Dodecyltributylphosphonium Bis((Trifluoromethyl)Sulfonyl)Imide: Exploring the Realities of an Ionic Liquid’s Place in Modern Chemistry

Historical Development

Decades ago, industries mostly stuck to a handful of trusted organic solvents. As environmental hazards from these older materials came into focus—think of all those chlorinated thinners in 1970s workshops—chemists started to look for alternatives. Ionic liquids arrived like new tools for the toolbox. Dodecyltributylphosphonium bis((trifluoromethyl)sulfonyl)imide, an ionic liquid with a tough-to-pronounce name and a reputation for stubborn stability, grew from this shift. It popped up in literature in the early 2000s as researchers dug for robust, non-flammable, and thermally stable liquids without corrosive volatility. I’ve watched the market for ionic liquids go from something only academics whispered about to something specialty suppliers now pitch to battery testers, eco-friendly engineers, and even the pulp and paper crowd.

Product Overview

Dodecyltributylphosphonium bis((trifluoromethyl)sulfonyl)imide stands out for its dual identity as both an organic cation and a bulky, fluorinated anion. This marriage grants it unusual characteristics—makeshift as both a solvent and an additive—something like the Swiss army knife of modern solvents. The cation, with its dodecyl group, behaves almost like a surfactant, helping solubilize long-chain molecules and greases, and its three butyl side-chains grant it extra oiliness. The paired anion, NTf2, shrugs off both water and reactivity. Products like this find use wherever stable solvents unlock chemical tricks: electrochemical setups, heat transfer, biomass processing, and as a part of antistatic coatings. It does not evaporate into the air at room temperature, cutting down workplace fumes—and that’s huge for anyone sick of solvent headaches.

Physical & Chemical Properties

It’s a clear, colorless to pale yellow liquid—dense enough to feel almost oily and heavier than most common organics. Water won’t easily mix with it. That hydrophobic behavior saves equipment from rust and corrosion, gives process engineers a break from endless maintenance cycles. Its melting point sits well below room temperature, which suits year-round use in most climates. Thermal stability reaches north of 300 degrees Celsius, so it can take some heat. Electrical conductivity sits in the range typical for ionic liquids: not quite metallic but enough to matter for electrical applications, especially in research labs playing with advanced batteries or capacitors. In the lab, I’d rather spill this on a benchtop than nearly any old-fashioned solvent—cleanup is straightforward and evaporation is glacially slow.

Technical Specifications & Labeling

Market suppliers give you this product in tightly-sealed, chemical-resistant bottles, both glass and high-density polyethylene. Labeling always emphasizes the structure, listing both the phosphonium cation and the NTf2 anion, and most reputable suppliers flag a purity over 97 percent. Moisture levels need to stay below 0.1 percent—most buyers will test for water content, because a dash too much can make all the difference in experimental work. The molecular formula comes in at C24H51F6NO4PSS2, with a molecular weight just shy of 660 grams per mole. The shelf life, kept at room temperature away from sunlight, runs several years with only minimal loss of quality or change in physical appearance.

Preparation Method

Most commercial suppliers follow a metathesis process. Start with dodecyltributylphosphonium chloride and then introduce lithium bis((trifluoromethyl)sulfonyl)imide. Mix both in water or a minimal organic solvent. After a short time, the target ionic liquid forms as the heavier, immiscible phase. Extraction follows with a non-polar solvent; careful washing strips away lithium chloride. In the lab, purification employs activated charcoal and vacuum drying, whittling down contamination with patience and precision. This DIY approach has its risks, so most labs buy ready-made material, trusting professionals to manage the safety and waste aspects.

