Dodecyltrimethylammonium Bromide: A Closer Look

Historical Development

Researchers first prepared dodecyltrimethylammonium bromide in the early 20th century as part of the larger surge in surfactant chemistry. Chemists, looking for effective ways to modify surface tension in water and stabilize emulsions, began exploring quaternary ammonium compounds. Over decades, industries noticed the reliability of this particular surfactant. The product gained traction across laboratories and manufacturing floors because chemists could harness its cleaning power, explore its biological effects, and fine-tune formulations for specialty applications. This gradual adaptation reflects a larger story about surfactants shaping both industrial routines and consumer landscapes.

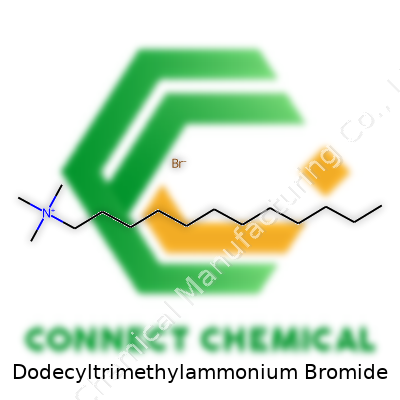

Product Overview

Dodecyltrimethylammonium bromide, often known by its shorthand DTAB, belongs to the family of quaternary ammonium salts. The structure brings together a hydrophobic dodecyl (C12) chain and a hydrophilic quaternary ammonium head, finished with a bromide ion. This balance between water-loving and oil-loving parts opens a wide range of practical uses, from detergents to experimental chemistry. Chemists, engineers, and formulators use DTAB because it steps cleanly into roles in cleaning, foaming, and even as a phase transfer agent where reactions demand a charged surface.

Physical & Chemical Properties

DTAB presents as a white, crystalline powder with a faint, soapy odor and a melting point around 250°C. This product stays stable under normal storage conditions, but it will decompose at higher temperatures. Solubility in water is high and forms a clear, viscous solution, a clue to its promise in surfactant applications. The compound boasts a molecular formula of C15H34BrN, a molar mass sitting at 308.35 g/mol, and ionic nature that spans both the laboratory and the washroom. It persists in the environment, linking chemical stability to real-world responsibility.

Technical Specifications & Labeling

Sourcing DTAB in pure form usually guarantees 98-99% minimum assay according to standardized chemical and pharmaceutical grade specifications. Reliable suppliers deliver comprehensive certificates of analysis verifying batch consistency, pH range, microbial content, and trace impurity limits. Material labeling always includes the product name, CAS number (CAS 1119-94-4), hazard statements, country of origin, and storage recommendations. Good labeling eliminates confusion and aligns with regulations found in the European Union and United States, helping to keep workflows safe and transparent.

Preparation Method

Most commercial production taps into a direct alkylation approach. Manufacturers combine trimethylamine with 1-bromododecane under controlled conditions, usually with excess bromide to ensure the reaction runs smoothly to completion. Synthesis ends in a careful crystallization, filtration, and drying process to produce a pure, stable result. This method remains attractive due to its simplicity, reliability, and yield, while alternative approaches using different leaving groups or solvents do exist, though few offer substantial advantages for large-scale output.

Chemical Reactions & Modifications

Chemists treat DTAB as a platform for modifications that unlock fresh applications. Alkyl group changes tune hydrophobic behavior, while swapping the bromide ion impacts solubility and biological effects. Some researchers substitute aromatic or longer alkyl chains to tailor surface activity for unusual detergency or to stabilize nanoparticles. Chemical laboratories explore these tweaks to push boundaries in analytical separations, controlled drug release, and molecular self-assembly, showing the reach of this simple molecule extends far beyond textbook detergency.

Synonyms & Product Names

DTAB turns up under multiple names in scientific catalogs and patents. Dodecyltrimethylammonium bromide, Lauryltrimethylammonium bromide, and N,N,N-Trimethyldodecan-1-aminium bromide all reflect its chemistry. Laboratories see synonyms like DTMAB, C12TAB, or for some suppliers, ‘Ammonyx 12.’ Recognizing these variants protects against confusion in purchasing, labeling, and literature review, especially where safety or process substitution depends on getting the right surfactant the first time.

