Ethyl 10-Bromodecanoate: Comprehensive Commentary on Its Development, Properties, and Future

Historical Development

Chemists have looked for cleaner and more direct routes to alkyl bromides since the early days of synthetic organic chemistry. Ethyl 10-Bromodecanoate, an alkyl bromide ester, entered the scene as researchers explored fatty acid derivatives and their halogenation patterns. Back in the 1950s and 1960s, the growth of surfactant and specialty chemical markets in both Europe and the United States pushed the discovery and refinement of more reliable methods to prepare high-purity intermediates, including long-chain bromo-esters like this one. Laboratories shifted from hazardous bromine gas approaches to safer liquid-phase bromination with tailored catalysts and better solvent control. That wave of industrial expansion—matching safety concerns with efficiency—shaped most of the commercial-scale production steps still in use today, showing how problem-solving in the laboratory can set the course for decades of manufacturing.

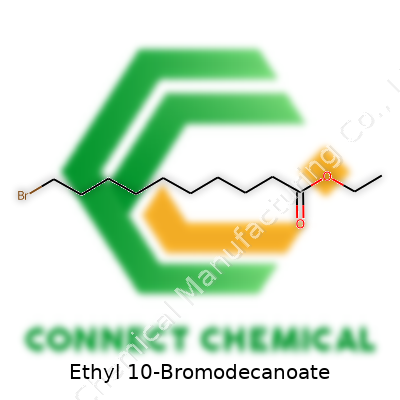

Product Overview

Ethyl 10-Bromodecanoate stands out as a specialty chemical, often used in synthesis rather than finding a direct place in household or consumer products. Its value comes from being a versatile building block in the chain of manufacturing, with its core decanoic acid backbone and reactive bromine atom. This structure lets chemists introduce substitutions, lengthen chains, or open up entire classes of transformations for pharmaceuticals, agrochemical intermediates, and even some fragrances. With a dedicated niche in organic synthesis, this ester’s straightforward reactivity and manageable storage requirements make it a practical staple in industrial laboratories.

Physical & Chemical Properties

The chemical formula for Ethyl 10-Bromodecanoate is C12H23BrO2, which gives a molecular weight around 279.21 g/mol. It appears as a slightly viscous, clear to pale yellow liquid at room temperature, with a faint sweet odor—much milder than the sharp bite of lower-weight bromo-alkanes. Heating releases bromine-containing fumes, so keeping this chemical out of open flames and maintaining strong ventilation stays crucial. In terms of solubility, the ester mixes well with most organic solvents like dichloromethane and ethyl acetate, but it resists dissolving in water. Hydrophobicity stands out, which can be both an advantage in organic-layer extractions and a disadvantage during clean-up stages. The compound boils at 323°C, well above room temperature, limiting vapor loss but reminding us to use proper containment at scale.

Technical Specifications & Labeling

Industrial and laboratory suppliers list this compound by its chemical name, along with its CAS number (53540-13-9). Purity grades usually range from 96% up to greater than 99%, depending on whether a customer seeks reagent or industrial quality. Containers carry UN hazard labels indicating its eye and skin irritation risk, and its flammability is usually low compared to lighter brominated solvents. Labeling includes manufacturer, batch number, and expiration date, per regulatory requirements for tracking and traceability. Shelf life often extends beyond one year if stored away from light and moisture, in polymer or amber glass bottles with tight-sealed lids.

Preparation Method

Standard laboratory synthesis of Ethyl 10-Bromodecanoate often starts from decanoic acid, which gets converted to its ethyl ester through Fischer esterification. The next step involves bromination at the terminal carbon—a process that typically uses N-bromosuccinimide (NBS) under radical conditions, but may also employ phosphorus tribromide or bromine in the presence of light or a peroxide initiator. Reaction temperature control and slow addition of brominating agents keep side reactions and overbromination at bay. Workup includes aqueous washing, separation from unreacted starting materials, and drying over sodium sulfate, followed by fractional distillation to ensure high purity. From my work in synthetic labs, even minor contamination at this step can foul later reactions or gum up analytical tools, so small investments in extra purification pay off during downstream use.

