Ethyl 4-Bromopentanoate: Building Block with a Proven Track Record

Historical Development

Ethyl 4-bromopentanoate entered the scene over half a century ago, carved out of a need for versatile intermediates within organic synthesis. Chemists in the mid-1900s sought new routes for complex molecular construction—especially those with carbon–halogen bonds. As demand for selectively brominated, easily handled esters grew, 4-bromopentanoic acid esters offered a gateway to a wide span of structural modifications, and practitioners noticed how a simple switch from methyl to ethyl esters made a tangible difference in reactivity and practical lab work. Over the years, labs from basic research settings to pharmaceutical companies began to source and harness ethyl 4-bromopentanoate for custom syntheses, often integrating it within the synthesis of key intermediates of emerging drugs or fine chemicals.

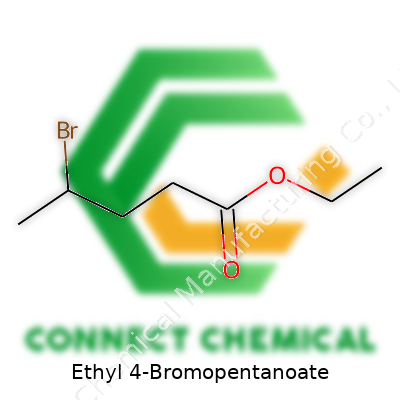

Product Overview

Ethyl 4-bromopentanoate springs from the family of haloalkyl esters, valued for both its manageable reactivity and compatibility with a broad range of solvents and reactants. This compound gets shipped as a colorless to pale yellow liquid, sometimes faintly odorous, packed in amber bottles to shield it from light-induced breakdown. The product’s value extends far beyond the chemical supply catalog—this little ester unlocks doors in both academic and industrial labs, from undergraduate organic chemistry benches to bustling specialty chemical plants that feed cutting-edge research.

Physical & Chemical Properties

On the bench, ethyl 4-bromopentanoate behaves as a relatively stable, moderately dense liquid, floating between 1.2 and 1.3 g/cm³. Boiling range often runs near 85-86°C at reduced pressure, with a melting point well below room temperature, making it simple to handle. Its nearly neutral pH and moderate vapor pressure keep risks manageable in controlled settings, provided ventilation and basic PPE are in order. Chemists note its solubility in organic solvents like ether, dichloromethane, and ethanol, but water resists dissolution, keeping it partitioned in organic phases during work-ups. The fragrance—sometimes compared to sweet chemicals—serves as a quiet warning of volatility. Under UV or intense heat, the molecule can decompose, which fits typical safety cautions for halogenated esters.

Technical Specifications & Labeling

Suppliers typically specify a purity level above 97%, communicated directly on the bottle alongside linear formula (C7H13BrO2), molecular weight (213.08 g/mol), and batch specifics like refractive index and moisture content. Labels also point toward hazard codes—pick up a bottle and you’ll see clear H-phrases regarding eyes and respiratory tract irritation or aquatic toxicity. I remember how a straightforward, legible label would quickly orient new users to critical specs, much more effectively than digging through digital material safety data sheets when a reaction needed immediate setup.

Preparation Method

Manufacture of ethyl 4-bromopentanoate commonly starts from pentanoic acid or 4-bromopentanoic acid, passing through either traditional Fischer esterification or direct bromination routes. Laboratory-scale synthesis often involves reacting 4-bromopentanoic acid with ethanol in the presence of a catalytic amount of sulfuric acid under reflux, followed by purification via distillation. Industrial routes may rely on brominating ethyl pentanoate using elemental bromine or N-bromosuccinimide under controlled conditions to minimize side reactions. These methods pull strongly from classic organic chemistry toolkits, and many researchers, myself included, learned their first lessons in handling volatile reagents and separatory funnel extractions during such syntheses.

