with labeling. Clearer instructions help stop overuse, which cuts down waste and exposure. Plant managers can invest in training that keeps people safe and reduces accidental spills. Households, too, have a role—using less and choosing alternatives where possible makes sense for everyone. Quats make life cleaner, but a little common sense keeps them from wearing out their welcome.

Looking Closely at a Common Ingredient

Dodecylbis(2-hydroxyethyl)methylammonium chloride shows up in a lot of cleaning and personal care products. It’s a mouthful to say, but most people wouldn’t recognize it as anything special. This chemical acts as a surfactant—meaning it helps things mix, spread, and clean better. That’s why it often hides in things that touch the skin, like shampoos and fabric softeners. Still, many folks want to know if it makes sense to let it sit on your skin or if that spells trouble.

What Science Tells Us

Toxicologists have tested chemicals like this for years. Safety data from sources like the European Chemicals Agency and the Cosmetic Ingredient Review panel says this ammonium compound usually gets the green light for rinse-off products, as long as the formulas stay diluted. Manufacturers also run patch tests to check irritation. At low concentrations—typically less than 1%—most people never see a reaction.

Problems start cropping up when someone uses it in higher concentrations or lets it linger on the skin for longer periods. Some cleaning products and industrial-strength solutions pack a much heftier dose, and those have sparked reports of skin reddening, itch, and burns after direct contact. It comes down to concentration and contact time. Most personal care products stick to the safer guidelines, and that keeps the risks pretty low.

Not All Skin Reacts the Same Way

Sensitive skin doesn’t play by the same rules as tough skin. People who live with eczema or allergies tend to react quickly to quaternary ammonium compounds—especially if the skin’s already broken or dry. I can relate. After scrubbing down a tub with a heavy-duty degreaser containing surfactants, my hands felt tight and red, even with gloves. It wasn’t dangerous, but it reminded me that not everyone’s skin stands up to harsh chemistry the same way. Age, medical conditions, and even the weather matter here.

Safe Use Starts with Information

Labels don’t always help a regular person figure out what’s in a product or why it’s safe enough for skin. Plenty of countries make companies list every ingredient, but not everyone reads those long, scientific words. Doctors and dermatologists have stepped up over the years, warning patients with sensitive skin to avoid the harshest formulas—especially concentrated cleaners or industrial products. The biggest risks come from accidental splashes and not washing up after.

Better Choices and Smarter Habits

Safer skin care starts with small steps. Avoid heavy-duty detergents on hands or face. Rinse off any cleaner as soon as you’re done, even if it’s just dish soap. Wearing gloves for serious cleaning jobs helped me cut down on dry, tight skin after regular chores. For people with eczema or allergies, sticking to fragrance-free and mild cleansers helps limit flare-ups, and a little moisturizer goes a long way to keep skin’s barrier strong.

Regulators in the U.S. and Europe continue to watch the science around dodecylbis(2-hydroxyethyl)methylammonium chloride. As with many chemical ingredients, moderation and careful use tend to keep most people out of trouble. For someone who cleans a lot or deals with allergies, it makes sense to check labels and look for more skin-friendly options. Skin holds up best when we stay curious and keep learning about what slides under the surface.

Understanding the Right Storage Habits

Storing chemicals isn’t just about keeping bottles on a shelf. Every substance brings a unique risk, and dodecylbis(2-hydroxyethyl)methylammonium chloride is no different. This compound, often used in personal care products and surface cleaners, has both benefits and hazards depending on how you handle it. Over the years working in a research lab, I've seen more issues come from rushed storage choices than from lab bench mistakes. Getting storage right means fewer headaches and far greater safety.

Temperature and Environment: Keeping It Stable

This chemical does best at room temperature—cool, constant conditions protect its integrity. Heat messes up stability and can turn even safe compounds into a problem. I keep similar surfactant-based materials away from direct sunlight and never near heat sources. Excess moisture in the air will clump powders or make liquids degrade, so dry conditions work best. Humidity sneaks into unsealed containers, leading to breakdown or even contamination. Consistent temperatures prevent surprises, like sudden crystallization or leaks, which I’ve seen wreak havoc in shared supply rooms.

