Ethyl 4-Chlorovalerate: A Down-to-Earth Look at Its Story and Uses

Historical Development

Years back, the search for unique building blocks in organic synthesis brought ethyl 4-chlorovalerate into labs. Chemists saw the need for reliable intermediates capable of supporting more complex creations in pharma, plastics, and flavors. Not one of the household names, but its roots stretch back to the early surge of ester chemistry in the last century. Folks grew used to handling related chlorinated esters for making medicines and perfumes, and with time, found usefulness in the selective placement of chlorines on alkyl chains. As industry priorities shifted towards efficiency and specificity, ethyl 4-chlorovalerate worked its way into more advanced applications, from research to pilot-scale production runs.

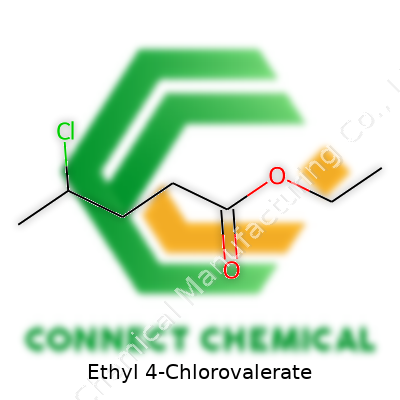

Product Overview

Ethyl 4-chlorovalerate belongs to the family of alkyl chlorides and esters, positioning itself between simple lab reagents and specialty intermediates. With a structure that combines a five-carbon backbone, a terminal chlorine, and an ethyl ester tail, it bridges easy handling and reactive potential. Manufacturers and research teams order it by purity and packaging, chasing consistent batches that keep complex synthesis rolling without setbacks. In my experience, this compound rarely gets left on the shelf, since it finds a place in everything from pharma experiments to advanced materials research.

Physical & Chemical Properties

Most first encounters reveal a colorless to pale yellow liquid. Its distinctive sweetish odor catches attention in poorly ventilated labs. The boiling point often hovers just above 200 °C, telling you it holds some thermal stability but shouldn’t be recklessly heated. Chemically, this compound offers a reactive chloride that opens the door to nucleophilic substitution, while the ester group sets up possibilities for transesterification or reduction. It dissolves in most organic solvents like diethyl ether, acetone, or dichloromethane, fitting neatly with common synthetic routes and purification steps. In my lab days, careful storage avoided any hydrolysis from damp air and frustration from unplanned impurities.

Technical Specifications & Labeling

Packaged for both research and industry, ethyl 4-chlorovalerate ships with detailed purity grades, usually from 95% up to 99%. Material safety data sheets spell out hazards, first aid, and reactivity under various storage conditions. Suppliers stick to UN shipping codes and clear labeling, which ensures anyone on the receiving end—chemist or warehouse manager—knows exactly what’s inside. Handling guidelines often stress the need for gloves, goggles, and decent ventilation. Errors in labeling or improper documentation in my early years almost always ended with interrupted work or even official audits, highlighting why detailed technical specs help avoid bigger legal and safety headaches.

Preparation Method

A classic route starts with 4-chlorovaleric acid, which itself comes from the controlled chlorination of valeric acid. Reacting this acid with ethanol under acid catalysis creates the desired ester. Sometimes, the acid chloride dances in first, but most folks favor direct esterification for cost and simplicity. Care with water exclusion ensures an efficient yield, letting the reaction reach completion without constant rework. In multi-kilo batches, continuous removal of water and temperature control becomes critical, since side products tank overall yield and purity. I’ve seen labs rely on Dean-Stark traps, drying agents, and non-aqueous distillation just to beat the odds of stray moisture.

Chemical Reactions & Modifications

Ethyl 4-chlorovalerate’s main job: act as a springboard in stepwise chemical synthesis. The reactive chloride doesn’t sit idle, often finding new partners in nucleophilic substitution, where amines or alkoxides displace chlorine for more functionalized offshoots. Grignard reagents, when added, can swap esters for more complex alcohols—tricks frequently used in medicinal chemistry. Hydrolysis under basic or acidic conditions quickly drops the ester back to the acid or even strips it to simpler, sometimes volatile, fragments. Modifications abound, depending on the group you introduce or remove, and every chemist picks the route that matches their desired end-point and available kit.

Synonyms & Product Names

Searching catalogues or scientific articles shows ethyl 4-chlorovalerate under a handful of aliases. Common labels include ethyl 4-chloropentanoate, 4-chlorovaleric acid ethyl ester, or even 4-chloropentanoyl ethyl ester. Each name cues chemists to its unique structure, easing literature searches and order forms. Different vendors might tag it by internal stock numbers, but the core identity stays clear. I’ve seen mis-orders trace back to mistaken identity, demonstrating why thorough double-checking of synonyms pays off in saved time and budget.