Chemical Reactions & Modifications

The bromine atom on the fourth carbon opens many synthetic pathways. Nucleophilic substitution reactions make the compound a convenient handle for introducing amines, thiols, or other functional groups at a precise site. In pharmaceutical R&D, this intermediate provides an easy pivot point for tuning molecular frameworks to chase biological targets. Alkylation, reduction, and further ester hydrolysis exemplify the broad toolkit that ethyl 4-bromopentanoate brings to the lab. Chemists value how readily it lends itself to cross-coupling chemistry, like the Suzuki or Heck reaction, once the bromine swaps for an organometallic partner. These reliable reactions help more advanced users stitch together increasingly sophisticated molecules for everything from agrochemical leads to custom ligands.

Synonyms & Product Names

This compound travels under several aliases: Ethyl 4-bromovalerate stands out, as does its registry name Ethyl bromopentanoate. Product catalogs sometimes shorten it to 4-bromopentanoic acid ethyl ester, and for those working with international suppliers or reviewing old patent files, it may surface as Pentanoic acid, 4-bromo-, ethyl ester or even Br(CH2)3COOC2H5. I’ve had orders delayed thanks to miscommunications when synonyms slipped into requisition forms, so double-checking the CAS number—usually 2969-81-5—saves hassle.

Safety & Operational Standards

Strict guidelines frame the handling of ethyl 4-bromopentanoate, especially due to the irritant qualities of both the ester and its vapors. Standard procedure includes chemical-resistant gloves, safety glasses, and operation inside a fume hood to limit exposure. Skin contact can lead to redness or irritation, while inhalation may provoke coughing or headaches. Waste disposal follows halogenated organic waste streams and requires professional oversight to prevent release into the environment. I’ve always stressed double-checking that all glassware and reaction surfaces get decontaminated after use, since the compound’s volatility mandates vigilance to avoid unintended exposure. Routine safety audits in production facilities focus on ventilation, labeling, and emergency response protocols, aligning with globally recognized standards like GHS.

Application Area

Ethyl 4-bromopentanoate has earned a place in medicinal chemistry, crop science, fragrance, and material research. In early-stage drug discovery, medicinal chemists incorporate it to build small molecule libraries for high-throughput screening, tailoring the final skeleton with impressive precision. Crop protection research employs it in the synthesis of novel pesticides, especially where stable aliphatic chains play a key role. Specialty chemicals companies source it for producing intermediates in flavors and fragrances, leveraging the ester’s volatility and reactivity. Material scientists also pick it as a customizable precursor for polymerizable esters, thus bridging organic chemistry and applied materials engineering. Across these fields, the ability to swap functional groups onto the pentanoic chain has practical consequences—finding applications not just on paper but right in the products or treatments people experience every day.

Research & Development

Active research around ethyl 4-bromopentanoate focuses on unlocking new transformations that save time, reduce hazardous byproducts, and plug into the needs of green chemistry. Enzymatic routes to produce or modify the ester offer lower-impact alternatives to metal-catalyzed chemistry, and recent years have seen journals publish strategies combining microwave irradiation or flow synthesis to scale up production without losing selectivity. As demands for sustainable practices grow, innovators test cleaner solvents and milder bromination agents. Universities and start-ups invest in mapping out reactivity under biocompatible conditions, which impacts the future of both pharmaceuticals and life sciences. My own colleagues often turn to this compound precisely because its reactivity offers plenty of possibilities—not just in improving synthesis, but in trialing new equipment or technologies that could change how labs work.

Toxicity Research

Studies on the toxicity of ethyl 4-bromopentanoate show that it acts as an irritant, both to skin and mucous membranes. In vitro tests and animal studies provide data on acute exposure, but long-term risks depend on factors like dose, duration, and route of exposure. Regulatory agencies keep a close eye on halogenated esters. Data reported in REACH dossiers suggest low acute toxicity but underscore the need for careful storage and waste management due to possible bioaccumulation or breakdown into more persistent byproducts in the environment. Research teams working on new applications must navigate a patchwork of safety data, often supplementing incomplete assessments with in-house studies to verify that process residues do not trigger unforeseen problems. It’s clear that vigilance, both in personal safety and environmental management, is not optional.