Chemical Reactions & Modifications

Its core holds up under most conditions: acids, bases, heat, and light don’t break it easily. If you work with strong nucleophiles, watch for slow degradation, since the phosphonium group resists basic conditions less than an imidazolium counterpart. Chemical modifications usually target the dodecyl chain, introducing subtle changes in behavior—a hydroxyl or halide group can radically shift how the liquid interacts with solutes. Researchers often blend it with other ionic liquids or tweak the anion to optimize for solubility or conductivity, especially in battery research or green solvent design. Mix it in multi-phase systems, and you’ll notice how the compound shrugs off water and clings to oily phases, outperforming legacy solvents on separation and extraction.

Synonyms & Product Names

Many brands and catalogues use synonyms for this material, including dodecyltributylphosphonium bis(trifluoromethylsulfonyl)imide, [P44412][NTf2], and DTP NTf2. Sometimes entries shorten it to "phosphonium ionic liquid NTf2 type," or mention the CAS number for ordering accuracy. In the chemical supply world, it pays to double-check the structural notation and avoid confusing products with similar-sounding names, like shorter-chain phosphonium salts or imidazolium-based counterparts.

Safety & Operational Standards

Safe handling guidelines for dodecyltributylphosphonium NTf2 match those for many specialty laboratory solvents, but there are distinct positives. This compound rarely evaporates at room temperature and doesn’t form toxic vapor clouds in normal use. Even so, standard lab PPE—gloves, splash goggles, and fume hoods—remain non-negotiable, since some data hints at skin absorption and mild irritation. Proper labeling, tight container seals, and careful tracking prevent accidental misuse and help even novice technicians feel confident managing the chemical inventory. Disposal routes go through licensed chemical waste facilities, not the regular sink, since long-term environmental effects remain unclear.

Application Area

You’ll find this ionic liquid in unusual places: as a solvent for cellulose in biomass transformation, as a heat-transfer fluid in challenging conditions, in electrochemical devices as a medium for high-voltage electrolytes, and in polymer processing to engineer advanced materials. Coatings, lubricants, antistatic agents, and even fuel cells benefit from its set of properties. In my experience, research teams experimenting with new ionic conductors or membrane materials turn to this compound when traditional solvents start to shortchange them on safety, purity, or chemical durability.

Research & Development

Over the last decade, research output on phosphonium-based ionic liquids has grown. Scientists dig into their tunable chemistry: swap a side chain, adjust viscosity or hydrophobicity, or anchor functional groups right onto the cation. Ongoing work dives into using these liquids as extractants for rare metals, carbon capture, and recyclable reaction media, and the Green Chemistry movement keeps pushing for alternatives that slash both waste and hazard. I see growing momentum, especially in battery research, where safety and non-volatility drive interest. Academic journals keep turning out new applications and insights, fueling further investment and industrial partnerships.

Toxicity Research

Toxicity data hasn’t kept pace with the hype. Assessments so far suggest limited acute toxicity in mammals; skin and eye contact typically cause irritation rather than burns, assuming immediate washing. Chronic studies lag behind the technology, though—there’s an urgent need to track environmental breakdown products and their persistence. European regulations push for full risk disclosures, so responsible suppliers include detailed MSDS sheets and upfront guidance on exposure limits. Until more data lands, most labs keep these compounds out of undergraduate classrooms and limit open handling to experienced workers, preferring excess caution over regret.

Future Prospects

The next few years will set the tone for how dodecyltributylphosphonium bis((trifluoromethyl)sulfonyl)imide gets used. Battery manufacturers want to solve safety and cycle-life headaches with more robust electrolytes that won’t catch fire and lose performance after a few months. Environmental chemists look for kinder solvents to replace legacy options in recycling, materials processing, and biomass refineries. Product cost remains a challenge: large-scale adoption depends on sustainable, lower-impact production routes and reliable recycling protocols. Researchers pitching “green” chemistry will need to validate environmental safety as part of the product pitch—green isn’t just a color, it’s the end result of responsible development. If the research community and industry balance enthusiasm with rigor, this ionic liquid and its relatives can solve problems where older chemicals come up short, without simply trading one set of hazards for another.

