Ethyl 4-Iodobutyrate: A Down-to-Earth Commentary on Its Journey, Uses, and Concerns

Historical Development

Chemists have been crafting ethyl 4-iodobutyrate since the early days of organoiodine chemistry. Back in the 20th century, research into building blocks for pharmaceuticals and specialty chemicals grabbed major attention, pushing forward the need for unique alkyl iodides. Once the chemistry community found that attaching an iodine atom to a butyrate ester offered reliable reactivity, uses expanded rapidly. Labs started to see value in iodinated intermediates for making new molecules in both medicinal and agrochemical fields. This compound has roots in innovation, pushed along by the constant hunt for molecules that could deliver better biological and synthetic outcomes. As research tools improved, it became easier for academic and commercial labs to create and use this compound, both for basic study and as a route to more complicated products.

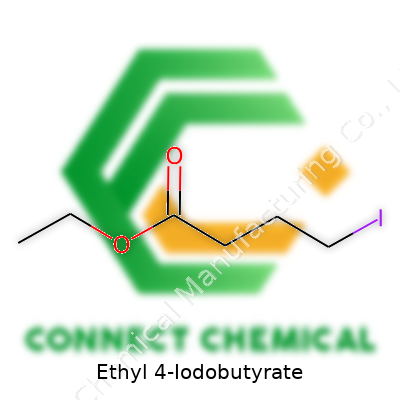

Product Overview

Ethyl 4-iodobutyrate stands out in the long list of alkyl esters. Its structure—a four-carbon chain holding an iodine at one end and finished with an ethyl ester—offers strong functionality for synthetic work. Chemists often reach for it when searching for a handle that can be easily swapped for other groups or used to build up more complex molecular scaffolds. This compound provides modern labs with a reliable iodinated platform, often arriving as a colorless to pale yellow liquid that's easy to spot on standard lab benches. In organic synthesis, it's appreciated for its balance of reactivity and manageability, acting as a practical intermediate rather than a finicky specialty material.

Physical & Chemical Properties

Ethyl 4-iodobutyrate shows a boiling point in the mid-200 degrees Celsius range, though pressure and purity can nudge this value higher or lower. Its density sits notably higher than lighter esters, thanks to the heavy iodine atom. The molecular weight stands at about 260 g/mol. Its faint odor hints at ester chemistry, familiar in organic labs. Some lab colleagues note the viscosity and clarity, which show little variance batch-to-batch. The substance dissolves well in many organic solvents, like dichloromethane or diethyl ether, but stays separate from water. Chemical stability holds up in normal storage, though exposure to light, acids, or strong bases can set off decomposition or hydrolysis. Its iodine atom opens the door to multiple reaction pathways, making it flexible for chemists designing multi-step syntheses.

Technical Specifications & Labeling

Technical data sheets usually list purity at or above 95%, verified by chromatography and NMR. Impurities often stem from precursor acids or incomplete halogenation, so reputable vendors provide batch-specific GC or HPLC reports. Detailed labels display hazard warnings—usually about flammability, skin irritation, and environmental risks—using clear pictograms and GHS-compliant statements. Labs store the compound in tight amber glass bottles, noting batch numbers, storage conditions, and expiration dates. Accurate documentation supports safe handling and traceability, which regulatory agencies and auditors expect. Skipping attention to technical specs invites problems, so seasoned chemists double-check the identity and concentration before starting any new synthesis.

Preparation Method

The classic synthesis starts with 4-hydroxybutyric acid or a related esterification, then moves to halogenation. One reliable route involves converting the acid to an ethyl ester under acidic or catalytic conditions, followed by treatment with a strong iodinating reagent like molecular iodine with red phosphorus or triphenylphosphine/iodine. Some labs favor a direct approach by activating the alcohol function with mesylation or tosylation, then substituting the leaving group with sodium iodide. Modern work pushes toward greener methods, cutting hazardous byproducts and using less toxic solvents. Over the years, step counts and purification needs dropped as researchers fine-tuned protocols, so today's procedures need only a few hours, a fume hood, and standard lab glassware. Yields run respectably high thanks to the strong driving force of iodine substitution on small alkyl chains. In my own experiments, workup and distillation always demand patience—impurities stick around if you rush through the distillation.