Safety & Operational Standards

Lab safety matters with ethyl 4-chlorovalerate. It can irritate skin and eyes; accidental splashes send you to the eyewash or shower. Vapors irritate lungs, reminding everyone to keep fume hoods running and wear protective masks if spills happen. Proper waste collection—never tipped straight down the drain—prevents accidental release into water systems. Operations within closed systems or properly vented setups remain best practice to reduce risk. Training newcomers in these standards prevents both minor headaches and large-scale lab emergencies. As I learned, even quick negativity tests reduce the odds of a near-miss.

Application Area

Pharmaceuticals lean on ethyl 4-chlorovalerate during early-stage synthesis, where chained modifications lead to candidate drugs. Agrochemical research uses it for new molecules with tailored physical and biological behaviors. Fragrance makers and specialty chemicals manufacturers like its versatility for building up base ingredients. Academic labs push boundaries in fields like catalysis and cross-coupling, drawing on its reliable reactivity to map new chemical territory or train students. Stories from colleagues show its value in small-scale invention and broader industry trends, tying one reactor experiment to global markets in medicine, plastics, and beyond.

Research & Development

Current research branches out in directions that test its patience and flexibility. Drug developers use ethyl 4-chlorovalerate to reach chiral frameworks hard to access by traditional means, sometimes setting new benchmarks for efficiency per step. Scientists explore lower-waste, greener production routes through continuous flow or biocatalysis, sparking intellectual debates about best practices and actual sustainability gains. In analytical work, improved detectors now catch parts-per-billion traces, tightening up batch purity controls for high-value syntheses. People publish new routes or catalytic cycles nearly every year, giving fresh context to longstanding chemistry.

Toxicity Research

Animal studies pin down acute and chronic toxicity profiles, flagging risks before plant workers or end-users face them. Most effects hit skin, eyes, and respiratory systems, matching real-life lab incidents. Data shows oral and dermal LD50 lays closer to the lower end for similar esters—enough for a few caution signs in storage. Environmental tests map out breakdown products, aiming to catch or neutralize the molecule before it lingers in soil or streams. Local regulations tighten standards, with many labs cycling through extra training or even switching solvents and distillation residues to certified waste handlers. My own experiences cleaning up minor spills underlined the sticky, sometimes persistent nature of chlorinated byproducts.

Future Prospects

Trends point to new methods for greener production, lower-waste disposal, and tighter tracking along the supply chain. Automated chemistry platforms and machine learning keep finding fresh ways to tweak preparation for less hazardous byproducts and higher overall yield. Regulatory controls push for smarter documentation, especially as consumer goods trace ingredients right to the source. From my perspective, the demand for versatile intermediates like ethyl 4-chlorovalerate won’t decline, since both old and new industries push for efficiency. As chemical innovation marches forward, the compound stands as one more piece in the evolving puzzle of modern synthesis, linking practical chemistry to larger questions of safety, sustainability, and global supply.

Digging Into Chemical Building Blocks

Ethyl 4-chlorovalerate might sound like a mouthful, but behind that name sits a substance with real-world ties to what we use and wear. This compound often pops up as an intermediate — basically, a stepping stone — in chemical manufacturing. If you’ve ever wondered how the flavor in some foods gets brighter or why certain fragrances linger, odds are good that intermediates like ethyl 4-chlorovalerate helped shape the molecules that make those products work.

Making Medicine and Health Products Work

For pharmaceutical labs, this compound stands out as part of the toolkit for building bigger, more complex drugs. Scientists rely on it to stitch together molecules used to combat infections, support heart health, or offer pain relief. Not every pill on the pharmacy shelf owes its kick to a blockbuster compound; plenty get their structure from careful, step-by-step work with ingredients like this one. Each batch depends on consistency and lab trust, both crucial for patient safety.

Flavors, Scents, and Everyday Chemistry

Take a second to think about your morning routine. From toothpaste flavors to the crisp scent of your favorite detergent, ingredients like ethyl 4-chlorovalerate often hide behind the label. They serve as the backbone for synthesizing other chemicals that flavor and fragrance companies count on. Around the globe, these industries keep close tabs on purity and sourcing, thanks to regulations that push toward safer, more predictable results for consumers.

Supporting Clean Manufacturing

As a chemical with a clear structure, ethyl 4-chlorovalerate slots into green chemistry efforts. Researchers keep tweaking how they make and use it to cut down on waste and avoid hazardous byproducts. In a world where factories get scrutinized for air and water pollution, safer intermediates become more valuable. I remember speaking with a chemist who described how her lab’s process changes meant local streams saw less chemical runoff. Small shifts in one step can ripple through an entire supply chain.

