Ethyl 3-Bromopropionate: A Deep Dive into a Key Intermediate

Historical Development

The progress in organic chemistry during the twentieth century pushed scientists toward seeking more versatile building blocks for pharmaceutical and material innovation. Ethyl 3-bromopropionate emerged as a favorite among early chemists for its knack at opening doors to complex molecular architectures. As organic synthesis grew, the demand for efficient alkylating and acylating agents put this compound in the lab spotlight. Back in the 1950s and 60s, textbooks started to mention this reagent for its simplicity and broad application, especially in drug and pesticide development. In my own research experience, the old synthesis routes relied heavily on direct bromination methods, often leading to inconsistent outputs. Years later, more controlled halogenation strategies brought this compound into industrial-level production lines, reflecting just how the needs of innovation shaped its path.

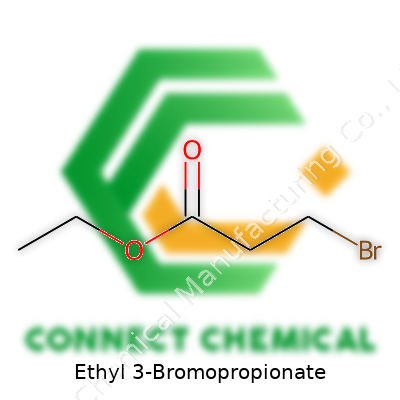

Product Overview

Ethyl 3-bromopropionate sits on the shelf as a clear, sometimes faintly yellow liquid, bottled tightly due to its volatility and sensitivity to moisture. As a haloalkyl ester, it fits neatly into the group of reagents prized for functional group manipulation. Research teams reach for it as a precursor for pharmaceuticals, agrochemicals, and specialty polymers. Its bromine atom and ester group together offer a dual handle for further reactions — a feature that sets it apart from simpler alkyl bromides or ethyl esters. I remember once using it to introduce a propionate chain into a candidate drug molecule. Compared with similar reagents, its manageable reactivity balanced by shelf stability makes it a staple — not an exotic or hard-to-source chemical.

Physical & Chemical Properties

Under standard laboratory conditions, ethyl 3-bromopropionate appears as a liquid with a pungent smell. Boiling point hovers near 180°C, and melting point doesn't enter the picture since it rarely freezes at room temperature. With a density around 1.42 g/cm³, it sinks in water and rarely blends into aqueous phases, though its solubility in ethanol, acetone, and other organic solvents is solid. Its chemical backbone features a reactive bromine atom three carbons from an ethyl ester, setting up a molecule that loves to act as an electrophile. That reactivity comes with caution; left exposed, the compound can hydrolyze, so keeping lids tight and bottles dry is non-negotiable. Exposure to strong bases or nucleophiles triggers fast substitution or elimination, which is both a useful tool and a hazard for careless chemists.

Technical Specifications & Labeling

On the commercial market, labels often read “Ethyl 3-bromopropionate (≥98% purity)” with clear hazard markings for harmful vapors and potential skin irritation. Lot numbers and production dates help track it both for inventory and regulatory compliance, supporting traceability — something regulatory agencies take seriously. The best suppliers publish full analytical details — NMR, GC, and sometimes IR — to guarantee the material’s identity. Regulations set by REACH in Europe and TSCA in the United States require that safety data sheets accompany every shipment, emphasizing hazards such as toxicity, environmental persistence, and storage considerations. I've dealt with stock that arrived outside spec; in those cases, immediate return to the vendor proved essential because small impurities often mean big trouble in downstream reactions.

Preparation Method

Manufacturing ethyl 3-bromopropionate typically involves treating ethyl acrylate with hydrogen bromide or reacting 3-bromopropionic acid with ethanol under acid catalysis. The former offers quicker access but needs strict control over reaction conditions to avoid unwanted by-products. In decades past, labs would often work with liquid bromine and an iron catalyst, but the push for greener chemistry has prompted a re-examination. More modern approaches use phase-transfer catalysts or one-pot procedures, cutting waste and raising yields. During my time in process development, switching from batchwise bromination to continuous-flow technology made a major impact—not so much in purity, but in operator safety and scale-up reliability.

