Ethyl 4-Bromobutyrate: From Synthesis Roots to Future Promise

Historical Development

Chemists started exploring the potential of halogenated esters over a century ago, and Ethyl 4-bromobutyrate entered the laboratory toolkit early in the twentieth century. Organic synthesis surged during this period, and the growing demand for new pharmaceutical intermediates and research reagents fueled attention on bromoalkyl carboxylic esters. Methods improved little by little, driven by the push to create reliable building blocks for medicinal chemistry. People in industrial research leaned in because the structure unlocked strategies for making new drugs and crop protection chemicals. As organic synthesis advanced, generations of chemists updated preparation routes to fit changing safety expectations, greener chemistry goals, and scale-up improvements. Researchers who cut their teeth in organic labs quickly learned the chemical’s quirks and advantages, and it ended up on lab benches from academic research to specialty production plants by the late 1900s.

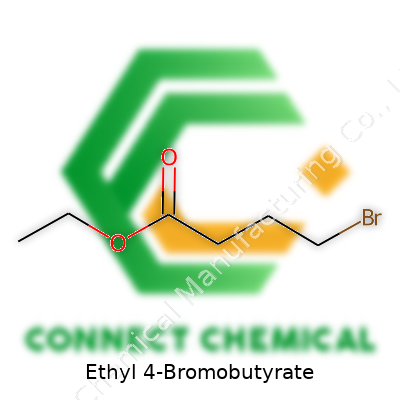

Product Overview

Ethyl 4-bromobutyrate has emerged as a trusted intermediate in countless synthetic routes. With its four-carbon backbone and reactive bromo moiety tethered far from the ethyl ester, it bridges gaps between molecular fragments—a real workhorse in alkylation, substitution, and ring construction. Chemists reach for it to add functional handles, extend chains, and tune molecules for pharmaceutical and agrochemical work. Here, it’s less about shelf glory and more about getting things done. Its reputation for consistency and dollar-for-value means both research and commercial outfits keep it on procurement lists. Over time, the product labels have stretched to include a handful of trade names, but experienced chemists spot its smell and viscosity from across the lab.

Physical & Chemical Properties

In the bottle, ethyl 4-bromobutyrate isn’t flashy—clear or pale yellow, oily, and dense. It won’t blend well with water, settling out and showing chemists its preference for organic solvents. With a molecular formula of C6H11BrO2 and a molar mass of 195.05 g/mol, its vapor is noticeable, prickling the nose, and its boiling point sits just over 200°C, making distillation straightforward for those with the right glassware. The carbon-bromine bond pulls plenty of polarity, setting the molecule up for a range of nucleophilic attacks. Unlike some smaller alkyl bromides, it lays low until pushed with decent reaction conditions. Hydrolysis under acidic or basic conditions turns it back into 4-bromobutyric acid, and any strong nucleophile will try to swap with the bromine. The ester group ensures lower reactivity toward saponification compared to shorter chain cousins, which means it stores reasonably well if the cap stays tight.

Technical Specifications & Labeling

Buyers expect tight product specs in every order — major suppliers peg purity above 97%, wiping out water, unreacted acids, and related esters. The best batches run clear with minimal byproduct. Safety data sheets lay out critical points, including boiling range, refractive index, flash point, and density. Chemical labeling under GHS guidelines flags acute toxicity and strong irritant warnings. Transport and storage rules reflect its flammability, and strict labeling helps prevent mishandling. Long storage and rough handling drive up peroxide formation and impurities, and suppliers chase down quality limits with regular batch testing. Those who cut corners on specs risk headaches in downstream reactions, especially in pharmaceutical work, so reputable labs demand signed certificates of analysis and detailed lot traceability.