Regulatory and Safety Focus

Handling tasks with chemicals, especially in bulk, means safety comes first. One company I visited in the Midwest ran constant training sessions for their crews, with everyone wearing gloves and eye protection each time even a small vial of ethyl 4-chlorovalerate got opened. Regulators require paperwork for transport and storage so that spills or accidents don’t become disasters.

Room for Improvement

International demand for reliable intermediates keeps growing. That brings up supply chain pressures, including sourcing quality raw materials and fair labor practices. With more watchdogs paying attention, manufacturers have to earn trust with each shipment — both on paper and in the drum. Automation and digital tracking stand out as options to keep records clean and batches traceable. Where firms follow the rules, end users benefit: purer products, fewer recalls, safer workplaces.

Building a Safer, Smarter Industry

So much of modern manufacturing depends on hidden helpers like ethyl 4-chlorovalerate. Drawing from lessons learned in both the lab and the warehouse, companies push toward cleaner synthesis, smarter regulation, and real-world impact for both industry workers and everyday people. The results end up in the things we trust every day, whether that’s medicine, a meal, or the air around us.

Molecular Formula and Weight: Facts, Not Mystery

Ethyl 4-chlorovalerate is a name that might sound like something reserved for a college organic chemistry exam, but it’s found well beyond the lab. Let’s get to the point: its molecular formula is C7H13ClO2. This arrangement gives you seven carbon atoms, thirteen hydrogens, one chlorine, and two oxygens. I remember squinting at skeletal formulas in textbooks, counting the lines and corners—hoping nothing slipped past. Organic molecules like this require a good bit of focus to visualize, but the core components never change.

If you work with chemicals, the molecular weight matters almost as much as the formula itself. Ethyl 4-chlorovalerate weighs in at 164.63 g/mol. This number is not just for trivia. Anybody measuring out reactants, whether in a pharmaceutical lab or a small synthesis workspace, learns to appreciate the difference a single chlorine atom makes. I once misread a label and used a similar compound in a reaction—off by a handful of grams, the calculations became useless, wasting time and money. This underscores why accuracy in molecular weight goes beyond paperwork.

Why Ethyl 4-Chlorovalerate’s Structure Deserves Attention

Chemistry classes always hounded me about the importance of functional groups. Ethyl 4-chlorovalerate carries an ethyl ester group connected to a valeric acid backbone, with a chlorine sitting on the fourth carbon. The combination packs unique properties. In applied settings, features like this matter: esters contribute to fragrances and flavors, while the chlorine atom can alter reactivity and metabolic pathways. This compound can pop up in synthetic routes for more complex molecules, sometimes appearing during the research of new drugs or agrochemicals.

Scientists act as detectives, tracing atoms through reactions to develop better medicines or safer pesticides. The chlorine’s presence might affect how a molecule breaks down or attaches to biological targets. In my years handling analogs, sometimes one small substitution—like this chlorine—meant the difference between a minor byproduct and a promising pharmaceutical lead. That’s real-world impact, not just theory.

The Risks and Responsible Use

With any compound, practical knowledge helps avoid trouble. Handling chlorinated esters demands proper ventilation and personal protection. I remember old labs with poor airflow; headaches and coughs turned routine tasks into headaches. No shortcut beats gloves, goggles, and a fume hood. Small mistakes add up quickly, and chemical safety culture grows from respecting every bottle’s label and datasheet.

Ethyl 4-chlorovalerate, like many synthetic intermediates, doesn’t grab headlines, but it fills an important niche. Synthetic chemists learn through experience that details count. Errors in molecular weight calculations or formula identification can ripple into experiments that flop or, worse, cause harm. The proper checks—like double-confirming the chemical’s identity and handling requirements—reduce waste, lower risks, and save resources.

Building Better Chemistry Knowledge

Accessing accurate information remains key to safe and innovative research. Basic facts, like the molecular formula and weight, may sound simple, but they underpin everything from school projects to advanced pharmaceutical development. My experience showed that seeking verified sources and consulting reliable databases helps avoid costly confusion. Simple steps—stopping for a moment to cross-check—make all the difference.

Ethyl 4-chlorovalerate teaches a lesson: chemistry rewards attention to detail. Whether mixing milligrams in a lab or reviewing a new research paper, the fundamentals shape every outcome, big or small. Getting those numbers right lets you focus on discovery rather than damage control.