Chemical Reactions & Modifications

The versatility of ethyl 3-bromopropionate lies in its facility to undergo nucleophilic substitution at the bromine, making it a workhorse for installing three-carbon ester chains where needed. Labmates turn to it to create amino esters through displacement with amines, or to craft sulfides and phosphonates. Reduction of the ester or debromination unlocks further utility, while reactions with organometallic reagents produce long-chain alcohols and acids. The bromine position, not at the terminal carbon but one step removed, plays a special role in selectivity — it helps avoid side reactions and delivers better control, which means less time wrangling with purification headaches. In my experience, this reactivity speeds up complex molecule synthesis, often trimming entire steps from traditional linear routes.

Synonyms & Product Names

Ethyl 3-bromopropionate answers to several aliases: the IUPAC name spells out ethyl 3-bromopropanoate, while catalogs may list it simply as E3BP or EBPA. Some chemical distributors label it with old nomenclature, like bromopropionic acid ethyl ester. For anyone working internationally or in a regulated industry, understanding these synonyms saves headaches due to cross-referencing mismatches. Even regulatory registries carry multiple entries, making thorough documentation key for safety, logistics, and procurement.

Safety & Operational Standards

Direct handling brings the usual concerns for halogenated esters — eye and skin irritation, respiratory sensitivity, and in some cases, chronic exposure risks. Lab protocols call for gloves, safety glasses, and reliable ventilation at a bare minimum. Staff using large quantities follow engineering controls, including fume hoods and double containment. Emergency protocols stress immediate washing for spills and fast evacuation for vapor release. Chemical waste needs separate collection, matching local hazardous rules, given potential for persistent environmental impact. Training sessions often remind new chemists about accidental exposure stories, both to drive home the point and to support a safety culture that prevents incidents before they start.

Application Area

Pharmaceutical innovators use ethyl 3-bromopropionate to design small-molecule drugs, customizing chain lengths or attaching functional groups to bioactive cores. Agrochemical research leans on it to create herbicides and fungicides, often because the haloester motif promises both efficacy and selectivity. Materials chemists have found roles for it, too, especially as a precursor in specialty polymer synthesis. In my group’s industrial collaborations, using this intermediate sped up candidate screening, cutting synthesis and testing cycles for everything from anti-inflammatories to novel insecticides.

Research & Development

Academic circles and industrial R&D both focus efforts on making synthesis greener and expanding reaction scope. Recent years saw a shift toward solvent-minimized processes or using safer alternative reagents for bromination. Novel catalytic methods are unlocking ways to make even more complex derivatives from this core scaffold — a big deal for researchers tackling drug-resistant bacterial strains or searching out new plant protection agents. Shared data across chemical databases keeps labs from duplicating work, allowing deeper dives into both structure-activity studies and mechanistic explorations.

Toxicity Research

Toxicology assessments show acute oral and dermal toxicity, with particular risk to skin and mucous membranes. Long-term studies remain limited, but evidence points toward possible organ toxicity with large exposures. Environmental watchdogs note the persistence of halogenated compounds, prompting careful logging and tracking to prevent accidental release. I’ve seen animal studies where exposure produced both reversible and irreversible effects, underlining the importance of careful dose management in test protocols. Worker safety groups consistently advocate for substitution or engineering controls wherever possible — a lesson reinforced by every close call in the lab.