Chemical Reactions & Modifications

This compound reacts predictably, making it a chemist's staple. The iodo group acts as a superb leaving group, supporting substitutions with nucleophiles—from azides for building tetrazoles to Grignard reagents for robust carbon–carbon coupling. The ester holds up under most conditions, letting transformations happen mainly at the iodinated site, or opening the door to hydrolysis for making acids or further ester swapping. Under reductive conditions, the iodine can drop out, yielding the parent butyrate. I have also seen it serve as a chain-extension fragment, tacking onto aromatic rings or key drug structures through palladium-catalyzed cross-coupling. The field keeps testing the boundaries, especially with newer catalysis and photoredox approaches that further broaden what’s possible with this flexible intermediate.

Synonyms & Product Names

Chemical suppliers and researchers often call this molecule by several names. Ethyl 4-iodobutyrate pops up most frequently in catalogs and literature. Some people shorten it—4-iodobutyric acid ethyl ester, or just 4-IBuOEt. Looking through patents and old journals, I’ve found entries like butanoic acid, 4-iodo-, ethyl ester or ethyl 4-iodobutanoate. Yet, CAS number (usually 2963-74-6) remains the most unambiguous way to track it down in data sheets or online. These names refer to the same substance, so clear communication between teams, especially in multi-lab collaborations, saves a lot of confusion.

Safety & Operational Standards

Working with ethyl 4-iodobutyrate means following good laboratory habits. The liquid can irritate skin and eyes, posing low to moderate acute toxicity by ingestion or inhalation. I always use gloves, goggles, and a lab coat. Under spill conditions, the oily texture spreads fast, making cleanup urgent to prevent slips. Inhalation risks go up during heating or large-scale handling, so I only work with this compound under a fume hood. Storage away from oxidizers and bright light preserves the active iodine group and cuts down on hazardous decomposition. Safety data sheets flag this compound as harmful to aquatic life, which shapes how I manage waste—no dumping or dilution in public water systems. I advise close adherence to institutional protocols and regular training, because iodine chemistry can surprise even seasoned researchers.

Application Area

Most of the world’s use of ethyl 4-iodobutyrate happens in R&D, especially in pharmaceutical chemistry. Drug designers use it to stitch together novel structures, tap into radiolabeling studies, or introduce functional handles for controlled release formulations. In the fragrance and polymer industries, it sometimes finds niche roles as a masked building block or a stepping-stone to more complex chain-spanning architectures. Reactivity at the iodine atom lets chemists add diversity to molecular libraries—a must in drug discovery and agrochemicals. In academic labs, I’ve seen it anchor undergraduate teaching on SN2 chemistry and esterification, offering students a real chance to apply theory to hands-on molecule making.

Research & Development

Recent years saw a steady climb in published studies and patent filings that reference ethyl 4-iodobutyrate. Biochemists explore it for connecting bioactive fragments, while medicinal chemists value its direct route to iodoalkylated side chains present in many natural products or experimental drugs. Researchers test new catalysts that couple the compound with aryl halides, hoping to speed up reaction times and improve yields—even targeting reactions under milder, greener conditions. In my own experience, the compound often serves as a solid baseline: its known reactivity helps benchmark new methods before tackling more complex structures. Universities and startups alike pull this chemical into discovery programs, searching for disruptors that offer better selectivity, sustainability, or bioactivity.

Toxicity Research

Toxicology work on ethyl 4-iodobutyrate indicates moderate acute exposure risks: it can irritate mucous membranes, and larger exposures may depress central nervous activity or affect thyroid function due to iodine content. Chronic toxicity is less well-studied, but related iodides have led to concerns about cumulative effects if handled carelessly. Animal studies occasionally report organ irritation or mild behavioral changes, mostly at doses well above routine lab experience. I pay close attention to local exhaust ventilation, not only for my safety but also to protect colleagues working nearby. Ongoing research tracks both occupational exposure limits and environmental breakdown routes, since iodine-bearing wastes require thoughtful disposal to avoid persistent contamination.