A Practical Look at a Common Chemical

Ethyl 4-chlorovalerate turns up in several chemical labs, mostly during synthesis. While its uses can feel distant to anyone outside the field, safe storage should matter to every person who works with it. I remember the first time I handled it during an undergraduate practical, the professor stressed preparation as much as procedure. Safety starts before opening the bottle.

Knowing the Hazards

This chemical isn’t something anyone should treat casually. It gives off vapors, and skin contact causes irritation fast. The label says “Harmful if swallowed,” but real concern kicks in before anyone even considers the taste. A spill fills a small room with an odor that lingers long after cleanup, a real sign this compound wants out if not managed right.

Key Storage Practices

Ethyl 4-chlorovalerate stores best in a spot that discourages leaks and limits accidental contact. A flammable liquids cabinet built to handle solvents works well. Cabinets should sit away from heating sources and direct sunlight, giving each bottle a calm, cool environment. I’ve seen what happens when these rules are ignored—a coworker paid the price with a cracked bottle and a strong, stinging cloud.

Temperature stability counts for a lot. Fluctuations can weaken container seals. A routine habit of checking lids for tightness makes a difference. Original containers offer the best guarantees. If repacking, always use glass or certain plastics designed for industrial chemicals. Containers never belong on shelves above shoulder height. If one tips, gravity does the rest, and splashes become more dangerous than they should have been.

Moisture and Chemical Compatibility

This ester reacts with water. Humidity sneaks into a cracked cap. Dehumidified storage areas, especially in regions with damp air, help prevent slow breakdown. It pays to list what else sits nearby. Storing acids or bases on the same shelf can cause big trouble fast. Any container that leaks or bulges deserves full attention—no one wants a surprise in the morning.

Labeling and Monitoring

Clear labeling helps everyone stay honest about what’s inside the jar. Permanent ink, chemical-resistant labels, and recorded dates make tracking age and condition easy. Ethyl 4-chlorovalerate won’t last forever. Over time, old stock becomes unstable or useless. Rotation makes sense. Using up older material before new keeps surprises to a minimum. I’ve dug out forgotten bottles that looked fine, but a cracked lid told another story.

Solutions That Actually Work

Many places now use digital inventory logs as a backup to handwritten labels. Sensors that track cabinet temperature and humidity don’t forget, even after a late shift. Installing a vented storage system in crowded labs isn’t a luxury—it’s a basic way to stop vapor buildup. Old habits make room for new safety gear too. Disposable gloves, splash goggles, and work aprons belong nearby storage areas, not at a distant station.

People Matter Most

Experience has shown me that accidents happen not from bad intentions, but from overlooked habits. Rules and facts support safety, but only real people keep each other honest. Regular reminders, group walkthroughs, and every set of eyes—these shape a lab culture. It only takes one mistake, but plenty of chances to get things right. Storing ethyl 4-chlorovalerate with respect does more than follow regulations. It protects every person who may come close, today and tomorrow.

Understanding the Chemical

Ethyl 4-chlorovalerate shows up in labs, especially those working with pharmaceuticals or specialty chemicals. Looking at its structure, you’ve got an ethyl ester and a chlorine atom in the mix. That combination nudges it into a category where a little more care makes sense. Anyone who’s handled organic solvents or esters in daily lab work might spot it on a shelf and instinctively reach for gloves and goggles—these moves come out of experience, not habit.

Hazards Aren’t Always Obvious

Chemicals don’t yell their dangers. You have to read between the lines—or the Safety Data Sheet. Ethyl 4-chlorovalerate isn’t as infamous as cyanide or hydrochloric acid, but experience with similar esters tells us fumes and splashes shouldn’t be ignored. Respiratory irritation, eye stinging, and skin reactions show up when these compounds get out of bottles. The chlorine part of the molecule raises my guard. Chlorinated compounds, especially if they land on skin or if you accidentally sniff the vapors, can leave a mark or worse, trigger headaches and coughs.

Special Handling Doesn’t Mean Overkill

Thinking back to long days in chemical research, basic lab sense always gave the best protection. Ethyl 4-chlorovalerate belongs in a fume hood, not out on a crowded benchtop. Splash goggles instead of regular safety glasses give your eyes a better chance if things go wrong. If you trust cheap latex gloves, even for a minute, those might dissolve or split—nitrile or neoprene proved sturdier choices after one too many close calls.

People sometimes skip over the importance of good ventilation. Even without a strong smell, a volatile ester evaporates quicker than you realize. Without a fume hood, vapor exposure adds up, especially in smaller rooms. Workers who stay alert to the telltale tickle in their throats or that acetone-like sweetness in the air can avoid trouble by moving to fresh air sooner rather than later.