Chemical Reactions & Modifications

The terminal bromine in Ethyl 10-Bromodecanoate drives its versatility. The compound serves as a launching point for nucleophilic substitutions, allowing attachment of azide, thiol, amine, cyano, or other functional groups. For pharmaceutical intermediates, this kind of platform lets chemists rapidly assemble libraries of related molecules. In polymer chemistry, it enables the construction of well-defined hydrophobic blocks by reacting with macromolecular nucleophiles. I’ve seen this used in the lab to graft segments into copolymer chains, making materials for drug delivery or surfactants with unique properties. The ester group resists many conditions used for bromine substitutions, so the backbone structure remains unchanged through most transformations, supporting efficient syntheses.

Synonyms & Product Names

Over the years, the compound acquired several names: Ethyl 10-Bromodecanoate, Decanoic acid, 10-bromo-, ethyl ester, and Ethyl 10-bromocaprate. Some catalogues even list it as “Bromodecanoic acid ethyl ester” or under its registry number. For import-export, customs paperwork, and regulatory controls, clear identification with a single CAS number remains important, and cross-referencing synonyms reduces shipping holdups and error risks. Anyone working in procurement or logistics knows the confusion a missed synonym can cause during audits, so keeping updated MSDS and harmonized product names always pays off.

Safety & Operational Standards

Handling Ethyl 10-Bromodecanoate requires standard protective measures—lab coats, gloves made from nitrile or neoprene, and tightly fitting goggles. Inhalation of vapors or mist should be avoided by working in fume hoods, a practice cemented during my years training junior staff after several close calls with similarly classified brominated compounds. The ester should never encounter strong bases or reactive metals, due to risk of violent reactions or decomposition. In case of contact with skin or eyes, flushing with copious amounts of water and seeking medical attention prevents longer-term irritation or burns. Waste handling goes to halogenated solvent waste streams—never down standard sinks or drains. Most facilities follow OSHA or equivalent national rules, with regular refresher training and documented SOPs for chemical spills.

Application Area

Pharmaceutical companies and agrochemical firms rely on Ethyl 10-Bromodecanoate as a linchpin in the multi-step synthesis of active molecules. Some fragrance developers value the length and reactivity of the ester, which can serve as a precursor for musk and macrocyclic lactones, giving lasting scent profiles in fine perfumes. The surface chemistry field uses related bromo-esters in specialty surfactants or as linkers on polymer backbones, developing new emulsifiers and dispersants for paints, coatings, and cosmetics. Academic research teams turn to the compound for structure-activity studies, appreciating how a single molecular tweak—swapping the bromine for another group—shapes function in everything from antiviral compounds to biodegradable plastics. I’ve seen it used in techniques like “click” chemistry and Steglich esterifications, where reliability and high yields save weeks of troubleshooting.

Research & Development

In academic and commercial labs, attention keeps shifting toward green chemistry. Researchers aim for bromination protocols with less waste and better atom economy, replacing classical halogen sources with safer, recyclable alternatives. Continuous-flow reactors have started to replace batch vessels, limiting exposure and making reactions both safer and more scalable. Analytical advances—like real-time NMR and improved GC-MS workflows—cut down purification headaches and help chemists tailor the product profile for emerging applications. Collaborations between chemical engineers and environmental scientists focus on reducing the environmental footprint for halogenated intermediates, including by-products and solvent recovery. Industry partnerships mean that today’s lab discoveries often become tomorrow’s safer, cheaper, and more sustainable process.

Toxicity Research

Concerns about the toxicity of organobromine compounds led to stepped-up study of Ethyl 10-Bromodecanoate’s breakdown paths and effects. Current data—mostly from in vitro and animal models—suggest moderate acute toxicity, with eye and skin irritation the most immediate risks. Long-term exposure does not yet show evidence of carcinogenicity, but caution persists, given analogs with more troubling profiles. Biodegradability is limited, which prompted further research into getting halogenated waste streams fully destructed instead of released untreated. Labs set airborne and surface contamination limits well below those that could trigger symptoms, while periodic updates to Safety Data Sheets keep risk communication accurate. Toxicokinetic research aims to clarify metabolic routes, with the hope of mapping how such compounds could be removed safely or broken down after use.