Key Uses in Modern Chemistry

Dodecyltributylphosphonium bis((trifluoromethyl)sulfonyl)imide, a long-winded name, stands out for its work as an ionic liquid. Labs put it to use in tough situations where regular solvents throw up their hands. Chemists value its thermal stability and resistance to breaking down, and these traits push it into center stage across research and manufacturing.

Electrochemistry: Batteries and Beyond

Folks working on new batteries keep turning to this compound, especially in applications demanding both high voltage and safety. The material’s ionic nature—its ability to conduct charge without being flammable like organic solvents—makes it a contender in lithium-ion and next-gen battery designs. The rise of electric vehicles and grid storage pushes materials like this straight into the limelight, since fires and short circuits in batteries spell disaster.

The salt doesn’t stop at batteries. Electroplating, where one coats metal surfaces using an electric current, also benefits. The compound’s stability lets engineers run reactions at higher temperatures and get better control over the film they deposit. This shows up in the aerospace and medical sectors, where reliable, consistent coatings can mean longer-lasting parts.

Catalysis and Green Chemistry

Green chemistry goals—cutting out hazardous solvents and waste—gain ground thanks to these kinds of ionic liquids. They help chemists run reactions that would normally demand harsh acids, toxic organics, or even heavy metals. With this compound, reactions often proceed at room temperature, saving energy and slashing emissions. This isn’t just hype; companies already scale up reactions using this and related salts, reducing their environmental footprint.

Separation Processes and Solvent Roles

Anyone who's worked with complex liquid mixtures—think pharmaceuticals, fine chemicals, or even edible oils—knows separation can get tricky. Traditional solvents boil off, mix where they shouldn’t, and leave a mess behind. Ionic liquids like dodecyltributylphosphonium bis((trifluoromethyl)sulfonyl)imide cut through these issues, thanks to their low vapor pressure and targeted solubility. In lab tests and pilot plants, manufacturers pull out tiny traces of metals or purify products without the dangers or emissions tied to older techniques.

Room for Growth and Real-World Hurdles

This compound isn’t perfect. It costs more than older solvents, and recycling techniques haven’t matched the sophistication of traditional methods yet. Some worry about long-term toxicity, especially if hundreds of tons are used every year. That said, many teams are pinning hopes on better recycling and recovery tactics, along with green chemistry tweaks to lessen risk.

In my own work with process development, real progress came from small changes—recovering the ionic liquid behind the scenes, tweaking conditions to cut waste, and swapping out hazardous chemicals for safer ones. With each challenge, the material showed its flexibility, and small-scale wins opened doors for wider adoption.

What Could Help Next?

Researchers push for cheaper raw materials and smarter recycling—two missing links that hold back broader use. Policy makers looking for safer, greener industry might want to back efforts in this direction. Collaboration gets more traction than working in silos; open data and shared pilot projects speed up the cycle from lab to factory.

Dodecyltributylphosphonium bis((trifluoromethyl)sulfonyl)imide may not be a household name, but its fingerprint shows up in cleaner, safer, and smarter chemical processes that most industries will need as pressure mounts to deliver more with less impact.

Everyday Concerns in Chemical Handling

Standing in a lab, faced with a bottle marked “Dodecyltributylphosphonium Bis((Trifluoromethyl)Sulfonyl)Imide,” most folks feel a spark of curiosity mixed with concern. The name alone hints at a complex structure, brimming with fluorinated bits and hefty organic parts. My own time juggling chemicals like this taught me that even if something isn’t blowing smoke, its risks can hide behind the label.

What Makes This Chemical Stand Out

At first glance, this one falls under the ionic liquid banner. These substances shift the game for research and industry with their low volatility, strength in dissolving tough customers, and flexibility for many experiments. Because it does not vaporize much at room temperature, the average person in the lab might feel secure just pulling the cap. That’s where comfort trips up reality.