Preparation Method

Textbooks detail a classic route for ethyl 4-bromobutyrate: start with 4-bromobutyric acid, push it through Fischer esterification with ethanol under acid catalysis. This lets most chemists get clean product at small and medium scales. Some labs branch off and build the brominated acid by direct bromination of butyric acid derivatives, then run it through the esterification. A handful of industrial outfits use alternative options, like transesterification of methyl 4-bromobutyrate with ethanol or even direct halo-esterification reactions. Each method offers tradeoffs: bromination first means more work-up and washing, but delivers higher yields at scale; esterification first brings fewer impurities but increases purification needs. Experienced process chemists tweak time, temperature, and reactant ratios for minimal side products and easier downstream work.

Chemical Reactions & Modifications

Ethyl 4-bromobutyrate takes part in a range of reliable organic transformations. Grignard reagents and other strong nucleophiles will swap out the bromine, building up longer carbon chains or adding functional sidearms. The ester group sits tight unless pH or hydrolytic force is applied, protecting the molecule during multi-step synthesis. Alkylation chemists use it for N-alkylation, O-alkylation, and C-alkylation, with decent yields in well-controlled conditions. Reductive debromination and other substitution reactions appear often in academic literature, especially in studies focused on creating prodrugs or amino acid derivatives. Every synthetic route exposes different quirks—overheating or sloppy exclusion of water can break down the starting material, and reactions with strong bases sometimes trigger unwanted elimination.

Synonyms & Product Names

Searching catalogs or literature for ethyl 4-bromobutyrate turns up a pile of synonyms: ethyl gamma-bromobutyrate, gamma-bromobutyric acid ethyl ester, and simply 4-bromobutyric acid ethyl ester. Some suppliers use proprietary codes or older IUPAC variants, yet the structure stays clear to those who know their esters. Common abbreviations can trip up newcomers, especially across languages or between regulatory bodies. Product branding never carries much weight here; experienced chemists focus on CAS number 2969-81-5 to clear up confusion and avoid mislabeling in inventory.

Safety & Operational Standards

Long experience in well-run labs hammered home the safety issues. Spills and splashes irritate the eyes and skin almost immediately—goggles and gloves are not optional. Inhaled vapors may trigger headaches or breathing trouble. Managers drill into staff proper waste disposal; never pour this one down the drain. Fume hoods stay busy during handling and reaction preparation to catch those low-level vapors. Storage in tightly closed, clearly labeled amber bottles reduces airborne loss and accidental exposure. These guidelines, enforced at every bench, have saved more than a few chemists from rough days. Staff turnover and inexperience amplify the risks, so new protocols stress proper storage, transfer under inert gas, and clear written logs. The move toward green chemistry limits waste, and engineers seek closed systems that reduce human error.

Application Area

The reach of ethyl 4-bromobutyrate cuts across pharmaceuticals, crop science, and even specialty flavor chemistry. Medicinal chemists leverage it as a precursor for making GABA analogs, muscle relaxants, anticonvulsants, and a basket of other compounds that hinge on substituted butyrates. In agrochemical development, the molecule often anchors synthetic schemes for insecticides and herbicides. Polymer researchers dabble in its building block potential, while others use it to access new surfactants or specialty plasticizers. Surprisingly, a few food scientists explored its use in ester blends, though regulatory and toxicity questions push it off most ingredient lists. Every field values its reliable reactivity and the control it allows when setting up multi-step synthesis, shaving weeks off project timelines.

Research & Development

For a synthetic chemist, the curious tails of this ester have inspired hundreds of research papers. Novel routes for chain extension, cyclization, and substitution keep showing up in the literature, which means the molecule helps fuel creativity and innovation. Bioconjugation efforts, especially those chasing new targeted drugs, draw on ethyl 4-bromobutyrate’s ability to anchor linkers or enable selective modification. Green chemistry moves shape R&D, shifting attention to less hazardous solvents and microwave-accelerated methods. On the analytical side, researchers probe the molecule’s reactivity patterns across different nucleophiles and design better purification tools for large-scale work. In collaborative projects, teams designing “smart” materials or responsive polymers sometimes borrow strategies built around the flexibility and reliability of 4-bromobutyrate esters.