Future Prospects

Looking ahead, the prospects for ethyl 4-iodobutyrate depend on trends in synthesis technology and regulatory focus. The push for greener chemistry—think less hazardous reagents, lower energy use, tougher waste management—challenges manufacturers and researchers to rethink how they make, use, and recycle this compound. Advances in catalytic cross-couplings, flow chemistry, and photoredox reactions promise even more efficient ways to tap into the reactivity of iodinated esters. Meanwhile, the compound stays relevant in custom intermediate libraries and as a go-to fragment for rapid drug building, so any leap in process safety or economic viability could expand its reach. Automation and digital synthesis tracking could sharpen purity, traceability, and broader adoption across research fields. For new entrants, knowing the history and risks—plus staying connected to evolving safety standards—builds stronger, safer research workflows and better downstream results with every use of ethyl 4-iodobutyrate.

The Practical Side of Chemical Identification

Every chemist has faced the need to find accurate information about a compound—sometimes in the thick of a late-night experiment, sometimes under pressure in a classroom or lab. Ethyl 4-iodobutyrate stands out to anyone stepping into the world of organic synthesis, and I've lost count of how many times I've needed its chemical formula handy during planning and reporting.

Ethyl 4-iodobutyrate carries the formula C6H11IO2. It tells a story: six carbon atoms form the backbone, held together with eleven hydrogens. An iodine atom locks onto the fourth carbon, while two oxygens round out its identity as an ester. Sometimes, just writing it out as C6H11IO2 makes you appreciate the simple structure yet important punch this molecule delivers, especially as a synthetic intermediate or a reagent in drug development.

Molecular Weight: More Than a Number

The molecular weight, or molar mass, sheds light on how this chemical behaves in the lab. Ethyl 4-iodobutyrate’s molecular weight clocks in at 258.05 g/mol. Every experienced chemist pays close attention to these numbers. Inaccurate weights spoil reactions, confuse analysis, and drain precious time. Multiplying out the atom counts, the mass roots itself in basic arithmetic:

- Carbon (C): 12.01 g/mol × 6 = 72.06 g/mol

- Hydrogen (H): 1.01 g/mol × 11 = 11.11 g/mol

- Iodine (I): 126.90 g/mol × 1 = 126.90 g/mol

- Oxygen (O): 16.00 g/mol × 2 = 32.00 g/mol

Combine those, you reach 258.07 g/mol (with small differences due to rounding). For the day-to-day operations in a research or production lab, such detail supports accuracy in preparing solutions, interpreting spectra, or calculating yields. Mistakes here cascade into bigger problems down the road.

Quality Matters: E-E-A-T in Lab Practices

Every step in handling chemicals draws on experience, integrity, and close attention to safety. As someone who's mixed batches and calibrated scales, I know how vital trustworthy information can be for safety data sheets and laboratory records. Laboratories that use Ethyl 4-iodobutyrate put safety and expertise first. The iodine atom signals extra caution; it's heavier, reacts in unique ways, and requires handling that respects both the science and the health of workers. Even small spills or mislabeling create risks, so documentation stays sharp and procedures never get sloppy.

Ethyl 4-iodobutyrate often serves as a building block. Whether in pharmaceutical research, medicinal chemistry, or specialty chemical production, missing data on formula or mass leads to waste. Screens get filled with spreadsheets, reports, and logs, and accuracy here saves mountains of time and resources. I’ve worked in places where an incorrect formula triggered entire product recalls—costing far more than the price of double-checking a number.

Strong Information Gives Strong Results

If research aims to lead footsteps forward, researchers need facts—not assumptions. Each property, from formula to weight, links to best practices. Keeping reliable data on hand lifts the whole field, helps prevent disasters, and builds confidence for everyone in the chain: from student to senior scientist.

Better training, clear documentation, and verified supplies make up the backbone of chemical education and industrial success. It turns chemistry class into real-world readiness and lines up every experiment for a smoother landing.