Future Prospects

The landscape for Ethyl 10-Bromodecanoate keeps shifting. Growing pressure from environmental and safety regulations has encouraged both end-users and manufacturers to prioritize greener bromination techniques and to explore new applications in biodegradable materials. As materials science pushes for smarter surfactants and specialty esters with better performance, this bromo-ester provides a reliable jumping-off point. I’ve watched sustainable synthesis projects gain traction—moving away from high-waste, energy-intensive methods and toward better atom-efficiency and recyclability. The field expects further demand for selective alkyl chain modifications in pharmaceuticals, biotech, and advanced polymer production, meaning that technical advances in making and handling such esters could have ripple effects across several sectors. The next wave will likely hinge on integrating digital process control, green chemistry, and rigorous safety, all while meeting the demands for purity and customization that end-users have come to expect.

Chemistry Beyond Textbooks

Ethyl 10-Bromodecanoate doesn’t spark conversations outside of labs, but it holds down a quiet spot in chemical synthesis. This compound, with a bromine atom stuck out on a ten-carbon chain and an ethyl ester for a tail, shows up most often as a building block. I’ve seen chemists reach for it because it gives access to a set of reactions tough to perform any other way. In personal experience, using a molecule like this means you want to move fast in the lab, developing new drugs or designing specialty materials, rather than struggling with dead-end synthetic routes.

Pharmaceuticals and New Molecules

Drug developers often need new ways to connect long carbon chains with small functional groups. Ethyl 10-Bromodecanoate offers a shortcut. Its bromine makes it really reactive for certain kinds of substitution reactions. If you’ve ever tried making analogs of fatty acids or working up a batch of intermediates for anti-inflammatory projects, you want something reliable and predictable as your base—this compound fits that bill. As of 2024, studies have shown that medium-chain bromoalkanoates, including this one, form a backbone for compounds that go on to fight infections, calm inflammation, or tweak the way different cells communicate.

Materials and More Than Medicine

Manufacturing new plastics and surfactants also brings Ethyl 10-Bromodecanoate into focus. The chain length, along with the bromine atom, lets the molecule plug into polymers or change the way surfaces behave in water. Growing up, I remember learning that small changes to a chain could mean the difference between a sticky mess and a solid rubber. That holds true with this compound. Today, researchers working on biodegradable plastics prefer to start with molecules that won’t hang around in the environment. Having an ester, like the ethyl group here, supports that push for cleaner chemistry. Real-world data shows that over the past decade, more projects opt for these types of building blocks to keep up with new regulations.

Safety and the Push for Better Practices

Handling bromine-based chemicals like Ethyl 10-Bromodecanoate takes respect. Brominated molecules sometimes raise red flags about toxicity. Lab safety data marks it as an irritant, and recent research shows it can break down to form more persistent substances. From direct experience, the best approach is clear labeling, reliable ventilation, and up-to-date safety training. Groups such as the European Chemicals Agency track the use and movement of these molecules as part of their REACH regulation, pushing everyone to look harder at safer alternatives.

Paths Forward

Scientists have begun searching for greener routes to make and use compounds with the features Ethyl 10-Bromodecanoate brings to the table. Some labs explore bio-based feedstocks instead of fossil-fuel inputs. Others look for ways to swap out the bromine for less hazardous atoms without losing the necessary chemical reactivity. In day-to-day research, the question keeps coming up: can the same job get done with less fuss and less impact? Keeping up with industry conversations and reading up on safety trends helps everyone move toward safer, more sustainable chemistry.

The journey of Ethyl 10-Bromodecanoate tells a story shared across chemistry—reactivity and usefulness up against safety and responsibility. Those old high school lessons about balancing equations turn out just as true for balancing progress with respect for health and the environment.