Future Prospects

The track record of ethyl 4-bromopentanoate points to continued use as a nimble intermediate, but there is also growing interest in pushing boundaries. Breakthroughs in catalytic chemistry may soon allow the selective functionalization of unactivated alkyl bromides like this, opening routes once considered too challenging for routine synthesis. Regulatory shifts, especially in Europe and North America, encourage cleaner production processes, so process chemists invest heavily in greener alternatives that maintain efficiency. Synthetic biologists keep exploring engineered microbes or enzymes that accept halogenated esters as substrates, hinting at a future where even more sustainable, scalable production becomes routine. The march of automation and digitalization in chemical research also changes the workflow, with reaction optimization, predictive modeling, and lab robotics taking a more direct role in developing or applying molecules like ethyl 4-bromopentanoate. In summary, history and ongoing innovation alike say this small ester will stay woven into the next generation of synthetic chemistry, as both a tool and a test case for modernizing operational standards.

Understanding the Chemical Makeup

Ethyl 4-bromopentanoate might sound intimidating to folks who haven’t dug through stacks of organic chemistry textbooks. Despite the long name, breaking down its formula follows a logic that makes chemistry less of a mystery and more of a puzzle. The name itself tells you what’s there: an "ethyl" group attached to a "4-bromopentanoate" skeleton. Out in the real world, knowing the exact chemical formula can help with more than just passing a quiz. Chemists, pharmaceutical teams, and manufacturers rely on that information to create, store, and label substances safely and accurately. The chemical formula for ethyl 4-bromopentanoate is C7H13BrO2.

Seeing the Structure in Everyday Work

Visualizing the connections isn’t for show—it keeps everyone safe and helps prevent expensive mistakes. In labs I’ve stepped into, even seasoned chemists double-check formulas because swapping one atom or group can mean the difference between a smooth reaction and a ruined batch. Ethyl 4-bromopentanoate stands out for its bromo group at the fourth position on a pentanoic acid backbone, and an ethyl group tacked onto the ester, which changes both how it smells (fruity, often) and how it reacts.

Why Chemical Formulas Matter Now More Than Ever

Misreading a formula in a professional setting isn’t just embarrassing. One wrong letter—the kind students sometimes mix up during a rushed exam—can derail a project in industry. I’ve watched teams burn through hours correcting labels and MSDS sheets after realizing a formula printed on an order slip was for a similar, but not identical, compound. Precision matters, especially for compounds like ethyl 4-bromopentanoate, which see use as building blocks in pharmaceuticals, agrochemicals, and specialty chemicals.

Trust and Accountability in Chemical Sourcing

Credentials count for a lot, but clear chemical formulas and a solid reputation mean even more when companies source fine chemicals. Buying from suppliers who gloss over details or mix up formulas can lead to regulatory headaches or, worse, unsafe working conditions. Ethyl 4-bromopentanoate, with its formula of C7H13BrO2, illustrates the need for companies to vet their sources and keep open lines of communication with their technical staff. I’ve seen trusted suppliers win lasting business for years, just by answering technical questions quickly and honestly, and being transparent about their own quality checks.

Solutions: Making Sure Details Don’t Slip Through the Cracks

Keeping things accurate doesn’t just rest on the shoulders of one chemist. It takes a chain of responsibility—lab managers who double-check incoming shipments, software systems designed to flag errors, and staff trained to recognize the difference between compounds with similar names but different formulas. Reviewing safety data and confirming supplier documentation can head off problems before they happen. Supporting continual training and quick access to reference materials helps everyone stay on the same page, and that pays off by building trust, reducing risk, and keeping the workplace a lot safer.

Why Chemists Care About Ethyl 4-Bromopentanoate

Chemistry has this knack for finding purpose in molecules most folks have never heard of, and ethyl 4-bromopentanoate fits right in. Most people outside of labs won’t spot it at the grocery store or hardware shop. Instead, this compound pops up in research papers and factory catalogs for one main reason: it makes for a sturdy building block in the world of organic synthesis.