Chemistry Behind the Name

Ethyl 4-iodobutyrate stands out as a building block for chemists who work on creating new molecules that change daily life. At first glance, the name might feel as memorable as a street address, but the story behind its use runs deep in modern chemical research and innovation.

Bridging the Lab and Medicine

Plenty of people outside of chemistry circles never cross paths with compounds like ethyl 4-iodobutyrate. Still, the pharmaceutical world looks at it as a tool to connect pieces together in larger syntheses. I spent early mornings in a university lab, watching postdocs rely on this molecule to craft intermediates, which led to drug candidates that pharmaceutical companies would eventually test for conditions ranging from cancer to neurological disorders. The presence of an iodine atom helps reactions happen cleaner and with less waste, a crucial detail for any company facing pressure to reduce harmful byproducts. Without these kinds of shortcuts, drug development slows down, costing time, money, and even patient lives.

Innovation in Agrochemicals

The search for new pesticides, herbicides, and plant-growth substances borrows a lot from early-stage research into molecular building blocks like ethyl 4-iodobutyrate. Farmers want solutions that target pests and weeds without risking crop health or causing environmental fallout. Research groups often turn to reactions using this compound because its chemical features let scientists stick new pieces onto its core structure, producing a range of molecules tested for agricultural use. If any become game-changers in the lab, they can end up protecting entire fields by the next season. My own friends in chemical research shared stories about running long reaction chains starting with ethyl 4-iodobutyrate, all aiming at smarter and safer crop protection formulas.

Role in Material Innovation

Material science seems like the quiet cousin to biochemistry, but it shapes electronics, coatings, and specialty plastics. A chain of atoms often determines if a surface will repel water, cling to paint, or allow electricity to flow. Ethyl 4-iodobutyrate has played a niche role in these efforts. It fits perfectly into strategies called “cross-coupling reactions,” which let scientists attach new fragments and create entirely new molecules. Over the years, some of the plastics or specialty materials around smartphones or medical devices have drawn on chemistry routes where this compound proved faster or more reliable than older methods. Even small tweaks in the laboratory can mean safer materials or less waste headed to the landfill.

Risk, Responsibility, and the Path Forward

Any specialty chemical, especially one with halogen atoms like iodine, poses responsibility. Wastewater or byproducts need careful management to protect health and local environments. I recall hearing about safety officers holding workshops in my undergraduate years, stressing safe handling and disposal—not just for the scientists but for the broader community. Companies at the forefront of green chemistry champion cleaner alternatives, keeping an eye on regulations that shift as understanding grows. Ethyl 4-iodobutyrate often factors into these conversations, pushing everyone involved to lower the environmental footprint with every synthesis cycle.

Looking Beyond the Bottle

The importance of molecules like ethyl 4-iodobutyrate runs deeper than a price tag or a chemical catalog can suggest. Each use—whether in pharmaceuticals, agriculture, or materials—draws a line back to the bench scientist, their skills, and the decisions they make about safety, efficiency, and environmental impact. All of us benefit when research pushes these boundaries while holding fast to high standards in both science and stewardship.

Why Respecting Chemical Safety Makes a Difference

People sometimes overlook safety protocols in the lab. It feels tempting to take shortcuts—grab a container, set it on any available shelf, and walk away. From a few years spent preparing organic syntheses, I've learned the hard way that neglect brings real risks. Ethyl 4-iodobutyrate isn’t just another bottle sitting in the storeroom. With its iodine content and volatility, improper storage or careless handling can lead to ruined projects or health scares.

Understanding the Hazards

Most folks working with organic chemicals know the uneasy sensation that comes from reading phrases like “harmful if inhaled” or “causes serious eye irritation.” Ethyl 4-iodobutyrate raises these red flags. Contact with skin stings and causes irritation. Its vapors make the eyes water and breathing even faint fumes leaves a taste in the back of the throat. The heavier-than-air vapors can pool in low spots, compounding exposure over time. Forgetting about gloves or eye protection introduces unnecessary harm, often discovered only after a lunch break interrupted by stinging skin or a headache.