Safety & Operational Standards

Handling DTAB calls for observing strict safety standards because this quaternary ammonium compound can irritate skin, eyes, and mucous membranes. Personnel wearing gloves, goggles, and lab coats reduce exposure risks. Spills don’t spark flames easily, though the fine powder asks for dust control measures and good ventilation to limit inhalation or accidental ingestion. Up-to-date Safety Data Sheets guide emergency actions and long-term storage. Many companies train their teams to spot subtle symptoms of overexposure, especially if large-scale usage or concentrated forms become routine.

Application Area

DTAB threads into daily life more than most people notice. In cosmetics and personal care products, it brings conditioning and cleansing muscle to shampoos and liquid soaps. Water treatment plants exploit its antimicrobial power to control biofilms in pipes and cooling towers. Laboratories choose DTAB as a cationic surfactant to mediate separations, boost reactivity in biphasic systems, or support electrophoretic analyses. Textile industries depend on it for dyeing and finishing, while pharmaceutical developers investigate its ability to encapsulate, solubilize, and release active compounds reliably. The range reflects the multipurpose heart of this molecule, ensuring it serves both science and commerce in ways that touch healthcare, hygiene, and research.

Research & Development

Ongoing research into DTAB uncovers new potential in biotechnology, nanomaterials, and drug delivery. Scientists use DTAB to construct micelles and vesicles that carry pharmaceuticals across biological barriers. Higher education labs deploy custom DTAB analogs to explore bacterial resistance or manipulate cell membranes. Environmental scientists analyze its fate after use, developing greener synthesis routes or biodegradable substitutes. Every breakthrough depends on collaborations among chemists, toxicologists, engineers, and policymakers who trade insights and pool data to refine old methods and shape safer, more effective new uses.

Toxicity Research

Knowledge about DTAB’s toxicity comes from both animal studies and long-term workplace monitoring. Concentrated solutions demonstrate eye and skin irritation in animal models, though toxicity lessens at the dilute levels typical for most cleaning and personal care products. Environmental testing flags concerns about persistence and aquatic toxicity. In wastewater, DTAB resists biodegradation and harms algae, crustaceans, and fish. Factories now look for closed-loop processes, safer disposal strategies, and the adoption of variants that break down faster after use, all backed by robust regulatory oversight and transparent toxicological review.

Future Prospects

Looking ahead, DTAB stands at a crossroads shaped by sustainability demands and the rise of green chemistry. Fresh research pushes to swap out persistent ingredients with eco-friendlier versions. Some teams pursue bio-derived feedstocks or add groups that assist natural breakdown after use. Analytical methods evolve to track residues at lower and lower concentrations, giving authorities and consumers more information than ever before. Demand for safer, lower-impact surfactants won’t slow down, and DTAB’s enduring popularity means it stays in the conversation, driving innovation at bench and plant alike.

Everyday Chemistry at Work

Shampoo lathers a certain way. A clean stainless steel surface shines after scrubbing. Electronic parts don’t just leap off the circuit board, free of dust and grime—they get processed. Dodecyltrimethylammonium bromide, known often by the shorthand DTAB, plays a role in all of this. It’s not a household name, but you’d be surprised at how often everyday moments trace back to chemicals like this one.

How Does DTAB Show Up in Real Life?

DTAB belongs to a family called quaternary ammonium compounds. People who work in labs or production sites run into it a lot because it’s easy to dissolve in water and likes to settle between oil and water, a classic behavior among surfactants. Surfactants make emulsions—think about mixing oil and vinegar for a salad and wishing they’d stay together instead of separating.

One of the big uses for DTAB comes in cleaning products and sanitizers. Hospital staff trust these solutions for keeping bacteria in check on hard surfaces. You’ll find traces of this compound in certain antiseptics and disinfectants, especially those used to scrub instruments that can’t handle heat. Hospitals rely on that quick kill of bacteria, viruses, and fungi, so the choice of DTAB over milder soap matters a lot.

Why Do Scientists Care?

Take a look at a scientific lab, and you’ll spot bottles of DTAB on shelves. Its chemical structure helps it break the surface tension of liquids, an important feature for researchers running experiments on how substances mix. In my grad school days, we used it to study vesicle formation, which teaches us about the way cell membranes work. Mixing DTAB into an experiment sometimes frustrated me, since too much can ruin an emulsion, but the right amount can really show you new things about the way molecules behave.

Analytical chemists often lean on the properties of DTAB to help separate out complex mixtures. Dropping a tiny bit into a solution helps break apart tiny oils or fats, which lets machines analyze what's inside a sample more accurately. Detergent makers and food scientists sometimes use it for that same reason—to get at what they’re looking for, fast and clean.