Waste and Storage: Real-World Risks

Every lab ends up with mystery bottles buried in the back of storage, but that’s where problems grow. Ethyl 4-chlorovalerate reacts with strong bases or acids and doesn’t play nice with oxidizers. Old containers lose their seals and vapor leaks out. Instead of playing lab detective later, folks label containers right away and tuck them into ventilated cabinets or safety cans. I’ve seen old solvents left without labels spark confusion and unneeded danger, especially for new staff or students.

Training and Preparedness

Safety starts before opening a bottle. My early mentors made sure everyone in the lab—students, techs, visiting researchers—knew not only the rules but the reasons. Emergency showers and eyewash stations need to be working and ready, without boxes or papers blocking access. Knowledge keeps people safe, and so does honesty. Someone who speaks up about a spill or an accident early gives the whole team a better shot at fixing things.

Small Steps, Big Impact

The bottom line: ethyl 4-chlorovalerate doesn’t call for a hazmat suit or triple flaring alarms, but it does deserve respect. PPE, ventilation, clear labeling, and straightforward training stop accidents before they start. In my own work, a bit of diligence upfront always paid off much more than any scramble to fix a mistake after the fact. Sometimes, it’s these overlooked middle-tier chemicals that surprise you most—they act quiet until someone pays the price for not paying attention.

Looking Beyond the Label: Why Purity Counts

Ethyl 4-chlorovalerate appears in research catalogs as a simple ester, but this molecule prompts big questions in real-world chemistry labs. For anyone tackling organic synthesis or scaling up a critical pharmaceutical pathway, purity isn’t just a detail. Even trace contaminants can rewrite reaction pathways or muddy up downstream analysis. So, researchers and manufacturing teams demand the kind of precise data that ensures results, not just repeatability, but also trust in their work.

Industry standards push for high purity, and that usually means 97% or greater for Ethyl 4-chlorovalerate. Major suppliers publish certificates of analysis with each shipment, showing not only the stated purity but also the major impurity profiles, moisture content, and even residual solvents. This transparency protects both small-scale labs, where a failed batch can waste months, and commercial production, where a contaminant could threaten product safety.

Packaging Matters: Matching Quantity with Demand

Most chemists remember the frustration of having either too little or way too much of a specialty reagent. With Ethyl 4-chlorovalerate, packaging isn’t just convenient; it protects against waste, exposure, and poor shelf life. Common supplier offerings start with 25-gram or 100-gram bottles, perfect for synthetic chemistry routines and method development. The 500-gram and 1-kilogram packaging suits pilot runs and mid-scale production, where you need steady quality across repeated uses.

Larger commercial partners sometimes request bulk quantities—think steel drums of 25 kilograms or more. But shipping bigger volumes poses its own risks, from exposure to air and humidity to breakage or spillage. Reliable suppliers use glass or specialized polymer bottles with high-integrity seals, sometimes surrounded by secondary containment, to avoid product degradation or loss during transit. Choice of packaging depends on how much material you need right now, but also on how you plan to store and use it in the coming months.

Where Lab Safety and Efficiency Intersect

Packing chemicals into smaller, properly labeled containers goes beyond cost control. Each transfer—from bulk drums to 100-gram bottles, for example—comes with risks of mix-up, impurity introduction, or contamination. Suppliers committed to quality control conduct packaging under controlled atmospheres, and batch numbers or lot tracking keep every gram accounted for. Researchers can then match exactly which batch delivered a specific set of results. This traceability supports not just scientific rigor, but regulatory compliance in fields like pharmaceuticals and food science, where documentation builds the legal framework for safe products.

Facing Real-World Challenges

Packing and purity often take a back seat to price for buyers under pressure, but every penny saved up front might come back as dollars lost in wasted effort or failed regulatory audits. I’ve seen colleagues spend weeks troubleshooting failed reactions, only to trace the outcome back to an old, off-spec bottle someone forgot in the back of a freezer. Spending a few minutes reviewing supplier documentation and ordering appropriate quantities at the right purity has saved both time and headaches.

Practical Solutions on the Table

Ordering from established suppliers who maintain transparent quality control, requesting lot-specific certificates, and sizing orders realistically for your needs—these habits keep most labs running smoothly and safely. Storing Ethyl 4-chlorovalerate in tightly closed containers, away from heat and direct sunlight, protects your investment. For those running larger programs, standardizing on a purity specification and working directly with manufacturers to arrange periodic quality audits offers peace of mind and consistency across product lines.

The purity and packaging of Ethyl 4-chlorovalerate aren’t just technical details—they make or break a safe, efficient lab. With knowledge, diligence, and a bit of foresight, research and industry teams can put this molecule to work reliably, batch after batch.