Toxicity Research

Toxicologists don’t turn a blind eye to ethyl 4-bromobutyrate. Data from cell culture and animal studies highlight acute irritation at relatively low doses. Direct ingestion or skin contact uncovers neurotoxicity and cellular stress tied to both the parent ester and the brominated metabolite. Environmental reports keep it off wastewater outlets; its breakdown products risk harm to aquatic species and may transform unpredictably in complex environmental matrices. Regulatory snapshots classify it among hazardous chemicals, and occupational exposure limits carry tight margins for error. Risk management in production and research strictly regulates use, focusing on improved ventilation, regular health checks, and predictive toxicity modeling. Over the last decade, some labs worked in tandem with regulatory bodies to tighten exposure thresholds and explore biodegradable alternatives, reflecting a stronger public health push.

Future Prospects

Ethyl 4-bromobutyrate won’t win awards for trendiness, but its future holds plenty of promise. Pushes toward more sustainable bromination processes and safer esterification steps open pathways for greener industrial adoption. Pharmaceutical expansion in global markets ensures demand for advanced intermediates keyed to macrocyclic drugs, prodrugs, and extended-release formulations—all of which pull on 4-bromobutyrate chemistry. Digital chemistry, machine learning, and automated process design could further streamline the molecule’s production, cracking older efficiency limits and boosting quality control. Toxicity continues to command attention, and safer-by-design approaches may spawn new derivatives that trim risk while keeping synthetic value. Young chemists entering the field find that the basic principles they learn with ethyl 4-bromobutyrate echo throughout their career, whether pushing toward new chemical space or answering tough environmental questions.

Inside the Lab: Where Science Gets Rolling

Ethyl 4-bromobutyrate usually lands on the bench in research and chemical development labs. It doesn't show up in household cleaners or on drug store shelves—this is a tool for trained hands. Folks use it mainly as a building block for creating more complex molecules. In everyday words, chemists reach for it to start or help along the process of making something bigger and more useful.

The Science Tucked in a Bottle

Few chemicals get this much attention on the synthetic side. You’ll find it in play when making specialty products in pharmaceuticals and materials research. Its value comes from that reactive bromine atom on the molecule. That spot acts like a handle, ready to get swapped out or stitched onto another chain to build up new substances. In drug development, research teams might use it to help form gamma-amino acids, which play critical roles in producing both experimental and approved medicines.

Personal experience in a university lab taught me how careful synthesis can open doors to breakthrough ideas. We used similar compounds to try modifying common drugs for better performance. Researchers appreciate molecules like ethyl 4-bromobutyrate for this reason: It gives them a way to tinker and test, exploring what shape or function a new drug might take.

Fine-Tuning Chemicals for Everyday Impact

On the fragrance and flavor side, ethyl 4-bromobutyrate sometimes steps up as a starting point for building aroma ingredients. The process isn’t direct—there’s a good bit of tweaking and finishing involved. In the end, these workhorse molecules help companies craft the scents that show up in perfumes and in foods ever so subtly. It doesn’t go straight into the bottle, but it sure helps make those bottles possible.

Safety, Smart Use, and the Need for Skill

I remember working with compounds like this in a training setting, where everyone took the time to understand the risks. Compounds in the brominated ester family can cause real problems—skin irritation and more—without careful handling. Regulations require strong ventilation, protective gear, and proper disposal. University and industry labs keep safety front and center, but risks go up if shortcuts get taken.

People talk about green chemistry a lot these days. Reducing hazardous waste, looking for cleaner alternatives, and improving recovery techniques for solvents and byproducts are on the agenda. The challenge often falls to chemists to design reactions that minimize risk but don’t block progress. Smarter process design and better ventilation systems can both cut down the exposure to potentially harmful substances.

Looking Ahead: Building the Right Chemistry

Ethyl 4-bromobutyrate might not grab headlines, but it keeps research running in many important fields. Lab work depends on having the right materials, strong training, and attention to safety at every step. If industry leaders keep investing in greener process methods and better safety infrastructure, this type of chemistry can continue to help build better medicines, flavors, and materials—without risking health or the planet.