The Pharmaceutical Angle

Drug makers run through long checklists of chemicals as they build new therapies. For many medications that treat infection, monitor heart rhythm, or even target cancer cells, small changes in the skeleton of a molecule can decide how well a medicine gets absorbed, reaches cells, or avoids side effects. Ethyl 4-bromopentanoate helps because it joins easily with other carbon-based pieces, which is the bread and butter of medicinal chemistry. Companies value this compound for its knack at introducing a five-carbon chain with a halogen twist—something that often boosts potency or lets researchers slot in further changes later on.

A strong example comes from the field of antiviral and antibiotic development. Adding segments shaped by ethyl 4-bromopentanoate can give those medications more staying power in the bloodstream or change how they sneak into bacteria or viruses. That small tweak often makes the difference between a so-so candidate and a promising new drug.

How It Shapes Agrochemicals

Farmers don't think much about chemical precursors, but folks designing crop protection do. Many pesticides, herbicides, and fungicides need a bit of tricky chemistry before they become effective in the field. Ethyl 4-bromopentanoate shows up at the half-way point in some of those recipes, giving chemists control over how a pesticide breaks down outdoors or how tightly it locks onto pests and weeds.

To keep crops safe and limit environmental side effects, chemists use compounds like this one to build new molecules that are strong enough to work, but not so stubborn they linger forever in soil. By starting with a brominated compound, scientists give themselves a handle for further reactions, such as swapping out groups that decide water solubility or environmental stability.

Material Science and Creative Synthesis

Outside medicine and farming, the specialty chemicals industry leans on ethyl 4-bromopentanoate as a launching pad for designing custom molecules. Surface coatings, flavor molecules, and even advanced polymers need backbone molecules that offer both length and flexibility. If a project needs to tack on a five-carbon chain—something found in everything from lubricants to adhesives—chemists often look for esters with a reactive twist like this one.

In research labs, both graduate students and senior scientists spend long hours combining it with amino acids, aromatic rings, or other small fragments. The results can be starting points for dyes, flavors, or even advanced diagnostic tools. This chemical doesn’t get spotlight billing, but it keeps R&D moving in both academic and commercial settings.

Handling and Regulation: Safety Matters

Direct contact with ethyl 4-bromopentanoate requires gloves, goggles, strong ventilation, and care with disposal. In the United States, the Environmental Protection Agency and Occupational Safety and Health Administration both outline steps for storing, labeling, and disposing of organic bromides. Following safety procedures protects workers while keeping accidental spills or leaks in check.

Where to Go From Here

The world of specialty synthesis will keep relying on compounds like ethyl 4-bromopentanoate. As students look to green chemistry and companies seek safer products, demand will shift toward routes that minimize waste and reduce hazards. Researchers also look for alternatives that use less toxic reagents, lower energy, and produce less byproduct while keeping the versatility that makes this compound a lab staple.

Why Respect the Chemical?

Working with Ethyl 4-Bromopentanoate reminds me of some lab jobs early in my career. As a young researcher, I found out quickly that clear, practical habits around chemicals make the difference between safe work and serious accidents. Ethyl 4-Bromopentanoate looks like a clear liquid, but hiding behind that appearance, it packs a punch. Breathing its vapors or splashing it on your skin can irritate, or worse, cause lasting harm. Because so many organic chemicals like this one slip easily through gloves, I learned that gear has to be chosen carefully, and not just based on price or comfort.

What Personal Protection Makes Sense?

Start with gloves tested for this family of esters and haloalkanes. Nitrile or Viton gloves block these chemicals much better than old latex ones. In my own lab work, nitrile became a staple, and doubling up never felt like overkill, especially on long syntheses. Goggles mean full goggles—no open-sided safety glasses. Faceshields join the mix if there’s risk of splashing. Chemical coats or aprons go on over regular clothes, and shoes cover any exposed skin, no flip-flops or sandals. Don’t skip the fume hood. I remember a colleague thinking a cracked window would air things out — not even close. Real airflow comes from a certified fume hood, and it makes a huge difference to air quality during and after an experiment.