Hidden Risks Lurk in the Details

Experience has taught me that low vapor pressure can lead to overlooked hazards. With Dodecyltributylphosphonium Bis((Trifluoromethyl)Sulfonyl)Imide, the main issues come from the trifluoromethylsulfonyl groups and the phosphonium base—neither belongs in the body or environment. Reports say these compounds irritate skin and eyes, and ingestion or inhalation could harm internal organs. Chronic exposure hasn’t been studied deeply, but long-chain phosphonium salts can break down into persistent pollutants. More than a handful of studies point to fluorinated segments as tough customers, sticking around in water and soil for ages.

What Responsible Handling Looks Like

Safe handling of this chemical means calling on every tool in the book. Proper gloves—nitrile or neoprene—block absorption through the skin better than latex. Safety goggles are a must for every experiment. Work in a fume hood makes inhalation nearly impossible. Even though spill risks feel small, chemical-resistant lab coats and closed-toed shoes keep splashes away from clothes and skin.

Every lab should have a clear spill response plan: absorb with inert material, collect in marked waste containers, and never let it hit a drain. Protective equipment is more than a checklist—it keeps accidents from becoming emergencies. No eating or drinking nearby, regular hand washing, and storage away from heat and incompatible chemicals build sensible routines.

What Science Tells Us—and What’s Still Missing

Reading studies and talking with safety officers, it’s easy to see that the knowledge base for this chemical is thin compared to old stalwarts like acetone or toluene. That gap means every user bears extra responsibility. Creating and following up-to-date safety data sheets, demanding supplier transparency, and seeking out more long-term environmental research all build trust in those handling the substance.

Learning from Real Labs

Colleagues often trade stories of close calls: gloves dissolved by aggressive solvents, eye flushes after accidents. Good habits became second nature, not because the rules told us but because someone saw an accident change a promising day. Safety training makes a difference. In one memorable case, fume hood alarms saved a team from exposure after a dropped flask. If one lesson stands out, it’s that no chemical becomes “safe” by reputation alone. Each compound demands vigilance and respect, especially when the data remains slim.

Moving Toward Safer Labs

Staying safe with Dodecyltributylphosphonium Bis((Trifluoromethyl)Sulfonyl)Imide means more than basic rules. Sharing experiences, updating safety protocols often, and pressing for more research protect the lab community and the world outside. With eyes open, gloves on, and a healthy dose of skepticism, researchers keep progress steady and mistakes rare.

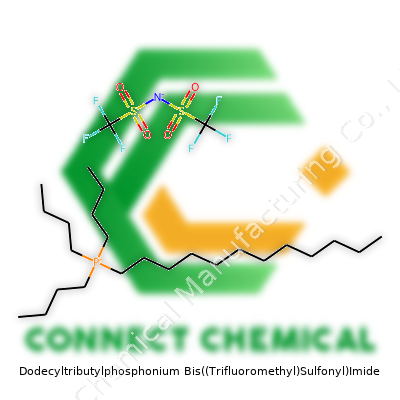

Chemical Structure at a Glance

Dodecyltributylphosphonium bis((trifluoromethyl)sulfonyl)imide, usually called a phosphonium-based ionic liquid, stands out for its unique molecular features. Its structure involves a phosphonium ion perched at the center, anchored to a long dodecyl chain and three butyl groups. The molecular formula for the cation piece is C24H54P+. The balancing act comes from the anion—bis((trifluoromethyl)sulfonyl)imide, often denoted as [NTf2]−. For one complete unit, the entire molecule weighs in at C26H54F6NO4P S2, wrapping everything into a neat package.

This might sound like a mouthful, but let’s break it down. The dodecyl group, with its twelve carbon stretch, attaches itself to the phosphorus atom, giving the molecule some real heft. The three butyl arms add bulk and help with solubility in organic media. On the flip—this is not some ordinary salt you find on the kitchen counter. The [NTf2]− counterion, with its nitrogen surrounded by two sulfonyl groups and decked out in fluorines, delivers the thermal and electrochemical stability that labs and industries crave.