Future Prospects

Demand for innovative molecules in medicine, agriculture, and advanced materials keeps ethyl 3-bromopropionate in steady use. Ongoing shifts toward sustainability are driving researchers to refine both the manufacture and use of this compound. The next horizon involves bio-based production routes, enzyme-catalyzed modifications, and less hazardous alternatives for both bromination and downstream transformations. I see major opportunities for startups and larger companies to invest in green chemistry and improved lifecycle management for this and related intermediates — not just to keep pace with regulations, but to drive responsible growth in every field touched by chemical synthesis.

An Unassuming Liquid With Big Potential

Most shelves in a research chemistry lab look the same: bottles, vials, labels you need a magnifying glass to read. Every now and then, one of those bottles holds a solution that sparks new ideas. Ethyl 3-bromopropionate is one of those. With a clear, colorless look, it doesn’t stand out next to the acids and bases everyone knows from high school. But start talking synthetic organic chemistry and things get interesting fast.

How Labs Put Ethyl 3-Bromopropionate to Work

I’ve spent hours balancing this compound on an electronic scale, then slowly dribbling it into a round-bottom flask. What happens next can change the shape and function of whole molecules. Chemists lean on ethyl 3-bromopropionate as a starting block for building more complex molecules. Think pharmaceutical ingredients, agricultural chemicals, or specialty materials. Its real magic comes from the bromine atom, tucked midway along a three-carbon chain, and the ethyl ester at the other end. Together, these groups open up reaction options.

A classic move: nucleophilic substitution. That bromine atom is happy to leave, pulling in other molecules to take its spot. I’ve watched researchers use this trick to add carbon fragments, create rings, or build in new chemical handles. These moves lay foundations for a wide number of drugs and lab tools.

From Theory to Toolbox: Synthesis and Real-world Impact

Colleagues in pharmaceutical research tend to get excited about what they call “building blocks”— simple pieces you snap together in new ways. Ethyl 3-bromopropionate plays a starring role in synthesizing beta-amino acids, dipeptides, and other structural motifs common in medicines. Novo Nordisk, Pfizer, and other industry leaders regularly run reactions using this molecule to test new painkillers or antibiotics.

In agrochemical labs, teams work with this compound to assemble herbicide and pesticide molecules. The global crop protection industry is projected to grow past $80 billion by 2030, so every tweak in synthesis can mean millions in value. Efficient reactions help speed new products to market.

What Could Go Wrong — And How To Deal With It

All this opportunity comes with a need for careful handling. Chemists treat ethyl 3-bromopropionate with respect. It can irritate the skin and lungs. Standard safety goggles and well-ventilated hoods keep harm at bay. As for environmental concerns, nobody wants halogenated chemicals spilling into the water supply. Labs need reliable disposal and containment systems, not just talk about “green chemistry,” but real action.

There’s also the challenge of keeping production sustainable. Industry pushes for greener alternatives and manufacturing methods that generate less waste. Some startups and universities test new catalytic systems that cut down on byproducts and energy use. These steps help lower the toll on local ecosystems and make high-impact synthesis safer for the people doing the science.

Bottom Line: A Lab Essential With Room to Improve

Ethyl 3-bromopropionate might not be flashy, but it helps drive change in medicine, agriculture, and materials science. Chemists keep finding new uses for it, often making things safer, more efficient, and more innovative in the process. Each time I work with it, I’m reminded of how small changes on the molecular level can echo into much broader solutions.

Breaking Down the Basics

Ethyl 3-bromopropionate brings chemistry out of the textbook and into all sorts of interesting places. You see this name, it sounds technical, but look deeper and you spot a simple story—a chain of three carbon atoms, one carrying a bromine, the other end tethered to an ethyl ester. Its chemical formula reads C5H9BrO2. That isn’t some dry string of letters. It’s a map—five carbons, nine hydrogens, a single bromine, two oxygens—each piece waiting for someone in the lab to put them to use.

The molecular weight comes out to 181.03 g/mol. Chemists spot that number and figure out exactly how much substance they need to weigh out on the balance for a reaction, which sounds small, but try working without the right mass someday—you’ll watch your yields disappear. Calculation goes back to the basic math: carbon weighs 12.01 per atom, hydrogen adds 1.01, bromine loads on a hefty 79.90, each oxygen gives 16.00. Add them up, you see where the number lands.