Understanding Its Structure

Ethyl 4-bromobutyrate goes by the chemical formula C6H11BrO2. Each piece of this formula carries meaning. There’s the ethyl group—two carbons and five hydrogens—linked to a butyrate chain, which comes from butyric acid, a four-carbon fatty acid. Adding a bromine atom on the fourth carbon of this chain gives the molecule new properties. Studying the way atoms join together in this formula opens a window into how chemistry influences the world we touch, from pharmaceuticals to organic synthesis labs.

Connection to Real-world Chemistry

Working in a research lab, handling a bottle labeled "Ethyl 4-Bromobutyrate" forces more than memorization. Mistakes with formulas can waste resources or worse, risk safety. Writing C6H11BrO2 on an order sheet means the warehouse team grabs exactly the right bottle. The stakes become real during synthesis: swap the number of carbons or miss the bromine, and the entire experiment loses its point.

I remember prepping reagents for an esterification, thinking nothing of chemical formulas. Only after a shipment with the wrong compound delayed a project by weeks did the lesson stick. Molecular formulas keep experiments on course, steering clear of disaster.

Applications Show Chemistry’s Everyday Reach

Ethyl 4-bromobutyrate appears in organic chemistry as a building block to create more complex molecules. Its bromine atom provides a hook for chemical reactions, making it useful for pharmaceutical development and even agricultural chemistry. Chemists modify this molecule to design new drugs or crop protection chemicals. This opens the door for innovation in fighting disease, optimizing food growth, and solving supply chain headaches in research labs.

Beyond direct applications, basic understanding of its structure helps students and young scientists see chemistry as a practical tool, not just textbook jargon. Everyone remembers models and stick figures from high school lab. Recognizing how a simple formula leads to real products bridges that gap—turns memorization into genuine understanding.

What Can Go Wrong—and How to Fix It

Errors with chemical formulas might feel trivial until real money, safety, and productivity enter the picture. One miswritten element means the difference between a harmless liquid and a hazardous substance. Labs and companies handle this by checking paperwork, running chemical analysis, and enforcing procedures. Mistakes still slip through. Training programs help, but experience remains the strongest teacher.

An easy way to stress safety and accuracy is slowing down when writing, ordering, or labeling chemicals. Sharing stories about real incidents reaches people more deeply than checking boxes on a form. I’ve watched senior researchers swap near-miss stories in meetings—those conversations stick with newcomers far more than reading policy manuals.

What This Means for the Future

The chemical formula C6H11BrO2 represents more than a compound; it stands for the details that specialists balance every day. Conscious handling of these building blocks—by being mindful of exact structures, by sharing knowledge, by valuing real-world experience—raises the bar for everyone in the lab. Better habits build safer workplaces and smarter discoveries, moving research from the classroom to real solutions.

Why Storage Conditions Matter

Ethyl 4-bromobutyrate shows up in chemical syntheses and research labs more often than folks might think. Handle it the wrong way and trouble isn’t far behind — irritation to skin, eyes, or worse, unwanted reactions. Once, early in my career, I saw a new researcher think the fridge was enough for every bottle with a scary label. He paid for that assumption when a bottle leaked and stunk up the cold room for a week. It’s not just about keeping chemicals out of reach; it’s about treating each one with the respect its risk demands.

Keep it Cool, Dry, and Sealed

Ethyl 4-bromobutyrate doesn’t play nice with heat or moisture. High temperatures speed up breakdown and chemical reactions. A cool, dry spot spells safer storage. A dedicated flammables cabinet works best, set between 2 and 8 degrees Celsius but far from freezing. Ordinary refrigerators don’t cut it — vapors may collect and spark trouble inside. Labs with means use spark-proof “flammable storage” fridges, especially for solvents and esters like this one.

I once tried to cut corners by squeezing small bottles below a desk. Not only did I get dinged at inspection, but the headaches from the fumes reminded me why those cabinets exist. It proved a real-life lesson in basic chemical storage discipline.