Why This Structure Matters

Working in labs for more than a decade, I’ve seen many chemical cocktails come and go. Only a handful pack the versatility and resilience of these phosphonium-based ionic liquids. The key difference is the molecular design. Unlike common salts, the big, bulky ions slow down the rigid crystal lattice and let the material flow like oil rather than forming brittle solids. The phosphorus center fosters a wide “ion cloud,” while the dodecyl tail’s flexibility cranks up the liquid range. Pour this over electrodes, catalysts, or even stubborn organic solutes—its fluid nature lets it soak in and do its magic.

Engineers and chemists often tap into this structure when working on batteries, fuel cells, and extractions. This isn’t just textbook stuff. I’ve run extraction experiments where traditional solvents fizzled out on hard-to-separate metal salts, yet this compound pulled through. The [NTf2]− anion brings chemical stability, with its C-F bonds resisting breakdown even under high heat or electrical stress. All these features trace straight back to the way the atoms line up and bond with one another.

Challenges and Opportunities

A snarl of carbon, phosphorus, fluorine, and sulfur in a bottle can’t be ignored. Environmental concerns swirl, especially because fluorinated anions are tough customers in water treatment. Regulations tighten year by year, raising the bar for disposal and application. It’s time to start thinking about better ways to design these ionic liquids or to reclaim and recycle them after use. Lately, I’ve seen a shift toward swapping out the more persistent components or integrating cleanup systems into the manufacturing chain.

On the bright side, the chemical backbone can be tweaked. By swapping the alkyl chains or choosing different anions, researchers keep stretching possibility. Some teams look into more biodegradable or less toxic cousins of the existing structures. The future seems open for safer, greener phosphonium compounds that keep the advantages but reduce the blowback to the environment.

In the Real World

Molecular formulae and line drawings only take you so far. Once you see what this stuff can do in a glovebox or at an industrial scale, you start to appreciate the power of chemical design. When I teach young chemists or train new hires, I stress how structure drives behavior and shapes the options on the table. Understanding details like those behind dodecyltributylphosphonium bis((trifluoromethyl)sulfonyl)imide helps us predict, innovate, and steer research in smarter directions.

Why Storage Matters for Advanced Chemicals

Anyone who’s handled ionic liquids like Dodecyltributylphosphonium Bis((Trifluoromethyl)Sulfonyl)Imide knows that proper storage isn’t just a textbook detail—it can make or break a research project or industrial process. I remember the first time I worked with unfamiliar phosphonium salts in a university lab. A colleague left a container unsealed, and we found degraded material three weeks later. Opportunity lost, lesson learned. Sensible storage stops waste, protects purity, and keeps projects moving.

Moisture: The Silent Enemy

Moisture turns many stable-looking chemicals into a nightmare. This ionic liquid draws water from the air like a magnet. Not only does that ruin its physical properties, it impacts conductivity and viscosity—two things many chemists count on for work in batteries, catalysis, or solvents. I once measured conductivity shifts from exposing a similar compound for a single afternoon; the difference was astounding. Desiccators, those simple glass or plastic sealed chambers, filled with silica gel or other drying agents, solve most of these problems. Regular checks make sure no-one’s left the lid off.

Light and Temperature Aren’t Afterthoughts

Heat and light sneak up on chemicals over months. Fluorinated ionic liquids tend to be more robust, but warmth kickstarts subtle decomposition, especially if the bottle sits near a sunny window or above a warm piece of lab equipment. My old supervisor taught me to stash sensitive bottles on the bottom shelf, far from heat sources, and never in direct sunlight.

Room temperature storage works if the lab stays cool—think 15–25°C—but hotter rooms push degradation forward. Refrigeration has pros and cons; it slows chemical reactions but can introduce water if you’re not careful with condensation. Low light and stable, cool temperatures reduce the risk of cloudy, yellowed samples that signal trouble.

Contamination Issues

Forget to use dedicated scoops or pipettes and cross-contamination creeps in silently. I saw this firsthand: mixed samples turned up, coloring reactions and blowing up analytical results. Fresh, clean utensils keep batches pure. Labeling bottles with the date opened and lot number makes tracking any changes much easier down the line.