Ethyl 10-Bromodecanoate: More Than Just a Chemical Name

This chemical, Ethyl 10-Bromodecanoate, might not grab headlines, yet its structure underpins a lot of chemistry in labs and industry. Every time I walk through a research space and spot a label with a long name like this, I think back to my college years. Our instructor once said, “Understand the formula, and you know what it does.” With Ethyl 10-Bromodecanoate, the formula spells out much more than its tongue-twisting name.

Piecing Together the Formula

Let’s break it down. “Ethyl” flags the presence of a two-carbon chain (C2H5), stuck by an ester bond to a larger molecule. The “deca” points to a ten-carbon backbone. “Bromo” at position 10 tells you a bromine atom attaches to the tenth carbon. Esters come from combining an alcohol and a carboxylic acid—here, decanoic acid and ethanol.

The underlying formula: C12H23BrO2. Every atom counts for chemists. Add those carbons from the chain, toss in the oxygen from the ester group, slot in bromine at just the right spot—this is no cocktail recipe, but it’s just as precise. Get one atom wrong and you are looking at an entirely different compound, possibly with wildly different properties.

Why Molecular Structure Gets So Much Attention

The arrangement of atoms in Ethyl 10-Bromodecanoate tells us how it behaves. During my time helping out in a fragrance development lab, chemists used this kind of compound for its distinct chemical reactivity. Given the bromine hanging off the tail, this molecule acts as a building block in making surfactants and specialty esters—things everyone meets in detergents or lotions.

If a manufacturer overlooks something like the bromine position or the ethyl group, the product may not deliver. That’s why researchers insist on verifying molecular formulas with precision. Getting it right means avoiding costly mistakes that could impact product safety, environmental toxicity, or customer experience.

Room for Learning and Improvement

A common struggle in chemistry education involves translating a name to a structural formula. I’ve watched students get tripped up by what looks like a jumble of prefixes and suffixes. The reality is molecular formulas anchor chemical safety, storage, and application. A formula like C12H23BrO2 holds regulatory implications, especially with brominated organic compounds under tighter scrutiny for persistence in the environment.

Teachers and companies should stress hands-on experience with molecule model kits and open-access software. It’s too easy to see these long names as barriers, yet familiarity turns obstacles into tools. Better training means fewer downstream errors and stronger stewardship in production and waste handling.

Reliable Knowledge Empowers Safer Chemistry

People trust researchers and producers to nail the basic chemistry before introducing molecules into everyday products. That trust only holds if the formula gets checked—and double-checked—for correctness. In my own work, I’ve learned to confirm a substance’s makeup with reference standards and to pore over safety data sheets for each atom in a compound. The formula for Ethyl 10-Bromodecanoate matters well beyond the pages of a textbook.

Learning from Everyday Lab Life

You never ignore safety with chemicals like Ethyl 10-Bromodecanoate. Once, a colleague left a capped bottle of a similar compound by a sunny window. Next morning, the liquid inside looked cloudy, and a strong smell filled the room. Just a little heat and light made it start to break down. That detail matters, because good storage isn't extra work—it keeps people, the chemist’s results, and expensive materials safe.

Main Risks Come Down to Light, Heat, and Moisture

This ester contains a bromine atom in its structure, making it more sensitive than plain alkyl esters. Strong sunlight or high temperature pushes brominated compounds to degrade or react. So, think “cool, dark, and dry.” Many labs baby such chemicals, keeping them at room temperature or just below, away from direct light. Sticking it in a flammable cabinet away from hot pipes and windows works well, based on years spent in chemical stockrooms.

Air introduces risk too. Once you open the bottle, you let moisture and oxygen in. Both can trigger slow hydrolysis, turning the ester back into the acid and alcohol. A tightly closed screw cap or even a septum avoids that headache. Sometimes, chemicals like this have to be kept under nitrogen, especially if the container gets opened often. Temporary nitrogen purges keep out water vapor from humid air, which is a trick I’ve watched industrial chemists use with good results.