Choosing the Right Storage Location

Labs that run efficiently take chemical storage seriously. I’ve seen groups toss a bottle onto a bench without much thought, only to deal with corroded labels or leaking lids later. Ethyl 4-iodobutyrate stays stable at room temperature just fine, but keep the bottle tightly sealed and away from direct sunlight. Heat and light prompt breakdowns or pressure buildup inside weak containers. Best practice puts it on a low shelf in a ventilated chemical cabinet, ideally away from incompatible materials such as oxidizers or bases, which can force hazardous reactions.

Flammable liquid storage cabinets work well because they keep temperature spikes to a minimum. Humidity control also helps. Many labs choose a dry environment since moisture or accidental spills could break containers or mess with purity. I remember one summer afternoon when humidity hit records; a few poorly capped bottles developed sticky residue and an odd smell. That single event cost the lab a week cleaning out and testing batches.

Handling With Care: What Practice Teaches

Anyone who’s transferred volatile esters knows the importance of fume hoods. Decanting ethyl 4-iodobutyrate in the open fills a room fast, making headaches and complaints almost inevitable. Drawing out small amounts requires patience—use dedicated syringes or pipettes, don’t rush, and always check for cracks or weak seals in your transfer gear. Wash hands right away, because the tiniest residue burns skin or transfers to eyes from a casual rub.

Good labeling helps everyone. “Unlabeled bottle” stories fill lab safety meetings. I once labeled a bottle half-heartedly, forgetting the date. A month later, questions about stability and content led to hours cross-referencing and wasted chemicals. Reliable labeling with clear hazard markings keeps everyone alert, especially newcomers or part-time researchers.

Keeping the Workplace Safe for Everyone

Safety routines only work if people understand their value. It’s not only about avoiding fines or annual inspections. A single spill, an unnoticed drip, or an unventilated cap puts everyone in the lab at risk. Know where eye wash stations and fire extinguishers sit, and trust peer reminders. Use the spill kit before a mess dries. Get rid of small waste portions in the right container and dispose of it quickly, following local environmental rules.

Respect and consistency matter more than rigid procedures. Experience with ethyl 4-iodobutyrate proves that small habits, like double-checking seals or storing bottles in the right spot, prevent problems that disrupt research and endanger health.

What Buyers Find on the Specification Sheet

Ethyl 4-iodobutyrate stands as a critical piece for many organic syntheses. Suppliers often push its purity front and center, and for good reason. The most common guarantee on the market sits at ≥98%, which means out of every 100 grams, fewer than two grams could be impurities. Some labs, particularly those trying to avoid pesky side reactions or chasing pharmaceutical-grade outcomes, look for even tighter numbers—≥99% or higher.

Why This Matters in the Real World

Not all chemistry happens in textbooks. Minute impurities can send experiments off track, waste money, or blow up the timeline for a project. In my own research days, a single bottle of so-called “technical grade” material once took an entire set of reactions off the rails simply because no one checked for unknown byproducts. The cleanup cost more than choosing a slightly pricier, better-tested stock would have. These kinds of stories stay with you.

Sigma-Aldrich, TCI, Alfa Aesar, and a few others make their specs public with certificates of analysis. For ethyl 4-iodobutyrate, they routinely report GC (gas chromatography) or HPLC (high-performance liquid chromatography) figures to back up the numbers, along with water content tested by Karl Fischer titration and lists of common contaminants. Everyone wants reproducibility. That certainty of purity feeds directly into whether a batch of drug intermediates or a crop of research compounds will turn out right, or if time gets wasted with unplanned troubleshooting.

What Can Go Wrong If You Ignore Purity?

Contaminants do more than slow things down. Halides, water, and leftover solvent can poison catalysts, wreck reaction yields, or introduce toxic side-products. One friend’s pharma group saw a clinical candidate dumped into cold storage for months after a rogue impurity made its way through because early screening skipped GC. That turned expensive, fast.

If you’re ordering for production or sensitive research, one phone call to the supplier’s technical team often reveals a lot about their practices—especially whether they control sources of raw iodine or ethanol, which can reflect in the impurity profile. Many buyers lean on supplier documentation because full purification in-house rarely makes sense, unless you’re set up for resynthesis or large-scale distillation. Purity isn’t about avoiding paperwork—it directly protects R&D dollars and staff time.