Environmental and Health Questions

It’s easy to forget about the clean-up after relying on a chemical like this. DTAB, like many strong cleaners, poses risks if rinsed down the drain without care. Water treatment facilities have the hard job of removing substances that can harm fish or disrupt plant life in streams. There’s a need for better wastewater treatment protocols wherever strong quaternary ammonium compounds are heavily used.

DTAB works well at killing bacteria, but it isn’t selective. Overuse can push germs to develop resistance. Hospitals already face strains of bacteria that brush off routine cleanings. Instead of relying only on stronger chemicals, facility managers can rotate among disinfectant styles, break up cleaning schedules, and pay close attention to residue build-up in pipes or on surfaces.

Finding Better Balance

DTAB gives us moments of convenience—from gleaming lab glassware to the simple peace of mind after wiping down a countertop. Its usefulness runs deep, but the more we depend on it, the more careful we must be. Training users, exploring natural alternatives, and developing tighter controls on rinse-off can each play a part in making sure we enjoy the benefits without turning a blind eye to long-term consequences. Watching how we use and dispose of these chemicals lets the rest of our support systems—like water treatment workers and healthcare staff—do their jobs a little safer and more effectively.

A Closer Look at a Common Surfactant

Dodecyltrimethylammonium bromide pops up in plenty of labs, cleaning agents, and even personal care products. The name might sound intimidating, but this chemical — usually called DTAB — works as a surfactant. In plain terms, it helps mix oil and water, making it handy for all sorts of industrial and research tasks. But once you dig into its safety record, things get complicated.

What the Data Says About Safety

Science has a clear record on DTAB’s effects. Animal studies show it can irritate skin and eyes. Anyone who’s worked with pure quaternary ammonium compounds can tell you that direct contact doesn’t go unnoticed. Even low exposure can sting. High concentrations can burn, so gloves and goggles aren’t optional. Inhaling DTAB dust, especially during spills or manufacturing, has been linked to respiratory irritation. Shortness of breath and coughing follow quick.

These facts line up with what’s published in the National Institutes of Health and European Chemicals Agency databases. DTAB scores a Hazard Statement for both skin and serious eye damage. My own time in a university chemistry lab taught me to respect this stuff. One accidental splash in a fume hood left a red patch on a colleague’s arm that took days to fade.

Toxicity and Environmental Impact

Toxic doesn’t always mean deadly in trace amounts, but DTAB brings enough risk to draw heavy regulation. Swallowing it in large amounts can damage the gastrointestinal tract, with symptoms like nausea and vomiting. That’s why labels on lab bottles put ingestion warnings in bold type. Those working in factories that manufacture surfactants use local exhaust ventilation systems to control airborne levels.

There’s also a wider impact. Surfactants run off into streams after use, and DTAB can harm aquatic life at surprisingly low concentrations. Some freshwater fish and invertebrates show toxic effects after only brief exposure. Water treatment plants partially remove these compounds, but traces can persist. As urban areas expand, the stress on local waterways grows. This reminds me of a summer job at a small-town wastewater facility, where we watched algae blooms spike after chemical-heavy storms.

How to Lower the Hazards

People keeping up with lab safety know that hazard protection requires more than just reading a label. Physical barriers like gloves and goggles are a start. Well-ventilated workspaces reduce the chance of inhaling powder or mist. Anyone handling DTAB gets trained to store it sealed and dry. The old habit of keeping “extra” chemicals in unmarked bottles still causes problems, so proper labeling and storage protect everyone.

Manufacturers can turn to safer alternatives for some uses, substituting less hazardous surfactants when possible. Regular training and clear guidelines boost safety. Prompt cleanup of spills and waste prevents secondary exposure and environmental contamination. Regulatory groups like OSHA and the EPA set exposure limits and require reporting—these rules exist for good reason. Strong science and clear communication between researchers, industry, and regulators keep big problems from sneaking up unseen.

Those who work with DTAB or products containing it carry a responsibility that goes beyond their own skin. Protecting health means constant attention to details, not relying on instincts or experience alone. The right habits keep risk low, and respect for the hazards keeps everyone safer.