Handling and Storage Habits from the Real World

Store Ethyl 4-Bromopentanoate in tightly closed containers made of glass or fluorinated plastic. Label them in clear, permanent ink so no one grabs the bottle by mistake. Keeping incompatible materials separated in storage cabinets seems common sense, but in practice, bottles end up shuffled so regularly it takes discipline to maintain order. I saw a near-miss in a university lab when acetone and a brominated ester mixed due to careless shelving. The lesson stuck: keep shelves tidy and consult the Material Safety Data Sheet for incompatibilities like strong bases, acids, or oxidizers.

Airing Out the Lab and Spills

Proper ventilation always matters. Some folks try to save energy by shutting off hoods or using makeshift setups. That’s playing dice with health. Ventilation systems, especially hoods, protect your lungs from both strong odors and invisible toxins. If a spill happens, don’t rush. My own mistake with a solvent spill—trying to mop up before grabbing the right absorbent materials—taught me that time spent prepping spills pays back in safety. Use inert absorbents, like vermiculite, and gather protective gear before even approaching the mess. Waste disposal isn’t just tossing the rags; seal waste in labeled containers and follow hazardous waste rules, or risk both fines and harm to others.

Training and Knowing the Signs

I’ve noticed even seasoned chemists sometimes treat refresher safety training as a hassle. But every new group member brings different habits, and clear demonstrations of good handling reinforce best practice. If you ever smell something sharp or sweet, or if your skin tingles or eyes water, it’s often a sign things aren’t right. Get fresh air fast and alert your coworkers. I keep emergency numbers and safety shower locations in mind on every job. It only takes one close call to realize you want those details automatic in your mind.

Keep the Focus Local and Personal

Working with chemicals isn’t about memorizing rules from a book. It’s personal. Every accident prevented means someone gets to go home healthy. The small choices—using tested gloves, storing properly, cleaning up with the right tools—stack up. I’ve seen the results of taking shortcuts, and I’ve seen the peace of mind that comes from practicing good habits until they’re second nature.

Understanding What’s at Stake

Chemists often cross paths with Ethyl 4-Bromopentanoate while preparing more complex molecules in the lab. I’ve handled it myself during an undergraduate synthesis project. Like many organic esters, it looks harmless—clear, colorless, has a familiar fruity smell, bottled up in amber glass. But there’s more to its storage than slapping it on a shelf and walking away. Responsible storage protects both the material and those who work around it. Open a poorly stored bottle and you might get a faceful of strong fumes, or discover it’s degraded, setting your research back days or weeks.

Storage Should Not Be an Afterthought

Every experimentalist learns quickly that environment shapes chemical stability. Ethyl 4-Bromopentanoate likes cool, dry, and dark places. I can remember one time, during a rush to get data, a colleague left a bottle in the sun near a window. Two days later, the contents smelled off and the bottle cap looked corroded. That lesson stuck. Direct sunlight triggers decomposition, which can break down your compound or turn it into something hazardous. Temperature swings and moisture let hydrolysis creep in—now your expensive ester has turned into a sticky mess and maybe even formed hydrochloric acid inside the bottle.

Best Practice: What Works in the Real World

At my lab, we store Ethyl 4-Bromopentanoate in a dedicated chemical refrigerator, set just above freezing, separate from acids and bases. This keeps the vapor pressure low so the ester stays put, not floating into the air. The bottle always closes tightly, and we label it with the date opened. I never trust generic shelves for reactive organics. On regular storage, even a little heat speeds up decomposition. Flammable liquid storage cabinets do a solid job at room temperature, but for anything you expect to use slowly or keep for months, cold storage wins out.

Humidity plays a quiet villain. Desiccators work for chemicals used infrequently. Moisture seeps in after enough time, so we replace desiccants each month. We keep chemicals in their original containers whenever possible. If transferring, only glass containers with PTFE-lined caps enter the fridge. Screw caps made from other plastics let vapors through and ruin your sample faster than you’d think.