Don’t overlook proper sealing, either. Stoppers and screw caps should fit tight, and if you hear a click or see a color change strip, trust your eyes and nose. Some companies have started using tamper-evident closures, making it easy to spot mishaps early.

Looking Forward: Smarter Storage Tools

Automation and monitoring in chemical storage are catching on. I’ve seen labs trial sensor systems that check humidity and temperature continuously, sending alerts if conditions drift out of range. For organizations handling big volumes of ionic liquids, these investments prevent much bigger losses. For smaller labs, daily checks and careful habits give about the same payoff.

Wrapping Up Practical Steps

Handle Dodecyltributylphosphonium Bis((Trifluoromethyl)Sulfonyl)Imide with the respect it deserves. Keep it dry, cool, protected from light, and free of accidental additions. Small steps guard product performance and cut down on surprise costs in reorders or failed experiments. This hands-on approach costs less in the end and delivers more reliable outcomes—something every researcher or technician appreciates.

Understanding Purity

Lab-grade chemicals like Dodecyltributylphosphonium Bis((Trifluoromethyl)Sulfonyl)Imide won’t make headlines, but for chemists and engineers, purity tells almost the whole story. In the field, I've handled plenty of ionic liquids and specialty salts, many used in electrochemistry or specialty syntheses. At this level, there’s a clear demand for high-quality material: anything less than 97% risks muddying downstream data or even ruining long-term testing where a contaminant could disguise the real effects or reactions. From my experience, purities offered by top suppliers tend to float between 97% and 99%, sometimes advertised as “high-purity” when they top 99%.

Small shifts in purity—just one or two percentage points—can separate passable from research-grade. Analytical labs and universities won’t settle for less; trace water content, organic impurities, or aging degradation products can seriously skew results. Quality control certificates do plenty of heavy lifting, but routine checks still have to back up what suppliers print on a label. Any lab with a stake in intellectual property knows the sting of uncovering an impurity after investing hours of precious research time.

Packing for the Real World

Experimental work takes plenty of planning, and that means packaging flexibility carries real weight. University researchers need a small bottle—not an industrial drum—since a typical protocol calls for milligrams, not kilograms. Most vendors I’ve encountered offer sample sizes starting at 5 grams or 10 grams. For bigger projects or pilot plants, packaging jumps straight past 25 grams and heads up to 100 grams, 250 grams, or even a full kilogram.

Even if research doesn’t end up scaling, having a kilo stash can offer some security for repeat experiments. Shipping costs and shelf life always demand attention. An open bottle sitting on the shelf too long can attract moisture or dust; secondary packaging and anti-static pouches keep the quality stable. In one of my own labs, we learned fast that resealable, amber-glass containers work best, especially for anything with ionic or sensitive functional groups. Once, we ordered a cheaper sample that shipped in a polyethylene liner, and within weeks the edge of the powder looked clumpy, basically unfit for the real project we had in mind.

Why It Matters

Ionic liquids and similar materials can cost hundreds—or thousands—of dollars for a small bottle, so nobody takes the decision lightly. Researchers picking between 98% and 99% pure samples often do so because there's no room for error. A single impurity can scramble a measurement or trigger regulatory headaches if scaling toward a commercial process. Care in packaging and storage means an experiment runs the way it was designed, without surprises halfway through.

Supply chain disruptions and storage concerns remind me that local regulations and customs checks can surprise buyers, so planning a purchase schedule matters. Working with established suppliers, ones who offer transparent documentation and reasonable lot sizes, minimizes risk. My tip: always ask for the latest batch analysis, even if you trust the brand. After all, even with a compound as niche as Dodecyltributylphosphonium Bis((Trifluoromethyl)Sulfonyl)Imide, real-world research doesn’t happen in the abstract—it happens with every single gram ordered, unpacked, and measured.