Why Do People Care About Ethyl 3-Bromopropionate?

Through personal experience in a university lab, I remember reaching for a bottle of this stuff when we needed to add a three-carbon chain with a bromine atom to a molecule. In synthetic chemistry, it serves as a valuable building block. The ester part—ethyl propionate—makes it easy for larger molecules to absorb or release this group. The presence of bromine turns this into a strong alkylating agent. Chemists depend on such groups to open up ring systems, link up with amines, or build new drug candidates. Students often find the smell memorable, but in research, the stuff signals that a real transformation is about to happen.

Ethyl 3-bromopropionate also matters in the context of pharmaceutical development. Any graduate student with a synthetic biology project knows that connecting carbon chains smoothly makes the difference between a successful molecule and a dead-end. There’s always talk in the lab about cost and efficiency: reagents like this give reliable performance without breaking a research budget.

Safety and Environmental Considerations

Even though ethyl 3-bromopropionate does its job in the lab, it deserves respect. Brominated compounds aren’t toys. A spill can irritate skin, eyes, or the lungs if ventilation isn’t set up. I’ve watched colleagues learn that lesson the hard way, with hurried washes at the sink. Responsible handling starts with gloves, goggles, and a fume hood. Disposal has to follow local environmental standards, for good reason—dumping halogenated organics into a drain can cause issues downstream.

One practical solution for those using chemicals like ethyl 3-bromopropionate involves regular training. Revisiting old safety protocols may seem repetitive, but missing a step often leads to lab accidents, sometimes with long-term effects. Many institutions now track chemical movement from shelf to disposal, lowering the odds that something hazardous lingers in the wrong place.

The Future of Synthetic Chemistry

The conversation about brominated esters like ethyl 3-bromopropionate is more than just vocabulary. Each molecule serves as a stepping-stone toward new therapies, new plastics, or agricultural tools that can change lives. As green chemistry gets stronger, there's steady pressure to find better alternatives with less environmental impact. Until then, careful, informed chemists will keep using compounds like this to solve problems and move science forward.

The Real Hazards Behind the Bottle

Ethyl 3-bromopropionate looks harmless at first glance. Clear, almost like water, it’s the sort of chemical that often gets tucked into a forgotten corner of a storage cabinet. It earns its place in research labs and chemical plants because it helps make pharmaceuticals, agrochemicals, and other fine chemicals. Despite its usefulness, it only takes a whiff or a careless spill to realize this liquid deserves more respect.

Missed Warnings Turn into Lessons

You don’t have to spend long in a lab to learn that strong-smelling esters can bring headaches, dizziness, and skin irritation. Fume hoods exist for a reason. Leaving ethyl 3-bromopropionate out on a bench or stashed with leaky caps creates two risks: escaping vapors and unexpected reactions with other stored chemicals. Breathing in those vapors on a daily basis can bring down anyone’s productivity, not to mention cause long-term health problems. Fact sheets from chemical manufacturers confirm the same dangers: prolonged exposure increases risks for respiratory irritation and allergic reactions.

Safety Shelves Speak Volumes

Whenever I see a container of ethyl 3-bromopropionate stored in a crowded solvent cabinet, alarm bells ring. Plastic gets brittle, metal corrodes—this is a chemical that breaks down certain storage materials over time. It eats through softer plastics and even picks fights with some metals, making all-glass or high-grade polyethylene containers smarter choices. Experience in older laboratories shows that storing this compound next to strong acids or bases often leads to slow leaks and sticky messes. Neighbors matter. Flammable solvents, strong oxidizers, and sensitive reagents shouldn’t share a shelf.