The Simple Power Behind Dodecyltrimethylammonium Bromide

Take a look at Dodecyltrimethylammonium Bromide, often shortened to DTAB. You’ll find this molecule at the core of many cleaning products, shampoos, and even some lab experiments. With the formula C15H34BrN, the chemistry behind DTAB holds far more value than its tongue-twister name suggests. The molecule itself has a chain of twelve carbon atoms (a dodecyl group) linked to a nitrogen with three attached methyl groups—creating a positive charge at the nitrogen. Bromide tags along as the counter-ion. This arrangement forms a classic quaternary ammonium compound: a structure designed to lower surface tension and disrupt biological membranes, making it dependable in disinfection and cleaning.

Why Structure Makes All the Difference

Pulling apart the structure, the long hydrocarbon tail pushes DTAB to act a lot like regular soap. It grabs onto oil and grease, pulling them away from surfaces. The positive charge on the nitrogen, thanks to those three methyl groups, helps it stick to negatively charged spots, especially on cell membranes. This explains why DTAB shows antimicrobial strength—its physical shape delivers practical, targeted results. Chemists can sketch the structural formula like this: a twelve-carbon straight chain (CH3(CH2)11–N+(CH3)3 Br–), not fancy-looking, but tough in the workplace.

Personal Experience: Lab Disinfectant and Beyond

During lab work, I relied on DTAB as a standard germ-fighter. With its stable quaternary ammonium backbone, only modest concentrations quickly wiped out bacterial colonies on benches and glassware. Unlike alcohol or bleach, DTAB avoided strong odors and harsh fumes, so working with it felt easier over long stretches. Veterinary clinics, food-service sanitizers, and even dental offices turned to DTAB-rich solutions for the same reasons—it’s fast, reliable, and blends into water without fuss.

Concerns About Environmental Impact

Widespread use comes with its shadows. DTAB’s strong surface activity means it can harm aquatic life, especially once washed down drains with shampoo and cleaning runoff. Research links quaternary ammonium surfactants to toxic effects in fish and the breakdown of beneficial bacteria in treatment plants. Regulations already tiptoe around this issue—some countries limit certain ammonium surfactants for consumer use. It makes sense to pressure companies toward eco-friendlier formulas, and to back research into alternatives that deliver on hygiene without baggage for rivers and coastlines.

Building a Safer Chemistry Future

Cleaner chemistry means more than industrial compliance. My time working with both classic and “green” surfactants gives me confidence that careful molecular design can trim risks while keeping performance. Sometimes, swapping DTAB for plant-based surfactants, like certain glucosides, handles simple washes just as well, though not always as robust against tougher microbes. Expanding choices for both consumers and industries, increasing transparency about ingredients, and demanding evidence on environmental effects can tip the balance toward health and sustainability.

Summary Table: Key Facts

| Property | Detail |

|---|---|

| Molecular formula | C15H34BrN |

| Main structure | Dodecyl (12-carbon) tail, Trimethylammonium head, Bromide counter-ion |

| Key use | Surfactant, disinfectant, cleaning agent |

| Environmental issue | Toxicity to aquatic life, persistence in water systems |

A Closer Look at Chemical Safety

Dodecyltrimethylammonium bromide shows up in labs that focus on detergents, cosmetics, or protein extraction. The white powder offers a lot of utility, but it brings along some serious hazards. I spent a few years in university research, so I’ve seen how routine errors turn into emergencies. Pay attention to a chemical’s quirks—this one reacts strongly to moisture, and careless storage often ends up costing time and, sometimes, people’s health.

Sensible Storage: Keep It Dry, Keep It Tight

There’s no reason this powder should absorb water from the air, yet I’ve watched people barely tighten the bottle cap or leave desiccators open. Wet dodecyltrimethylammonium bromide can clump, degrade, or, in rare cases, release harmful vapors. Always seal containers after every use. Store these in a dry place, avoid direct sunlight, and keep the temperature steady—room temperature works for most labs, but humidity matters more than heat.

Good habits make the difference. Use a desiccator with fresh desiccant if you’re in a humid environment. Store it on a shelf away from sinks, windows, and heat vents. Don’t shove the bottle into a drawer or on a bench, where spills or breakage are likely and nobody will notice until a problem surfaces. Label everything clearly, noting both contents and hazards.

Handling: Don’t Skip the Basics

Gloves and a lab coat feel like overkill to some, but people underestimate skin sensitivity and inhalation risks. Contact with this compound can trigger irritation fast. I’ve seen colleagues break out in rashes, or worse, cough after accidental dust exposure. Many folks get casual about weighing powders and create dust clouds without realizing it. Take a slow, steady approach when opening and measuring. Work in a fume hood, especially for large batches.