Avoiding Water, Strong Bases and Oxidizers

Spillage or leaks near open water can spoil ethyl 4-bromobutyrate fast. The compound hydrolyzes, putting off unpleasant odors and possibly generating toxic byproducts. Store it with a cap tight and always in original packaging or compatible glass bottles. Keep it away from strong bases or oxidizers. Cross-contamination risks heap up, especially in overpacked storage areas where folks get careless. If a bottle gets cloudy or pressures up, disposal is smarter than risking a lab accident.

The bottle’s label cries for a date and hazard sticker. Nothing good comes from old, mystery chemicals. Regular inventory helps prevent forgotten containers from turning into bigger issues later — a routine every researcher should treat as a habit, not a chore.

Health Hazards and Ventilation

Breathing in vapors or letting the liquid touch bare skin might not seem dramatic at first, but over time, exposure adds up. Not everyone realizes headaches, nausea, or rashes can trace back to repeated mistakes in storage or handling. The material safety data sheet (MSDS) stays taped on the inside of the cabinet door in the labs I’ve worked in, just to cut down the excuses for not knowing the facts.

Good ventilation matters. Closed storage inside a vented cabinet or fume hood limits vapor build-up. Simple strategies can outwit big hazards; opening a bottle by a window or using it under the hood works better than hoping good luck lasts.

Simple Steps Make a Safer Lab

Follow the basics: dry space, steady temperature, sealed containers, no mixing with incompatible chemicals, and clear labeling. Regular audits and mandatory training make a difference, so don’t brush those off. I’ve seen too many avoidable mishaps fixable with these modest investments. Storing ethyl 4-bromobutyrate by the book may not win anyone a Nobel, but it keeps folks safe, helps research run smoother, and keeps regulators off your back. That’s worth more peace of mind than any shortcut in the lab.

Why This Chemical Demands Respect

Ethyl 4-bromobutyrate has a knack for catching even experienced chemists off guard. If you’ve spent any time working with esters and bromine compounds, you’ll know how easy it is to overlook the dangers when you get too comfortable. This liquid can sneak vapor into places you might not expect and leaves a nasty sting if it ends up on skin or in your eyes. It doesn’t smell strong, so relying on your nose can be a fast ticket to exposure. Trust what you know about chemistry, not your senses, to tell you it’s there.

Personal Protection That Works

Labs are full of short cuts and bad habits, but with 4-bromobutyrate, risks build up fast. Splashing some on your hands or face can set off itching, redness, or blisters since it reacts with your skin. Good nitrile gloves remove this risk. I know folks who have trusted latex, but bromine compounds can eat through thin barriers if exposure stretches out. Safety goggles protect against the quick burn of chemical splashes. Go for a proper lab coat and, if you’re transferring or pouring, a face shield does wonders for peace of mind.

Know Your Space and Surfaces

Using a fume hood stands out as non-negotiable. Fumes don’t just coat your nose and throat, they can cause headaches or trigger asthma. Hoods with even airflow pull dangerous vapors right out. Working on open benches has landed people in the nurse’s office with more than a headache. Line your work surface with disposable pads. These soak up droplets and save you time at the end of the day. If a spill shows up, a quick wipe might not get it all. Absorbent pads plus a proper solvent—think isopropanol or similar—clear it out without spreading hazardous residues around.

Safe Storage Keeps Problems Small

I’ve seen chemicals stored next to snacks, electronics, even open flames. Don’t do it. 4-bromobutyrate should sit out of direct sunlight, at room temperature or lower, in a tightly sealed container with a strong cap. Bulging caps hint at trouble. Use containers with real seals, not hastily cut parafilm and hope. Separate from strong bases, acids, or oxidizers. These combinations start reactions you won’t want in a shared workspace. Long-term storage? Write clear labels and keep an inventory. More than a few times, someone’s used an old bottle by mistake, ruining experiments or worse.