Don’t Ignore Ventilation and Safety

Sneaky fumes are enough of a risk with most esters. I once had a bottle leak inside a storage bin, and the smell filled the prep room. That was a wake-up call—good airflow and spill containment aren’t optional. Work upwind of storage, avoid opening old containers inside crowded spaces, and store spill kits and absorbent pads nearby.

Staying Ahead of Problems

Lax storage brings regulatory headaches too. Many countries treat esters with bromine as hazardous: they need proper labeling, records, and disposal logs. I routinely check bottles for crystal buildup or cap corrosion, which point to leaks or decomposition. If something’s wrong, I tag it and arrange safe disposal.

Getting storage right means fewer wasted experiments, improved personal safety, and lower risk of dangerous breakdowns. Reliable containers, cold temperatures, dry environments, and good ventilation—these habits add up to hassle-free, safe chemistry, whether you’re making grams or prepping for pilot scale.

A Real-World Look at Chemical Grades

People working in labs, small companies, or universities often see a long list of purity options before buying chemicals. Ethyl 4-Bromopentanoate is no exception. Some suppliers display “technical grade,” “laboratory grade,” and “analytical grade” right on the page. The differences aren’t just labels—they shape everything from price to the way research turns out.

Quality Really Matters

I’ve seen a researcher double-checking certificate of analysis documents before ordering. She knew the stakes: an impurity or trace solvent could cancel weeks of work. With ethyl 4-bromopentanoate, small changes in purity can swing yields in synthesis or cause strange side reactions. A few percentage points of extra water or leftover byproducts, and a whole experiment can head off in an unexpected direction.

The high-purity grade usually lands in highly sensitive tasks, like pharmaceutical intermediate development or targeted organic synthesis. Low-grade material sometimes finds use in industrial-scale testing, teaching labs, or other spots where slight inaccuracies won’t wreck a process or pose a safety risk.

Ease of Purchase, Safety, and Trust

Online shopping for chemicals looks simple on the surface, but cutting corners rarely pays off. Cheap, untested ethyl 4-bromopentanoate sometimes comes without clear labeling, and that puts both safety and scientific reliability on thin ice. I’ve heard about colleagues who ended up with mislabeled grades, causing headaches that could have been dodged by buying from well-reviewed vendors. Lab fires, exposure, or unexpected fumes make people slow down and look for detailed safety data sheets before even touching new bottles. Extra leftovers, traced in the analysis, could introduce hazards that escape basic training or routine assumptions.

Cost Versus Results

Everyone worries about budgets—especially in academic or start-up environments. Spending double for the highest grade stings at first, but nothing hurts like repeating an entire series of syntheses. Analytical and high-purity grades carry a premium, but ending up with reliable, reproducible results makes the cost worthwhile for complex research. Anyone doing routine or industrial chemistry can decide if a technical grade will work, but it pays to check what’s really in the bottle. Some grades might include extra water, traces of other esters, or unknown hydrolysis products. These contaminants can swing simple yields but cause bigger issues in regulatory or quality-controlled environments.

How to Make an Informed Choice

Reading technical bulletins, customer reviews, and supplier certifications guides people past clever marketing toward solid choices. Transparent suppliers provide assay data, spectroscopic confirmation, and reproducible specs. That creates trust. Many labs require chain-of-custody paperwork, batch certifications, or direct communication with tech support before a purchase. Skipping these steps can mean introducing variables into otherwise careful work or even risking safety. Anyone ordering ethyl 4-bromopentanoate can benefit from picking up the phone, asking about quality controls, or asking peers about supplier history. Cross-checking details gives peace of mind and better outcomes.

What Works: Sharing Knowledge and Solutions

Building strong channels of communication across labs and suppliers solves real problems. If a supplier starts offering a new grade with better specs or safety info, a single email thread can inform a whole department. Online forums and group discussions help colleagues avoid common pitfalls or discover new, reliable sources. Reliability and safety benefit from sharing real experiences, not just reading catalog entries. Judging the right grade takes experience, documentation, and a bit of trust—but those who invest in learning the details save time, money, and headaches in the long run.