Storing Ethyl 3-Bromopropionate for Safety and Peace of Mind

Proper storage of this compound starts with temperature. It stays stable at normal lab temperatures, but keeping it cool, away from open flames or heat sources, makes accidents less likely. Direct sunlight breaks down the molecule, sometimes generating toxic byproducts. Chemical databases and materials safety data sheets consistently recommend dry, well-ventilated spaces—areas where vapor build-up doesn’t sneak up on you. Labels with last-opened dates, names, and contact information prevent mystery bottles from lurking in the dark.

Keys and restricted access matter. Any container with ethyl 3-bromopropionate belongs behind locked doors, especially in facilities where new staff pass through regularly. Lower shelves work best for heavy bottles; spills from up high do more damage—ask anyone who has cleaned up after one.

Responsibility on the Individual and Organizational Level

Safe storage shouldn’t fall on just one person. Teams thrive when everyone gets training on chemical hazards, PPE, and what to do during leaks or exposures. Labs where senior staff demonstrate proper protocols give younger workers the confidence to handle things correctly without shortcuts. Audits—those dreaded inspections—often catch storage mistakes, but simple checklists for weekly reviews can keep problems from growing.

Don’t count on memory for expiration dates or safety limits. Inventories updated monthly do more for safety than automated reminders alone. Local regulations often set maximum quantities and storage container requirements, and facilities that skip compliance not only put staff at risk, they invite costly fines.

Solutions within Reach

Chemical-resistant cabinets with proper ventilation and clear labeling offer the best defense. Companies that invest in up-to-date storage solutions rarely regret it. The up-front cost pays for itself in avoided spills, healthier staff, and fewer surprise visits from safety inspectors. Training should include case studies from real incidents, not just checklists and quizzes. Nobody forgets the day a bottle of ethyl 3-bromopropionate cracked and cleared a wing of the building for half a day. The lessons learned—keep it cool, keep it labeled, and never stash it next to reactive chemicals—stick longer than pictures in a manual.

Understanding the Hazards and Why Safety Matters

Ethyl 3-Bromopropionate brings convenience to organic synthesis, but its risks stick around longer than a lingering odor. The chemical can cause irritation just by making contact with skin or eyes. Its vapor sneaks into your lungs and toe-to-toe exposure can bring headaches, nausea, or worse if enough builds up. Many of us recall stories from lab mates who skipped the gloves, only to regret it when itching, redness, or a trip to health services followed.

Ignorance breeds carelessness. The label might sound complicated, but don’t get thrown off by the name. This chemical has teeth, and ignoring that never pays off. I’ve seen experienced researchers rush through setup, thinking familiarity is armor, then end up scrubbing hands at an eyewash station because that last pipette pull went wrong.

Essential Personal Protective Equipment (PPE)

Treating Ethyl 3-Bromopropionate like water gets people hurt. Solid nitrile gloves, safety glasses with side shields, and a fresh lab coat form your best defense. Short sleeves mean chemicals meet skin, and cloth gloves just won’t cut it against halogenated esters. Folks often grab latex because it’s cheap, but nitrile resists penetration better. If you expect any splashing, a face shield brings extra peace of mind.

Respiratory protection rarely comes up unless you’re working with quantities large enough for vapor to build up, but it never hurts to know where your nearest cartridge respirator lives. Fume hoods cut vapor exposure drastically. I’ve seen folks try to wing it on the open bench, usually to save time, but their mistakes turn into real learning moments for everyone nearby.

Good Handling Habits and Lab Setup

Don’t underestimate how easily spills happen. Every transfer deserves a spill tray underneath. Have absorbent material and neutralizers within reach because scurrying around looking for them wastes precious seconds in a spill emergency. Limited quantity dispensing keeps messes manageable and leaves less to clean up if something tips.

Label everything clearly. Handwriting sometimes gets messy during a long day, but sharpies and printed labels cut confusion. Unmarked vials end up swapped or forgotten, which only increases your risk down the line. Storing this chemical in secondary containment bottles reduces your risk when bottles crack or seals fail.