Good Habits Pay Off

Don’t pipette by mouth; yes, people still do this. Label waste containers for all brominated organics. If you toss scraps into the wrong bin, you end up making future disposal a headache for everyone. If a spill hits your skin, the best move is to rinse with plenty of water for at least fifteen minutes and alert a supervisor or trainer. Call your local poison control if you think you’ve been exposed. Symptoms can creep up.

Training Prevents Accidents

Refresher sessions about chemical handling really help. After a small fire during my grad school days caused by poor storage and cleaning, our department upped its game. Everyone practiced spill kits, eyewash use, and reporting near-misses. Nearby colleagues matter. If you’re working alone on a late-night synthesis, let someone know. Safety isn’t just about rules. It builds a culture where people take care of each other.

Why Purity Isn’t Just a Technical Detail

Anyone who’s spent time in a chemistry lab or worked in the pharmaceutical world knows that purity isn’t just a number printed on the side of a drum. Whether you’re running a research experiment at a university or trying to manufacture a drug, the quality of reagents can shift results in ways that’ll keep scientists up late. Ethyl 4-bromobutyrate looks like a simple building block to anyone leafing through catalogs, but what’s stuffed into those bottles goes far beyond a single formula or label. Grades and purities shape what you can do safely and reliably.

Grades on the Shelf: From the Bench to the Factory Floor

People buying reagents often face a choice between regular “technical” grades and more refined “analytical” or “pharmaceutical” purities. Technical grade products might contain trace contaminants—leftovers from shortcuts in the synthetic process—which are usually tolerable for large-scale industrial processes, like making agrochemicals. But these same traces could cause real headaches in drug production, where regulators look closely at every impurity that could compromise patient safety.

Academic researchers I’ve worked with know their budget limits. Sometimes, they’ve taken what they can get—choosing between 95% and 98% pure. On the other hand, a pharmaceutical team making an active ingredient won’t settle for less than 99% purity, and often they demand certificates of analysis for every lot.

Mixing Science With Business: How Labs and Plants Decide

Companies don’t just care about purity for the sake of getting results—their reputation and liability depend on what’s really inside every bottle. Minor impurities can destroy sensitive catalysts, ruin yields in a multistep synthesis, or put patients at risk if they end up in the final product. I’ve seen projects delayed by a simple mistake in ordering a high-purity reagent because a cheaper grade promised delivery within a week. That lost time costs money and trust—something everyone learns fast after making a first error.

Analytical labs test for known impurities. Process engineers get involved long before production, planning extra purification steps if the raw material varies from batch to batch. There’s never a one-size-fits-all answer—picking a grade means balancing risk against the cost, and often, the decision comes down to how much a mistake might cost in wasted batches, lost contracts, or failed experiments.

Facts on Availability and Buying With Confidence

Ethyl 4-bromobutyrate is widely available from long-standing chemical suppliers in varying purities, though the catalog rarely tells the whole story. Reputable producers, especially those audited by global agencies or supplying to medicinal markets, will provide proof—chromatograms, heavy metals testing, and even how the product was handled and packaged. The best trust comes from seeing this paper trail, not just taking a supplier’s word.

Choosing the right grade means asking: what’s at risk in your process? For a high-value pharmaceutical, the added cost for extra purity isn’t a luxury—it's a safeguard. For a non-critical industrial process, saving on input costs can keep a business afloat in a competitive market. In either case, transparency from suppliers matters.

Toward Smarter Choices: What Buyers Can Do

Buyers help themselves and their teams by checking for third-party audits, reviewing certificates of analysis, and keeping lines open with suppliers. I’ve found that reliable suppliers rarely shy away from questions or paperwork. If you hear vague answers about purity or grading, that’s your warning to look elsewhere. Demand details. Understand your process. Ask for documentation. Every shortcut in sourcing turns into a potential headache downstream.

Tools and regulation can’t replace an educated buyer. Understanding why purity and grading matter pays off every time, whether the product will fill hundreds of vials in a factory or just run a reaction or two on the bench.