Use the Right Containers

Glass works better than plastic here. Bromine-based solvents can eat away at certain plastics over time, and that spells trouble for quality and safety. Clear glass looks appealing but isn’t the best choice. Amber or brown bottles absorb more light, reducing the risk of changes from sunlight creeping into a storeroom. Anyone who’s come back to a discolored sample knows it’s a pain to remake or re-order.

Label for Safety

Good labeling helps everyone who shares storage space. If the label peels or blurs, the risk doubles—now you might grab the wrong chemical or not know when it was opened. I’ve found that permanent marker plus a printed label lasts, but adding the date opened and one-line safety notes (like “avoid moisture”) makes life easier for everyone down the line.

Addressing Spills and Possible Leaks

Sometimes something drips or cracks. This isn’t just a mess—it can harm people and damage possessions. Keeping absorbent pads or a small spill kit nearby pays off. Ethyl 10-Bromodecanoate doesn’t attack skin quickly, but gloves and goggles stay within arm’s reach. If a leak ever happens, you want folks to sweep it up safely, not panic or put off cleanup.

What Helps in the Long Run

Strong storage leads to fewer surprises. Regular checks on containers and inventory save more chemicals than fixing mistakes later. If using a lot of this ester, separating bulk storage from daily-use bottles pays off. It lets you minimize exposure and catches some of those small accidents before they get big. It helps to have a culture in the lab where people actually tell someone if they see cracks, faded labels, or expired stock.

Looking at the Big Picture

Chemicals like Ethyl 10-Bromodecanoate play an important part in research and production, but careless habits around storage can undo careful work fast. Using the right containers, avoiding heat and light, and paying attention to labels raise the standard for safety and success in any lab.

The Chemical Behind the Name

Ethyl 10-Bromodecanoate lands in the spotlight most often in synthetic chemistry labs or specialty manufacturing. It’s an ester, pieced together from 10-bromodecanoic acid and ethanol. On the surface, such chemicals don’t appear in daily life for most folks, but people working in chemical plants, research institutions, or in the supply chain for flavors and fragrances might cross paths with them. That means there’s a responsibility to know what sort of risk this compound brings along.

Toxicity and Exposure Risks

Hazards mostly depend on how a person might come into contact with Ethyl 10-Bromodecanoate. Direct skin or eye contact can produce irritation. Inhaling its vapors (usually in a warm or poorly ventilated space) could leave a throat burning or spark headaches. From time in college chemistry classes, even the seemingly innocuous organic compounds could surprise people with unexpected reactions—this one is no exception. Chronic exposure hasn't been studied thoroughly in the public domain, but the presence of bromine in its structure draws plenty of caution from toxicologists. Organobromine compounds sometimes tie back to nervous system symptoms and long-term effects if used recklessly. Safe handling, gloves, and goggles aren’t optional here; they're a baseline.

Comparing to Familiar Hazards

Brominated chemicals sometimes get lumped in with familiar problem compounds like PBDEs, which regulators flagged years ago for environmental persistence and possible health links. Ethyl 10-Bromodecanoate hasn’t sparked that level of concern yet, but it’s easy to see why companies anticipate strict regulation. There haven't been high-profile poisoning cases or infamous disasters, but chemical users shouldn’t mistake silence for safety. The toxicity profile stays incomplete until more research fills in the gaps.

Proper Handling and Safety Controls

The Material Safety Data Sheet (MSDS) sets a clear tone: prevention outpaces treatment. Safe storage in a well-ventilated, cool area works as a basic first step. Splashing or inhaling calls for emergency eyewash stations and a ready shower. Accidental spills can’t just be wiped up—the right absorbents and prompt cleanup matter. Training goes a long way; most lab accidents stem not from the chemicals, but from human error or missing knowledge. In my own years working with specialty reagents, the right advice from a seasoned lab director changed many close calls into minor incidents. A sturdy respect for hazardous labels acts as your first shield.