Eye protection takes no effort and blocks the worst outcomes. Accidental splashes into eyes aren’t common with powders, but even a small gust of wind or shaky hands can change that. If you do get exposed, rinse thoroughly and report it. Don’t try to tough it out. The lab handbook exists for a reason, and following its steps protects everyone down the line.

Minimizing Accidents Before They Happen

Small tweaks make a real difference. Keep material safety data sheets close and read them—don’t assume last year’s training is enough. Train everyone in spill control, not just the manager or the “chemical safety guy.” In a spill, scoop up solids with disposable tools, bag them tightly, and clean surfaces with approved cleaners, not just water and paper towels.

Look for substation options when available, especially for large-scale processes. Research and industry facilities should use the smallest quantity needed for the task, which cuts risks and reduces waste disposal fees. If the workplace seems lax about storage or handling, bring it up early—chemical safety rewards proactivity, not silence.

Long-Term Thinking Saves More Than Products

People worry about their own exposure, but chemicals move through supply chains and waste streams, affecting workers, communities, and the environment. Choosing smart storage methods and practicing safe handling cuts down on loss and contamination. I’ve found that most accidents start with one shortcut or a forgotten rule. Stay alert, keep your space organized, and teach new folks what works. Simple steps protect people, property, and research results far beyond what any label warns.

A Common Name, an Uncommon Utility

Dodecyltrimethylammonium bromide, often called DTAB, crops up often in both research labs and big manufacturing sites. A lot of folks working in chemistry or materials science keep a bottle on their shelves. I remember the first time I measured out that slick, white powder, not realizing just how many ways it could change a process or experiment. The stuff acts like an all-purpose fixer in many operations, doing jobs that would otherwise take three or four different chemicals to accomplish.

Cleaning Up: The Surfactant Role

In many cleaning products, DTAB goes to work as a surfactant. It grabs on to oil and grease, pulling them away from surfaces. This makes it a popular choice for industrial detergents where stubborn grime can slow down production or even damage equipment. Textile factories often drop DTAB into their wash cycles to strip away unwanted residues. Hospitals lean on products with this compound to disinfect, because it busts up microbial cells, clearing out germs before they cause trouble.

Research Applications: Beyond the Obvious

University and commercial labs often choose DTAB when studying micelles and colloids. Micelles act like tiny delivery trucks, packing up molecules and ferrying them through water-based solutions. I’ve seen biochemists use it to keep enzymes or proteins stable during experiments. The structure of DTAB helps it slip into cell membranes, making it useful for extracting proteins without shattering everything in the process. That unique property also makes it a favorite for DNA extraction, as the compound keeps delicate strands separated and clean.

Advancing Medicine and Healthcare

Pharma companies sometimes rely on DTAB in the process of making drugs, because it helps dissolve ingredients that usually hate water. In creams or ointments, it creates smooth blends by making oil-based and water-based parts work together. In my own experience, hospital cleaning crews trust products containing DTAB to wipe down equipment and floors, because evidence shows that it destroys a broad range of bacteria and some viruses. It doesn’t just clean; it slows the spread of infection.

Nanotech and Material Science

In the world of nanoparticles, controlling particle size and distribution makes or breaks a study or a prototype. DTAB influences the growth and shape of nanoparticles, changing their properties in ways that help manufacturers create new materials with unusual strengths or characteristics. Electronics companies find value in using the compound to process or coat tiny components during manufacturing, because it creates the right chemical environment for complex reactions to take place.

Safety and Sustainability Concerns

But every coin has two faces. DTAB doesn’t break down as easily as some older compounds. Factories need strict waste management protocols to keep it from reaching waterways, because it poses risks to aquatic life even in small doses. I’ve spoken to folks at facilities who are working on greener processes, such as recycling water or switching to biodegradable alternatives when possible. Strict storage and disposal policies help minimize exposure in the workplace, and safety training goes a long way toward preventing accidental spills or health risks.

The Way Forward

New research drives improvement. Scientists keep testing DTAB against newer, plant-based surfactants that work just as well without the environmental baggage. Regulations and consumer demand for sustainable products push industries to check their ingredient lists more carefully. For now, DTAB earns its place by solving problems across many sectors, but the push for less harmful substitutes continues, guided by real-world results and a growing respect for ecosystems outside the lab and factory walls.