What Buyers Can Do

Trust but verify. Even if the spec says ≥98%, ask if they have more granular breakdowns on what the other 2% includes. Look for COA batches, not generic promises. Checking for batch-specific test results versus “typical values” exposes how transparent a supplier really is. If a job could suffer from even small traces of unrelated organics, buy a sample, and run it through your own analytics. In one contract lab, we took to running our own GC on every high-impact purchase; not once did that feel like wasted effort.

The best fix for upstream impurity headaches is prevention. Get consistent suppliers whose products don’t swing from batch to batch. Push for documentation—batch-level, not marketing fluff. Tap into industry peer networks to flag brands with repeating issues. No one likes finding out about a purity problem in the middle of a six-step synthesis.

Real Risks in Handling Lab Chemicals

Anyone who has spent time in a lab will tell you that it pays to respect every bottle, no matter how obscure the label. Ethyl 4-Iodobutyrate might not pop up in a high school chemistry class, but folks using it in research or specialty synthesis see it often enough. The first thing that hits you is the sharp smell — a signal that you’re dealing with an ester, and a clue that this compound won’t play nice if mishandled.

What We Know About Toxicity

The chemical’s core hazard starts with its structure. The iodo group opens it up to potential for harm. Iodinated organics don’t usually get much clinical attention; they avoid the spotlight, but that doesn’t give a free pass. Inhale too much vapor or let the liquid contact your skin, your body might react much more strongly than it would to plain vanilla esters. There’s a risk of irritation — eyes, skin, and airways don’t take kindly to this stuff. Based on related compounds, repeated exposure could mean headaches or even worse symptoms if not managed right.

In my time assisting a busy synthesis lab, even skilled chemists sometimes got caught off guard. I remember one afternoon, a graduate student dropped a flask and the odor filled the room; goggles on, gloves up, all it took was an ill-timed breath for him to end up with stinging eyes and a cough. Later, we read up and realized the Material Safety Data Sheet (MSDS) warned about those exact things. Vapor can sting like crazy, and the risk for skin absorption shouldn’t be underestimated. This isn’t liquid to splash or sniff — those who get careless can pay with skin blisters or respiratory irritation that takes days to go away.

Fire and Chemical Reactivity Risks

Beyond direct toxicity, flammable liquids demand attention. Ethyl esters light up fast, and adding an iodine atom doesn’t help. Spills and open flames don’t mix. You sweep up and bottle with ventilation hoods whirring, making sure that any open heat source stays far away. Working late at night, I’ve seen a fume hood snuff out a would-be spark — not because someone expected trouble, but because you always treat unknown reactions as potentially volatile.

Then there’s the chemical reactivity angle. Iodides sometimes catalyze weird side reactions, especially in the presence of strong bases or oxidizing agents. It doesn’t take much to trigger a breakdown, releasing toxic vapors or making the next step unpredictable. A routine disposal can end in mystery sludge or a foul-smelling cloud — and you’ll only make that mistake once.

Minimizing the Dangers

Putting safety first means real, detailed protocols. Before uncapping a bottle, you want gloves resistant to organic solvents, splash goggles, and a real lab coat (not a thin cotton shirt). I always double-check the hood airflow and keep a spill kit within arm’s reach. For storage, you put the bottle far from acids, bases, and heat, on a low shelf behind a locking door. Disposal takes just as much thought — lots of folks forget that esters like this don’t play well with sink drains or regular trash pickup.

Labs using Ethyl 4-Iodobutyrate should keep clear, readable safety sheets posted. Every team member benefits from a drill or two: practice mop-ups, medical responses, and clear evacuation routes. It saves time and nerves if something ever goes wrong.

References:- Sigma-Aldrich Safety Data Sheet for Ethyl 4-Iodobutyrate

- PubChem Hazard Summary: Ethyl 4-Iodobutyrate

- Personal experience: 2015–2020, academic chemical research lab