Environmental Fate and Disposal

Once a hazardous chemical finds its way into wastewater or soil, the problem rarely stops at the fence. Brominated esters like Ethyl 10-Bromodecanoate have potential to break down into stubborn, mobile byproducts. Without the right disposal routines, one small mistake in a single drum could cascade into bigger headaches: regulatory fines or, worse, contaminated groundwater. Certified chemical waste handlers take these compounds, log each movement, and ensure incineration at approved facilities prevents long-term pollution. For anyone managing a small lab or chemical stockroom, it pays off to know your local and national hazardous waste laws by heart. Trusting those steps has kept my own colleagues out of plenty of regulatory trouble.

What Needs Work

There’s a missing puzzle piece: more public research. Industry secrecy and low commercial volume have kept Ethyl 10-Bromodecanoate off most academic radar. Universities and regulatory bodies should step in with independent studies to map out its environmental and human health impact. That information feeds into better labeling, smarter handling rules, and fewer nasty surprises at work or in the supply chain. Better communication between manufacturers and end-users also prevents mishandling. Open, honest hazard communication turns uncertain risks into manageable challenges for everyone along the line.

Why Purity Matters in Chemical Supply

Purity drives the real performance of specialty chemicals like Ethyl 10-Bromodecanoate in a laboratory or a production facility. Years ago, working on a project requiring sensitive organic syntheses, a colleague once told me, “Impurities have a way of showing up just when you least expect them.” That truth stays with anyone who has seen a perfectly planned reaction turn to chaos because the starting material wasn’t clean enough.

Common Specifications in the Market

Ethyl 10-Bromodecanoate is usually supplied at a high purity, typically above 97%. Laboratories and chemical companies target specifications of 98% or higher, and the remaining fraction tends to include related esters or trace inorganic salts. This isn’t just a marketing game. Even trace elements can change the yield or selectivity of key synthetic steps. When used in pharmaceutical research, a misstep can force entire batches to be discarded.

Water content also sits on the radar for buyers, especially in syntheses where esters can hydrolyze. Producers list Karl Fischer titration values below 0.5%. Heavier industrial buyers might request tighter controls if working under cGMP conditions. Solvent residue tends to creep in during manufacturing or storage. Most reputable suppliers provide gas chromatography data and keep total solvent levels below 0.2%.

Testing and Verification

Every scientist knows that lab reality doesn’t always match the supplied certificate of analysis. Relying on third-party labs or in-house NMR and GC-MS verification gives a truer picture. I often run thin-layer chromatography out of habit, especially with brominated esters, to catch by-products before they become a headache downstream. The most trusted suppliers share detailed spectral data, giving chemists confidence to proceed.

Low heavy metal content signals that modern manufacturing controls are in place. For most synthetic and pharmaceutical applications, heavy metals like lead, cadmium, and mercury must register below 10 ppm. This level aligns with international safety recommendations.

Applications Drive Specification Needs

A straightforward application, like using Ethyl 10-Bromodecanoate as an intermediate in the synthesis of surfactants, tolerates slightly lower purities. In contrast, for active pharmaceutical ingredients, the margin for error nearly disappears. Some teams build extra clean-up steps in their process, but this costs extra time and resources. In my consulting work, I see teams push for purer starting material to avoid unnecessary risk. Sourcing from a supplier with transparent documentation and batch-to-batch consistency keeps operations running smoother.

Transparency is Key for Trust

Reputation carries weight in the chemical supply chain. It’s tempting to chase bargains, but experience continually shows that consistent quality and responsive supplier communication save far more money in the long run. The best suppliers document their analytical methods, provide clear lot number records, share safety data, and respond quickly to technical questions or recall issues.

Looking for Solutions

Improving supply often means open communication from both sides. Buyers who explain the critical details of their applications receive better support in return. Suppliers who update specifications to meet customer feedback earn lasting loyalty. Developing long-term partnerships with respected manufacturers and building quality-control checks into production planning stands out as the surest way to safeguard both research progress and commercial outcomes.