Ventilation and Compatible Storage

Many forget about air quality where chemicals are kept. Good ventilation stops fumes from building up and makes life safer if a spill happens. In my own lab, opening windows isn't enough; investing in chemical storage cabinets with proper vents kept air clear and headaches rare. Storing dodecylbis(2-hydroxyethyl)methylammonium chloride apart from acids and oxidizers keeps them from reacting unexpectedly. Once, a colleague learned this lesson the hard way after a shelf mix-up—lost time, ruined product, and a call to the safety officer.

Choosing Proper Containers

Not all chemical containers do the same job. Polyethylene or glass usually handle most surfactants just fine, but some plastics react after long exposure. I always check containers for wear or cracks before reuse. Tight lids stop spills, and airtight seals block out humidity. This advice sounds simple, but skipping it cost suppliers entire batches of raw material, especially in humid summers with half-closed lids.

Labeling and Organization Prevent Trouble

Clear labeling helps at a glance, especially if containers look alike. Listing both the chemical name and concentration keeps things specific. If a bottle ends up in the wrong spot, the risk of confusion grows. More than once, proper organization saved me from costly mix-ups that could have halted a week’s worth of work. Shelves grouped by compatibility—not just alphabetically—make life smoother for anyone grabbing stock.

Preparing for Spills and Emergencies

Mistakes happen, no matter how careful anyone is. Good storage only matters if clean-up equipment waits nearby. My own bench always has absorbent materials and gloves close at hand. Spill kits aren’t something to keep hidden away—they belong right by the storage area. Training everyone to recognize hazards makes storage smart, not just safe.

Looking Ahead: Building Good Habits

Learning the quirks of each compound saves time, money, and health issues down the road. Dodecylbis(2-hydroxyethyl)methylammonium chloride deserves as much care in storage as in use. Ongoing review of storage conditions—and a willingness to toss old habits—keeps workspaces safer for everyone handling chemicals, from researchers to janitors. Consistent attention now prevents complicated problems later on.

Understanding the Compound

Dodecylbis(2-hydroxyethyl)methylammonium chloride is a mouthful to say, but the chemistry behind it tells a practical story. Sometimes it’s just called a quaternary ammonium compound, a group well known from both lab benches and real life. These compounds stand out in disinfectants, fabric softeners, and even hair conditioners. Knowing the exact formula goes a lot deeper than a test question; it connects lab work with everyday products.

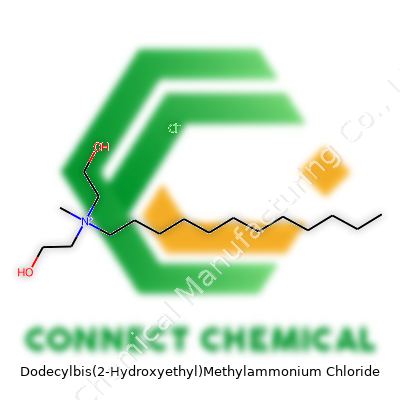

The Formula Itself

The chemical formula for Dodecylbis(2-hydroxyethyl)methylammonium chloride is C17H38ClNO2. In real life, that string of letters and numbers means something pretty familiar. The core of the molecule holds a nitrogen atom with four groups: a dodecyl chain (twelve carbons in a row, which gives detergents and surfactants their soapy powers), a methyl group (just one more carbon with three hydrogens), and two hydroxyethyl groups (each bringing a little more solubility, thanks to their alcoholic -OH tip).

Why Formulas Matter in Everyday Life

For those who’ve ever wondered why some detergents cut through grease better or why some cleaners irritate your skin less, the answer often hides in the formula. The arrangement of atoms and the length of the side chains in molecules like this one make some quaternary ammonium compounds gentle enough for personal care products, while others shoot straight into industrial cleaning supplies. Each tweak on the chemical formula changes how it works and how safe it stays with regular use.

Knowledge around these molecules doesn’t drift far from safe homes and workplaces. According to industry reviews, quaternary ammonium compounds form a critical part of hospital sanitation protocols. The Centers for Disease Control and Prevention (CDC) list these compounds as frontline agents against major healthcare-associated pathogens. Dodecylbis(2-hydroxyethyl)methylammonium chloride stands among these for its antibacterial action, thanks to the way the molecular structure breaks down microbial membranes.