Safe Storage and Emergency Response

Store Ethyl 3-Bromopropionate in a cool, dry space away from sources of ignition and keep incompatible substances on a different shelf or cabinet. Ventilated flammables cabinets offer solid protection. Don’t crowd the cabinet; chemicals need space so bottles can breathe and won’t fall over when you grab one from the back.

Accidents still happen. Know your eyewash and safety shower locations and make sure exits stay clear. Keep up-to-date with the chemical's safety data sheet (SDS). Quick thinking counts during emergencies, but those seconds matter more when you know the response plan cold.

Continuous Training and Team Vigilance

Labs run safer when everyone holds each other accountable. I’ve learned the value of refreshing safety protocols as part of weekly group meetings. Nobody grows out of double-checking their gear or asking for a second opinion on a risky procedure. Respecting the risks and chasing safer habits helps protect not just the individual but the whole research team. It pays off every day when everyone heads home safe and healthy.

What’s Behind the Different Grades?

Ethyl 3-bromopropionate pops up in research labs and chemical syntheses. Some days, I remember weighing out this reagent for a colleague’s project, and he double-checked the label on the bottle twice. He wanted to make sure the purity matched the protocol, because chemistry doesn’t forgive sloppiness. Specialty chemicals like this usually arrive in more than one form. Laboratories might stock “analytical grade” or “reagent grade” bottles, while factories may use a “technical grade” for certain processes.

Purity isn’t just a sticker on a bottle. It tells you how much of the chemical in the bottle is actually what you want, and how much is something else mixed in. The higher the percentage, the more trustworthy it is in delicate applications. Low purity often means leftover water, chloride, or other organics remain. These sneak in from shortcuts during manufacturing or from poor handling and storage.

Who Cares About Grades?

Universities and research centers usually pick the highest grade they can afford, because a failed experiment eats up more time and resources than a slightly pricier chemical. If a process creates a new drug candidate or an important intermediate for a pharmaceutical, every impurity must be tracked. Even a pinch of an unknown contaminant can change how reactions behave or introduce safety concerns down the line. Frankly, I’ve seen projects grind to a halt because a cheaper chemical wasn’t quite pure enough.

In the industrial world, requirements change. Not every use needs top-tier purity, and sourcing becomes a balancing act. For large-scale manufacturing—think industrial polymers or bulk intermediates—a technical grade might cost less and still achieve the desired end product. Purity might slide, but the application decides where the cut-off sits.

Checking the Label Isn’t Enough

Nobody should take a supplier’s word at face value. Reliable businesses back up their numbers with certificates of analysis and batch-specific data sheets. I’ve seen researchers call up chemical suppliers for more details, sometimes asking for gas chromatography reports or nuclear magnetic resonance data. If the company hedges or can’t provide details, that’s a red flag.

Purity grades also affect how safely a chemical can be handled. Contaminants sometimes skew toxicity or change how a compound reacts with others. In regents like ethyl 3-bromopropionate, trace bromide can bump up corrosion rates in metal containers or impact storage stability. Knowledge in handling comes not just from lab training, but also from firsthand mishaps. I once watched an unexpected reaction from stale stock; a lesson that stuck with everyone in the lab.

Solutions: Choose Carefully, Store Properly

It helps to keep things organized. Separated storage for different grades, clear labeling, and regular inventory checks can save a lot of headaches later on. Sourcing from reputable suppliers pays off, not just in better product, but in consistent performance over time. Staff training and transparency in the supply chain can reduce mistakes. One overlooked contaminant can undo months of work, so taking extra steps in procurement and quality testing really matters.

Every discipline working with ethyl 3-bromopropionate needs to figure out what purity level fits its process, both for results and for safety. Too many people have found out the hard way that good chemistry starts with the right grade—and ends in wasted effort otherwise.