Personal Experience and Real-World Impact

I’ve worked with cleaning supplies in food service, and learning how some products left surfaces squeaky and others left slippery residues taught me more than most chemistry classes. It all came down to structure. The dodecyl tail in this compound grabs at fats, while those hydroxyethyl groups keep things from drying out skin or leaving residue. Safety data sheets back up that the chloride counterion offers stability, but it’s the rest of the structure that builds the performance and reduces risks of harsh reactions.

Product manufacturers scrutinize this formula to balance cleaning strength and user safety. A longer alkyl chain can boost cleaning action but also increase irritation, according to comparative studies published in contact dermatitis journals. Regulatory bodies like the Environmental Protection Agency keep an eye on these molecule tweaks, reminding researchers and producers to keep improving both power and safety.

Better Choices Through Chemistry

With new regulations and consumer demands for skin-friendlier, greener cleaning agents, chemists dive into compounds like dodecylbis(2-hydroxyethyl)methylammonium chloride looking for workable improvements. Replacing traditional surfactants with safer, biodegradable ones sometimes leads right back to this formula as a compromise between cleaning, cost, and environmental impact. Exploring these compounds, rather than just erring toward newer fads or fear-driven trends, builds a stronger foundation for working homes and healthy public places.

What’s at Stake With This Surfactant?

Scan the ingredient list on most industrial cleaners, fabric softeners, or institutional disinfectants, and you’ll likely spot a cluster of chemical names that sound more at home in a research notebook than under your kitchen sink. Dodecylbis(2-hydroxyethyl)methylammonium chloride pops up often, mostly because it works well as a quaternary ammonium compound—often called a “quat”. Many get used for their strong germ-killing action as much as their ability to reduce surface tension. As someone who works with municipal wastewater teams, I’ve watched these compounds flow into treatment plants, and eventually out into the rivers and streams beyond.

Digging Into the Biodegradability Question

“Biodegradable” gets tossed around a lot, usually meaning a chemical doesn’t hang around in the environment, gets broken down, and doesn’t pose a risk for long. For dodecylbis(2-hydroxyethyl)methylammonium chloride, the story’s not that simple. Most quats, especially ones with longer hydrocarbon chains, stick around much longer than we’d like; they resist breakdown by bacteria and other natural decomposers. Research—including studies out of European water authorities—shows these compounds build up in aquatic environments. This particular compound’s dodecyl chain (twelve carbons long) slows microbial attack, and the presence of two hydroxyethyl groups doesn’t boost breakdown much.

Ask folks at a wastewater lab, and they’ll probably nod in agreement: standard treatment processes—biological breakdown in activated sludge, for example—don’t always knock out quats efficiently. Data from the International Journal of Environmental Research and Public Health suggests persistent residues even after secondary treatment. I’ve seen first-hand how concentrations do drop, but never to zero. That leaves some residue making its way into local ecosystems.

Why Persistent Surfactants Matter

Quats can disrupt sensitive organisms, especially those with membranes easily disturbed by detergent-like molecules. Water fleas and fish embryos react strongly to some quats. USGS water samples from around urban areas often reveal low but measurable levels. Toxicologists raise concerns about longer-term low-level exposure. I once spoke with a local river restoration group who struggled to bring back mayfly larvae and other indicator species—many of whom are sensitive to compounds like these. For people living downstream of urban areas, this becomes part of a bigger question about water safety and environmental health.

Better Outcomes: Policy and Consumer Shifts

Some countries, especially those in the EU, have moved to tighten limits. Registration, Evaluation, Authorisation and Restriction of Chemicals (REACH) assessments now flag difficult-to-breakdown surfactants for more scrutiny. Companies looking to keep up with stricter rules need to invest in finding alternatives with shorter chains and easier degradation. Making data from environmental monitoring public also helps watchdog groups and concerned citizens press for safer substitutes.

On the consumer side, looking for “readily biodegradable” on cleaning or personal care labels translates to less lingering chemistry in your local waterways. It makes a difference—household demand shapes what big suppliers keep on the shelf. My own experience swapping out harsher products after seeing what passed through our local water treatment plant shows small changes add up, especially when working across entire neighborhoods.

Aim for Safer Formulas, Clearer Labeling

Educating industry workers, janitors, and consumers about what happens after the suds go down the drain makes a real impact. Researchers and policy-makers need to keep pressure on companies to disclose biodegradability data for their ingredients. Pushing for transparent safety sheets and third-party testing stops greenwashing and helps users make smarter choices for their family and the environment. Every step toward less persistent chemistry counts.